Method for preparing foamed ceramic from metallurgical high-temperature flow-state steel slag

A technology of foamed ceramics and steel slag, applied in the field of building materials, can solve the problems of unstable composition, high power consumption of mixing materials, poor stability, etc., and achieve good social and economic benefits, wide application prospects, and stable phase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

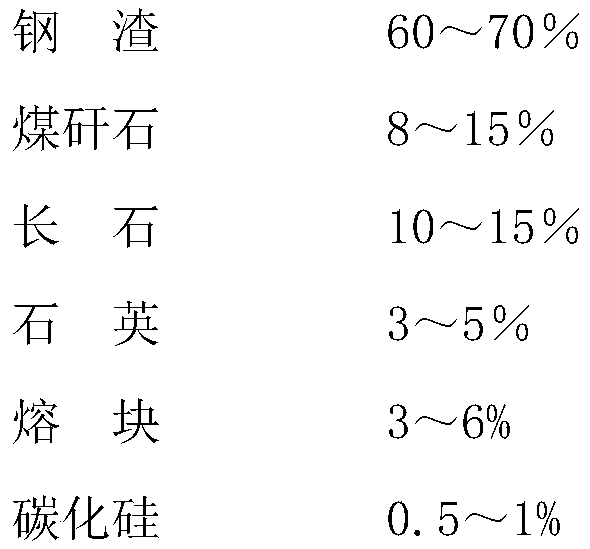

[0039] (1) Weigh raw materials with the following weight percentages:

[0040]

[0041] (2) Weigh coal gangue, feldspar and quartz according to the above weight percentage, grind coal gangue, feldspar and quartz into powder less than 100 mesh respectively, and mix, and obtain auxiliary raw materials for subsequent use;

[0042] (3) The 1300 degree steel slag in the steelmaking production weighed by the above weight percentage is poured into the smelting ladle in a molten state, and kept warm for use;

[0043] (4) Add the auxiliary raw materials of step (2) into the smelting ladle of step (3), and stir for 10 minutes while feeding, at a stirring speed of 100 rpm to form a silicate ceramic melt;

[0044] (5) Weigh the frit and silicon carbide according to the above weight percentage, so that the particle size of the silicon carbide is 250 meshes, mix the weighed frit and silicon carbide evenly to obtain a mixture, and add the mixture to the glass tank kiln, Heating to 1100°C...

Embodiment 2

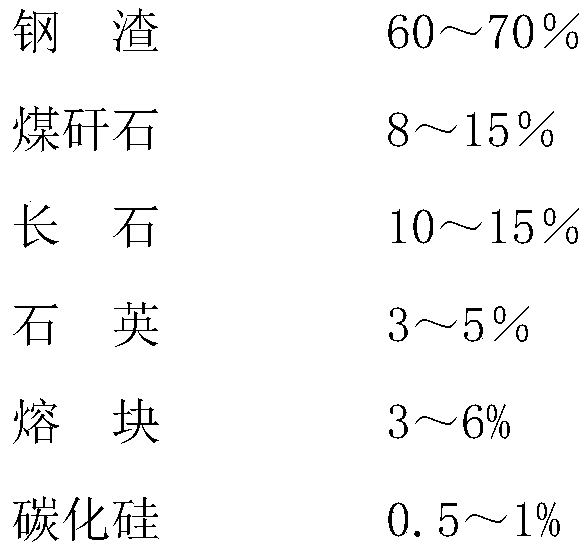

[0048] (1) Weigh raw materials with the following weight percentages:

[0049]

[0050] (2) Weigh coal gangue, feldspar and quartz according to the above weight percentage, grind coal gangue, feldspar and quartz into powder less than 100 mesh respectively, and mix, and obtain auxiliary raw materials for subsequent use;

[0051] (3) Pour the 1400°C steel slag in the steelmaking production weighed by the above weight percentage into the smelting ladle in a molten state, and keep it warm for use;

[0052] (4) Add the auxiliary raw materials of step (2) into the smelting ladle of step (3), and stir for 12 minutes while feeding, at a stirring speed of 120 rpm to form a silicate ceramic melt;

[0053] (5) Weigh the frit and silicon carbide according to the above weight percentage, so that the particle size of the silicon carbide is 300 meshes, mix the weighed frit and silicon carbide uniformly to obtain a mixture, and add the mixture to the glass tank kiln, Heating to 1100°C to ...

Embodiment 3

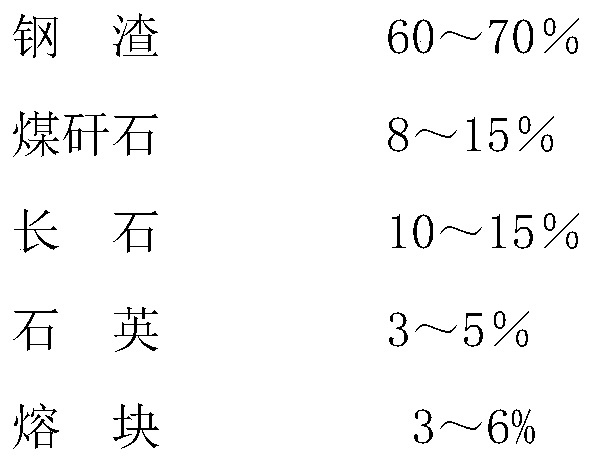

[0057] (1) Weigh raw materials with the following weight percentages:

[0058]

[0059] (2) Weigh coal gangue, feldspar and quartz according to the above weight percentage, grind coal gangue, feldspar and quartz into powder less than 100 mesh respectively, and mix, and obtain auxiliary raw materials for subsequent use;

[0060] (3) Pour the 1200°C steel slag in the steelmaking production weighed by the above weight percentage into the smelting ladle in a molten state, and keep it warm for use;

[0061] (4) Add the auxiliary raw materials of step (2) into the smelting ladle of step (3), and stir for 8 minutes while feeding, at a stirring speed of 80 rpm to form a silicate ceramic melt;

[0062] (5) Weigh the frit and silicon carbide according to the above weight percentage, so that the particle size of the silicon carbide is 600 meshes, mix the weighed frit and silicon carbide evenly to obtain a mixture, and add the mixture to the glass tank kiln, Heating to 1100°C to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com