Kelp and mung bean healthcare steamed bun and preparation method thereof

A technology of kelp and steamed bread, which is applied in the fields of mung bean health-care steamed bread, preparation of kelp, and kelp, which can solve problems such as side effects, complicated dry powder production process, and drug residues, and achieve good taste, ensure taste and flavor, and improve high blood pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

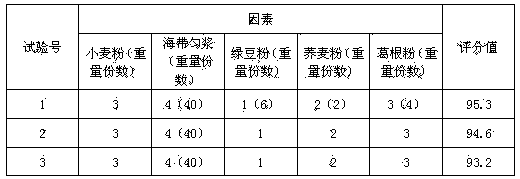

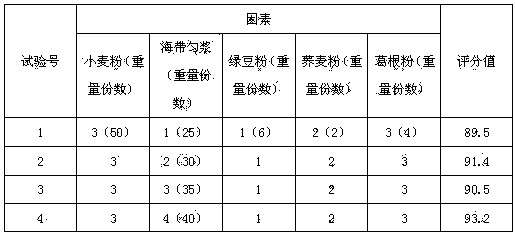

Method used

Image

Examples

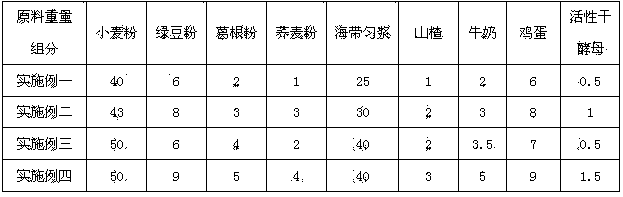

Embodiment 1-4

[0035]

[0036] (1) Raw material preparation and pretreatment of some raw materials: Examples 1-4 carried out weighing and preparation according to the above-mentioned weight ratio of each raw material. Among them, the kelp homogenate is dried kelp after weighing, rehydrating with 3% saline at room temperature for 3 hours, cleaning the impurities on the surface, chopping the kelp, and making dry kelp according to the ratio of adding water: water is 1: (20-30) add water Beating to obtain kelp homogenate;

[0037] The mung bean powder is steamed in water for 15 minutes to remove the fishy smell with damp heat;

[0038] After cleaning the hawthorn, removing the core, drying at 60°C for 4 hours, crushing, passing through a 20-mesh sieve to obtain hawthorn powder;

[0039] The mung bean powder in the above raw materials can also be replaced by mung beans. When mung beans are used as raw materials, the weight ratio remains unchanged. After the mung beans are cleaned, they are dr...

Embodiment 5-10

[0074] (1) Raw material preparation and pretreatment of some raw materials

[0075] According to parts by weight, it is 50 parts of wheat flour, 6 parts of mung bean powder, 4 parts of kudzu powder, 2 parts of buckwheat powder, 40 parts of kelp homogenate, 2 parts of hawthorn, 3.5 parts of milk, 7 parts of eggs, and 0.5 part of active dry yeast.

[0076] Among them, the kelp homogenate is dried kelp after weighing, rehydrating with 3% saline at room temperature for 3 hours, cleaning the impurities on the surface, chopping the kelp, and making dry kelp according to the ratio of adding water: water is 1: (20-30) add water Beating to obtain kelp homogenate;

[0077] Mung bean powder is processed according to the method listed in table 9;

[0078] After cleaning the hawthorn, removing the core, drying at 60°C for 4 hours, crushing, passing through a 20-mesh sieve to obtain hawthorn powder;

[0079] Steps (2)-(8) are carried out according to the method of Embodiment 1-4;

[0080...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com