Ultrathin porous N doped g-C3N4 photocatalyst and preparation method thereof

A photocatalyst, g-c3n4 technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high recombination probability of photogenerated electron-hole pairs, low quantum efficiency of hydrogen production, and constraints Problems such as the process of industrialization, to achieve the effects of NO gas degradation and pollutant degradation performance improvement, low raw material cost, and improvement of reduction performance and oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

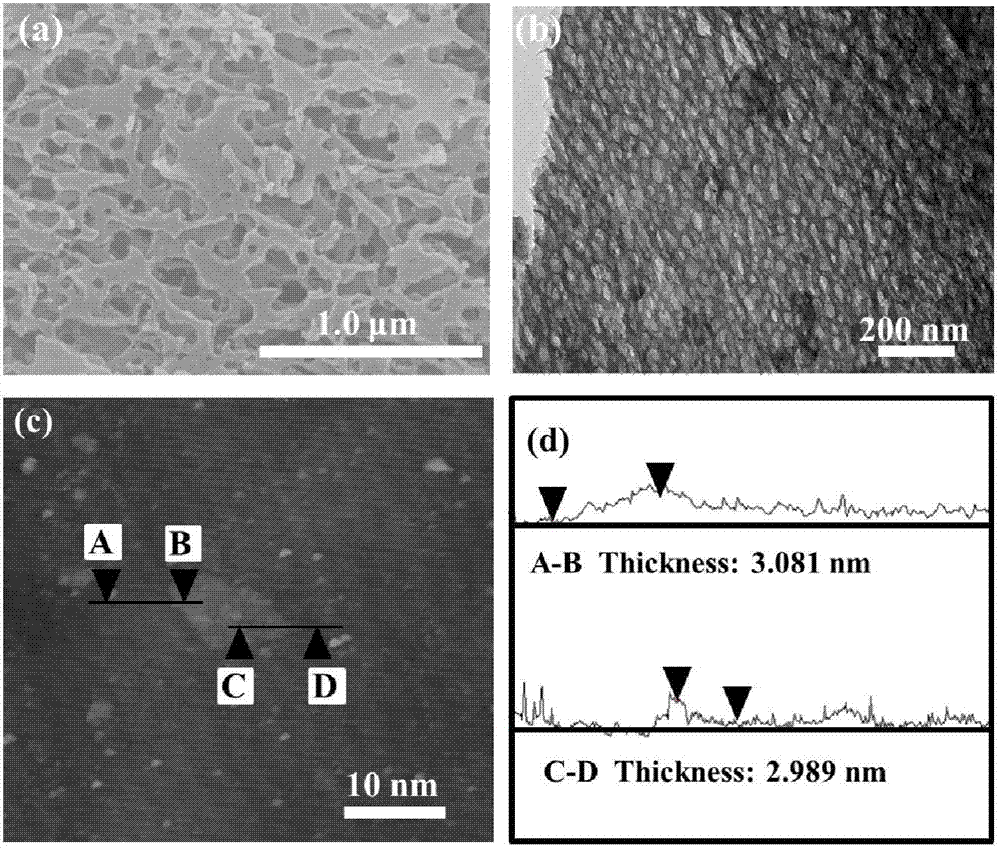

[0019] Embodiment one: carry out according to the following steps:

[0020]In the first step, urea and melamine were added to 50ml of distilled water in a molar ratio of 1:1, placed on a constant temperature magnetic stirrer and stirred for 30min, and then the solution was transferred to a 100mL polytetrafluoroethylene-lined hydrothermal kettle. Then put the hydrothermal kettle into the oven at 180 degrees and keep warm for 24h;

[0021] In the second step, after the hydrothermal kettle is naturally cooled to room temperature, the white matter in the kettle is washed with distilled water for 3 to 5 times, and then dried in an oven (60 degrees for 10 hours). Grind the dried white substance and put it into a corundum crucible, then put the crucible into a muffle furnace for calcination at 520°C for 4h, with a heating rate of 3°C / min.

Embodiment 2

[0022] Embodiment two: carry out according to the following steps:

[0023] In the first step, urea and melamine were added to 50ml of distilled water in a molar ratio of 3:1, placed on a constant temperature magnetic stirrer and stirred for 30min, and then the solution was transferred to a 100mL polytetrafluoroethylene-lined hydrothermal kettle. Then put the hydrothermal kettle into the oven at 180 degrees and keep warm for 20h;

[0024] In the second step, after the hydrothermal kettle is naturally cooled to room temperature, the white matter in the kettle is washed with distilled water for 3 to 5 times, and then dried in an oven (60 degrees for 10 hours). Grind the dried white substance and put it into a corundum crucible, then put the crucible into a muffle furnace for calcination at 520°C for 3h, with a heating rate of 3°C / min.

Embodiment 3

[0025] Embodiment three: carry out according to the following steps:

[0026] In the first step, urea and melamine were added to 50ml of distilled water in a molar ratio of 6:1, placed on a constant temperature magnetic stirrer and stirred for 30min, and then the solution was transferred to a 100mL polytetrafluoroethylene-lined hydrothermal kettle. Then put the hydrothermal kettle into an oven at 200 degrees and keep warm for 16h;

[0027] In the second step, after the hydrothermal kettle is naturally cooled to room temperature, the white matter in the kettle is washed with distilled water for 3 to 5 times, and then dried in an oven (60 degrees for 10 hours). The dried white substance was ground and put into a corundum crucible, and then the crucible was put into a muffle furnace for calcination at 500°C for 3h, and the heating rate was 3°C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com