Modulator for gas chromatography

a module and gas chromatography technology, applied in the field of modules for gas chromatography, can solve the problems of easy breakage of the column, limited oven maximum temperature, and insufficient robustness for long use, and achieve the effect of optimizing the analytes treatmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The main feature and further features of the modulator according to this invention are reported in claim 1 and respectively in the dependent claims.

[0022] The invention will be more deeply described with reference to the accompanying drawings, wherein:

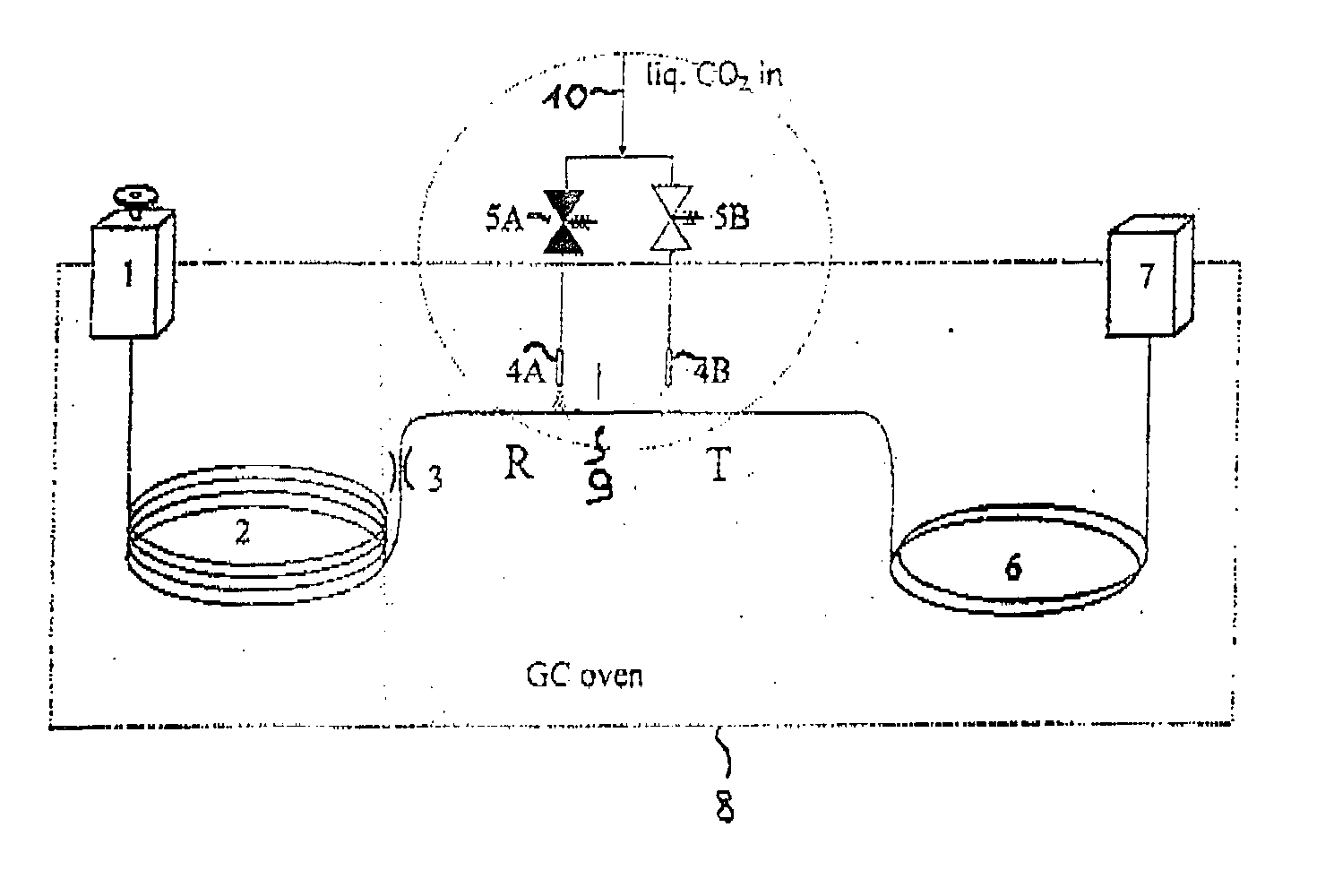

[0023] FIG. 1 is a scheme of the GCxGC system.

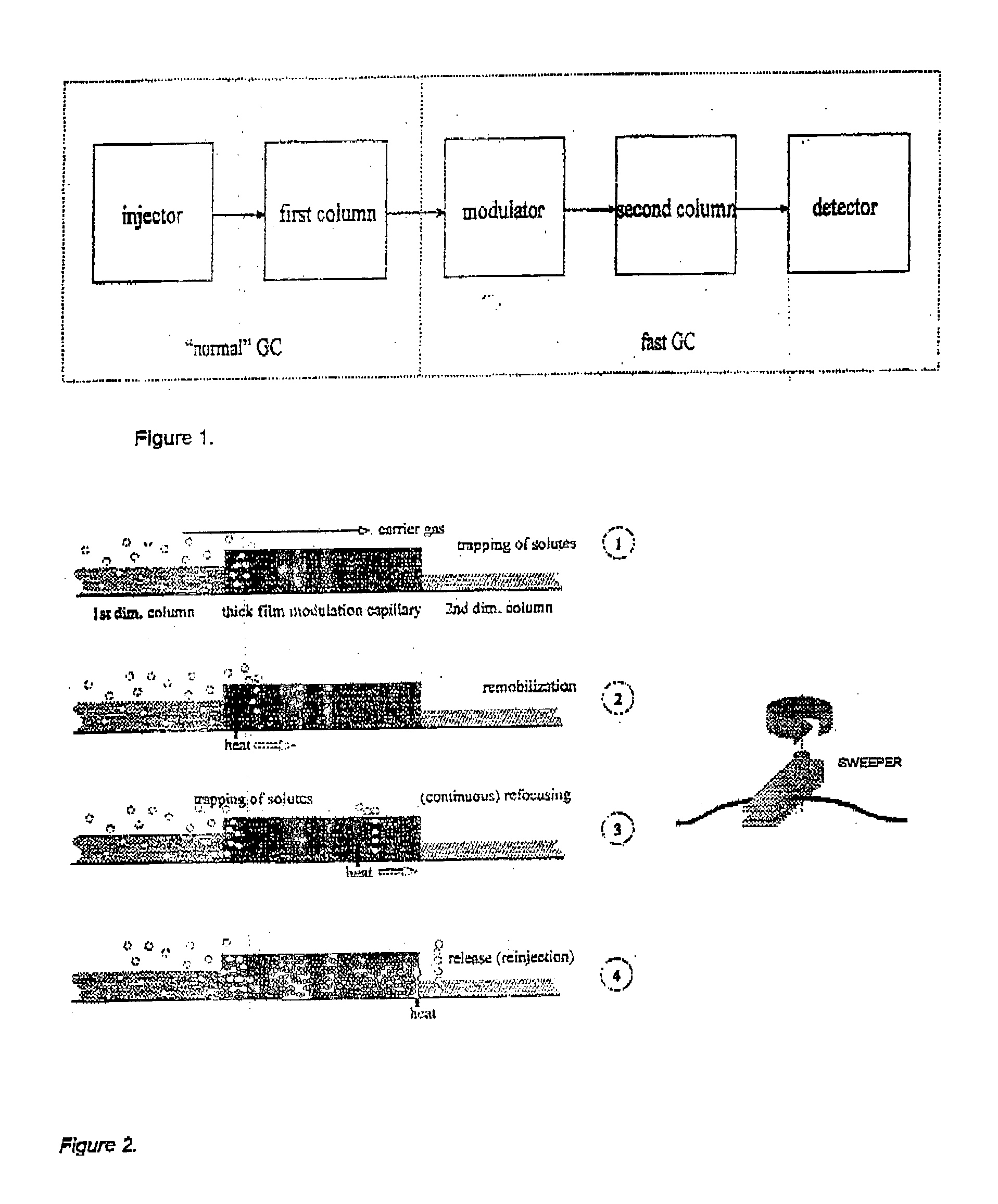

[0024] FIG. 2 is a scheme of the known heating modulation system (sweeper).

[0025] FIG. 3 is a scheme of the known cryogenic modulation system.

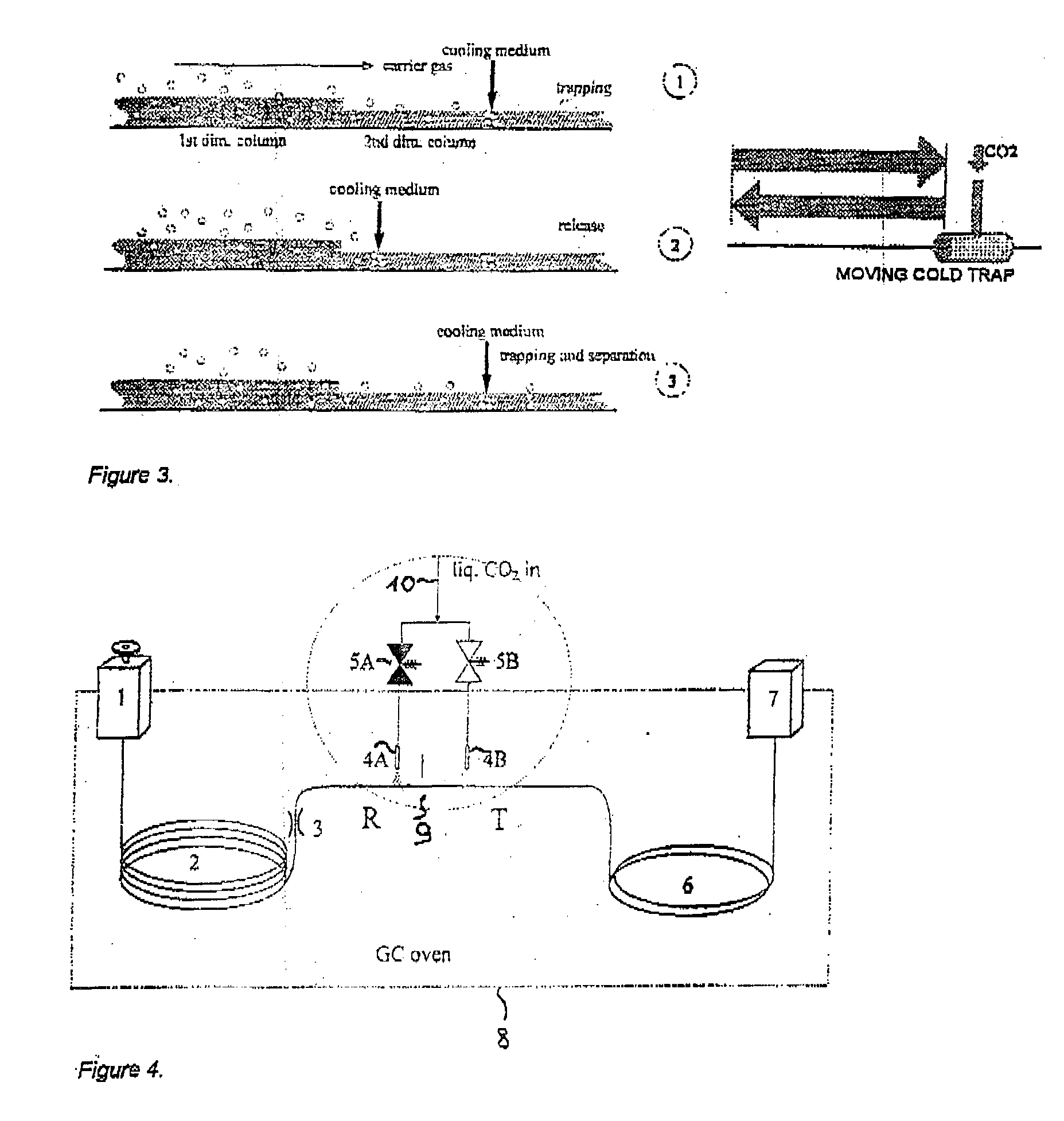

[0026] FIG. 4 is a scheme of a modulator according to the present invention.

[0027] FIG. 5 is a detail of the jet configuration of the modulator of FIG. 5.

[0028] FIG. 6 is a chromatogram obtained by means of a GCxGC separation of C.sub.8 through C.sub.18 with a modulator according to the present invention.

[0029] FIG. 7 is a chromatogram obtained by means of a GCxGC separation with a modulator according to the invention and showing the shape of the modulated n-C.sub.14 peaks.

[0030] FIG. 8 is a scheme of a modulator according to the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| cycle time | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com