Molybdenum-tailings microcrystal foaming material and preparation method thereof

A technology of microcrystalline foaming and molybdenum tailings, which is applied in the field of building materials, can solve the problems of insufficient utilization of tailings resources, unstable firing temperature, and excessive addition of auxiliary materials, and achieve stable and improved chemical composition and physical properties. Quality, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

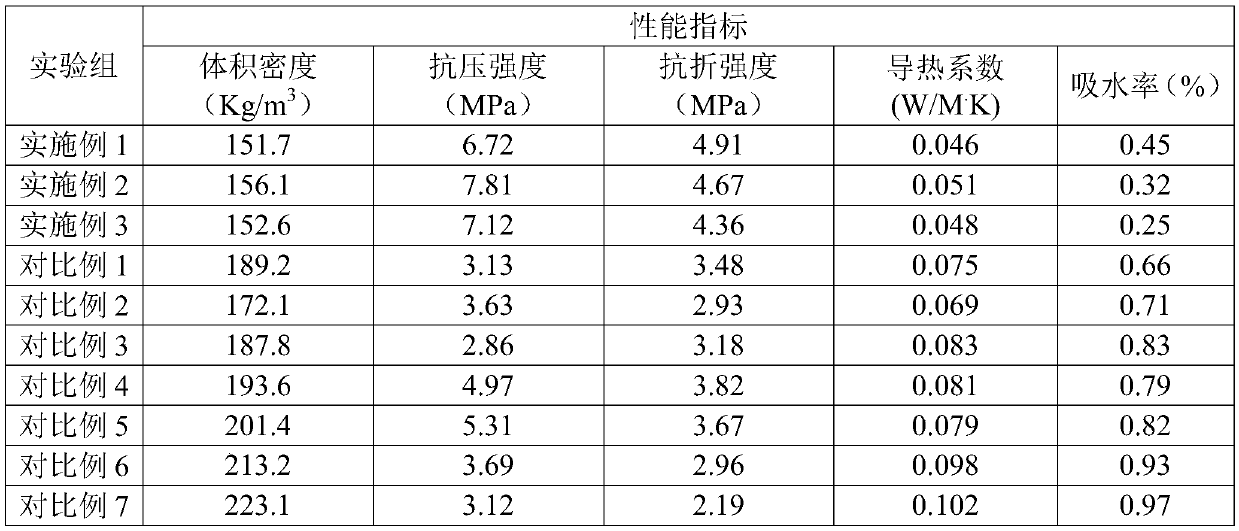

Examples

Embodiment 1

[0037] (1) Get 92% molybdenum tailings, 2% silicon carbide, 5% iron tailings, 0.5% boron nitride, 0.5% aluminum nitride, grind to 350 mesh in a ball mill, mix and stir, ingredients;

[0038] (2) Control the moisture content of the ingredients within 5%, and use the air distribution system and pneumatic conveying system to transport it to the granulation tower; then use the multi-mouth water atomization system to atomize and humidify the ingredients to 10% for granulation, Finally, it is dried at 200°C to obtain pellets.

[0039] (3) Put the pellets into the mold with an automatic distributing machine, first raise the temperature to 300°C at a rate of 20°C / min, and keep warm for 0.75h; then raise the temperature to 800°C at a speed of 20°C / min, and keep warm for 0.75h; finally Raise the temperature to 1190°C at a rate of 10°C / min, hold for 25 minutes, and sinter to shape;

[0040] (4) First cool down to 800°C at a rate of 5°C / min and hold for 1.5h; then cool down to 400°C at ...

Embodiment 2

[0042] (1) Get 90% molybdenum tailings, 0.5% silicon carbide, 0.5% sodium bicarbonate, 8% iron tailings, 0.2% boron nitride, and 0.8% aluminum nitride, and grind them in a ball mill until 325 mesh, mixed and stirred to obtain ingredients;

[0043] (2) Control the moisture of the ingredients at 5%, and use the air distribution system and pneumatic conveying system to transport it to the granulation tower; then use the multi-mouth water atomization system to atomize and humidify the ingredients to 8% for granulation, and finally After drying at 250°C, pellets were obtained.

[0044] (3) Put the pellets into the mold with an automatic distributing machine, first raise the temperature to 200°C at a rate of 15°C / min, and keep it warm for 1h; Heat up to 1180°C at a rate of 20°C / min, hold for 30 minutes, and sinter to shape;

[0045](4) First cool down to 700°C at a rate of 10°C / min, and hold for 2 hours; then cool down to 300°C at a rate of 15°C / min, and hold for 0.5h; finally coo...

Embodiment 3

[0047] (1) Take 95% molybdenum tailings, 3% sodium bicarbonate, 1% iron tailings, 0.8% boron nitride, 0.2% aluminum nitride, grind to 400 mesh in a ball mill, mix and stir , get ingredients;

[0048] (2) Control the moisture content of the ingredients within 2%, and use the air distribution system and pneumatic conveying system to transport it to the granulation tower; then use the multi-mouth water atomization system to atomize and humidify the ingredients to 15% for granulation, Finally, it is dried at 180°C to obtain pellets.

[0049] (3) Put the pellets into the mold with an automatic distributing machine, first raise the temperature to 400°C at a rate of 20°C / min, and keep warm for 0.5h; then raise the temperature to 700°C at a speed of 20°C / min, and keep warm for 1h; Heat up to 1200°C at a rate of 10°C / min, hold for 20 minutes, and sinter to shape;

[0050] (4) First cool down to 800°C at a rate of 5°C / min and hold for 1 hour; then cool down to 400°C at a rate of 10°C / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com