Separator for secondary battery having excellent electrolyte wettability and method for manufacturing same

A kind of secondary battery, electrolyte technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the polyolefin-based substrate is not limited, and is classified into a dry method and a wet method according to whether a solvent is used. The dry method is a method in which a crystalline polyolefin-based polymer is melt-extruded, molded, and a sheet is produced and heat-treated, and then stretched at a low or high temperature to form pores to prepare a separator. Since the dry method does not use a solvent, the process is simple and the productivity is excellent, but there are the following disadvantages: it is not conducive to the production of products with a wide width, the thickness of the separator is likely to be uneven, and mechanical strength is caused by uniaxial stretching. direction dependence etc. As for commercial polyolefin-based substrates prepared by the dry method, for example, Celgard series products of Celgard Company, U-Pore series products of Ube Company, and products of CS TECH Company can be cited.

[0031] The so-cal...

Embodiment

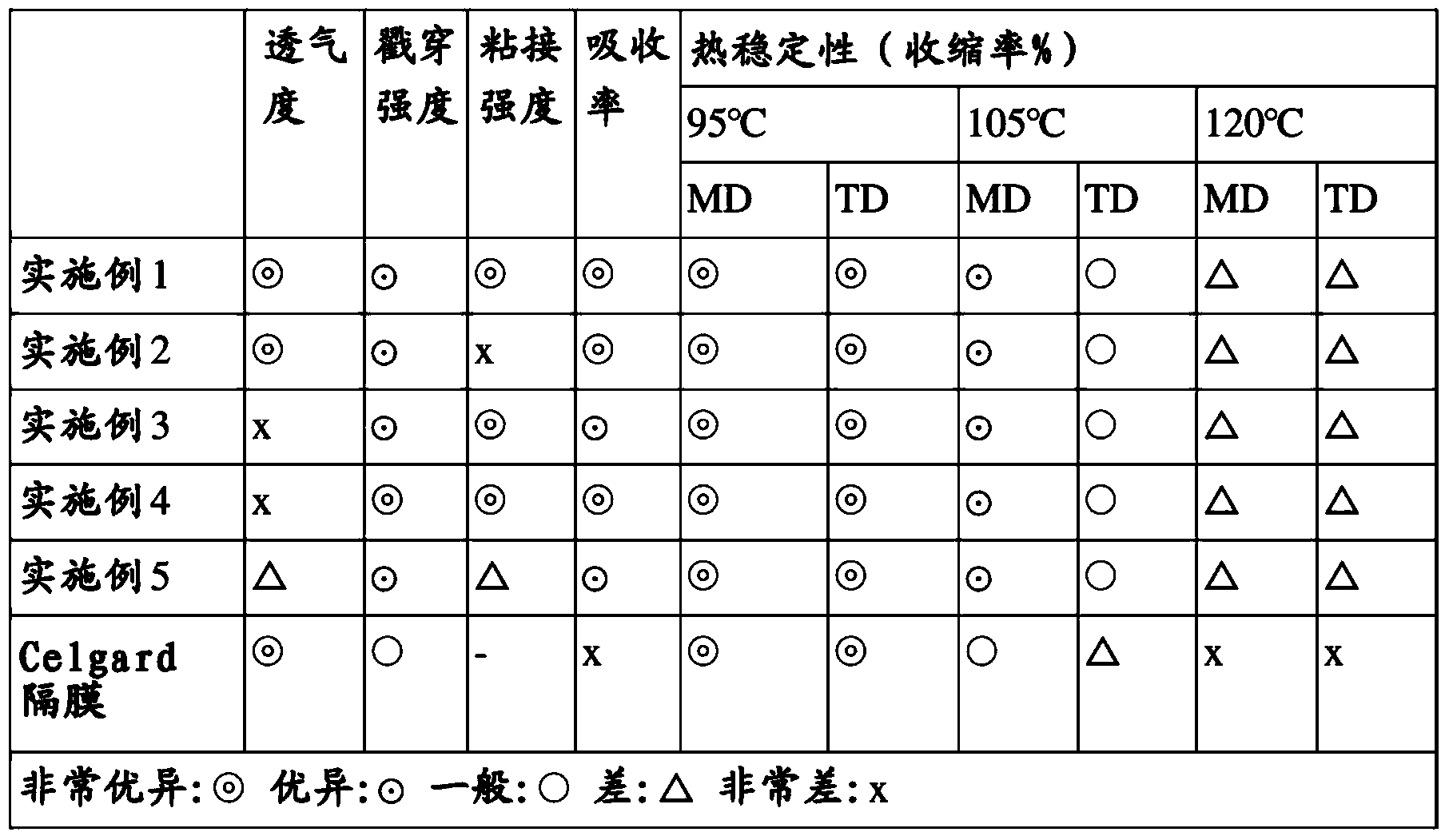

[0058] Hereinafter, the present invention will be described in more detail based on examples. These examples are only used to illustrate the present invention more specifically, and it will be obvious to those skilled in the art that the scope of the present invention is not limited to these examples

[0059]

[0060] 1. Puncture Strength

[0061] For puncture strength measurements, the samples were fixed in the test frame after being laid flat without creases. Apply a force of 1kgf to a needle with a diameter of 1mm until the fixed sample is pierced. The value at the time of poking is recorded in gf units. Samples were measured 10 times and the average value was taken.

[0062] 2. Air permeability

[0063] As far as air permeability measurement is concerned, it is set to a pressure of 600Pa and the measurement unit is cm 3 / cm 2 / s after the measurement. The samples were cut without wrinkling to 100mm in length and 100mm in width. Using air permeability measurin...

preparation example 1

[0072] [Preparation Example 1] Hot-melt first electrospinning composition

[0073] The hot-melt resin uses the EVA product HM7150PS of Okong bond Co., Ltd., which is added to the xylene (Xylene) solvent at a weight ratio of 20%, and the temperature is raised to 2-3 ° C per minute while stirring at a mixer speed of 1000 RPM. 40°C. After the temperature was raised to 40° C., stirring was carried out for 6 hours to completely dissolve the EVA resin in the xylene solution. After the temperature of the dissolved solution was lowered to 25°C, 0.3% of a conductivity modifier and 3% of a viscosity modifier (BYK company, VISCOBYK-15130) were added as additives, and stirred for 1 hour to prepare the first electrospinning combination. The prepared composition had a viscosity of 600 cPs and an electrical conductivity of 9 ms / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com