Porous metal halide film, fabrication method thereof, and fabrication method of organometal halide having perovskite structure using the same

A technology of porous metals and metal halides, applied in halide preparation methods, chemical instruments and methods, lead halides, etc., can solve the problems of low material cost and insufficient large-scale research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

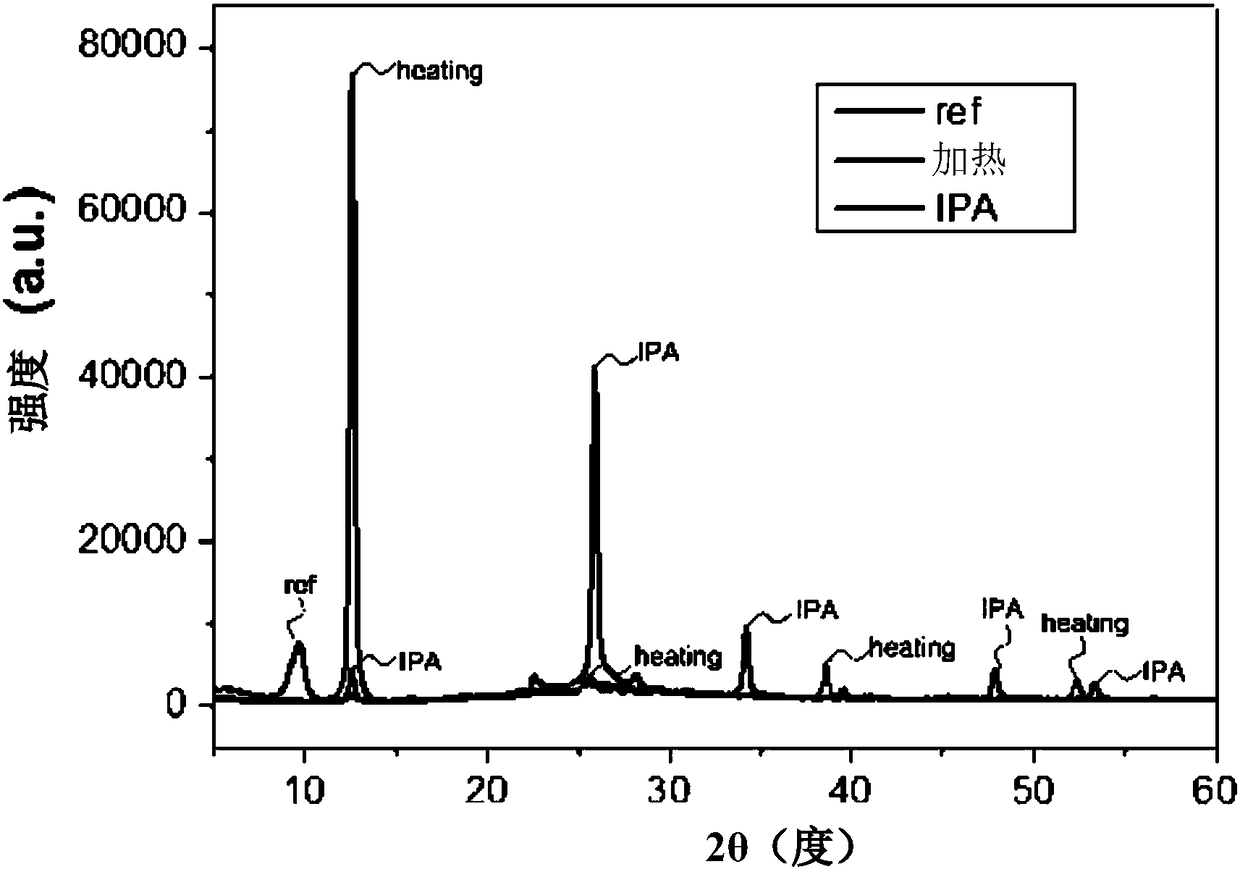

[0149] The preparation method of the metal halide film of the present invention comprises making a precursor film (adduct layer) containing a metal halide-guest molecule adduct (adduct of metal halide and guest molecule) and satisfying the polar proticity of the following relational formula 6 The step of preparing a porous metal halide membrane by contacting with a solvent.

[0150] (relational expression 6)

[0151] δ h (gm)h (pa)

[0152] In relation 6, δ h (gm) is the hydrogen bond component (δ h , hydrogen bonding component, MPa 0.5 ),δ h (pa) is the hydrogen bond component (δ h , hydrogen bonding component, MPa 0.5 ).

[0153] In a precursor film containing a metal halide-guest molecule adduct, the metal halide-guest molecule adduct can be composed of metal cations and halide anions and guest molecules (guest molecule, hereinafter, GM) that constitute the perovskite compound. compound of.

[0154] In detail, the metal halide-guest molecule adduct may be a compou...

Embodiment 1

[0270] The PbI of 0.6g will be purchased from Sigma Aldrich (SIGMA-ALDRICH Co.) 2 Powder (Lead iodide, 99%) was dropped into 0.2ml of methyl sulfoxide (DMSO) (relative to 1 mole of PbI 2 , 2.17 moles of DMSO) and 0.8 ml of N,N-dimethylformamide (DMF) in a mixed solvent to prepare an adduct solution.

[0271] The prepared adduct solution was injected into the FTO substrate (coated with fluorine-containing tin oxide glass substrate, FTO; F-doped SnO 2 , 8ohms / cm 2 , Pilkington) on the spinning center, spin-coating at a speed of 3000 rpm for 30 seconds to prepare a dry precursor film (thickness of the film is 0.3 μm).

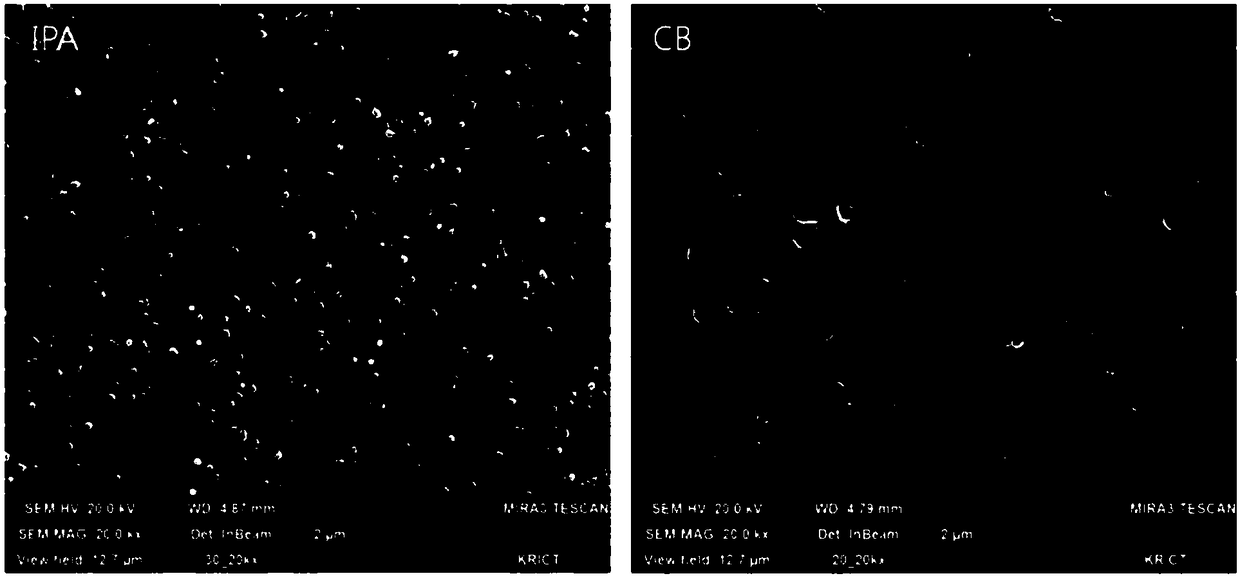

[0272] After immersing the prepared precursor film in isopropanol (anhydrous 2-propanol, IPA, Sigma-Aldrich) for 20 seconds, separate and recover the film and blow it with an argon gun with a weak wind, and dry it at room temperature to prepare the guest molecule (DMSO) Removal of porous metal halide membranes. Afterwards, the prepared porous metal halide memb...

Embodiment 2

[0288] The same as in Example 1, but immersing the precursor film in isopropanol for 10 seconds to prepare a porous metal halide film. Afterwards, in the same manner as in Example 1, the prepared porous metal halide membrane was respectively immersed in an organic halide solution (40 mg of NH 3 CH 3 1 / 1ml of isopropanol) for 10 seconds, 20 seconds or 30 seconds to prepare the perovskite compound film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com