Activated charcoal carried copper oxide catalyst and process for preparing same

A technology of activated carbon and copper oxide, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as application limitations and high prices, and achieve easy operation, Low price, high COD removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0017] Implementation method one, the steps of the preparation method of the activated carbon-supported copper oxide catalyst loaded with CuO 1.0%:

[0018] (1) 50 g of activated carbon was impregnated with 300 mL of 10% NaOH solution for 24 hours, filtered, and washed with deionized water until neutral;

[0019] (2) The activated carbon treated in step (1) was treated with 300mL 10%HNO 3 The solution was soaked for 24 hours, then filtered, washed with deionized water until neutral, placed in an oven, and dried at 100°C;

[0020] (3) Prepare 0.2mol / L Cu(NO 3 ) 2 Solution 200mL, in the solution, add 30g of active carbon treated with step (1), step (2) and stir fully, add dropwise 20% NaHCO 3 Precipitating agent until a large amount of precipitation occurs, aging for 24 hours, filtering, washing with deionized water until no metal ions are precipitated, and drying in an oven at 100°C to obtain a solid copper oxide supported on activated carbon.

[0021] (4) The activated car...

Embodiment approach 2

[0022] Implementation method two, the steps of the preparation method of the activated carbon-supported copper oxide catalyst loaded with CuO 5.0%:

[0023] Steps (1), (2) are the same as the implementation method one;

[0024] (3) Prepare 0.3mol / L Cu(NO 3 ) 2 Solution 200mL, in the solution, add 30g of active carbon treated with step (1), step (2) and stir fully, add dropwise 20% NaHCO 3 Precipitant until a large amount of precipitation occurs, mature for 24 hours, filter, wash with deionized water until no metal ions are precipitated, put it in an oven and dry at 110°C to obtain a solid copper oxide supported on activated carbon.

[0025] (4) Activate the activated carbon-supported copper oxide solid obtained in step (3) at 280° C. for 2.5 h to prepare an activated carbon-supported copper oxide catalyst with 5.0% CuO loaded.

Embodiment approach 3

[0026] Implementation method three, preparation method of activated carbon-supported copper oxide catalyst loaded with CuO 1.0%

[0027] Steps (1), (2), (3) are the same as the implementation method one;

[0028] (4) The activated carbon-supported copper oxide solid obtained in step (3) was activated at 270° C. for 2.5 h to prepare an activated carbon-supported copper oxide catalyst containing CuO 1.0%.

[0029] The method for treating coking wastewater with activated carbon-supported copper oxide catalytic oxidation of the present invention:

[0030] Take 100mL of coking wastewater and put it into a 250mL Erlenmeyer flask, add 1.5g of the prepared CuO 1.0% activated carbon-supported copper oxide catalyst, and then add 0.5-1.0mL of 30% H 2 o 2 , react at 35-40°C for 25-30 minutes, filter, and the filtrate is the treated wastewater.

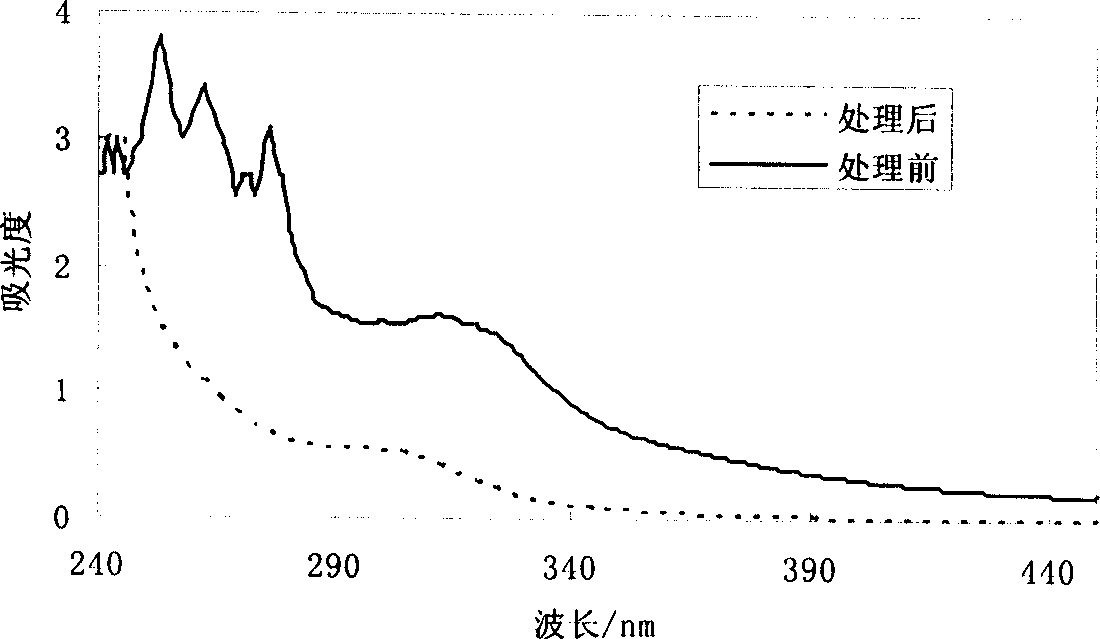

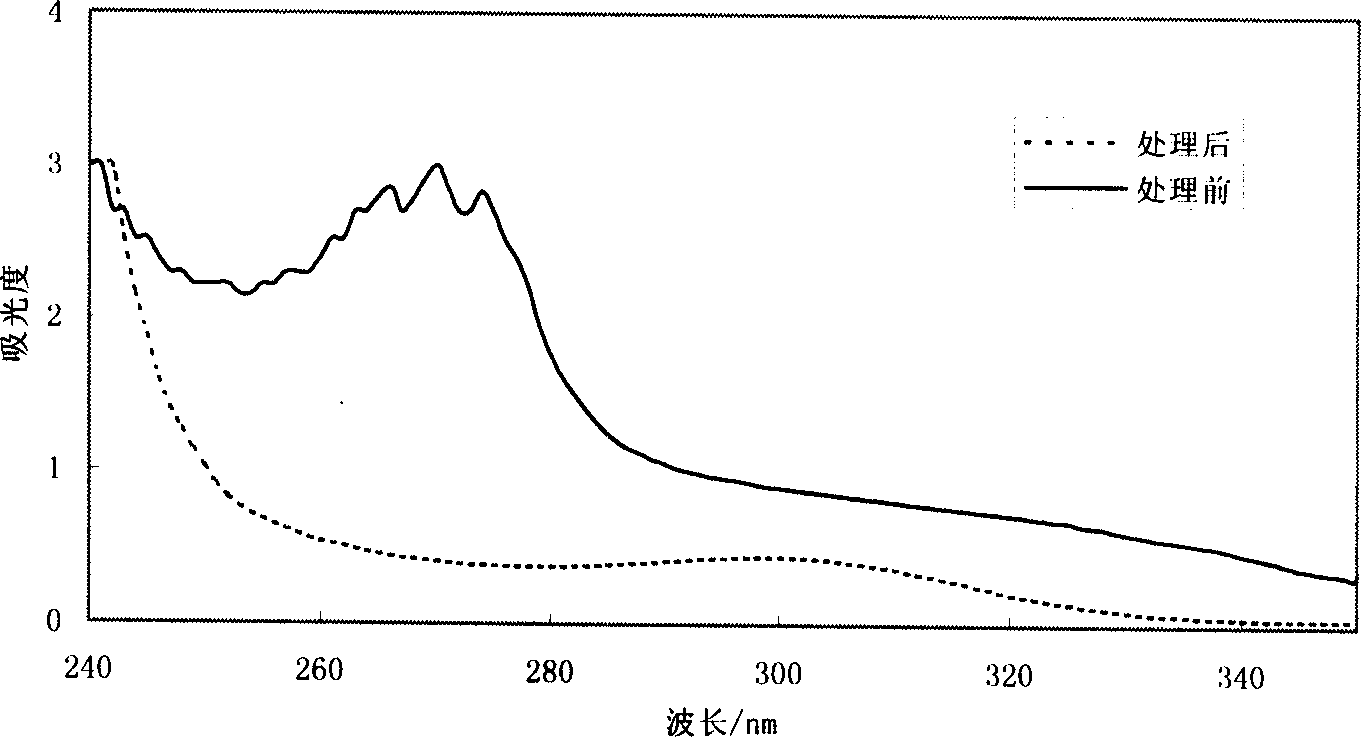

[0031] The present invention's activated carbon-carrying copper oxide catalyst treats the Anshan Iron and Steel Works coking wastewater with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com