Method for modifying hydrophobicity of ceramic membrane, its application and its apparatus

A hydrophobic modification and ceramic membrane technology, which is applied in the field of ceramic membranes, can solve the problems of new membrane materials limiting the industrial application of membrane distillation, and achieve the effects of good modification effect, expanded source, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

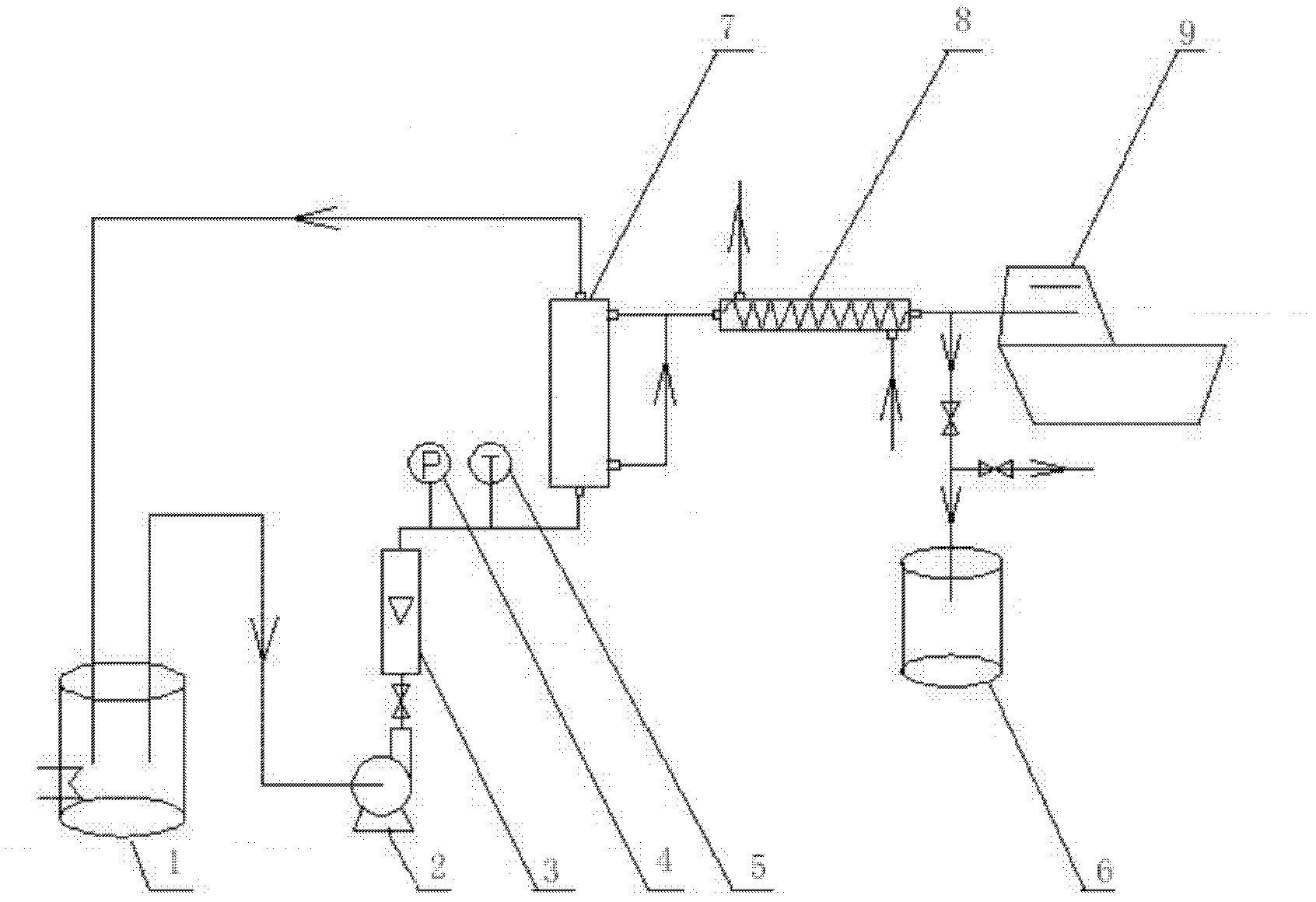

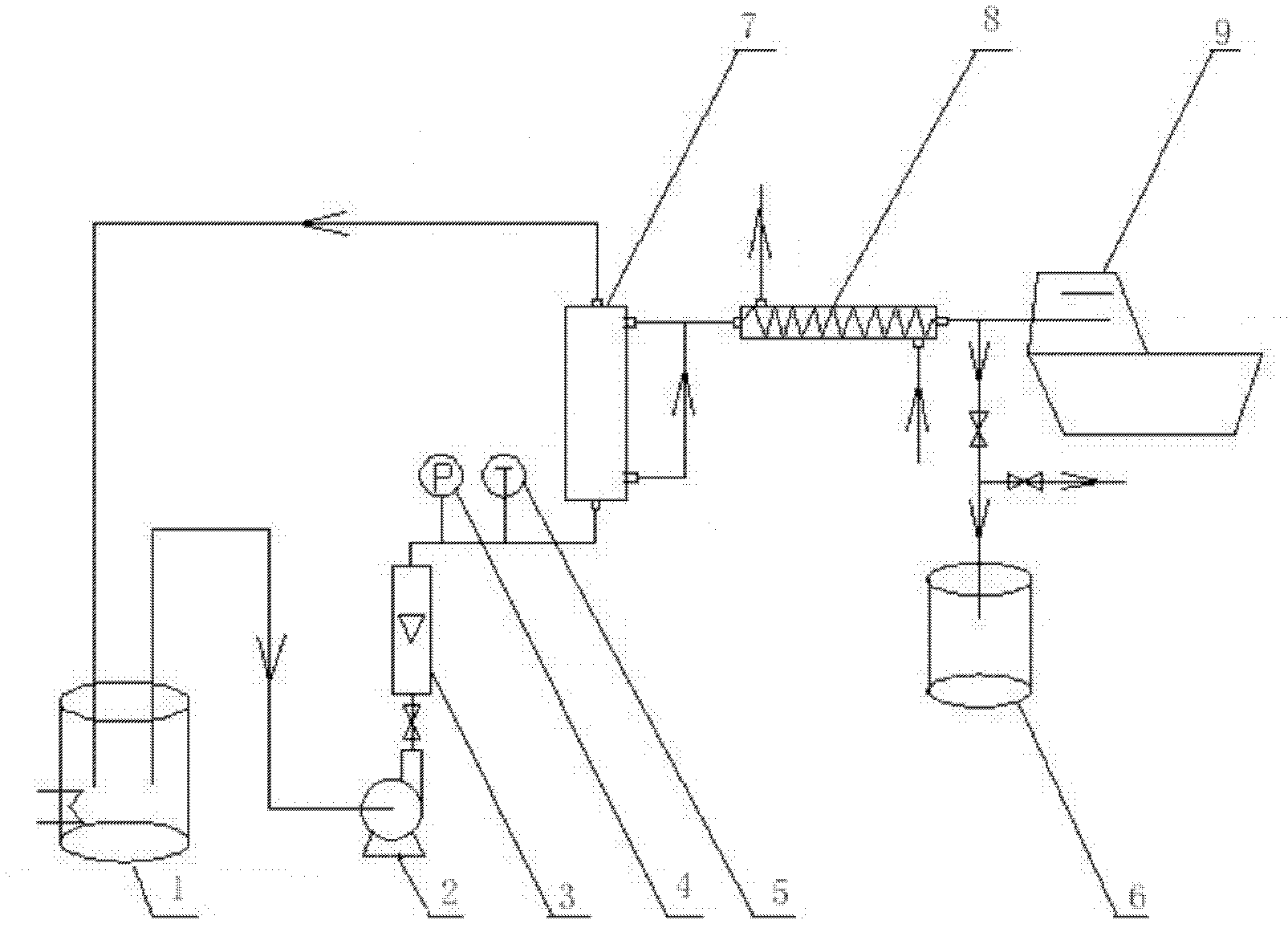

Method used

Image

Examples

Embodiment 1

[0025] A method for hydrophobic modification of a ceramic membrane, the specific steps of which are:

[0026] (1) The selection of organic precursors, choose dimethyl dichlorosilane ((CH 3 ) 2 SiCl 2 ) as an organic precursor, because chlorine has low surface activation energy, high hydrophobicity and oxidation resistance;

[0027] (2) Preparation of modified solution, the selected organic precursor 2mol / L was dissolved in cyclohexane, and vigorously stirred for 12 hours at room temperature to obtain modified solution;

[0028] (2)Al 2 o 3 The ceramic membrane was pre-treated, soaked in NaOH solution (3mol / L) for 10 minutes, washed with chloroform and deionized water, placed in an oven at 150°C for 1 hour, and then cooled to room temperature;

[0029] (3)Al 2 o 3 The surface grafting reaction of the ceramic membrane; the pre-treated Al 2 o 3 Soak the ceramic membrane in the organic modification solution for 24 hours; the chemical modification reaction generally occurs...

PUM

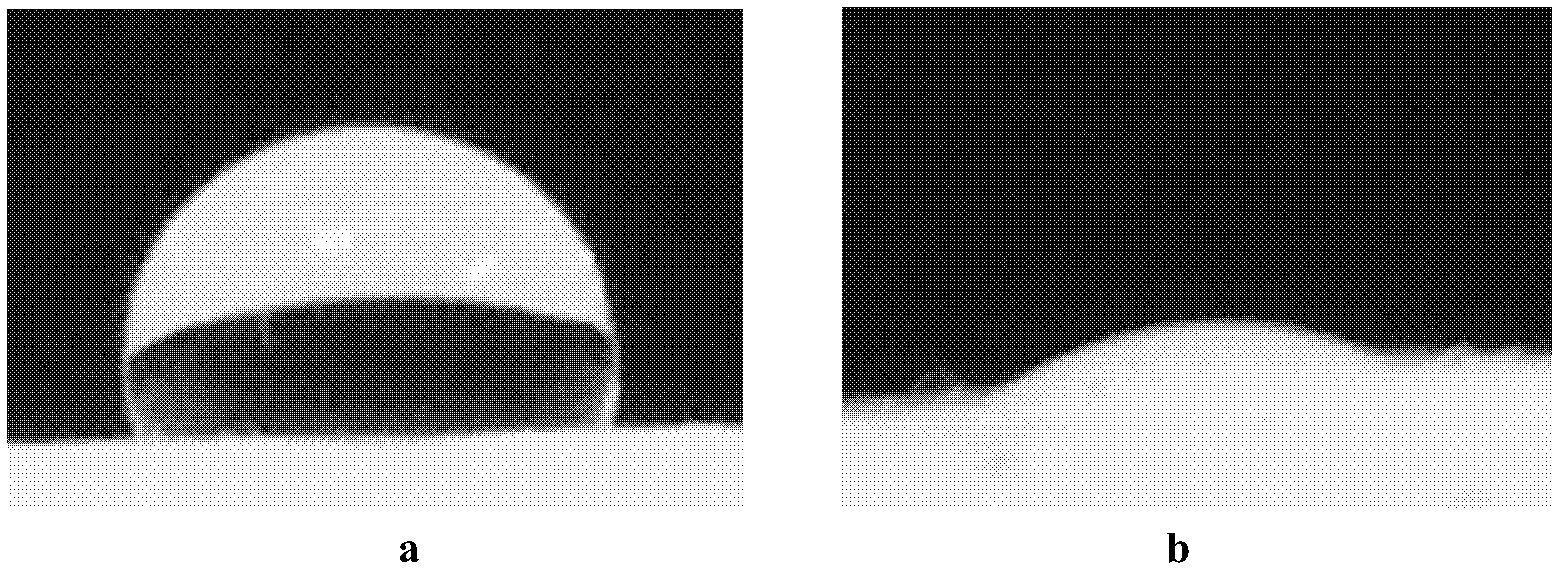

| Property | Measurement | Unit |

|---|---|---|

| Surface contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com