A water-resistant foamed gypsum insulation material and its preparation method

A technology of foamed gypsum and thermal insulation materials, which is applied in the field of building materials, can solve the problems of failure to become a mainstream product of thermal insulation materials, high maintenance costs, poor water resistance, etc., and achieve low cost, low equipment investment cost, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The water-resistant foamed gypsum insulation material of this embodiment is made of the following raw materials in parts by weight: 100 kg of modified desulfurized building gypsum powder, 5 kg of polymer composite emulsion, 0.5 kg of polyvinyl alcohol fiber, and 40 kg of mixing water; The permanent desulfurization building gypsum powder is made by mixing the following raw materials by weight and grinding them in a ball mill for 1 hour: building desulfurization gypsum powder 100kg, sodium aluminate 2kg, trona 5kg, sodium citrate 3kg, rice husk ash 5kg, trisodium phosphate 1kg The polymer composite emulsion is made by mixing the following raw materials by weight and heating and stirring at 60°C for 30 minutes: 10kg of polyacrylate emulsion, 0.05kg of bone glue treated with quicklime, 0.5kg of VAE emulsion, and naphthalene-based high-efficiency water reducer 0.05kg, 0.1kg of formaldehyde solution of melamine, wherein the bone glue treated with lime is made by uniformly mixi...

Embodiment 2

[0032]The water-resistant foamed gypsum insulation material of this embodiment is made of the following raw materials in parts by weight: 100 g of modified desulfurized building gypsum powder, 10 g of polymer composite emulsion, 0.1 g of polyvinyl alcohol fiber, and 60 g of mixing water; The desulfurization building gypsum powder is prepared by mixing the following raw materials by weight and grinding them in a ball mill for 0.5h: 100g building desulfurization gypsum powder, 10g sodium aluminate, 1g trona, 1g sodium citrate, 20g rice husk ash, trisodium phosphate 3g; the polymer composite emulsion is prepared by mixing the following raw materials by weight and heating and stirring at 80°C for 10 minutes: 10g polyacrylate emulsion, 0.1g bone glue treated with quicklime, 0.1g VAE emulsion, naphthalene-based high-efficiency water reducing 0.1g of melamine formaldehyde solution, 0.5g of formaldehyde solution of melamine, wherein the bone glue treated with lime is made by mixing qui...

Embodiment 3

[0039] The water-resistant foamed gypsum insulation material of this embodiment is made of the following raw materials in parts by weight: 100 catties of modified desulfurized building gypsum powder, 6 catties of polymer composite emulsion, 0.4 catties of polyvinyl alcohol fiber, and 45 catties of mixing water; The modified desulfurized building gypsum powder is prepared by mixing the following raw materials in parts by weight and grinding them in a ball mill for 0.8 hours: 100 catties of building desulfurized gypsum powder, 7 catties of sodium aluminate, 2 catties of trona, 1.5 catties of sodium citrate, rice 10 catties of shell ash, 2.7 catties of trisodium phosphate; the polymer composite emulsion is made by mixing the following raw materials by weight and stirring at 70°C for 20 minutes: 10 catties of polyacrylate emulsion, 0.07 catties of bone glue treated with quicklime, 0.2 catties of VAE emulsion, 0.08 catties of naphthalene-based high-efficiency water reducer, 0.2 catties...

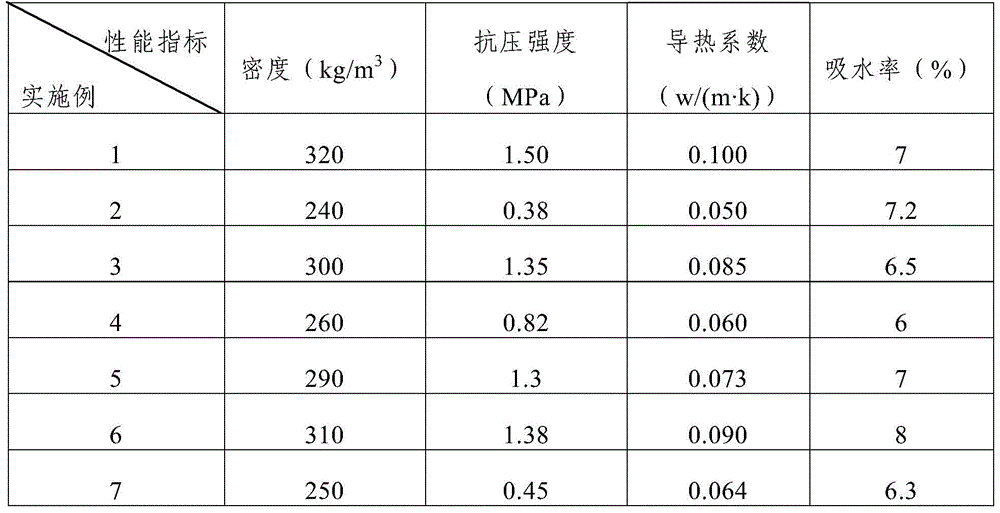

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com