Patents

Literature

36results about How to "Improve cooling reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus for preparing food

ActiveUS20140083992A1Improve cooling reliabilityImprove reliabilityDomestic stoves or rangesOven air-treatment devicesEngineeringFood preparation

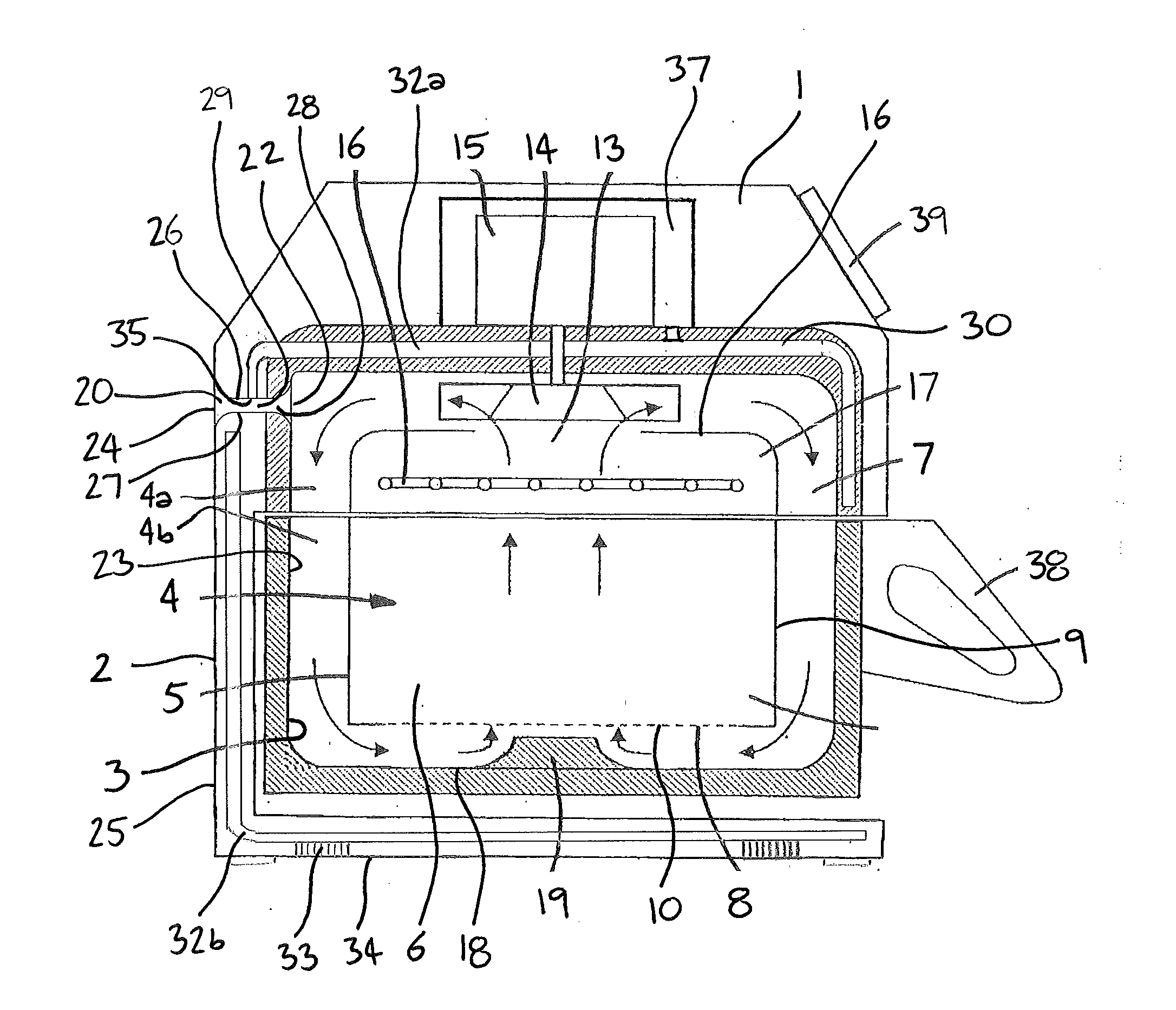

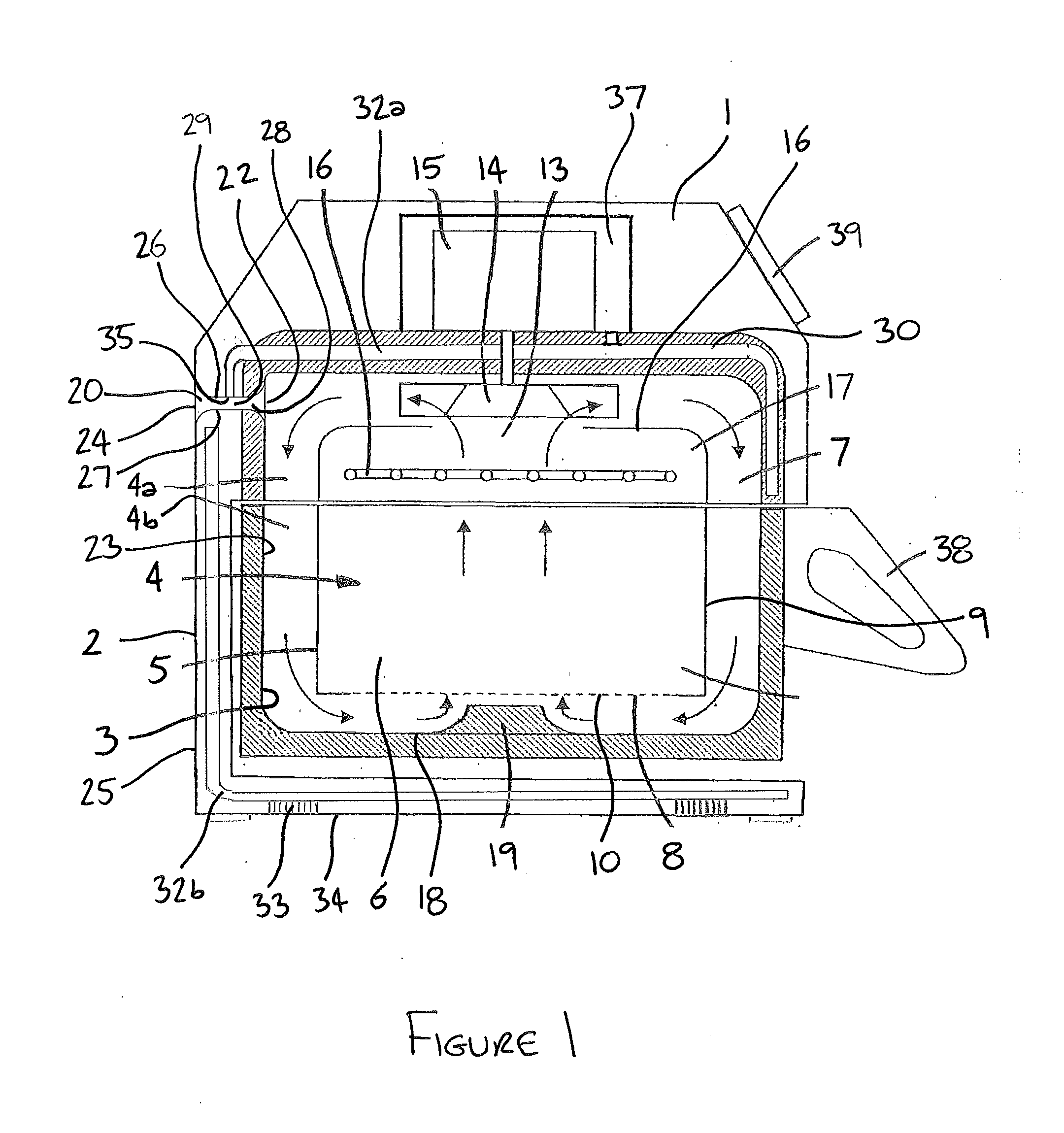

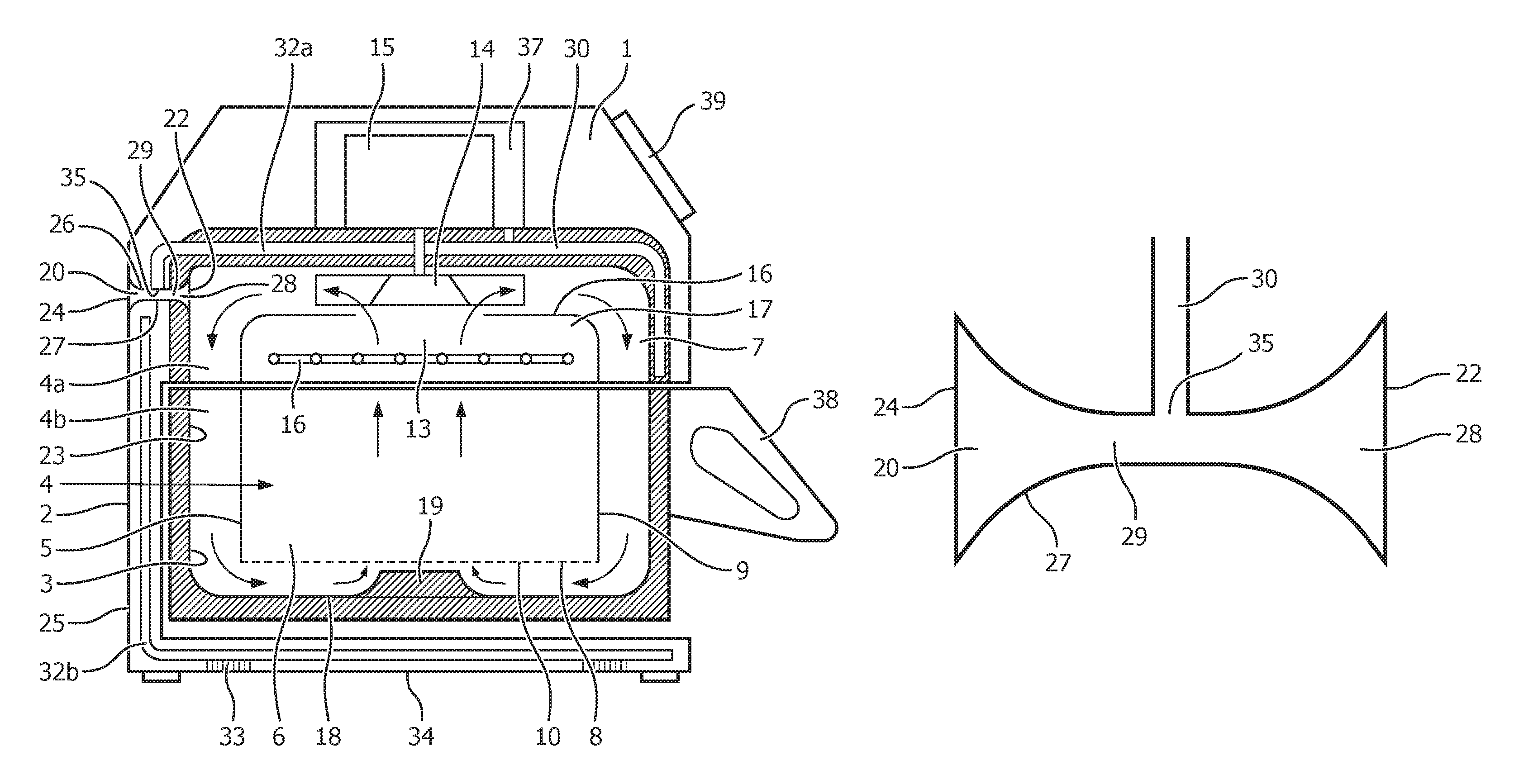

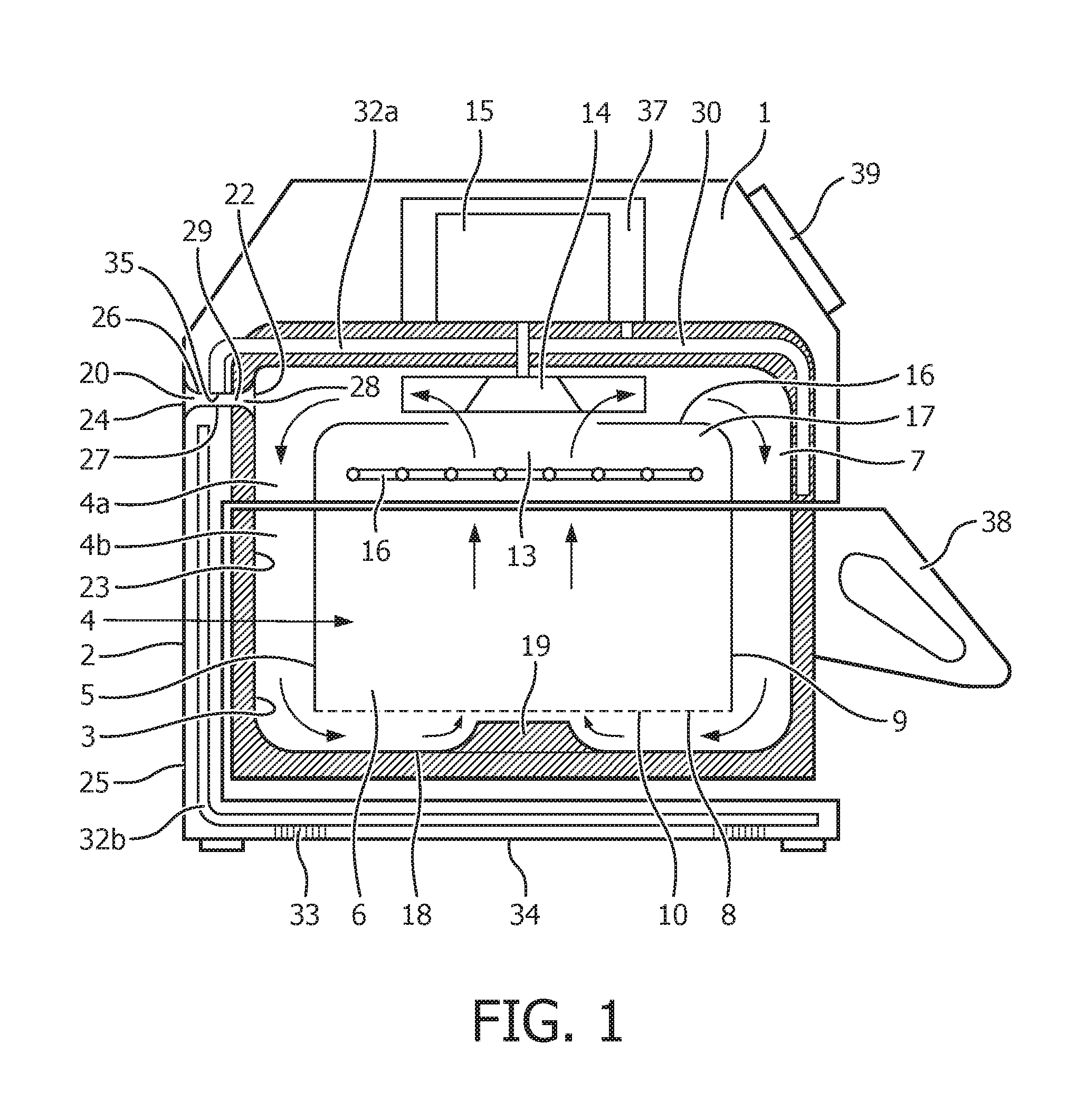

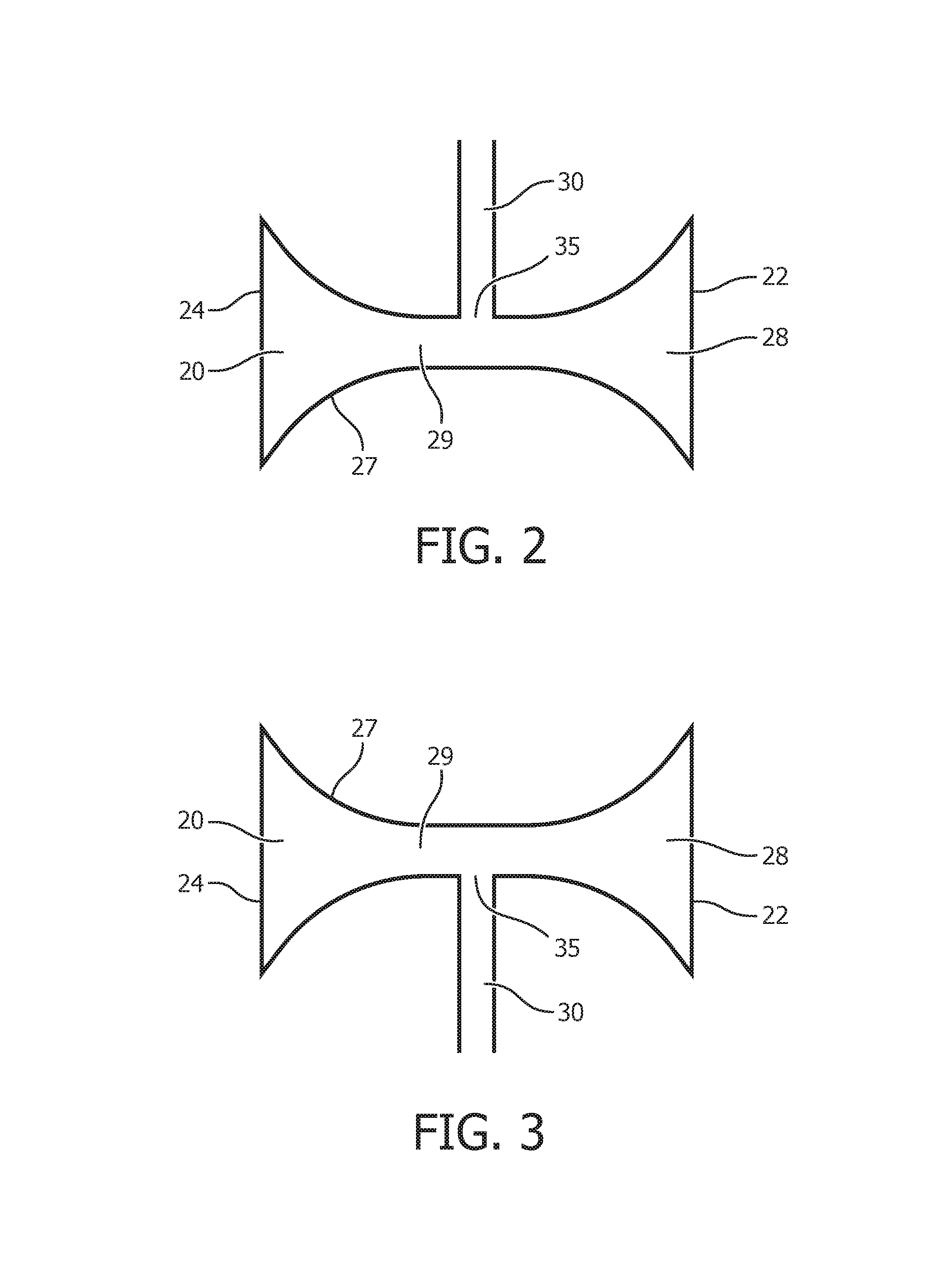

The application relates to an apparatus for preparing food. The apparatus includes a housing (1), a food preparation chamber (4) in the housing (1) having an inner wall (5) defining a food receiving space (6) with an air entry aperture (10) and an air discharge aperture (13), a fan (14) for moving a flow of hot air successively through the air entry aperture (10), the food receiving space (6) and the air discharge aperture (13), and an air guide passage (7) for returning the flow of air from the air discharge aperture (13) towards the air entry aperture (10) separate from the food receiving space (6). The housing (1) comprising a cooling air channel (30) and a hot air vent (20) for exhausting the flow of hot air from the food preparation chamber (4) to outside the housing (1) with a constricted section (29) having a reduced cross-sectional area such that a venturi effect is generated in the hot air vent (20). An outlet (35) to the cooling air channel (30) communicates with the hot air vent (20) at the constricted section (29) such that a region of low pressure is formed at the outlet (35) and a flow of cooling air is drawn along the cooling air channel (30) and into the hot air vent (20).

Owner:KONINKLJIJKE PHILIPS NV

Apparatus for preparing food

ActiveUS9353954B2Reduce the cross-sectional areaImprove cooling reliabilityDomestic stoves or rangesOven air-treatment devicesEngineeringMechanical engineering

The application relates to an apparatus for preparing food. The apparatus includes a housing (1), a food preparation chamber (4) in the housing (1) having an inner wall (5) defining a food receiving space (6) with an air entry aperture (10) and an air discharge aperture (13), a fan (14) for moving a flow of hot air successively through the air entry aperture (10), the food receiving space (6) and the air discharge aperture (13), and an air guide passage (7) for returning the flow of air from the air discharge aperture (13) towards the air entry aperture (10) separate from the food receiving space (6). The housing (1) comprising a cooling air channel (30) and a hot air vent (20) for exhausting the flow of hot air from the food preparation chamber (4) to outside the housing (1) with a constricted section (29) having a reduced cross-sectional area such that a venturi effect is generated in the hot air vent (20). An outlet (35) to the cooling air channel (30) communicates with the hot air vent (20) at the constricted section (29) such that a region of low pressure is formed at the outlet (35) and a flow of cooling air is drawn along the cooling air channel (30) and into the hot air vent (20).

Owner:VERSUNI HLDG BV

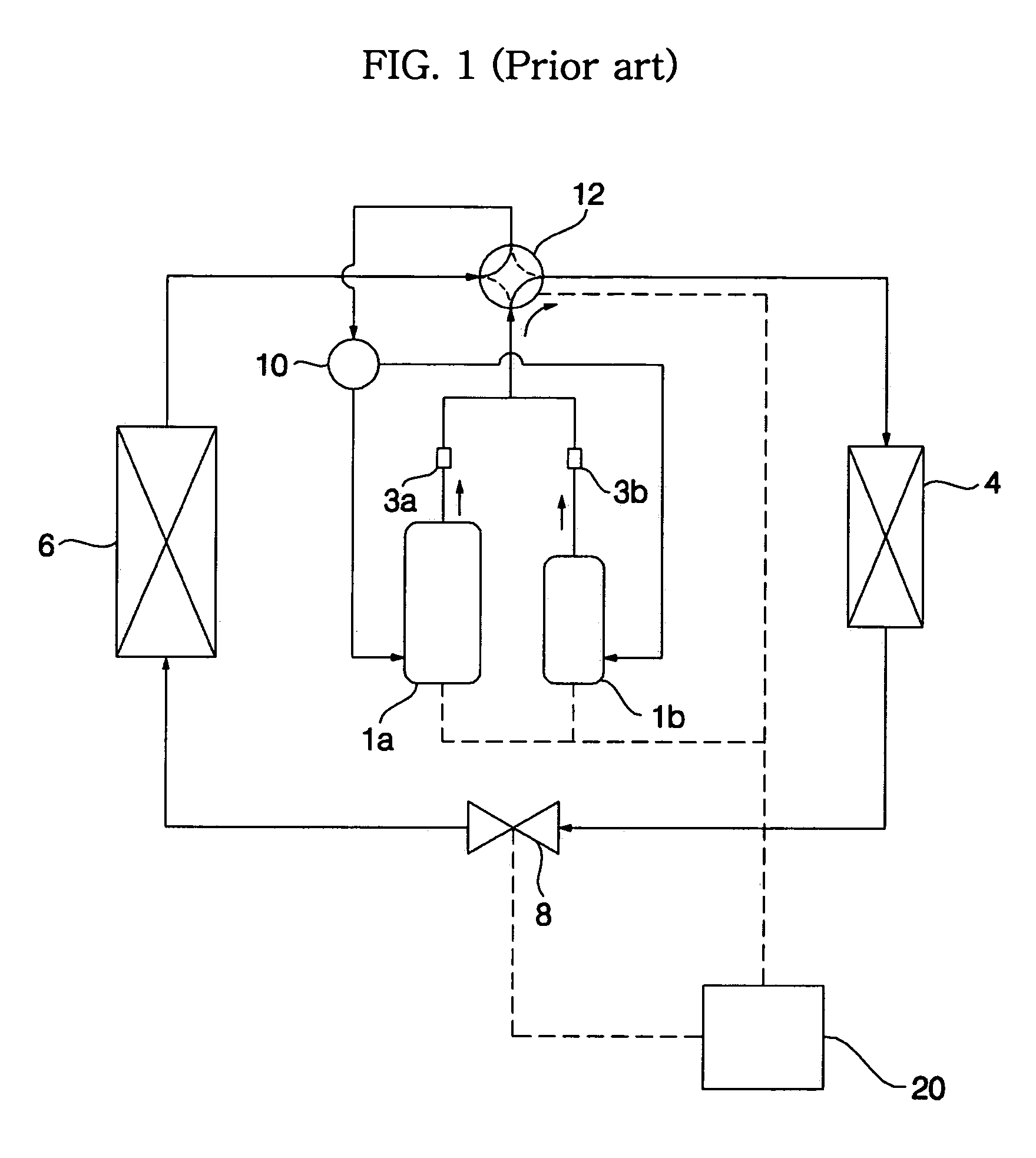

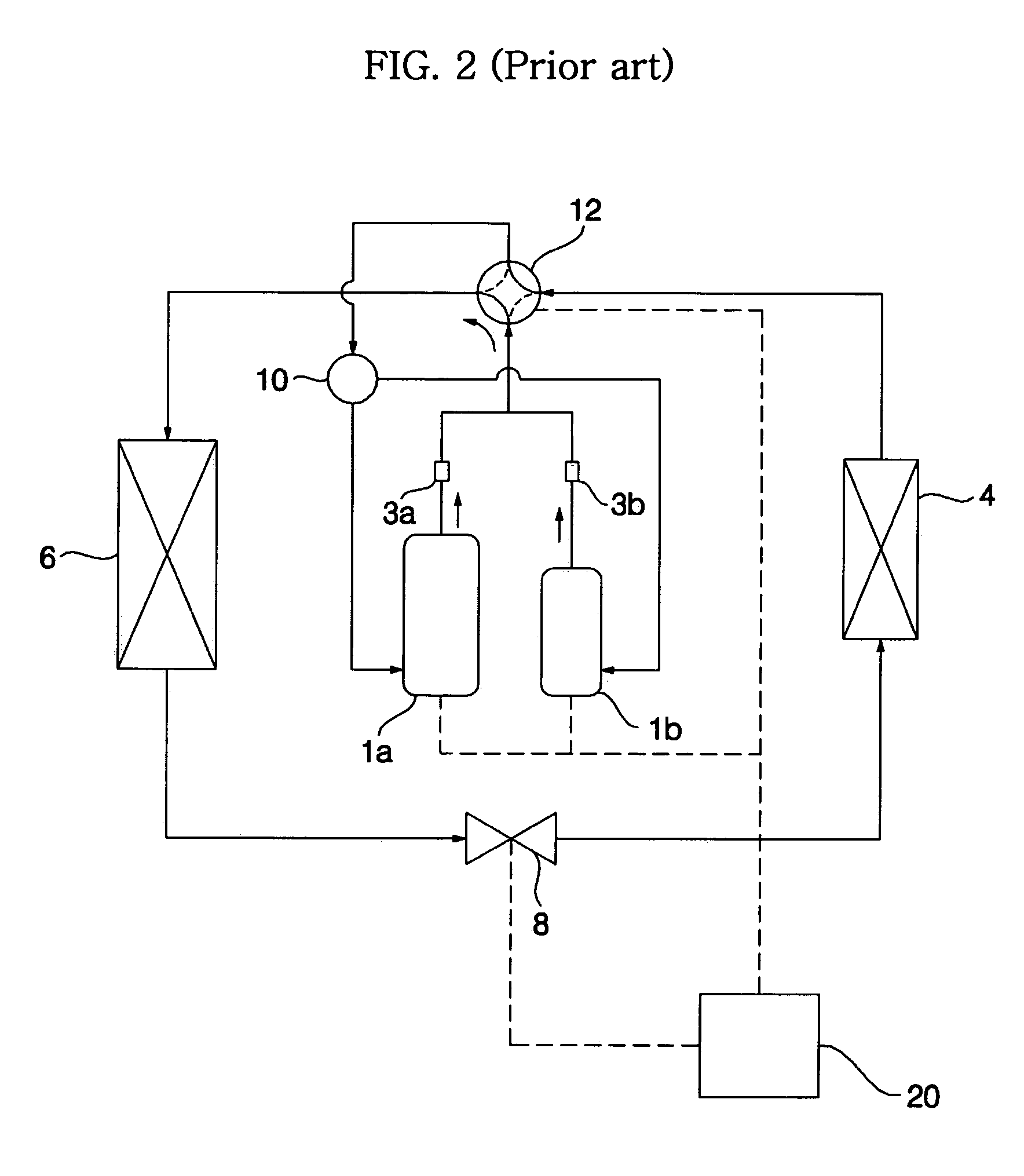

Multiple-connecting air conditioner and control method thereof

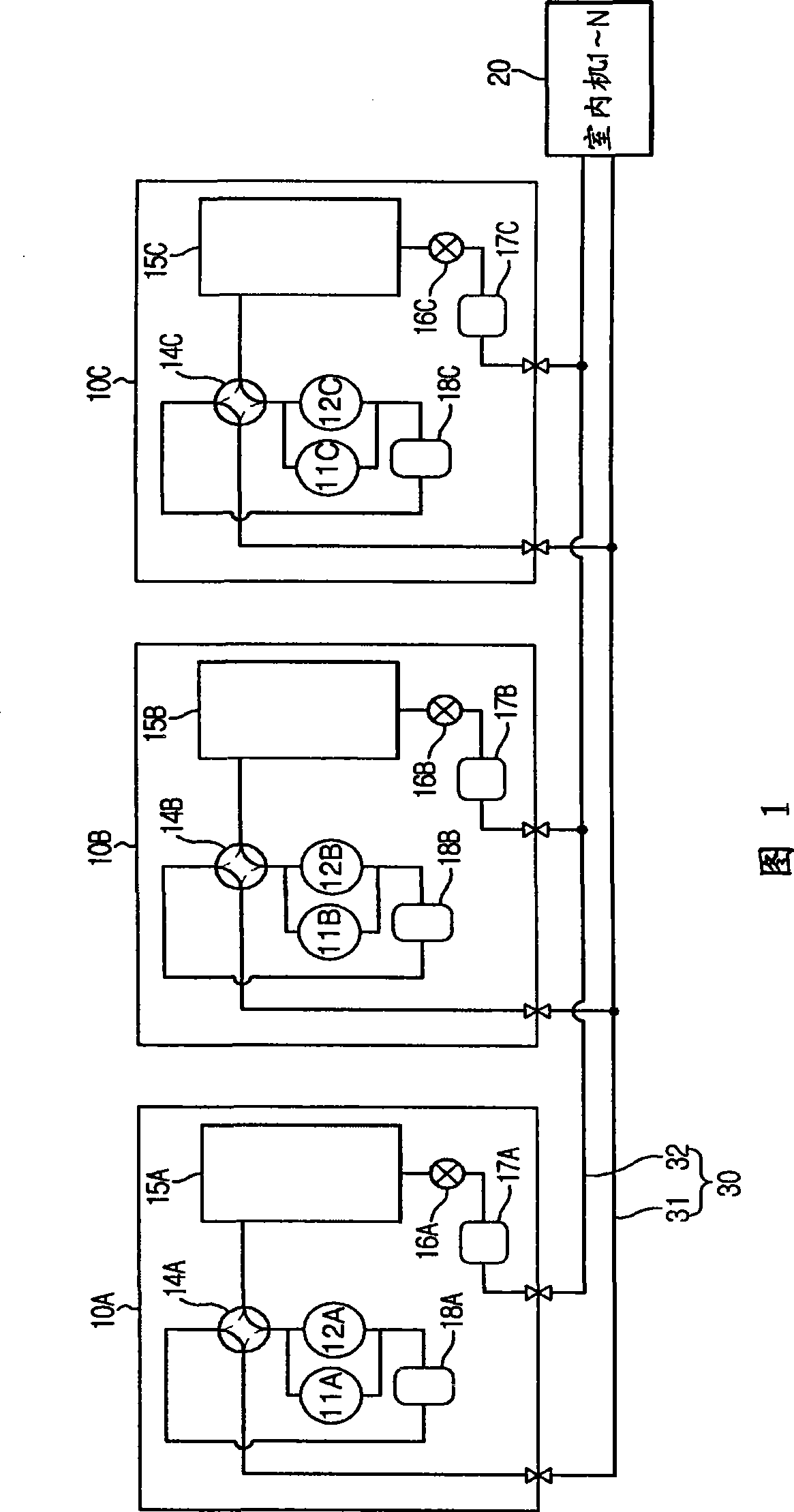

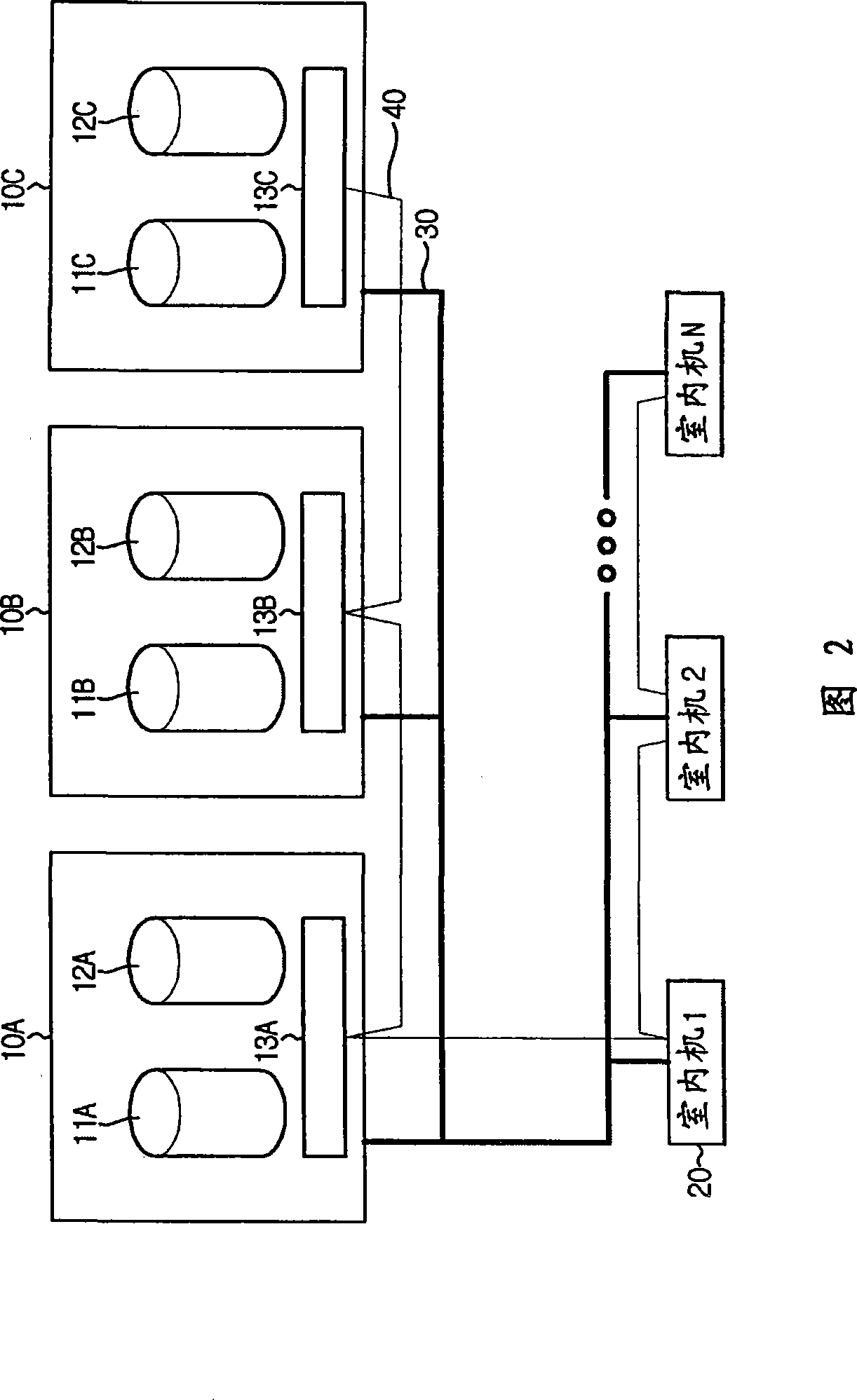

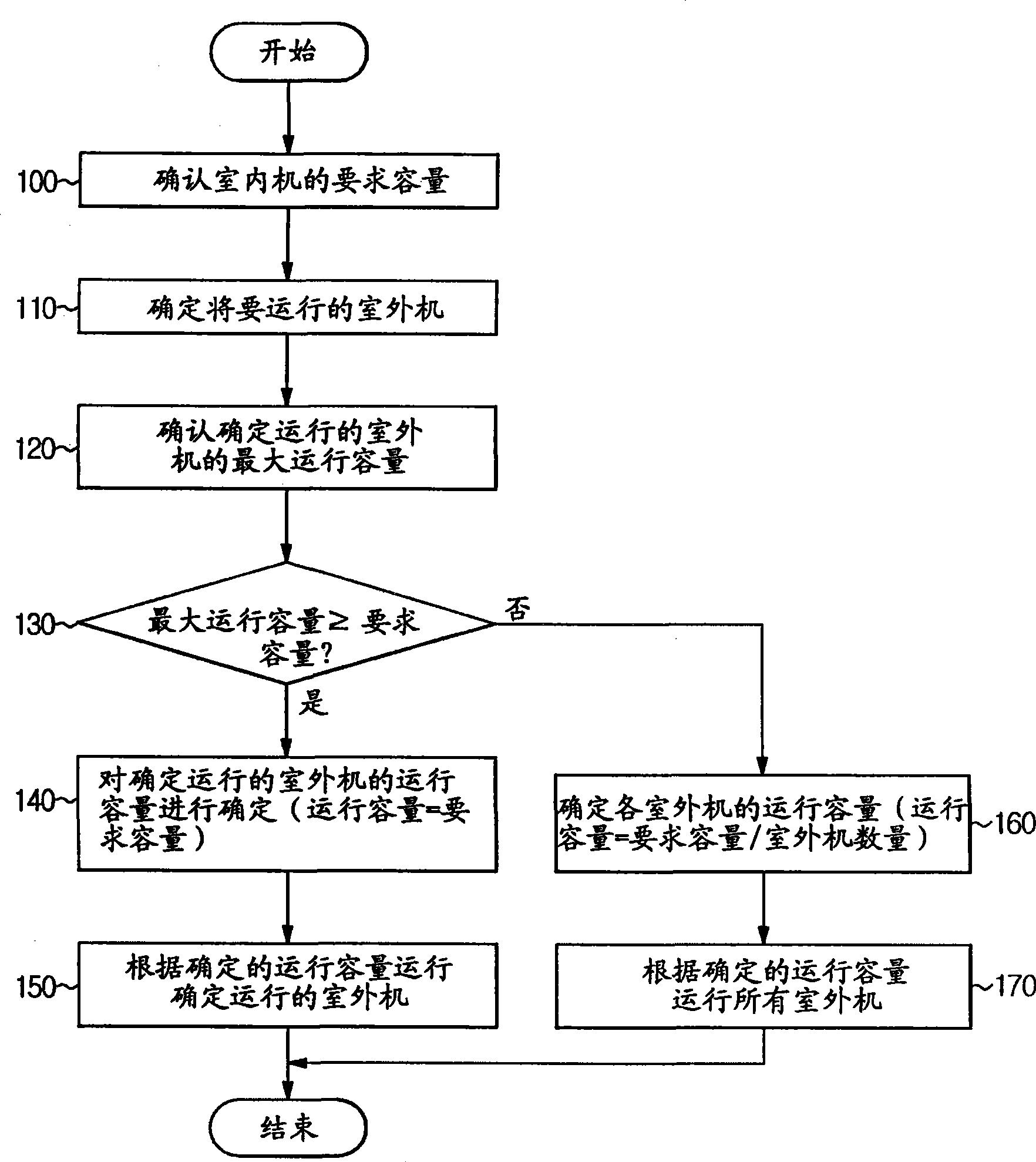

InactiveCN101435614AReduce noiseImprove cooling reliabilityMechanical apparatusSpace heating and ventilation safety systemsMulti unitLow load

The invention relates to a multi-unit air conditioner and the controlling method thereof, in particular to that in a multi-unit air conditioner consisting of a plurality of outdoor units which are only provided with a compressor with variable capacity for each, the required capacity of the indoor unit can drive an outdoor unit alone through a low load dealt with by an outdoor unit, while in high load, all the outdoor units work by distributing the required capacity of indoor unit evenly, thereby minimizing the damage caused by changing and unloading of the minimum running capacity; even when the outdoor temperature is very low and the required capacity of indoor units is under a certain level, the reliability can be also be raised and the noise of outdoor units can be reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

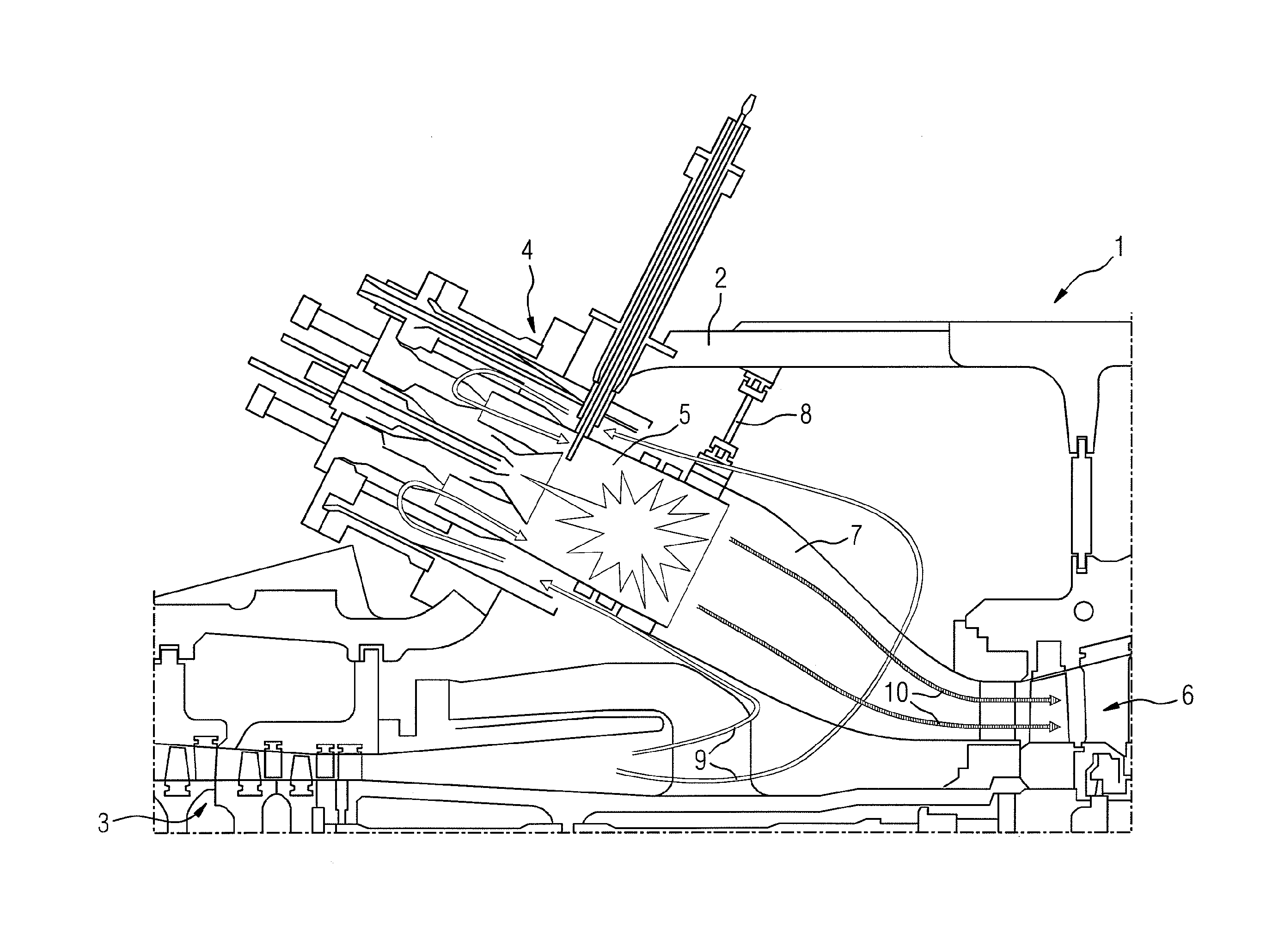

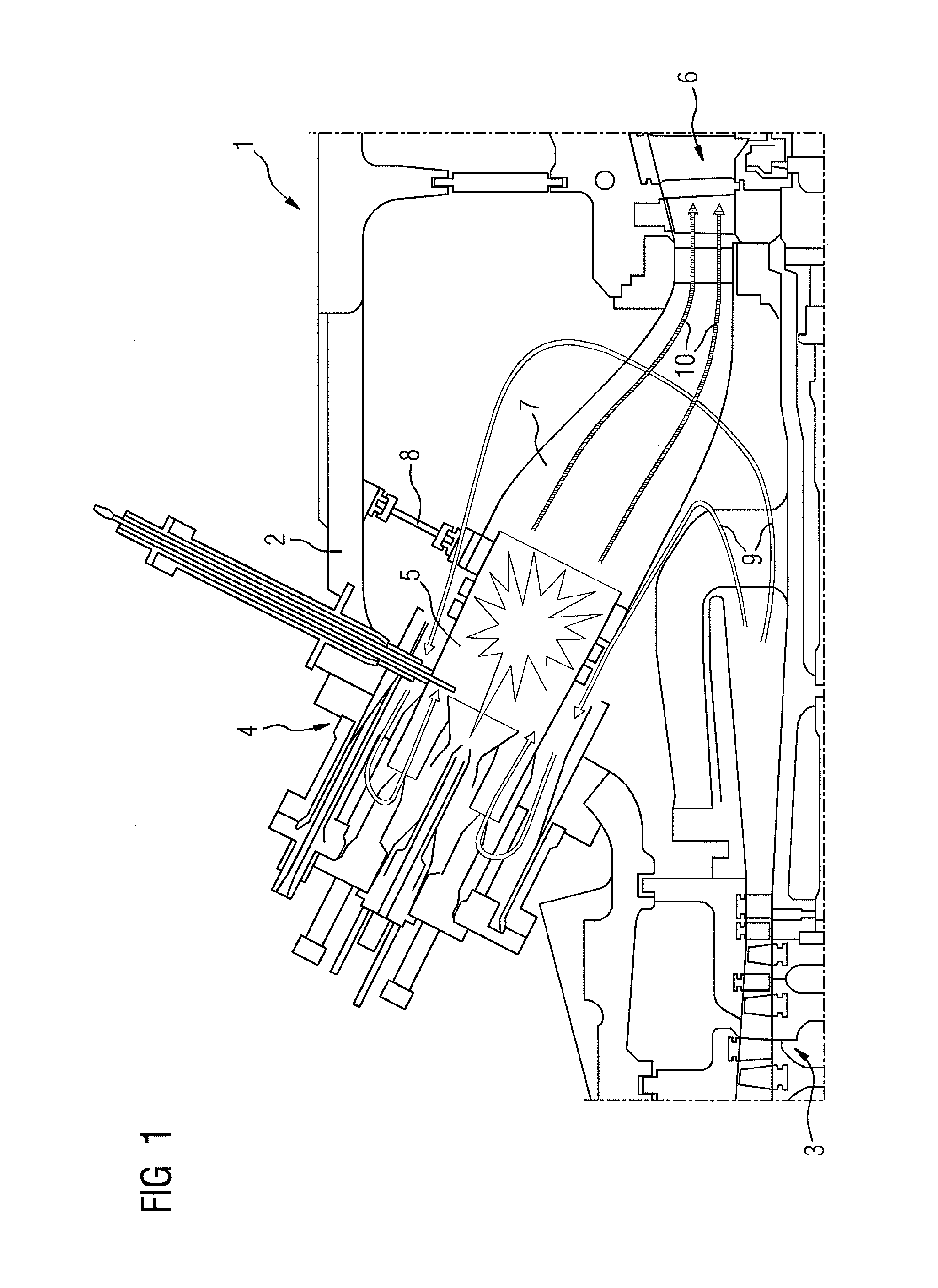

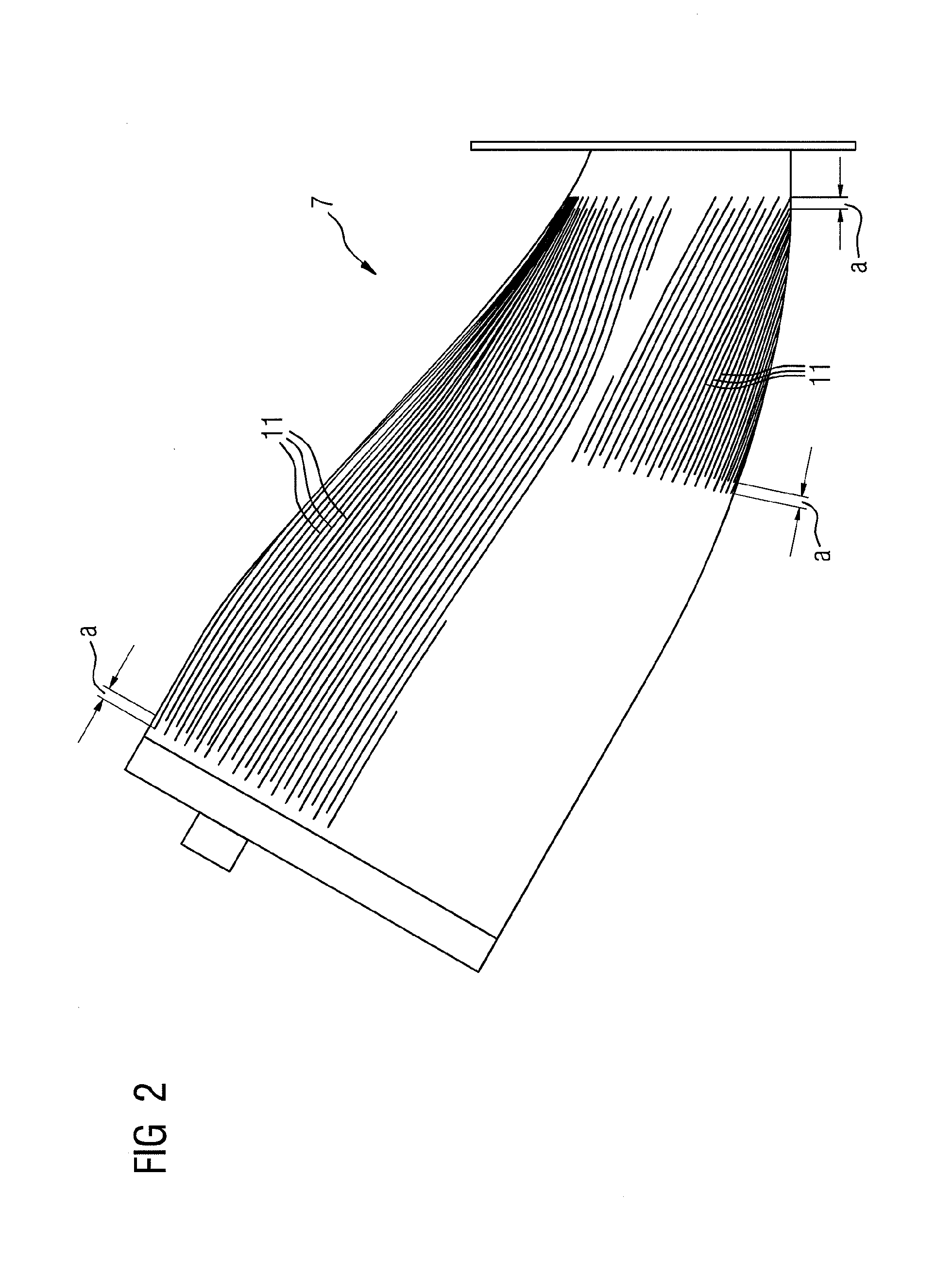

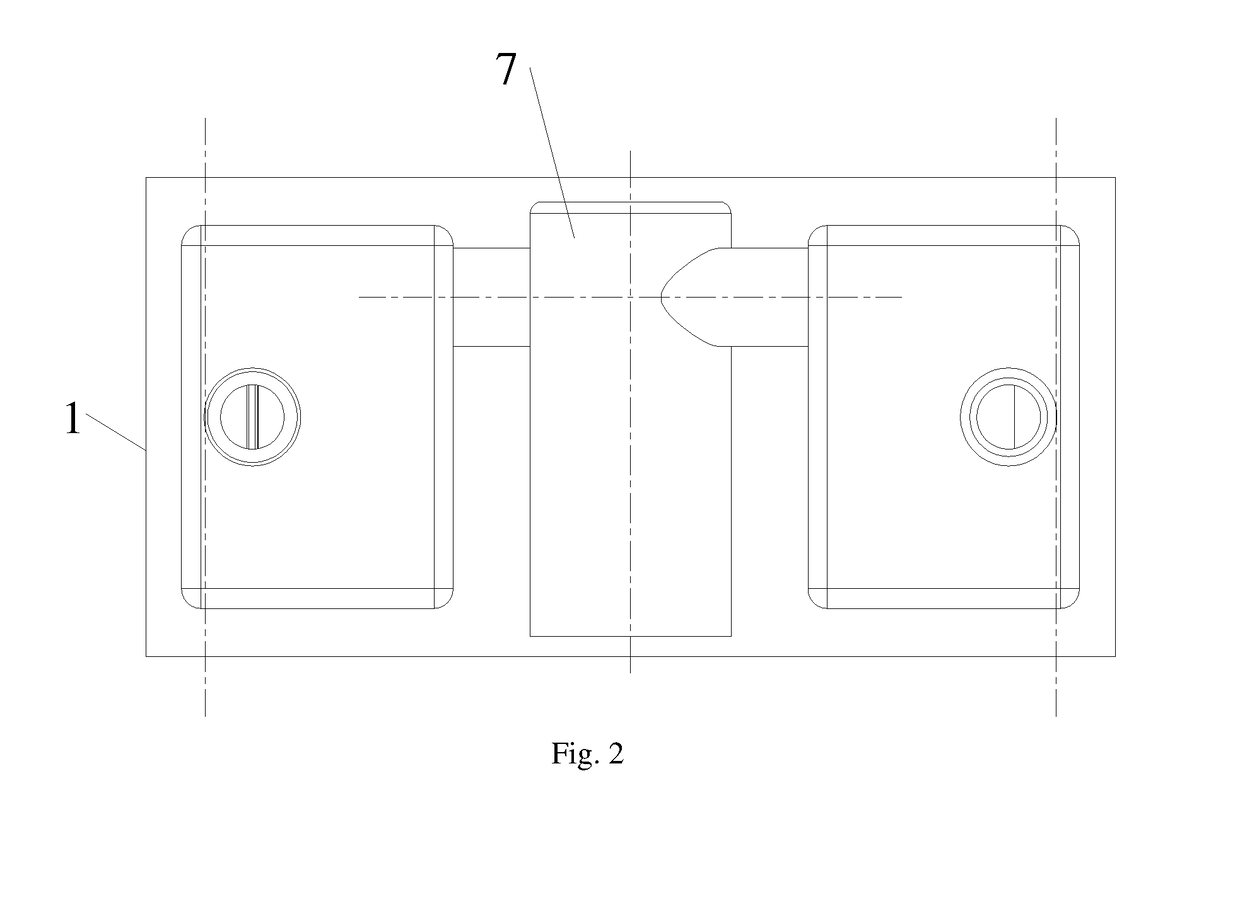

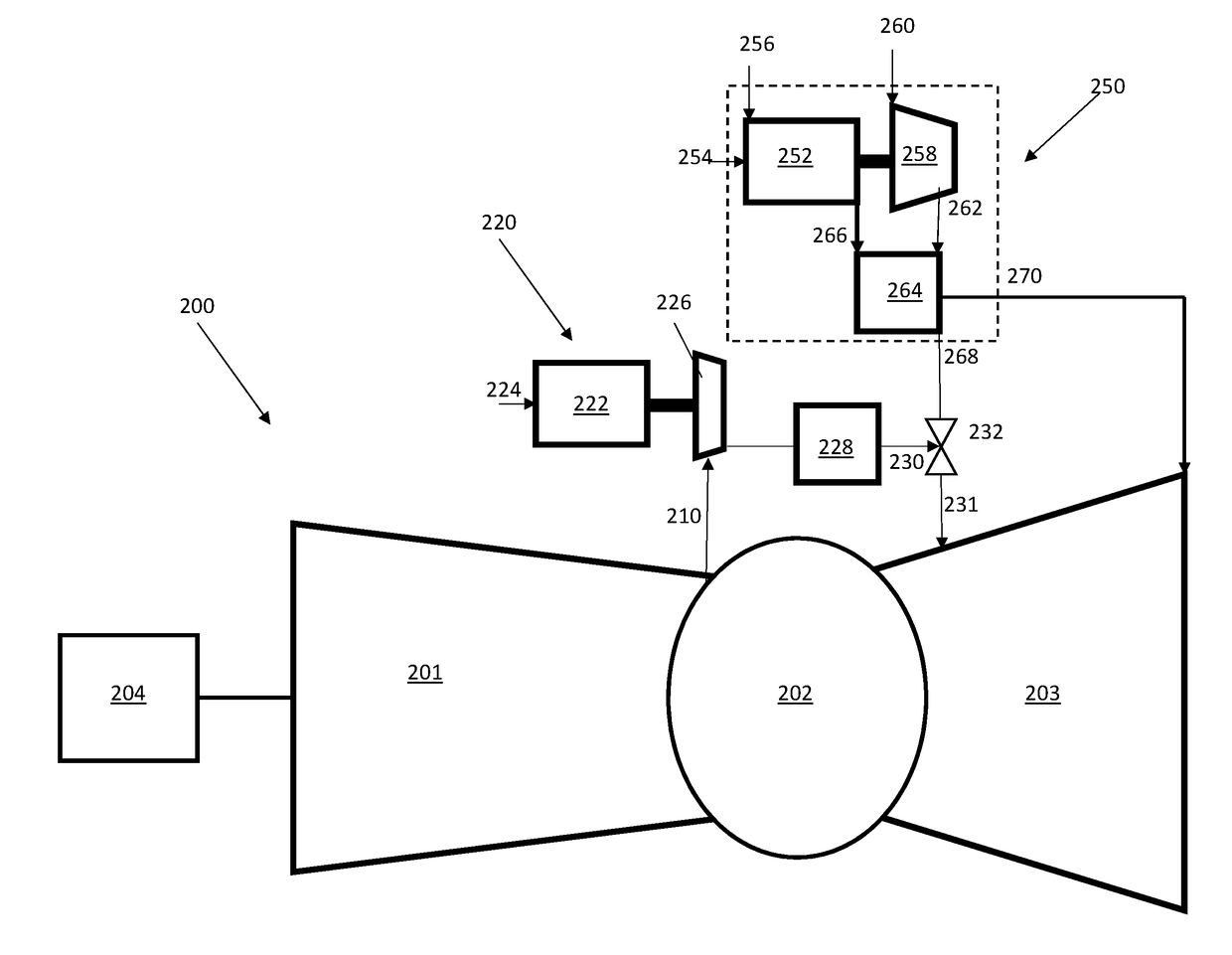

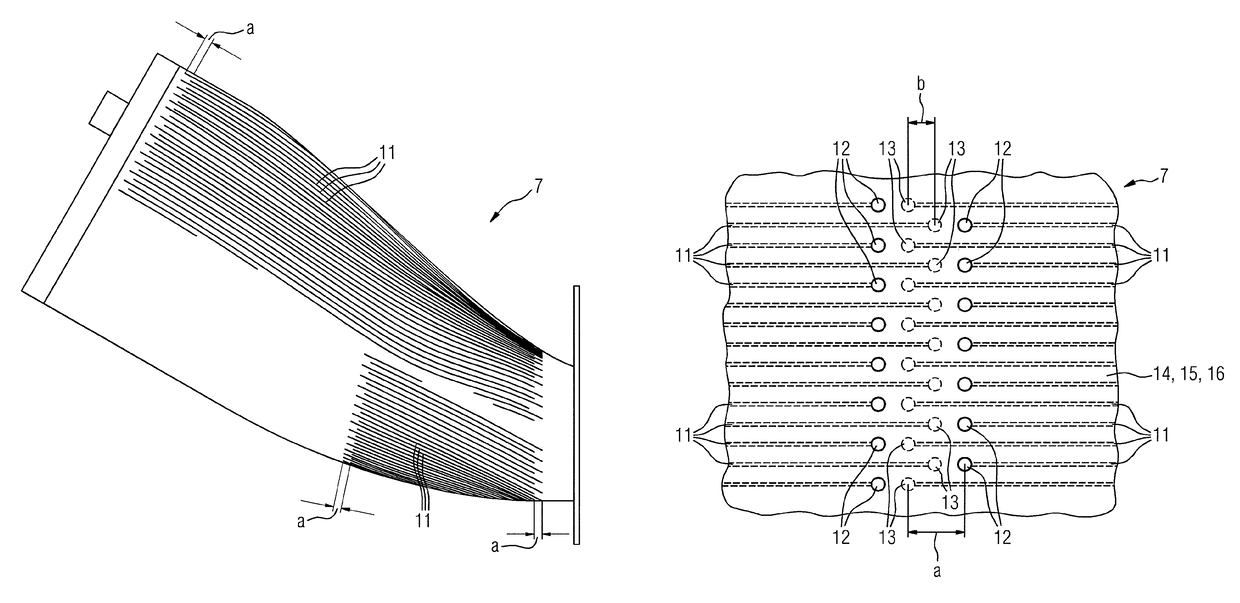

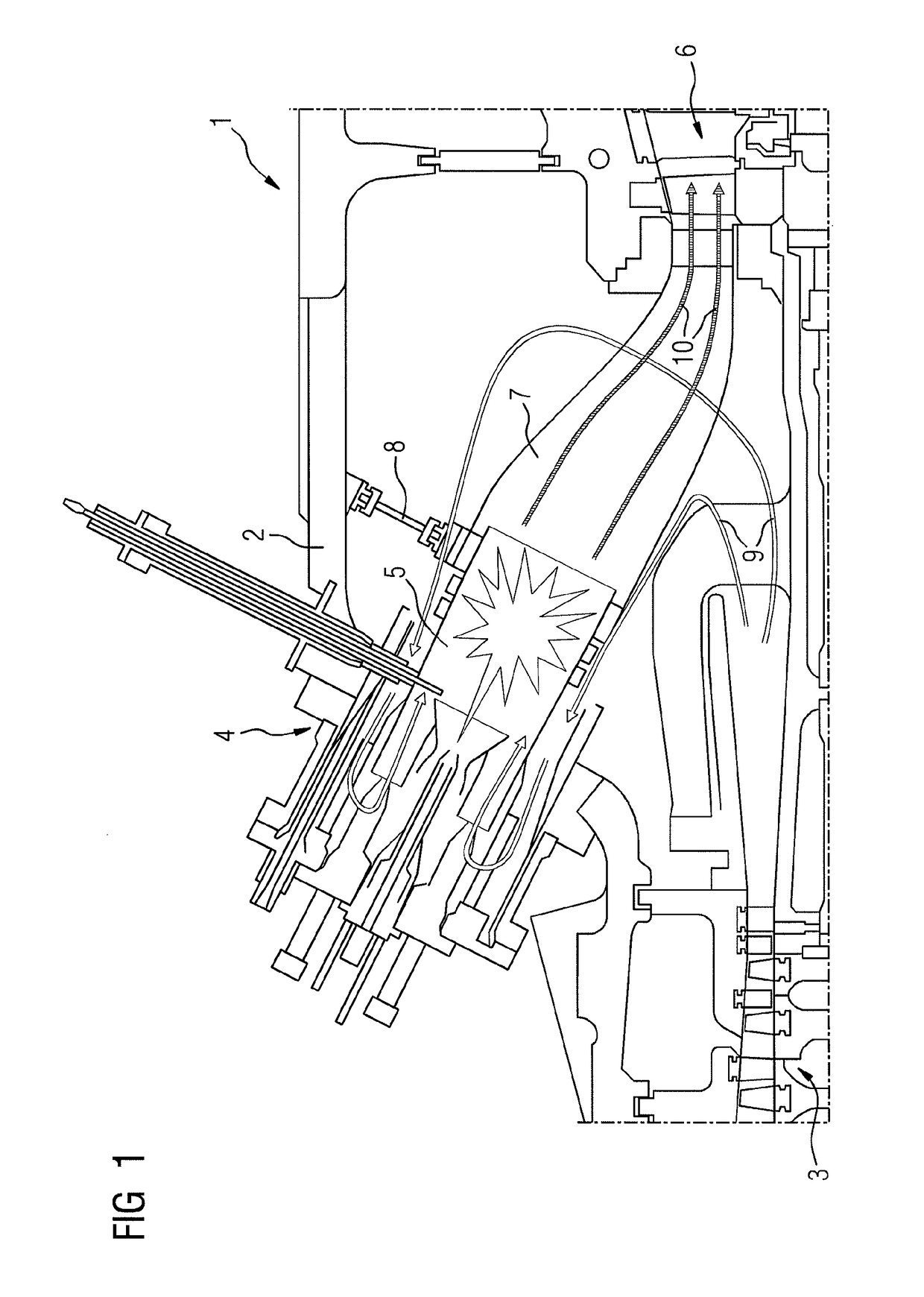

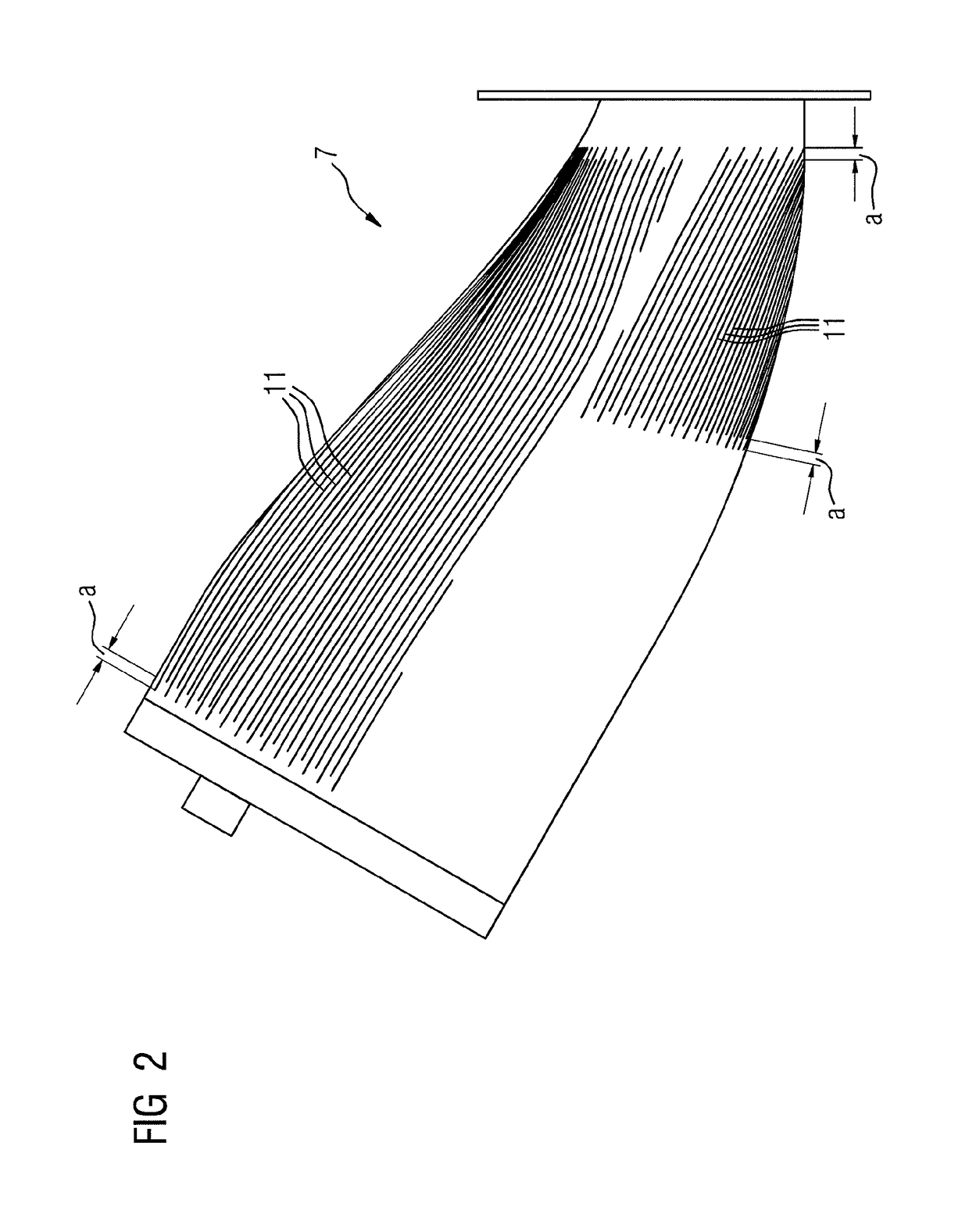

Gas turbine system

ActiveUS20160047312A1Adjust cooling efficiencyAdjust mechanical robustnessContinuous combustion chamberEngine fuctionsCombustorCombustion chamber

A gas turbine system (1) including a burner arrangement having a tubular combustion chamber (5), a turbine (6) and a transition duct (7) connecting the combustion chamber (5) and the turbine (6), wherein the transition duct (7) is provided with an axially extending cooling air channel (11). The transition duct (7) includes a plurality of axially extending cooling air channels, and wherein each cooling air channel (11) is provided with one single inlet (12) opened to the outside of the transition duct (7) and with one single outlet (12) opened to the inside of the transition duct (7).

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

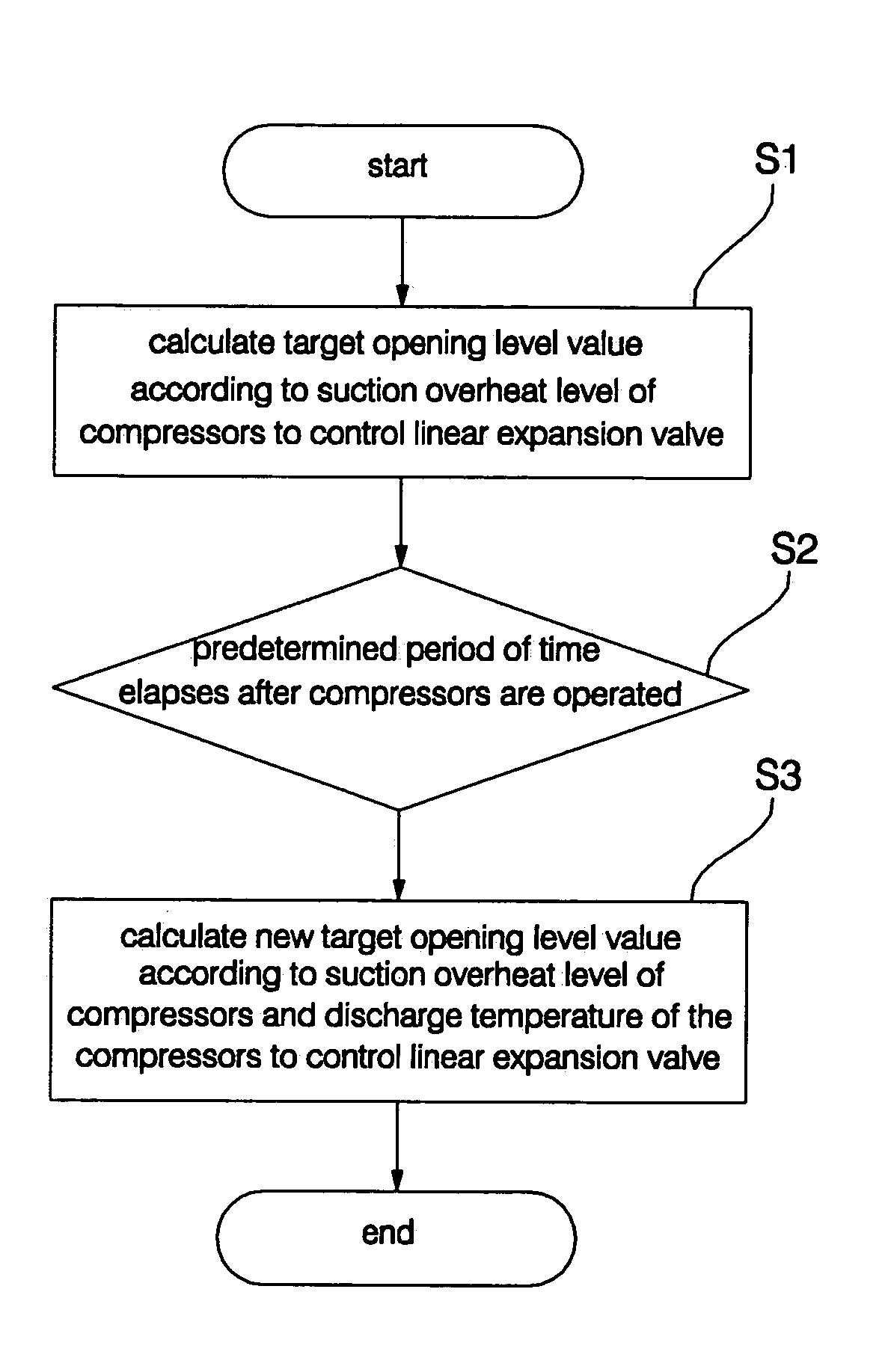

Cooling cycle apparatus and method of controlling linear expansion valve of the same

InactiveUS7509817B2Improve cooling reliabilityImprove reliabilityMechanical apparatusCompression machines with non-reversible cycleControl theoryCooling cycle

Owner:LG ELECTRONICS INC

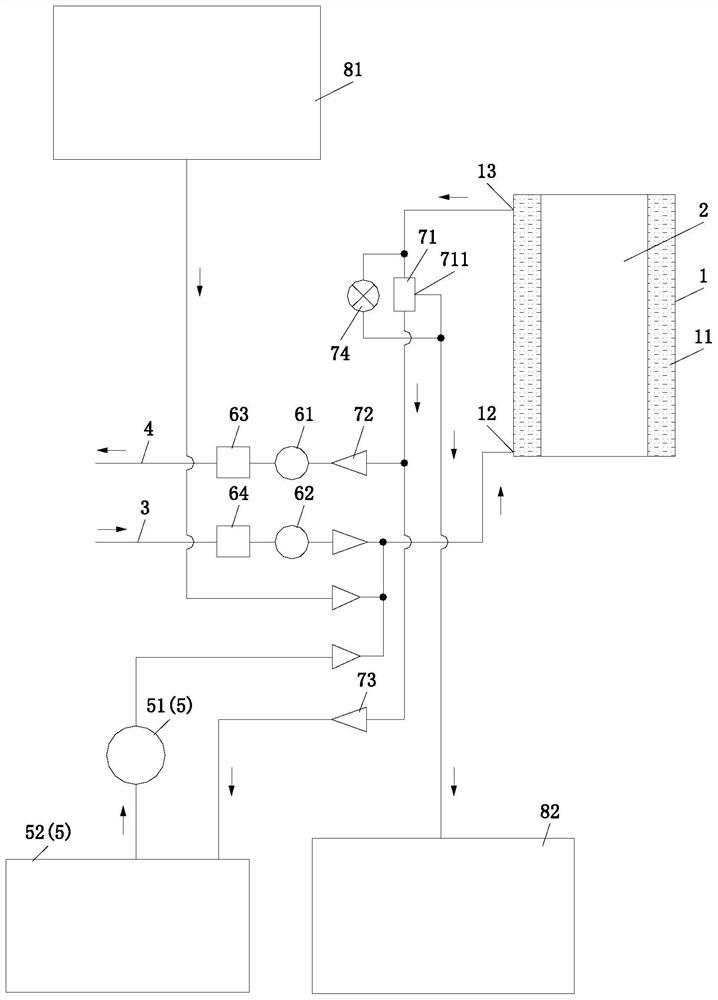

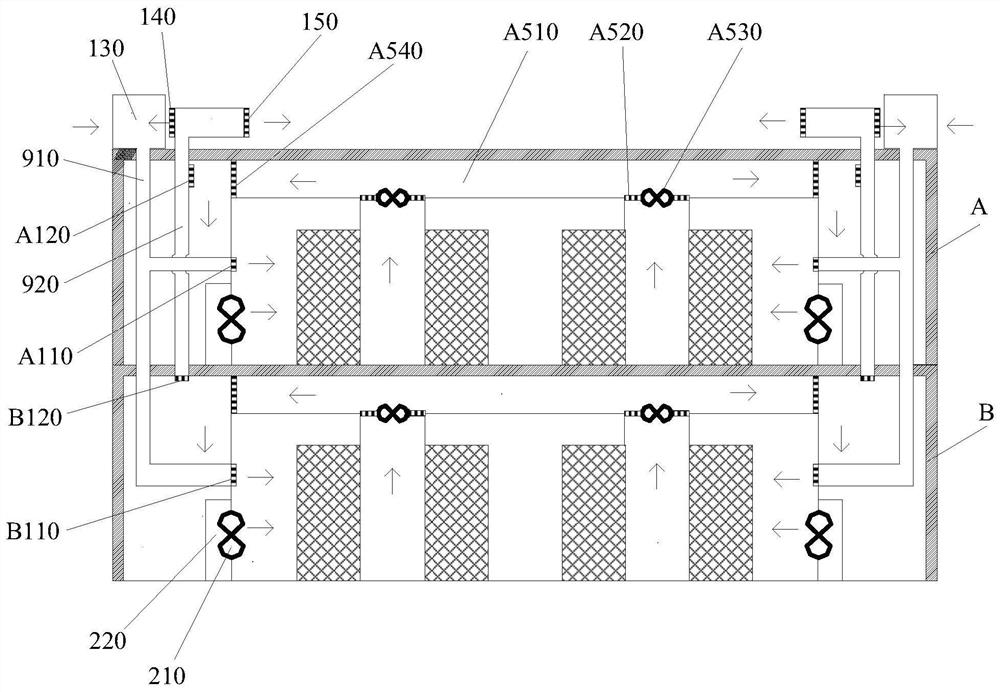

Refrigeration system and data center

ActiveCN110691492AReduce resistanceRefrigeration intelligenceCooling/ventilation/heating modificationsTemperature controlData center

The invention belongs to the technical field of air conditioning, and provides a refrigeration system and a data center. The refrigeration system includes a direct evaporative refrigeration device, anair conditioner, a main controller, and an indoor temperature acquisition device. The direct evaporative refrigeration device includes a direct refrigeration mechanism arranged on the sky face, an air supply valve which is communicated with the direct refrigeration mechanism for supplying air to the data center, and a hot air return valve which is communicated to the data center. The main controller is used to acquire the indoor temperature collected by the indoor temperature acquisition device, control the air supply temperature of the direct refrigeration mechanism and / or the air supply temperature of the air conditioner according to the indoor temperature, and control the opening of the air supply valve and the hot air return valve. The data center includes at least one data center room and the refrigeration system. According to the invention, the refrigeration system and the data center automatically control the air conditioner and the direct refrigeration mechanism according tothe indoor and outdoor temperature, so that the refrigeration is more energy-saving and at the same time saves space.

Owner:厦门华睿晟智能科技有限责任公司 +1

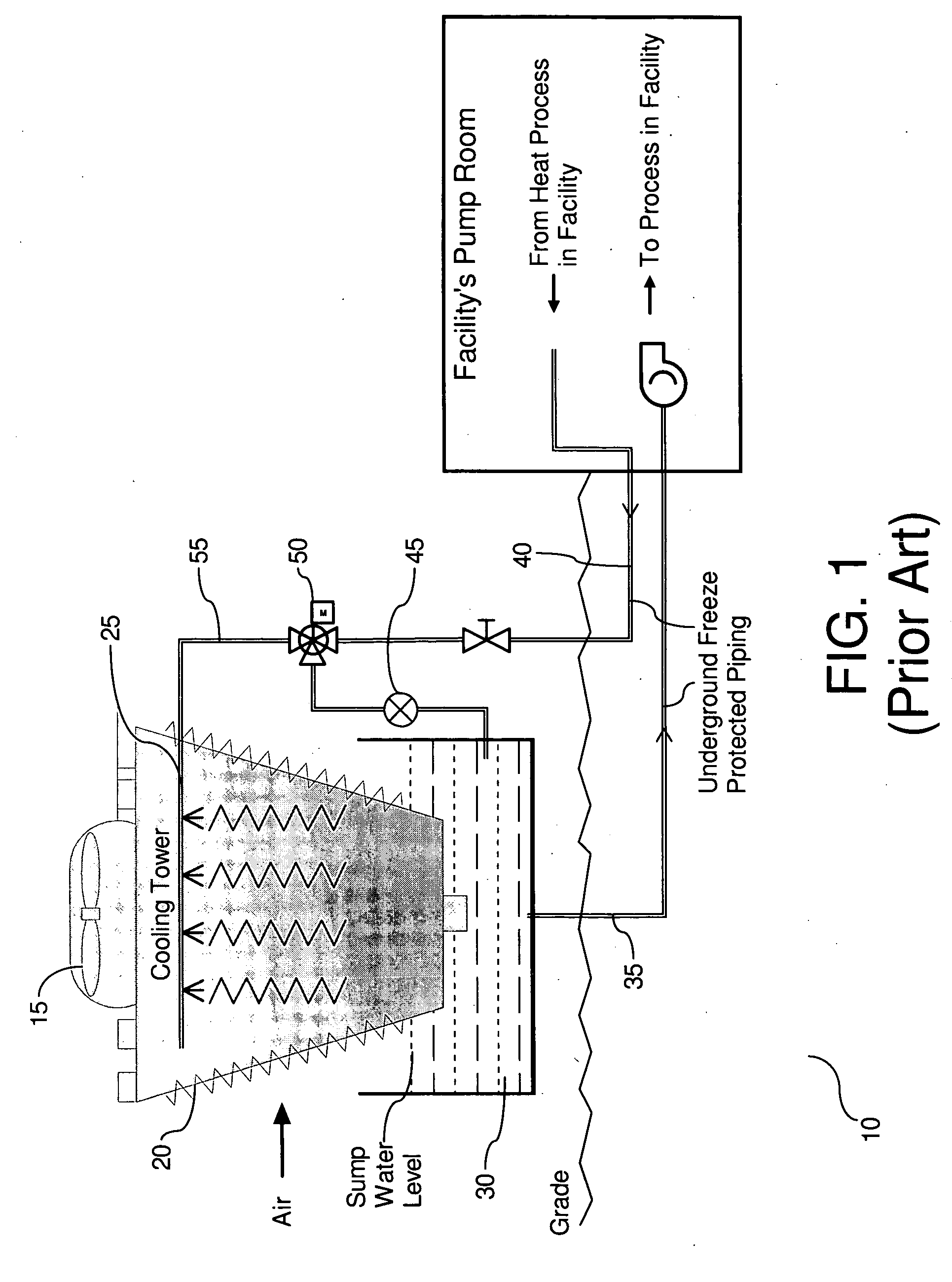

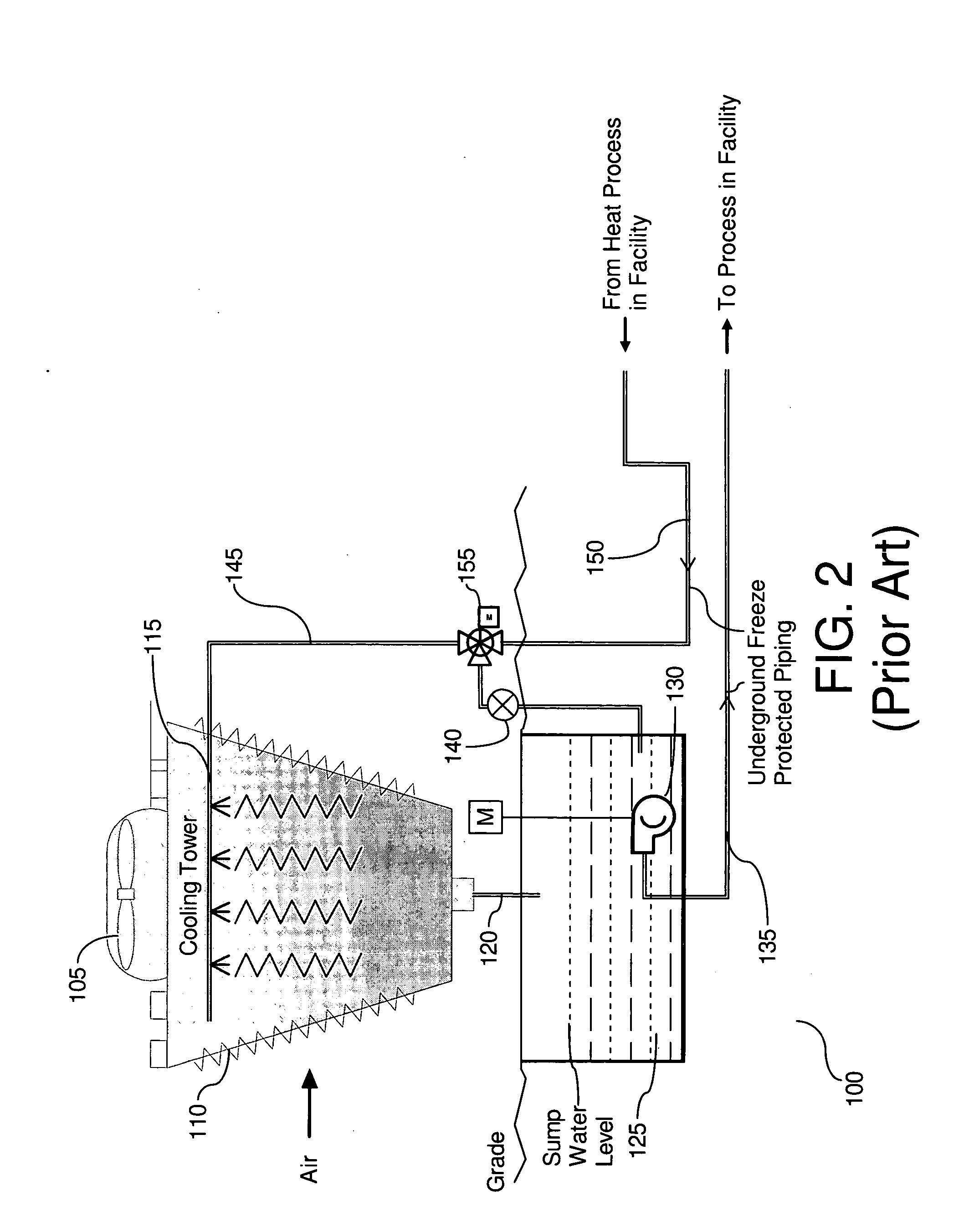

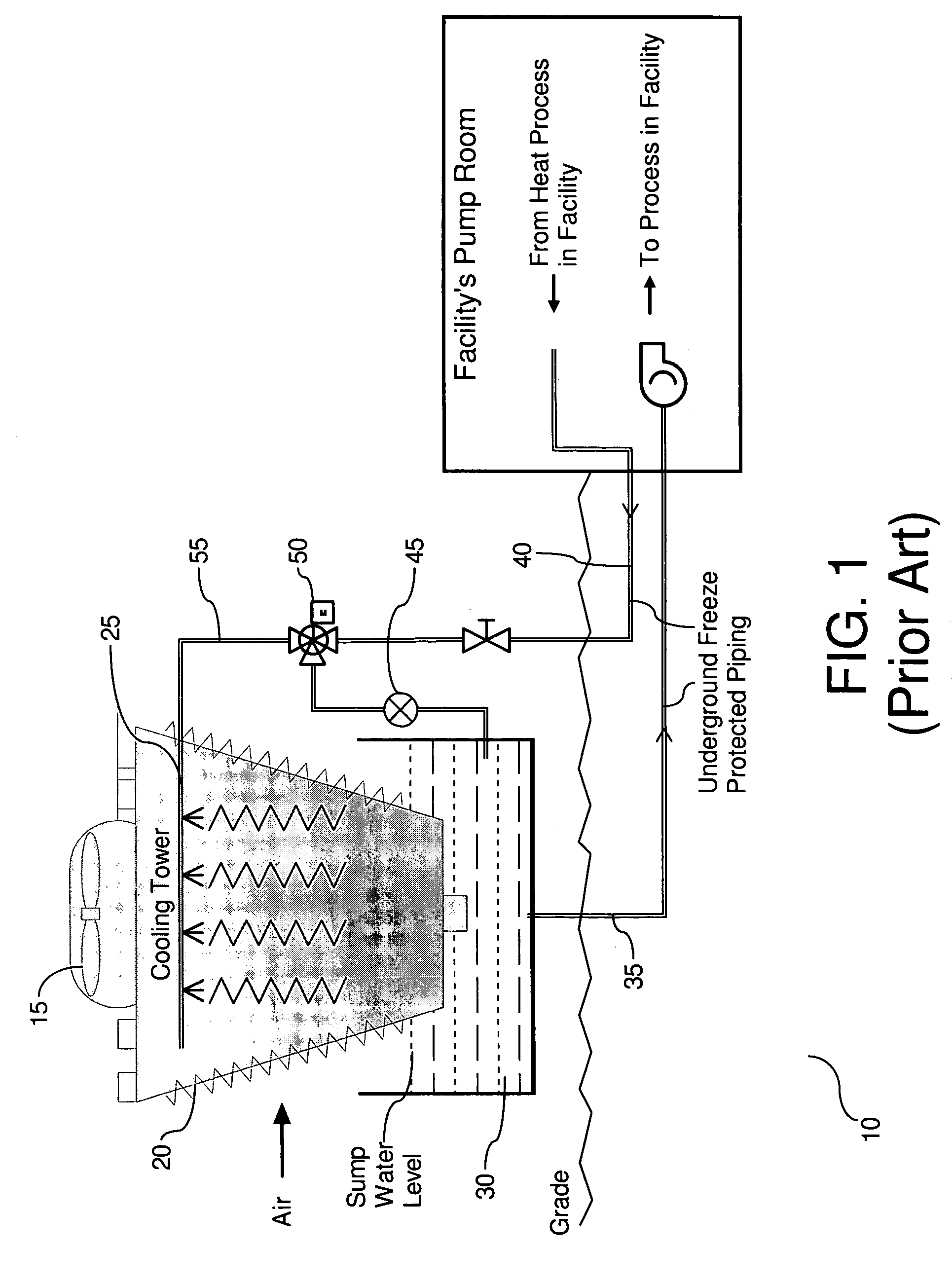

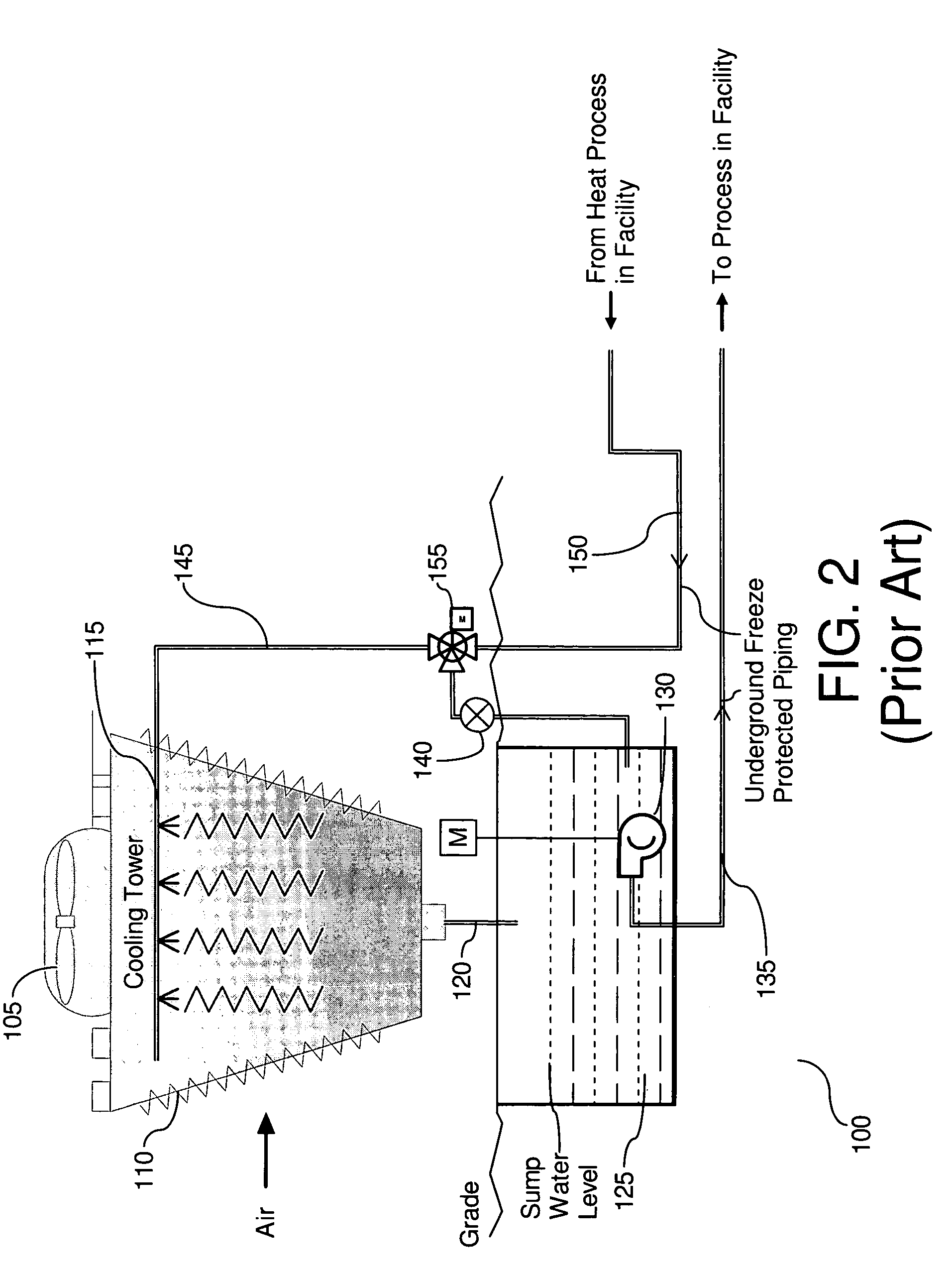

Collector sump cooling tower

InactiveUS20060125124A1Eliminates freezing riskEasy to operateMixing methodsUsing liquid separation agentCooling towerSpray nozzle

The present invention relates to a cooling apparatus and method wherein a supply sump and turbine are below grade. Water cooled from an above grade cooling tower fan and fill flows into the supply sump and is pumped through below grade pipes into a facility. Heat rejected water from the facility then flows through below grade pipes into a below grade collector sump. A collector sump pump pumps the heat rejected water above grade into a nozzle and back into the fill to be cooled. The present invention is constructed such that water is not idle in any above grade component. Accordingly, the risk of water freezing within the above grade components is drastically reduced. Moreover, the heat rejection water can by-pass all above grade components and travel directly into the supply sump in the event of reduced load from the facility.

Owner:X NTH INC

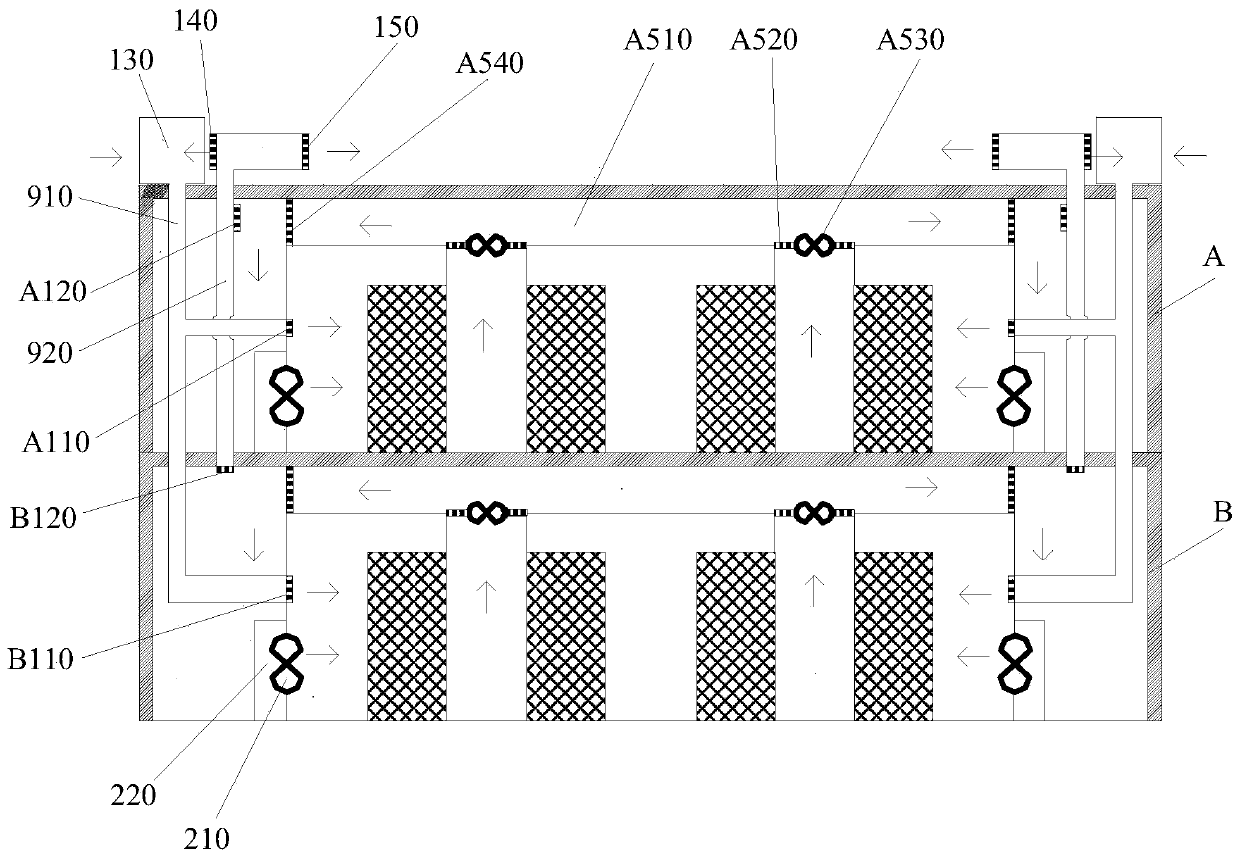

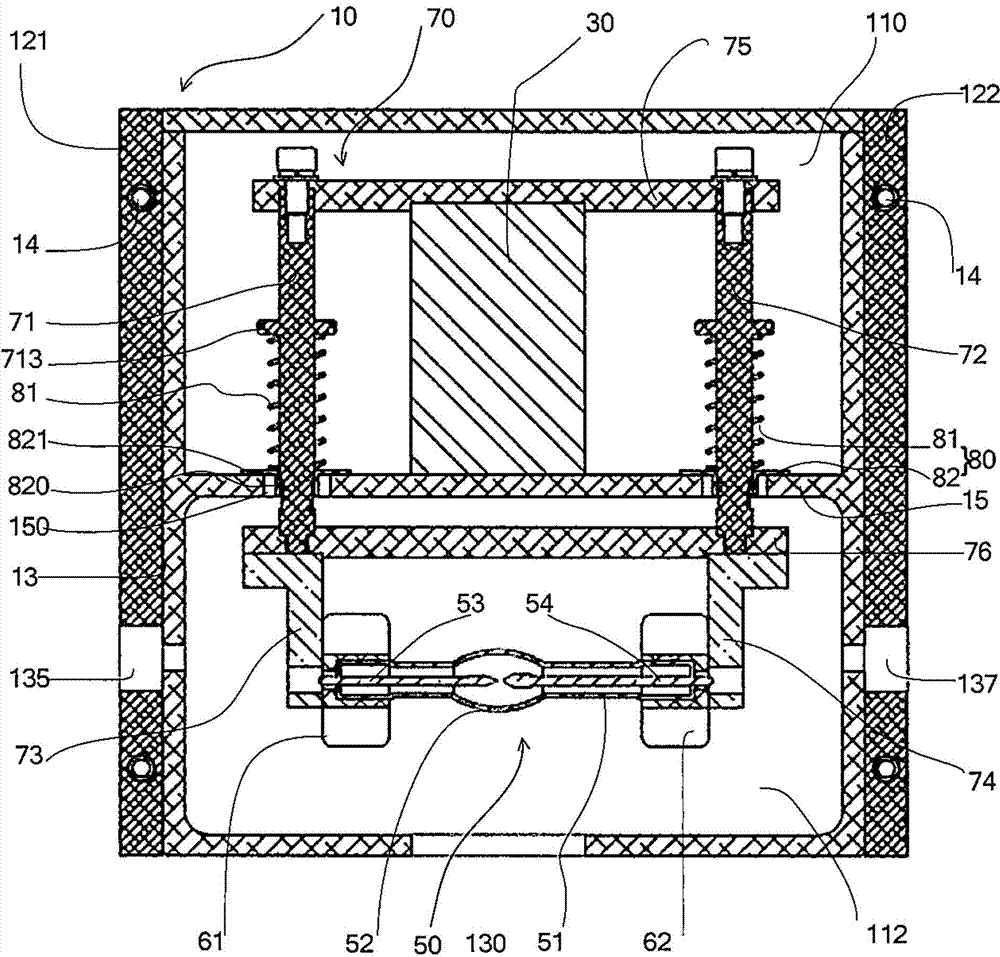

Integrated liquid cooling device and method thereof

InactiveUS20180195804A1Ensure safetySimple structureDigital data processing detailsSemiconductor/solid-state device detailsEngineeringIntegrated circuit

An integrated liquid cooling device comprises a housing, a first liquid reservoir, a second liquid reservoir, at least one first liquid channel for heat dissipation, a second liquid channel appressed to a heat source device, at least one third liquid channel for heat dissipation and a liquid transfer cycle driver; the first liquid reservoir is connected to the second liquid channel through the first liquid channel; the second liquid channel is connected to the second liquid reservoir through the third liquid channel; the first liquid reservoir and the second liquid reservoir are independent to each other and connected through the liquid transfer cycle driver; the liquid transfer cycle driver transfers the liquid in the second liquid reservoir to the first liquid reservoir. The invention saves the space and reducing the risk of leakage.

Owner:BLACKBEZT LIGHTING TECH CO LTD

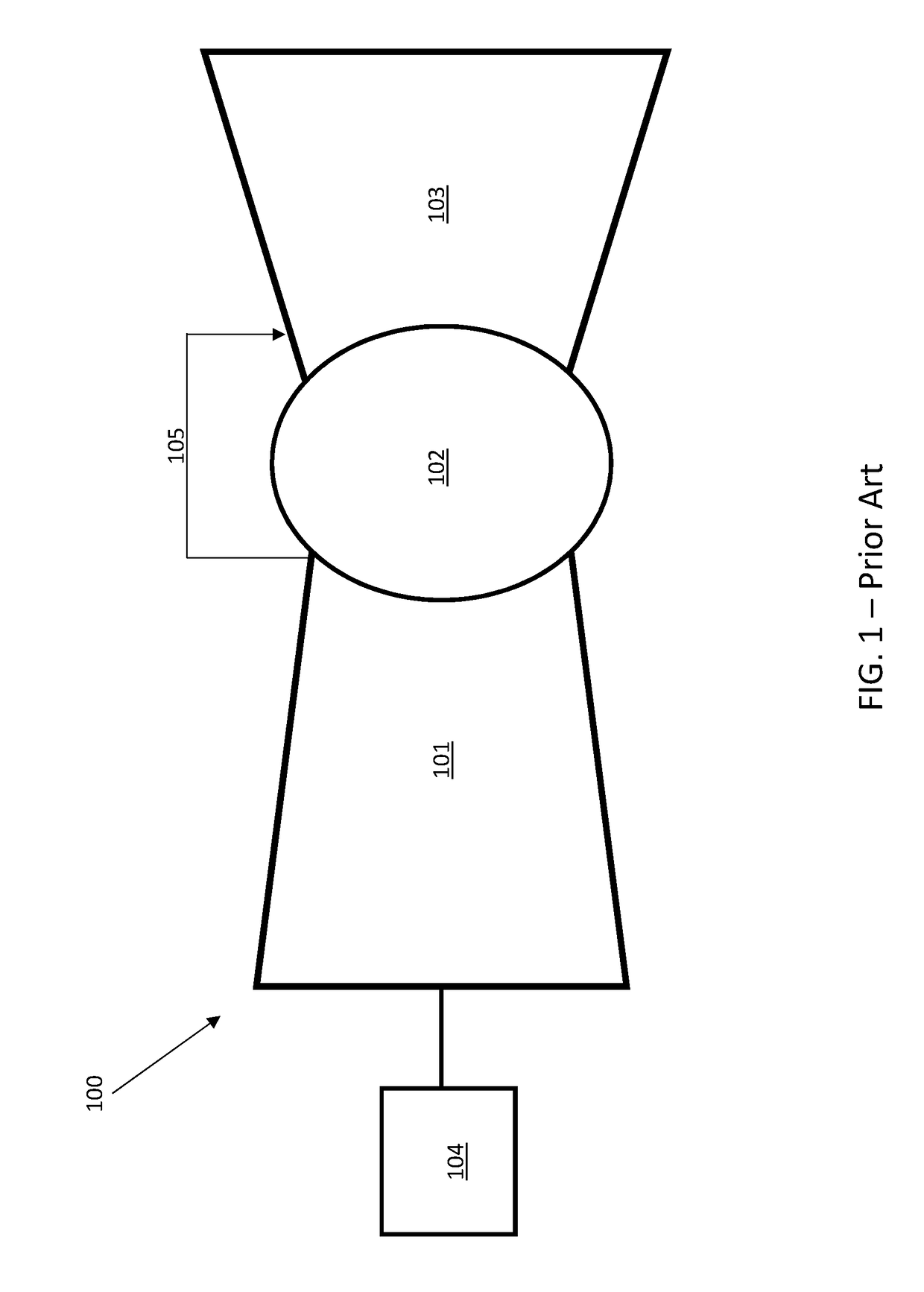

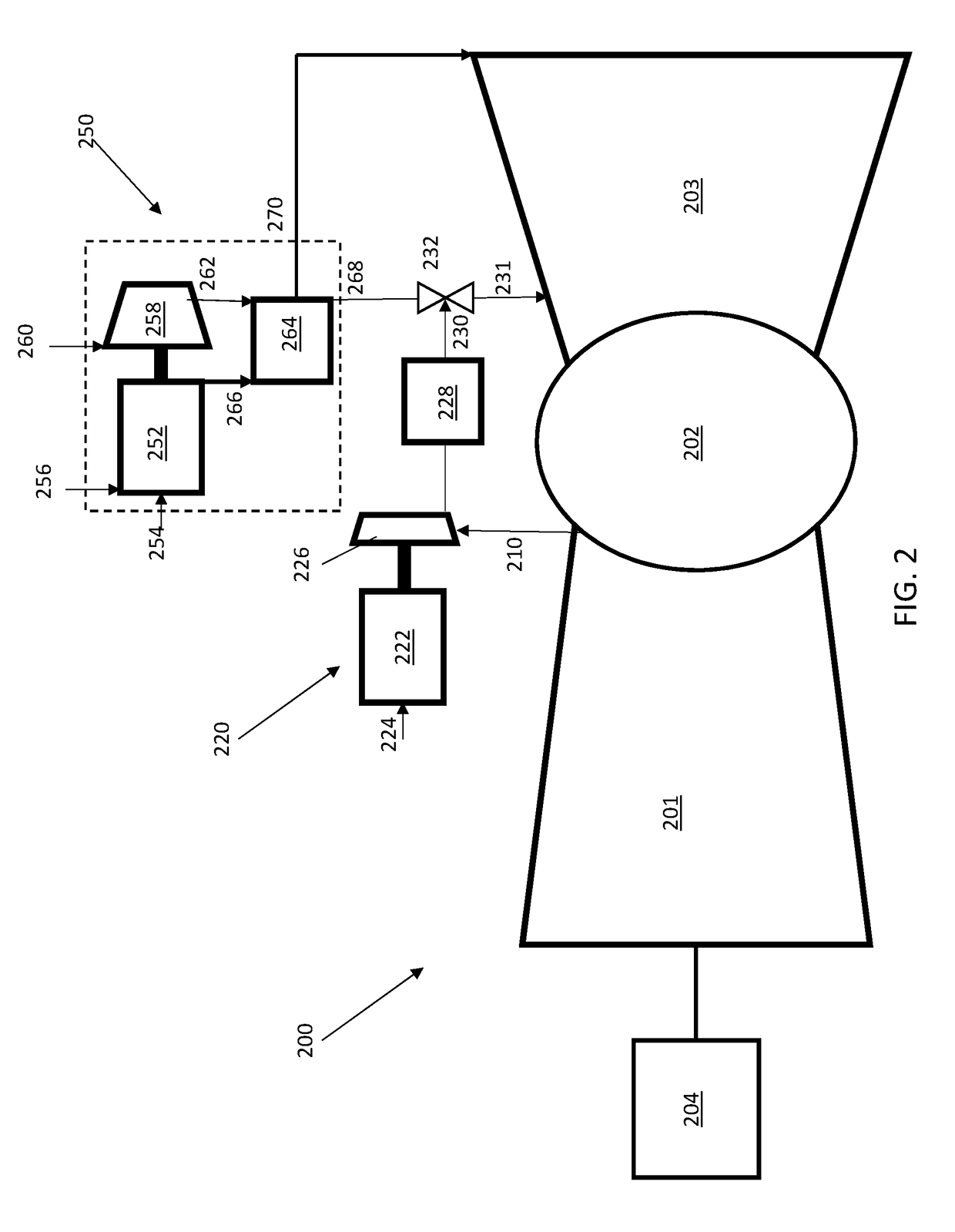

Backup system for supplying compressed air to a gas turbine component

ActiveUS20170234227A1Improve cooling reliabilityImprove reliabilityEngine fuctionsTurbine/propulsion engine coolingTurbineGas turbines

The invention relates generally to gas turbine engines used for electrical power generation. More specifically, embodiments of the present invention provide systems and ways for improving gas turbine engine reliability through an electric motor backup system for cooling features of the turbine section.

Owner:POWERPHASE

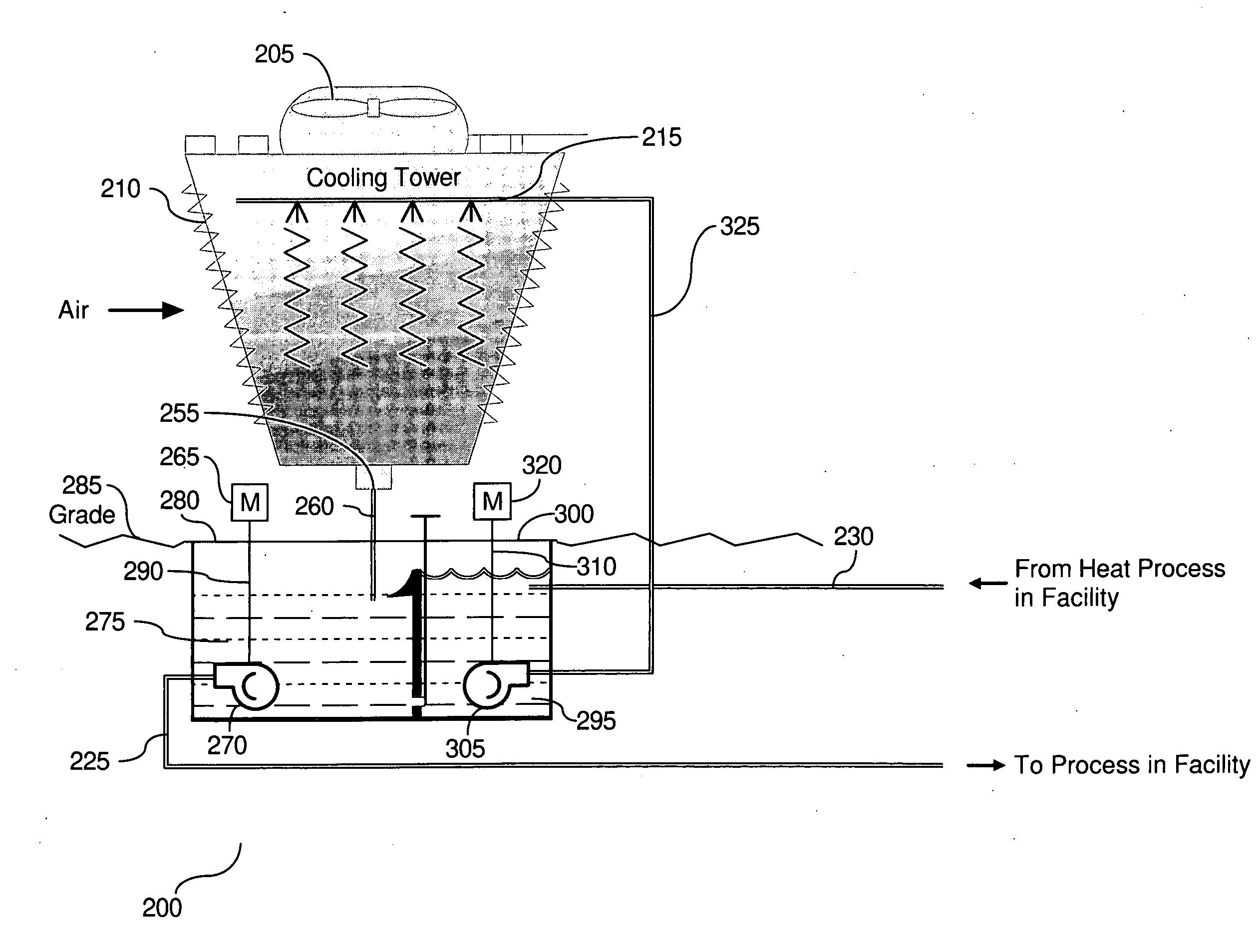

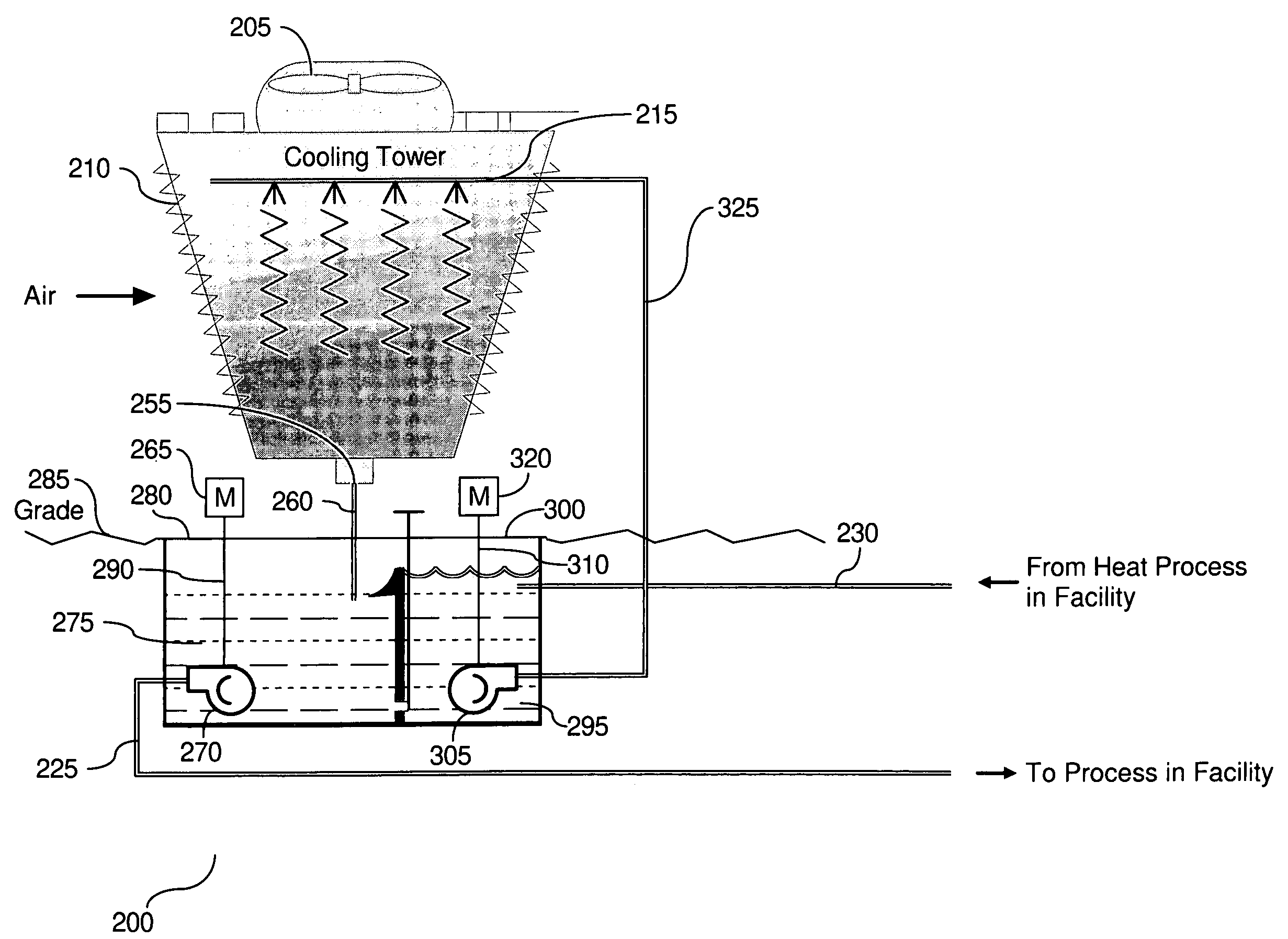

Collector sump cooling tower

InactiveUS7243909B2Improve cooling reliabilityEliminate riskMixing methodsUsing liquid separation agentCooling towerSpray nozzle

The present invention relates to a cooling apparatus and method wherein a supply sump and turbine are below grade. Water cooled from an above grade cooling tower fan and fill flows into the supply sump and is pumped through below grade pipes into a facility. Heat rejected water from the facility then flows through below grade pipes into a below grade collector sump. A collector sump pump pumps the heat rejected water above grade into a nozzle and back into the fill to be cooled. The present invention is constructed such that water is not idle in any above grade component. Accordingly, the risk of water freezing within the above grade components is drastically reduced. Moreover, the heat rejection water can by-pass all above grade components and travel directly into the supply sump in the event of reduced load from the facility.

Owner:X NTH INC

Gas turbine system with a transition duct having axially extending cooling channels

ActiveUS9840924B2Reduce nitrogen oxide emissionsWide load rangeContinuous combustion chamberEngine fuctionsCombustion chamberCombustor

A gas turbine system (1) including a burner arrangement having a tubular combustion chamber (5), a turbine (6) and a transition duct (7) connecting the combustion chamber (5) and the turbine (6), wherein the transition duct (7) is provided with an axially extending cooling air channel (11). The transition duct (7) includes a plurality of axially extending cooling air channels, and wherein each cooling air channel (11) is provided with one single inlet (12) opened to the outside of the transition duct (7) and with one single outlet (12) opened to the inside of the transition duct (7).

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

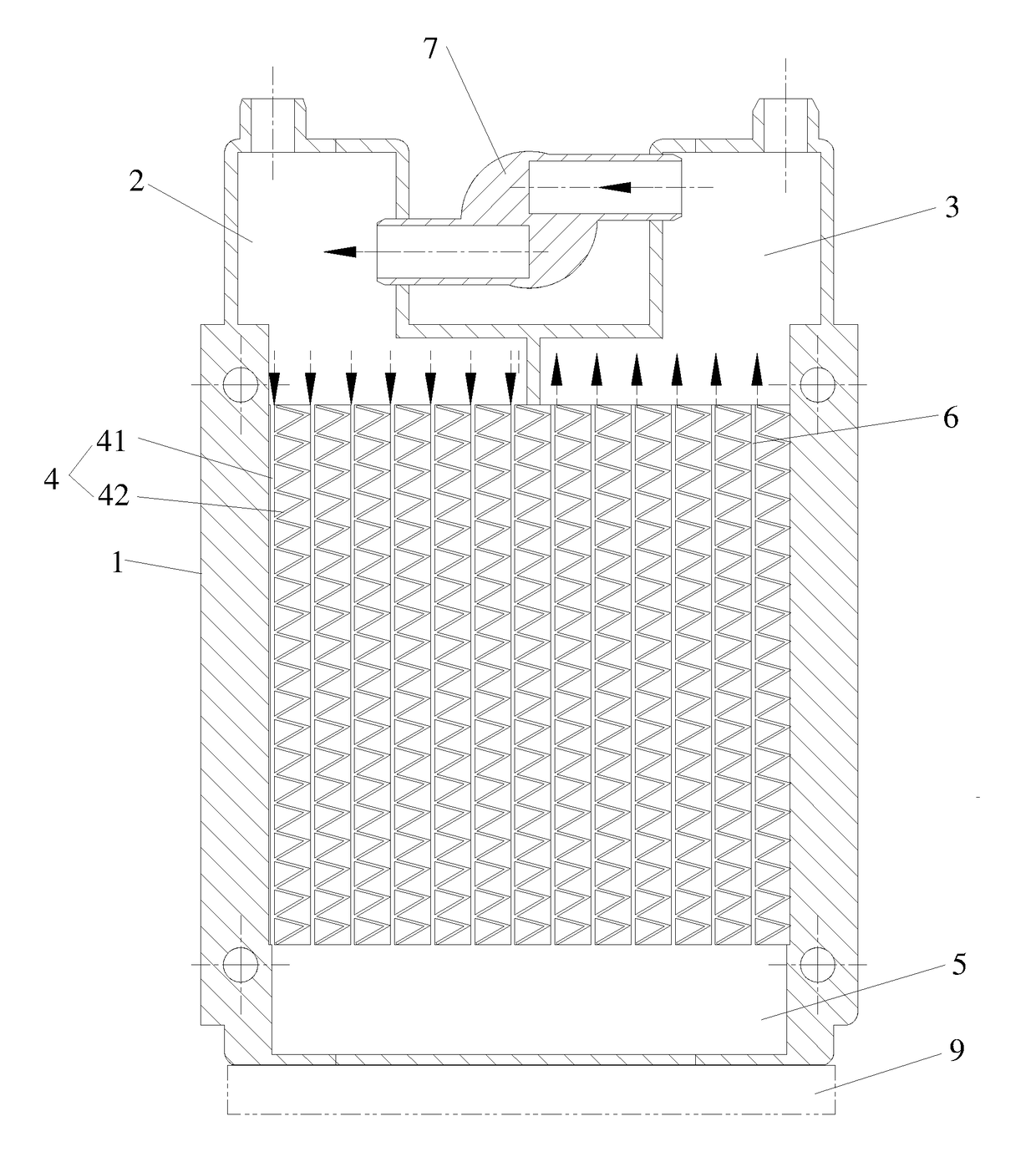

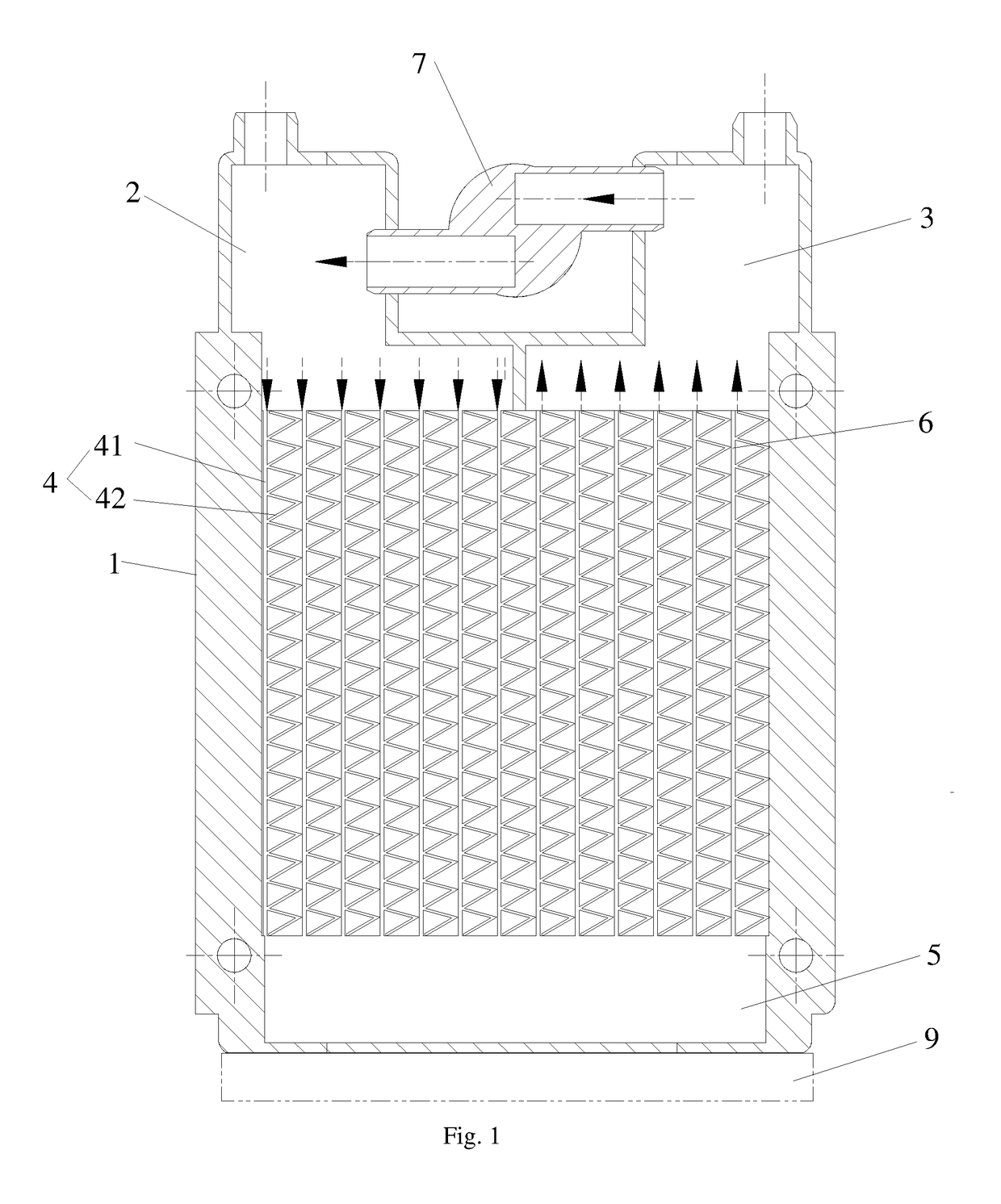

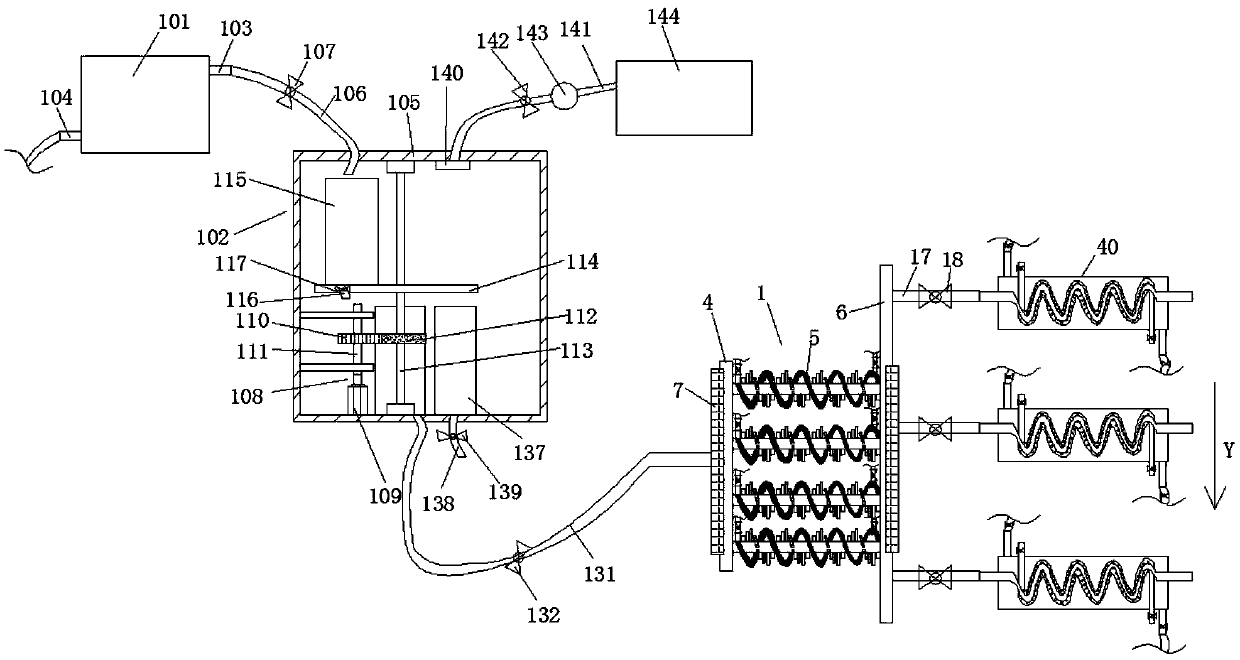

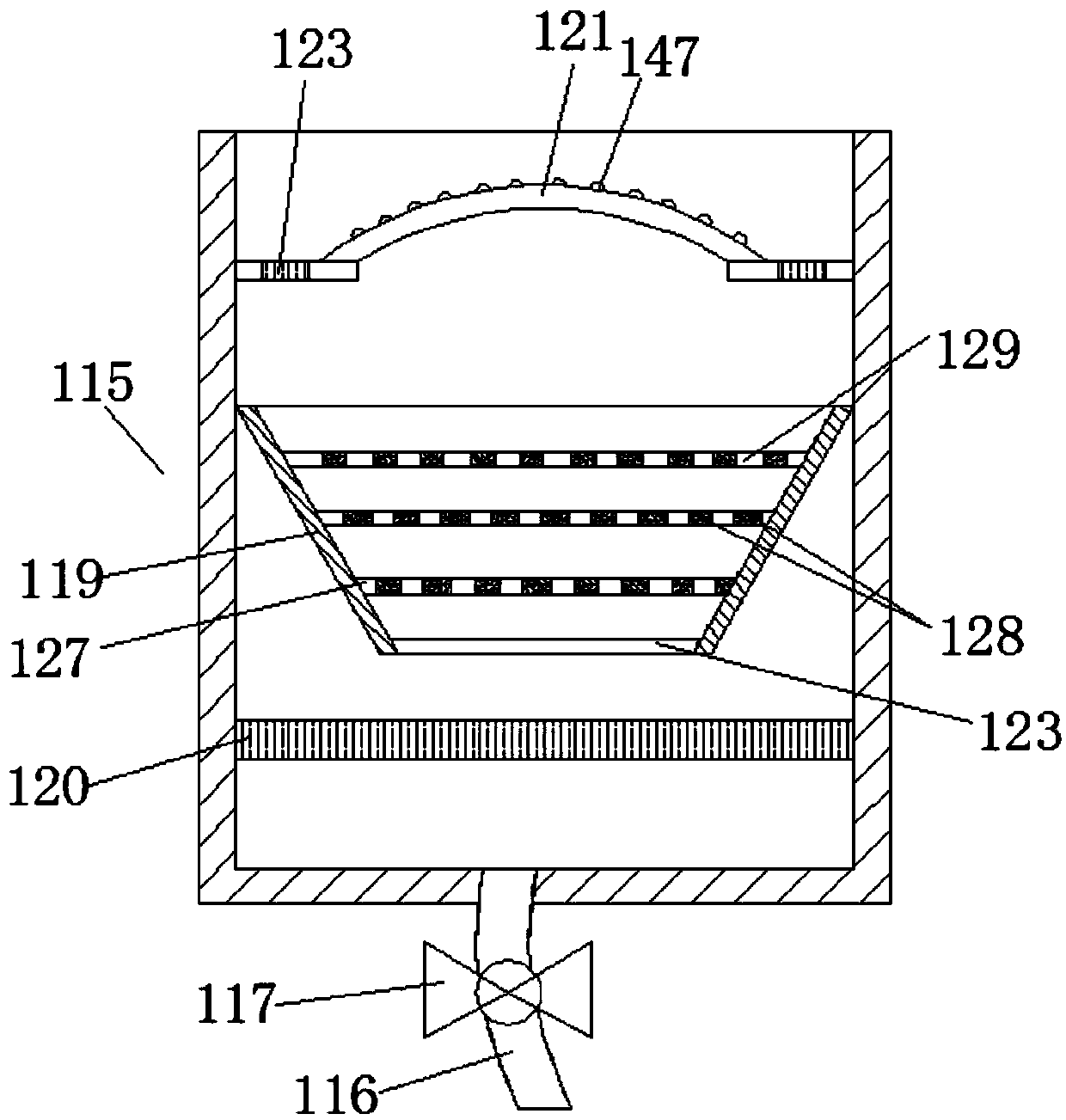

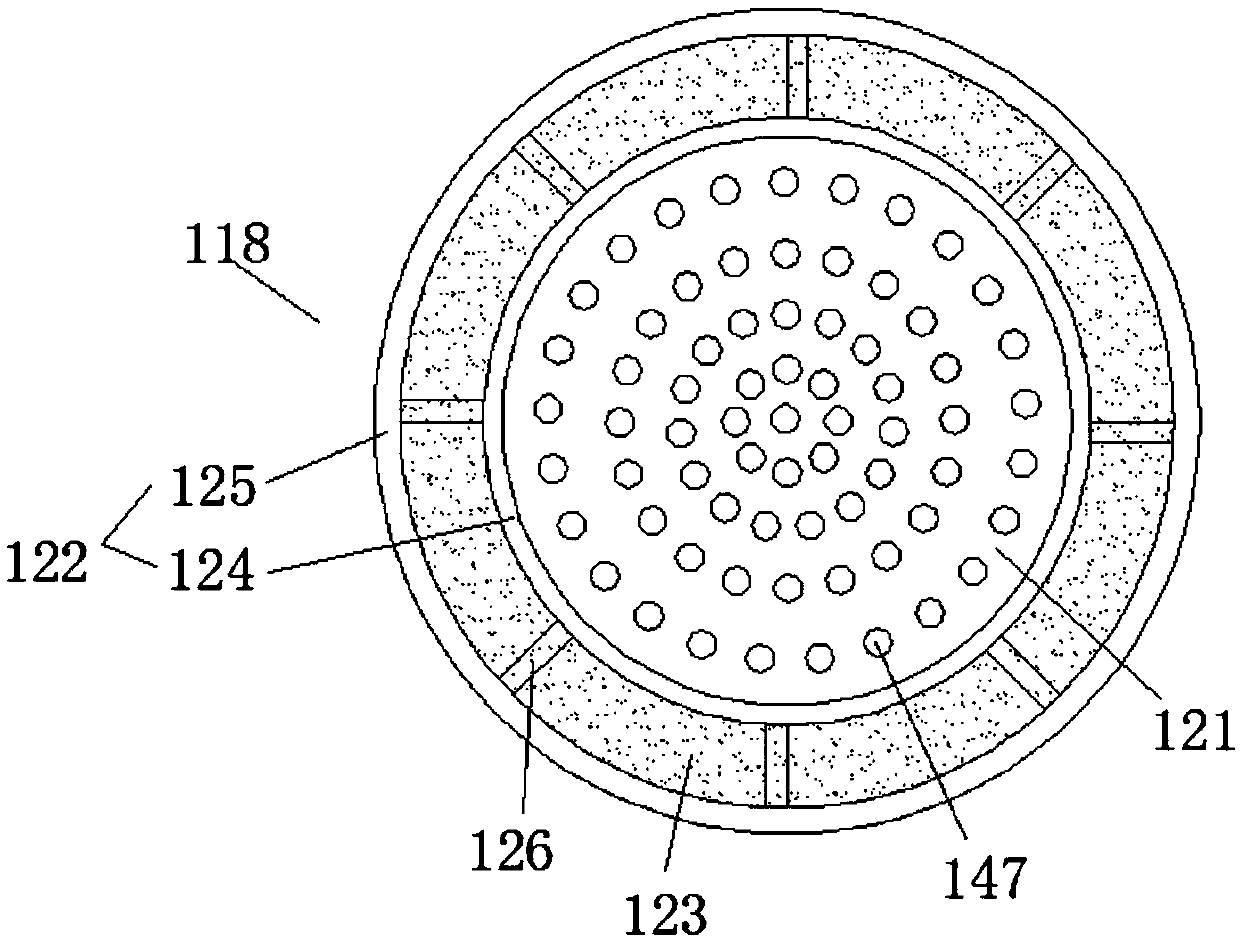

Oil tank of hydraulic machine

PendingCN111197600ANovel structurePracticalPump assembliesFluid-pressure actuator componentsLiquid level sensorElectromagnetic valve

The invention provides an oil tank of a hydraulic machine. With the oil tank, a filtering device and a radiating device are used for removing impurities and cooling for hydraulic oil to ensure stableoperation of the hydraulic machine; the filtering work of the hydraulic oil in a first filtering cylinder and a second filtering cylinder is sequentially completed through a driving device, the cleaning work of the first filtering cylinder is completed, the working strength is greatly reduced, the continuity and the high efficiency of the filtering work of the first filtering cylinder are guaranteed, and the influence on the filtering effect caused by the residue of the filtering impurities is avoided; automation and intelligentization of the filtering device are realized by utilizing a PLC, liquid level sensors and electromagnetic valves, so that cleaning and filtering are more convenient; a main branch pipe plays a shunting role, so that the hydraulic oil is preliminarily cooled in a first radiating pipe, and the heat loss of the hydraulic oil in the first radiating pipe is accelerated by combining water cooling with air cooling; and the hydraulic oil is secondarily cooled through cooling devices, the cooling time of the hydraulic oil in inner pipes is prolonged by utilizing inner and outer spiral structures of a second radiating pipe, and the cooling reliability is greatly improved.

Owner:建湖奥托斯液压机械制造有限公司

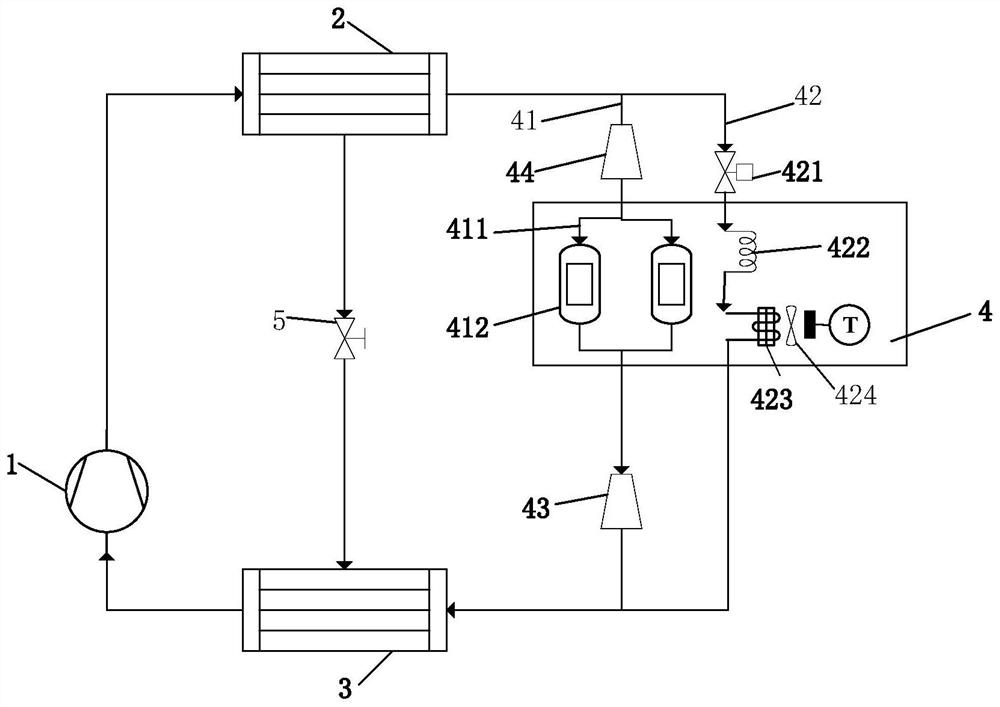

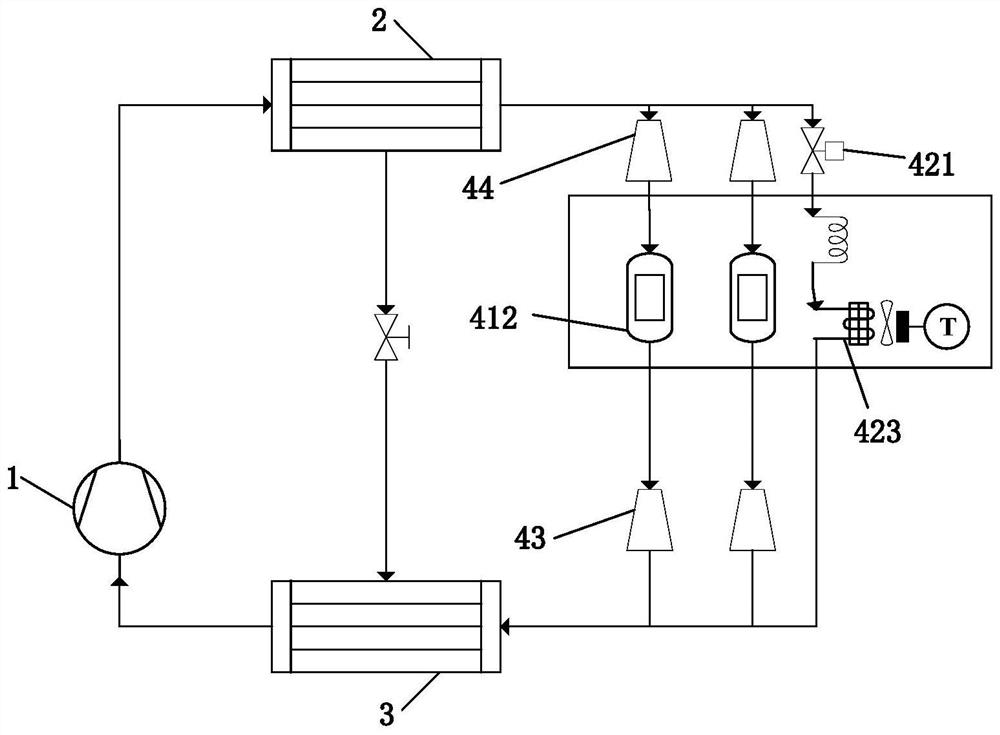

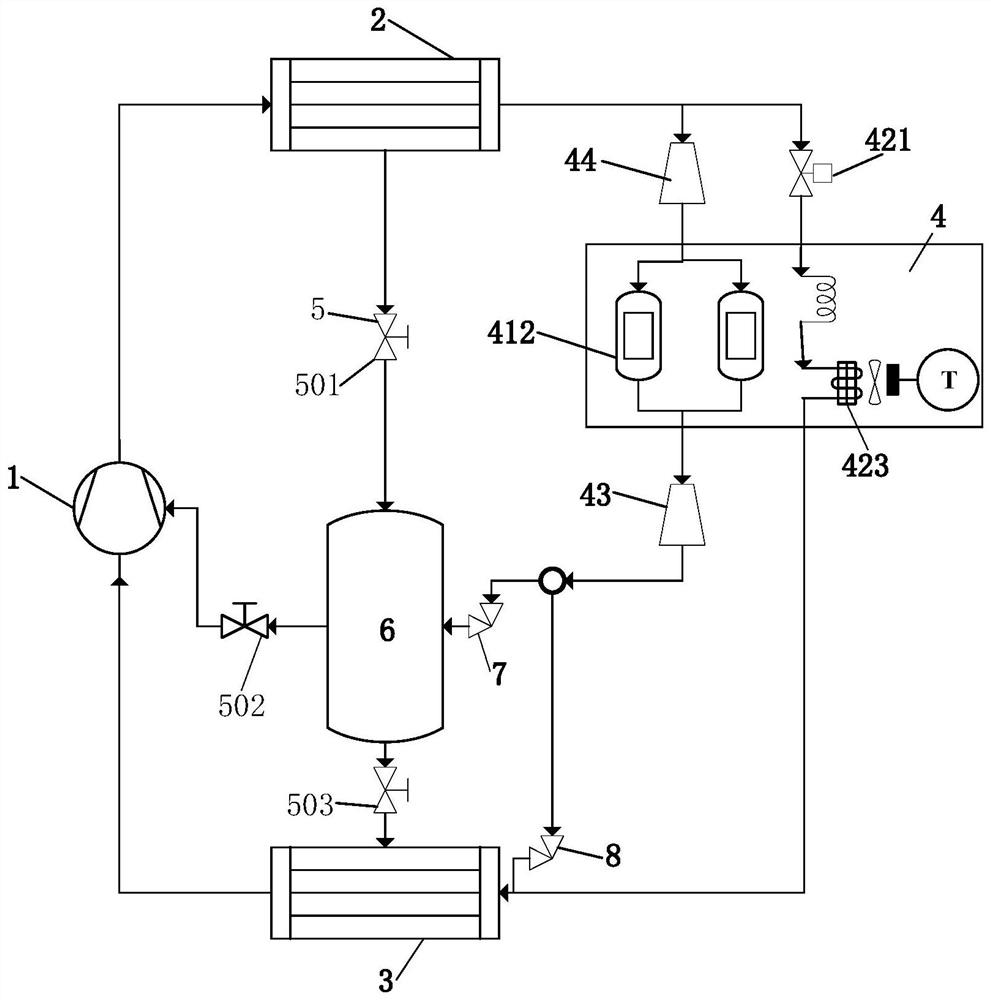

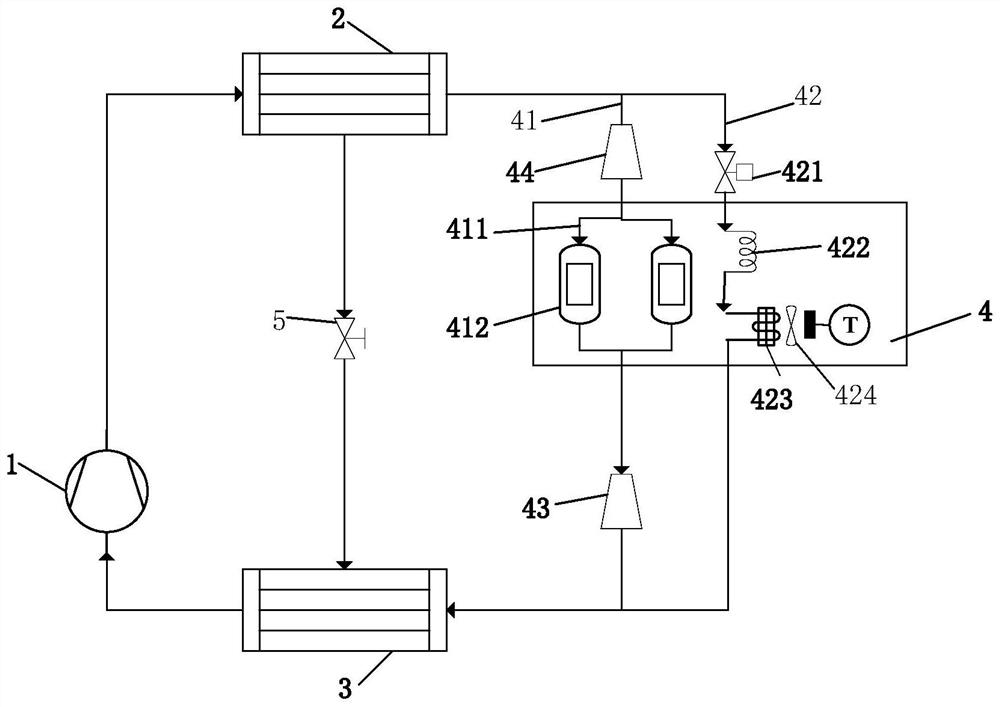

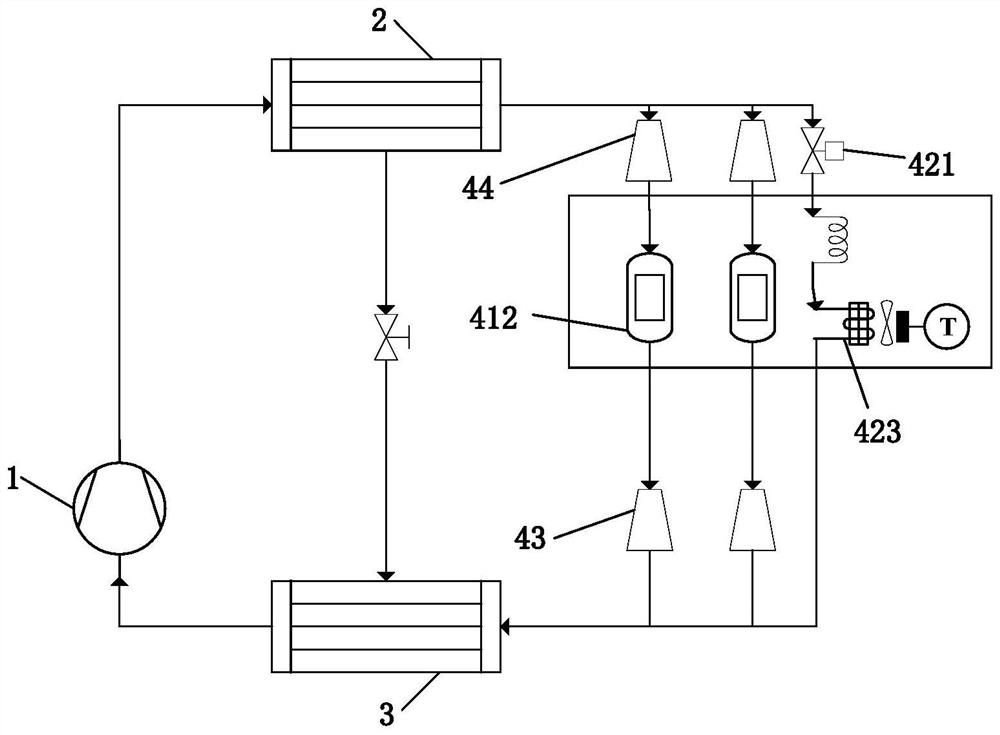

Frequency converter heat management system of air conditioning unit, air conditioning unit and control method

ActiveCN112460755AImprove cooling reliabilityImprove reliabilityMechanical apparatusFrequency changerCooling Units

The invention discloses a frequency converter heat management system of an air conditioning unit, the air conditioning unit and a control method. The frequency converter heat management system specifically comprises a control unit, a temperature detection unit, a frequency converter cooling unit, first switch modules and second switch modules, and the control unit is respectively connected with the temperature detection unit, the first switch modules and the second switch modules; the inlet end of the frequency converter cooling unit is connected to a condenser in an air conditioning unit refrigerating system through the second switch modules, and the outlet end of the frequency converter cooling unit is connected to a main evaporator in the air conditioning unit refrigerating system through the first switch modules; and the temperature detection unit is used for detecting the temperature of a refrigerant in the frequency converter cooling unit and sending the temperature to the control unit, and the control unit controls the opening values of the first switch modules and the second switch modules according to the detected temperature so as to maintain the refrigerant in the frequency converter cooling unit within a preset range. According to the above scheme, the advantages of accurate temperature control, high applicability and the like are achieved.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

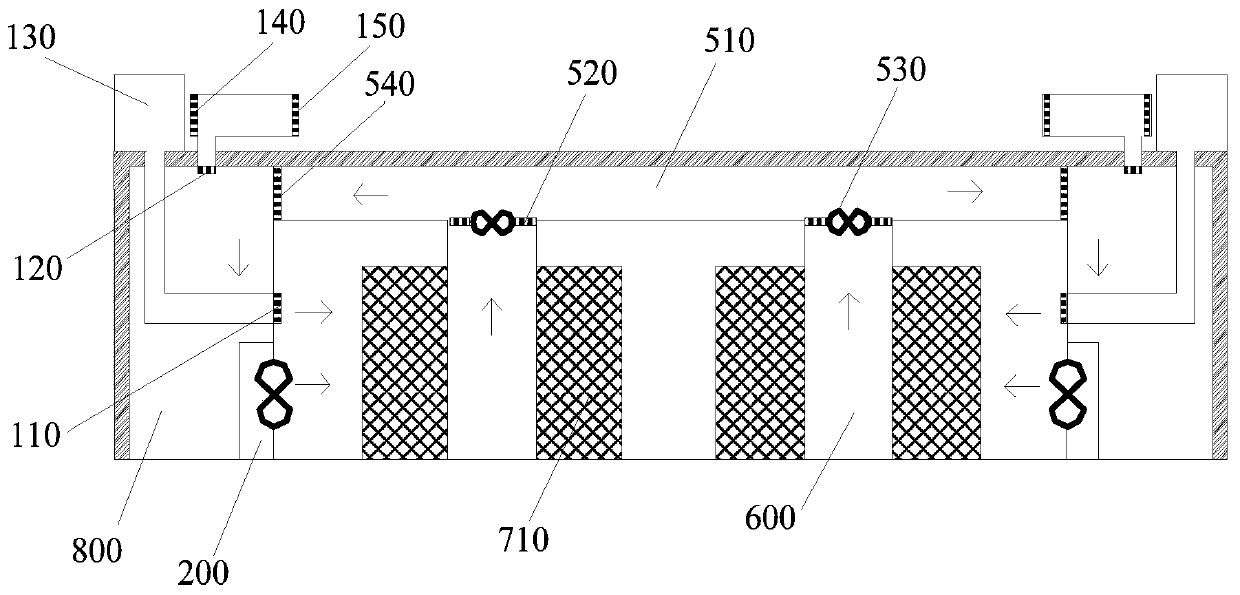

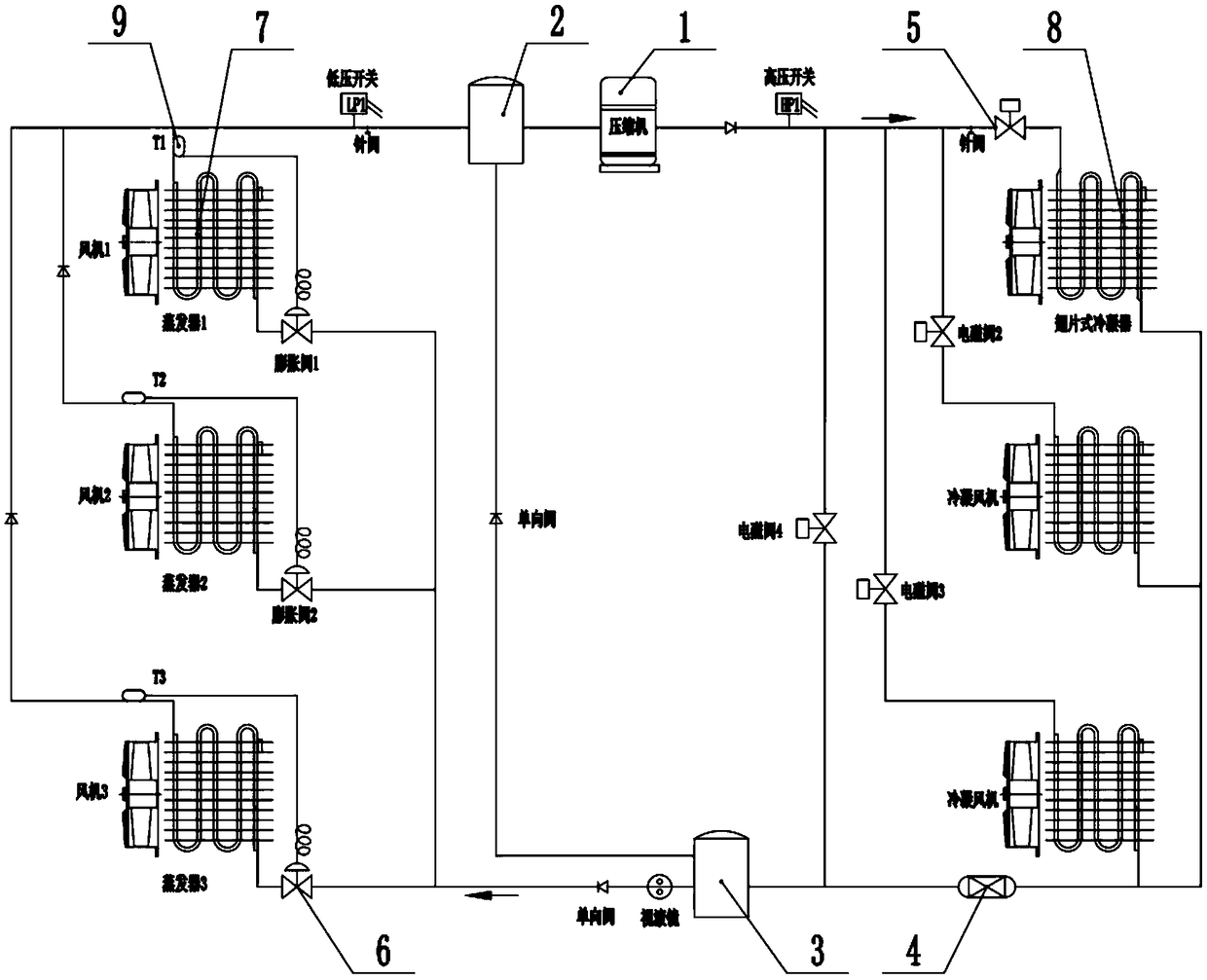

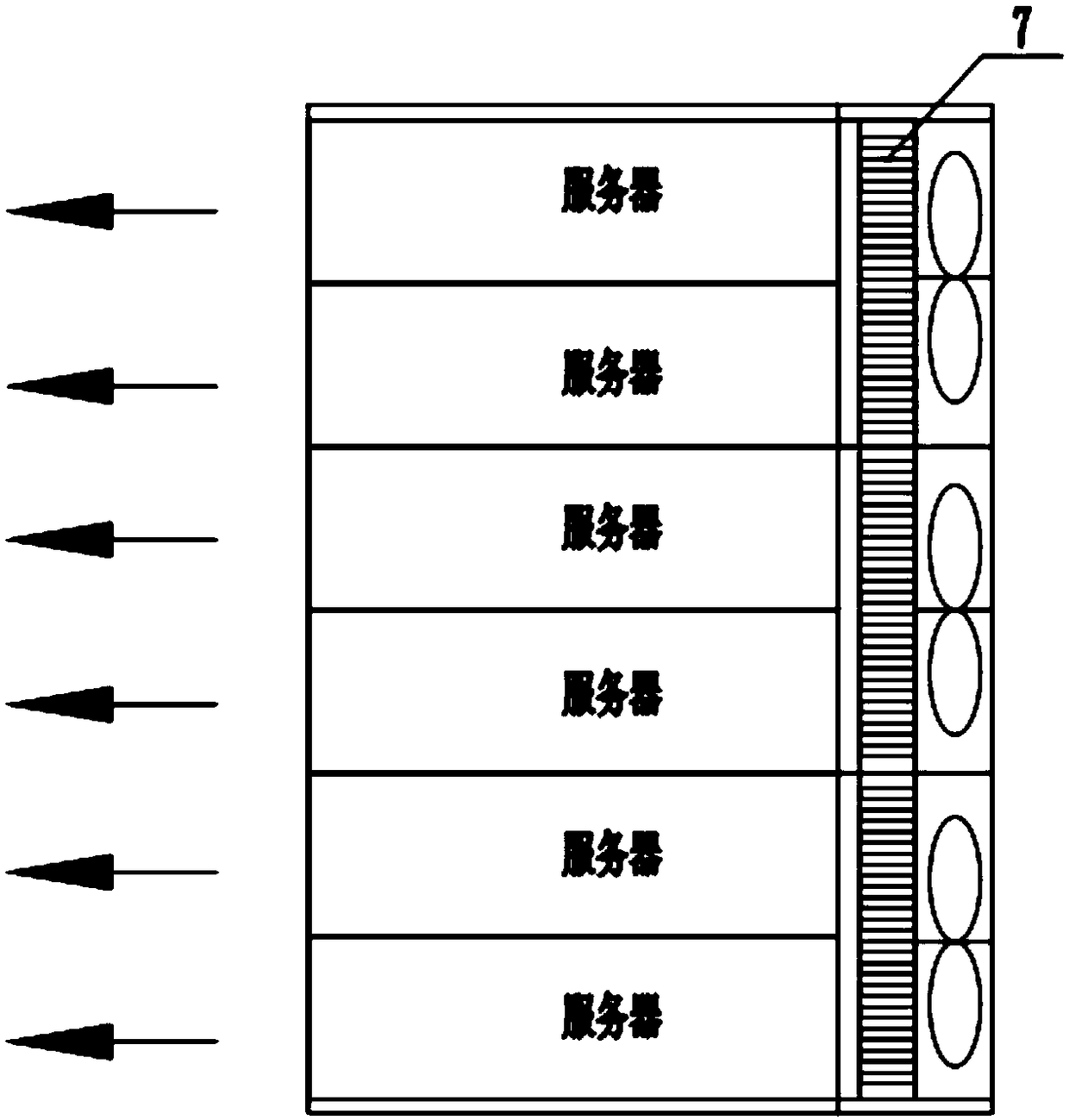

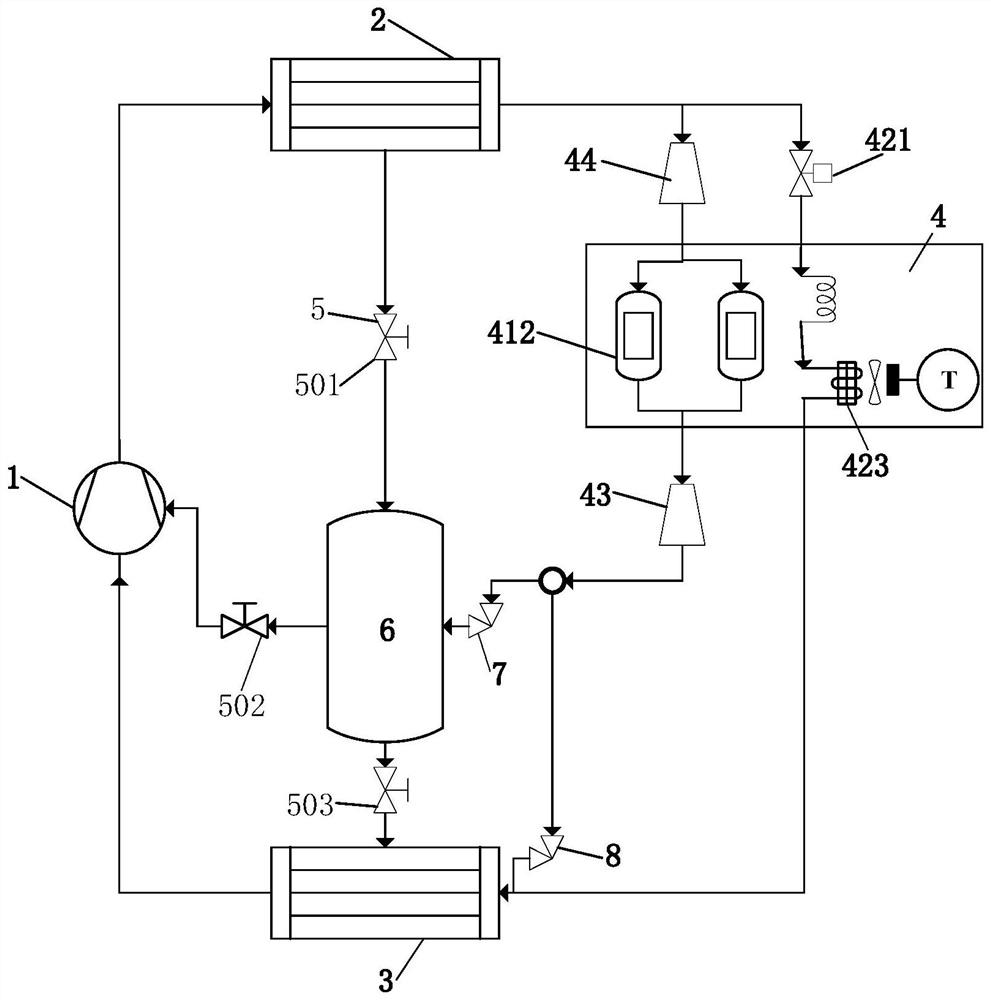

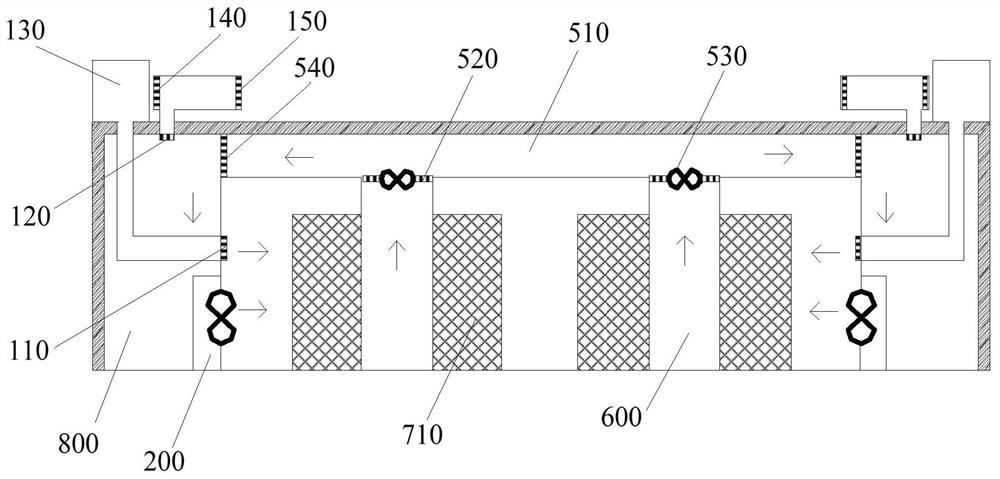

A machine cabinet level server cooling system

InactiveCN108990393AImprove cooling reliabilitySame temperatureCooling/ventilation/heating modificationsVapor liquidVapor–liquid separator

The invention discloses a cabinet-level server cooling system, comprising a compressor, an evaporator and a condenser, wherein the compressor is connected with a condenser through an electromagnetic valve, the condenser is connected with an evaporator through an expansion valve, the evaporator is connected with an input end of the compressor through a gas-liquid separator, and a liquid reservoir is arranged between the condenser and the expansion valve. The compressor sucks the low-pressure steam from the evaporator into the compressor, and the refrigerant enters the condenser with higher pressure and temperature through the compression work of the compressor. In the condenser, the high-temperature and high-pressure refrigerant vapor condenses into low-temperature and high-pressure liquid;The refrigerant enters the evaporator and absorbs heat and vaporizes to reduce the heat generated by the server equipment after passing through the expansion valve and turning into a low temperatureand low pressure vapor-liquid mixture. Through evaporation temperature control technology and air-conditioning bypass technology, the purpose of improving the cooling reliability of the server is achieved, through the different height of the cabinet evaporator with different degrees of refrigeration, that all the servers in the cabinet temperature is the same is ensured.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

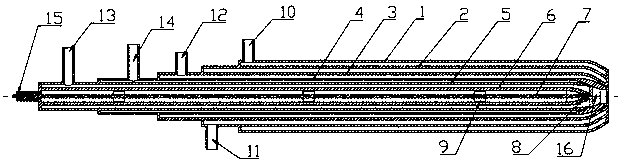

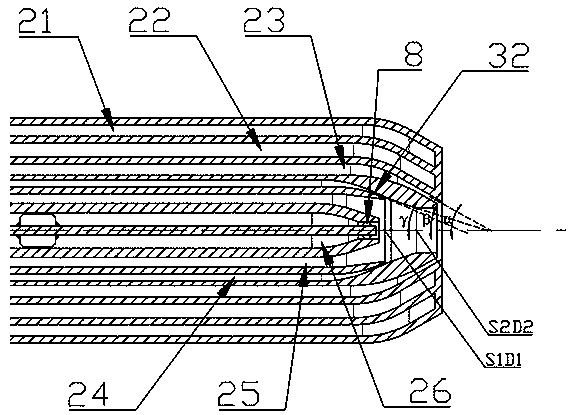

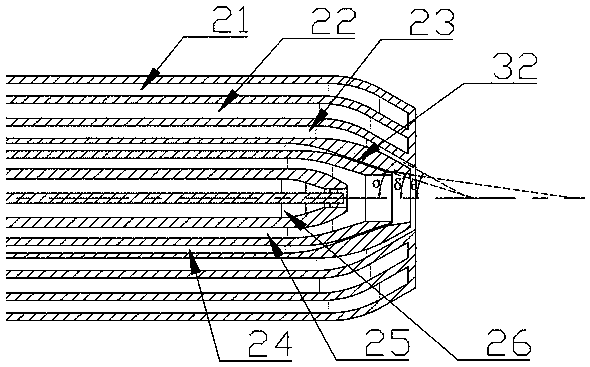

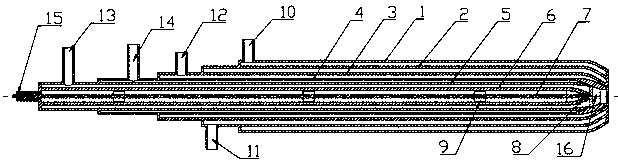

Integrated water/oil/tar/coal slurry process nozzle with gas film protection function

ActiveCN109810729AReduce direct contact frictionExtended service lifeGranular/pulverulent flues gasificationEpoxyTar

The invention discloses an integrated water / oil / tar / coal slurry process nozzle with a gas film protection function. The integrated water / oil / tar / coal slurry process nozzle is of a sleeve-type structure and sequentially comprises a nozzle cooling water outer pipe, a nozzle cooling water inner pipe, an outer epoxy pipe, a gas film oxygen pipe, a coal slurry pipe and a central oxygen pipe from the outermost layer to the innermost layer; an ignition rod is arranged in the central oxygen pipe, and the length of the gas film oxygen pipe can be larger than the length of the outer epoxy pipe and can also be 1 / 2 smaller than the length of the outer epoxy pipe; and the ignition end of the nozzle is in a necking shape, and the outlet end close to the central oxygen pipe is provided with an ignitionrod rotational flow support for supporting the front end of the ignition rod. Through isolation of different channels, direct contact friction between water / oil / tar coal slurry and the inner wall faces of the channels can be greatly reduced, thus the protection effect is achieved, and the service life of the nozzle is greatly prolonged; and the ignition rod rotational flow support is adopted, theaxial speed of the water / oil / tar coal slurry and a central oxygen mixing medium after internal mixing is decreased, the axial speed of the mixing medium is increased, the water / oil / tar slurry and central oxygen are internally mixed more uniformly, and the atomization performance of the nozzle is improved.

Owner:中国东方电气集团有限公司 +1

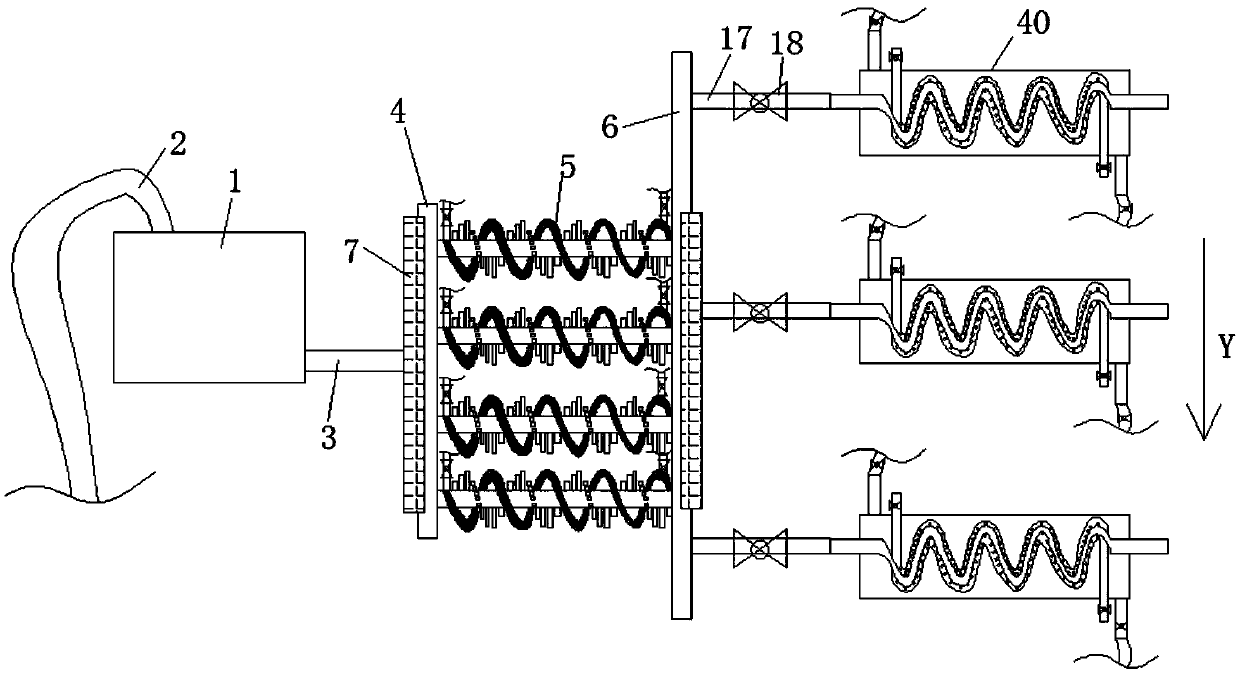

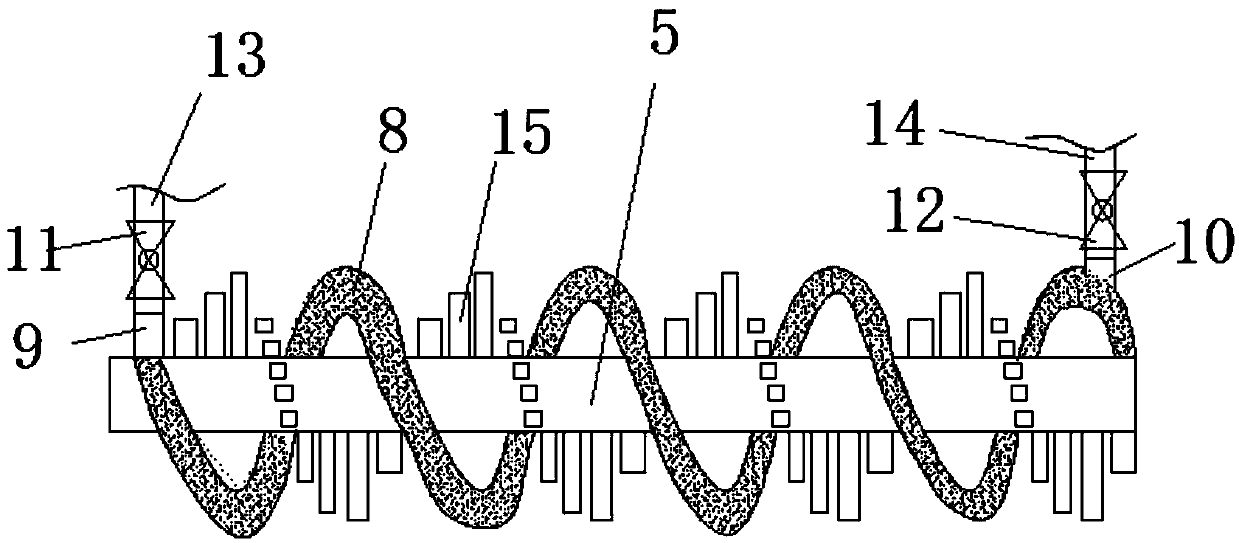

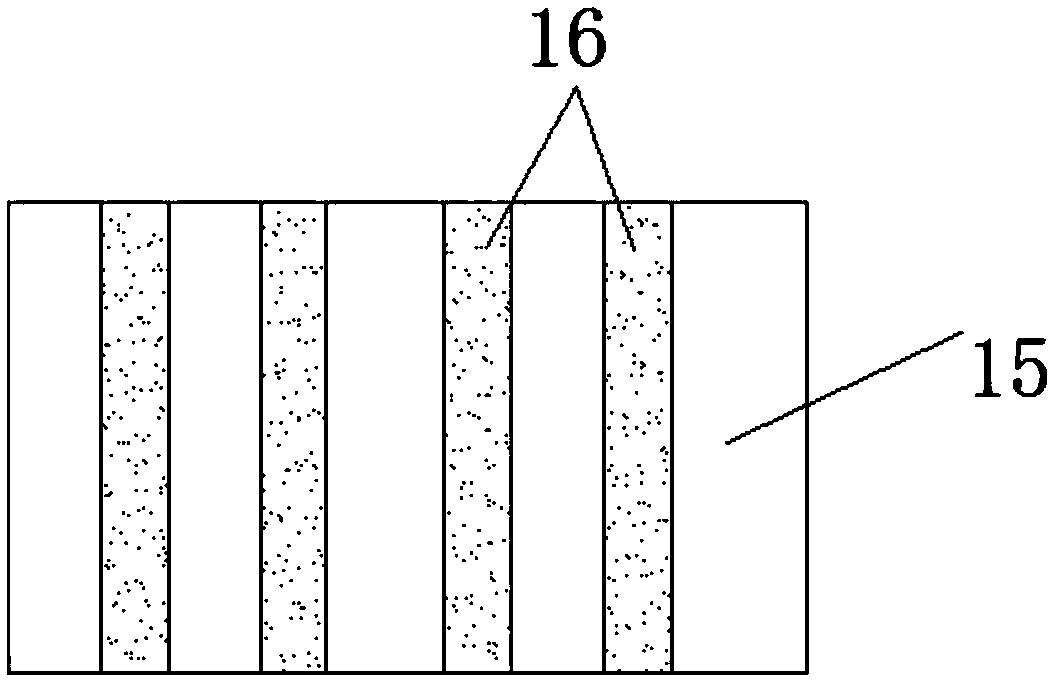

Hydraulic machine hydraulic oil cooling device

PendingCN111207134AExtended cooldownSpeed up the flowFluid-pressure actuator componentsCooling effectOil cooling

The invention provides a hydraulic machine hydraulic oil cooling device. The hydraulic machine hydraulic oil cooling device is good in cooling effect and high in cooling efficiency. According to the hydraulic machine hydraulic oil cooling device, hydraulic oil is distributed through a main distribution pipe and is initially cooled in first radiating pipes; through combination of water cooling andair cooling, cooling water is introduced into cooling strips, fans are used for accelerating air flow between the first radiating pipes so as to accelerate heat loss of the hydraulic oil in the firstradiating pipes; a plurality of arc-shaped grooves formed in each cooling fin form multiple air channels, so that the air passes through the arc-shaped grooves to improve the cooling efficiency; cooling devices are used for secondary cooling of hydraulic oil, and the cooling time of the hydraulic oil in inner pipes is prolonged through internal and external thread structures of second radiating pipes; through the cooling fins, the heat exchange area is increased, and cooling water in outer pipes form turbulent flow to improve the cooling efficiency; and the second radiating pipes are arrangedin a box to form tertiary cooling, and the cooling reliability is greatly improved.

Owner:建湖奥托斯液压机械制造有限公司

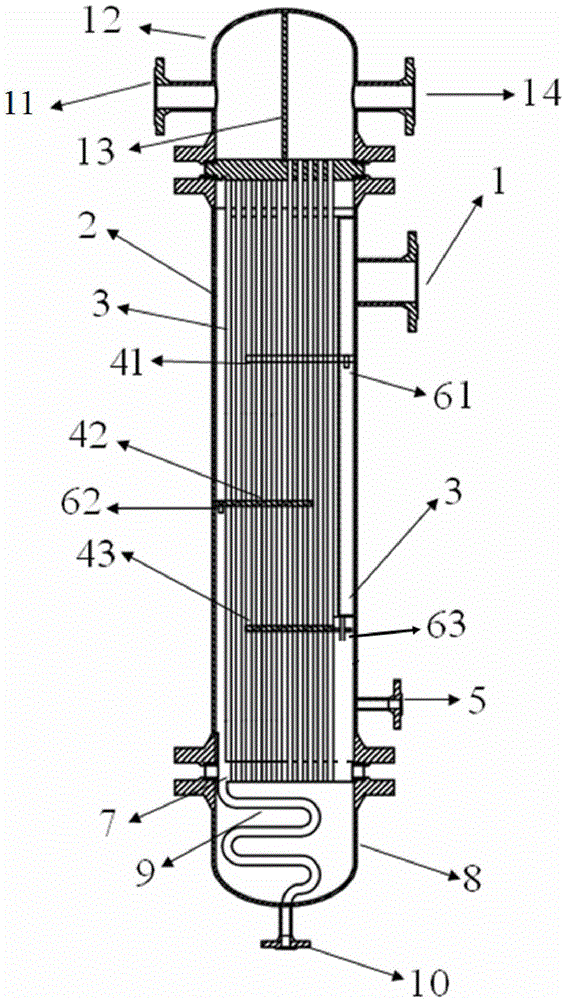

Vertical type condensing heat exchanger and heat exchange method thereof

ActiveCN104390496ASimple processIncrease disturbanceStationary tubular conduit assembliesEngineeringHigh pressure

The invention provides a vertical type condensing heat exchanger and a heat exchange method thereof. The vertical type condensing heat exchanger comprises a condenser body, an in-tube cooling liquid heat exchange unit and an out-tube steam condensing heat exchange unit. The condenser body comprises a cylinder unit, a heat exchange tube bundle is arranged in the cylinder body, a first head and a second head are arranged on two sides of the cylinder unit respectively, a condensate collector is arranged between the cylinder unit and the second head, an in-tube cooling liquid cooling unit is arranged in the cylinder unit, and the out-tube steam condensing heat exchange unit is arranged on the cylinder unit. Cooling liquid is partitioned by a partition plate in the upper head to flow in two directions, namely from top to bottom and from bottom to top, and absorbs out-tube steam condensing released heat in in-tube travel, high-pressure steam returns to flow in a shell pass to wash a cooling tube transversely to achieve out-tube condensing, and condensate collected by each baffle board is subcooled in the second head, so that reliability of a heat exchange system is guaranteed.

Owner:福建蓝海节能科技有限公司

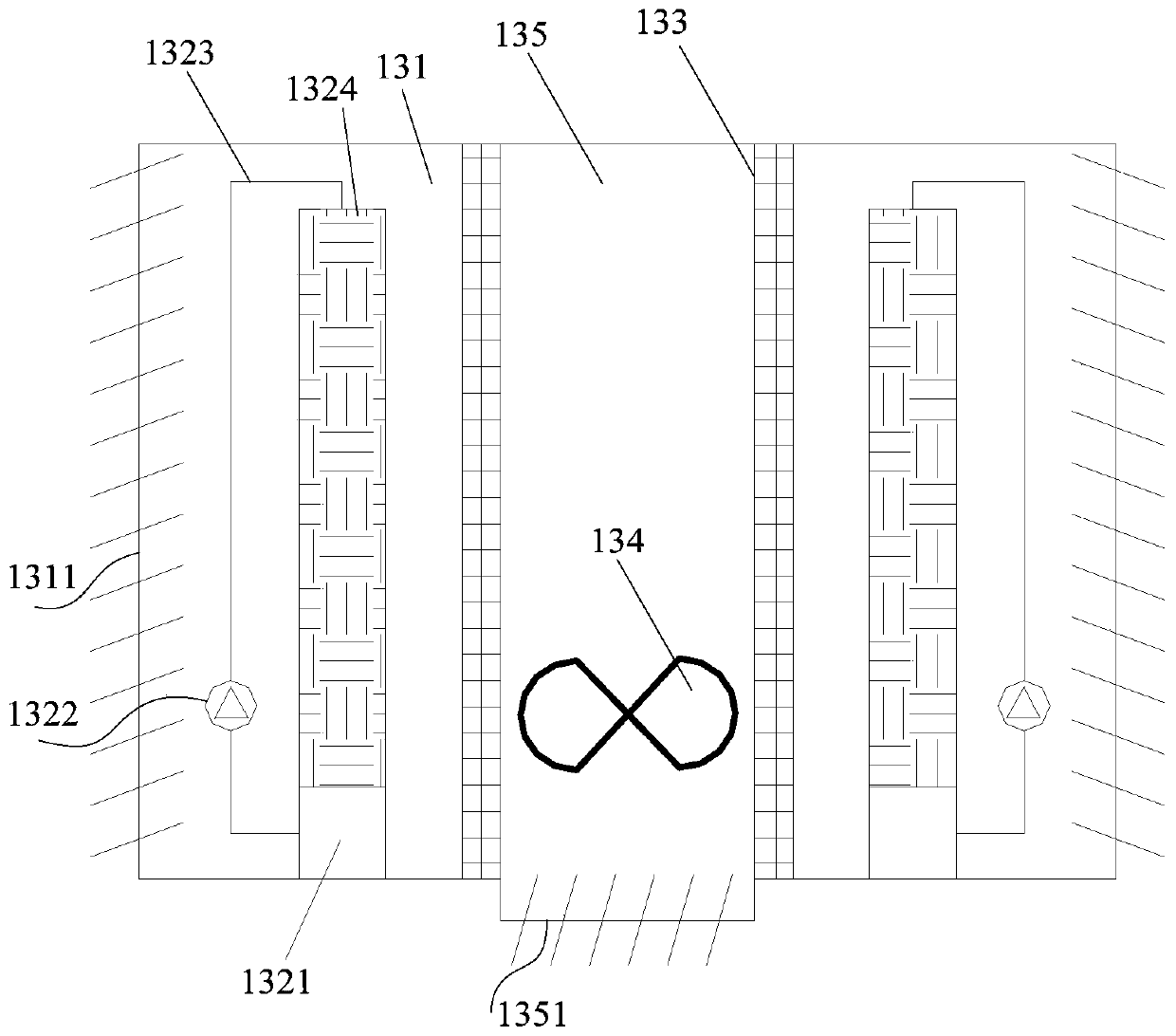

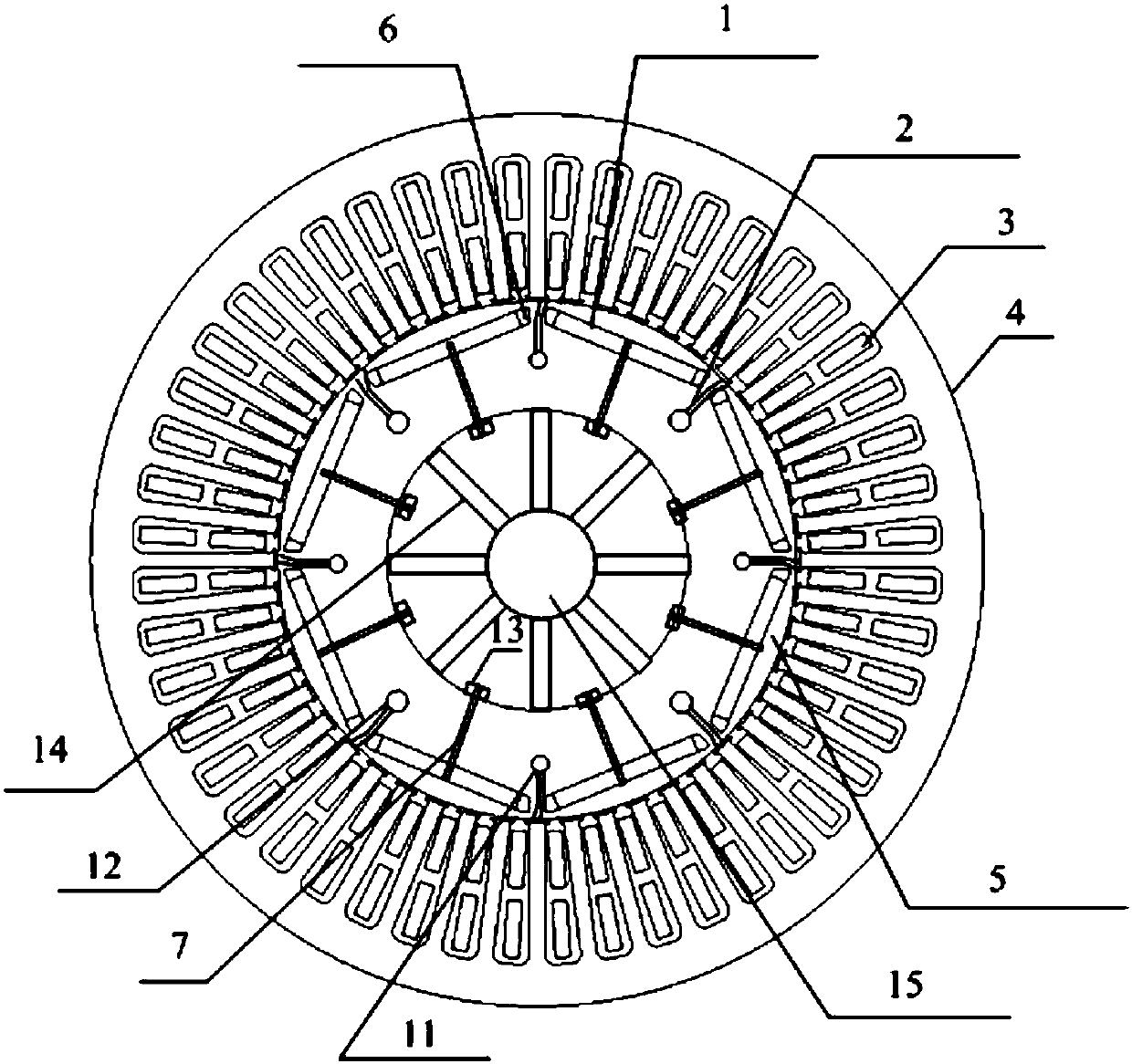

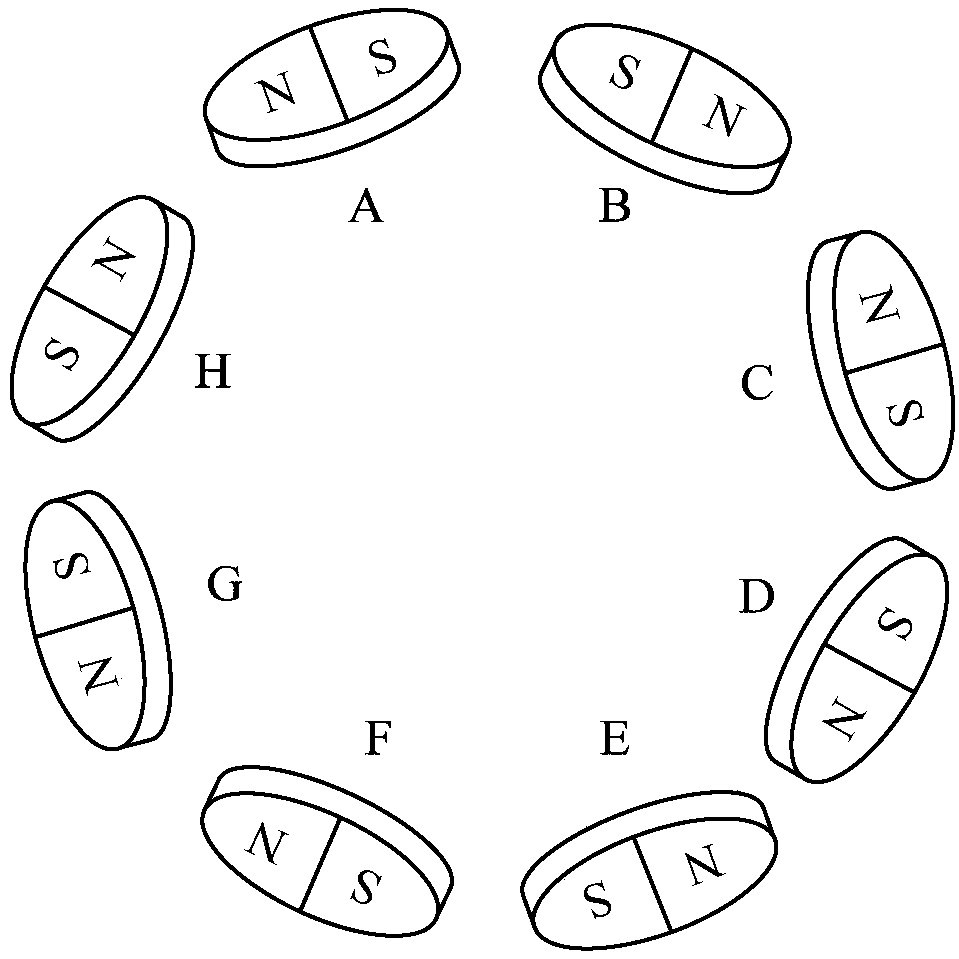

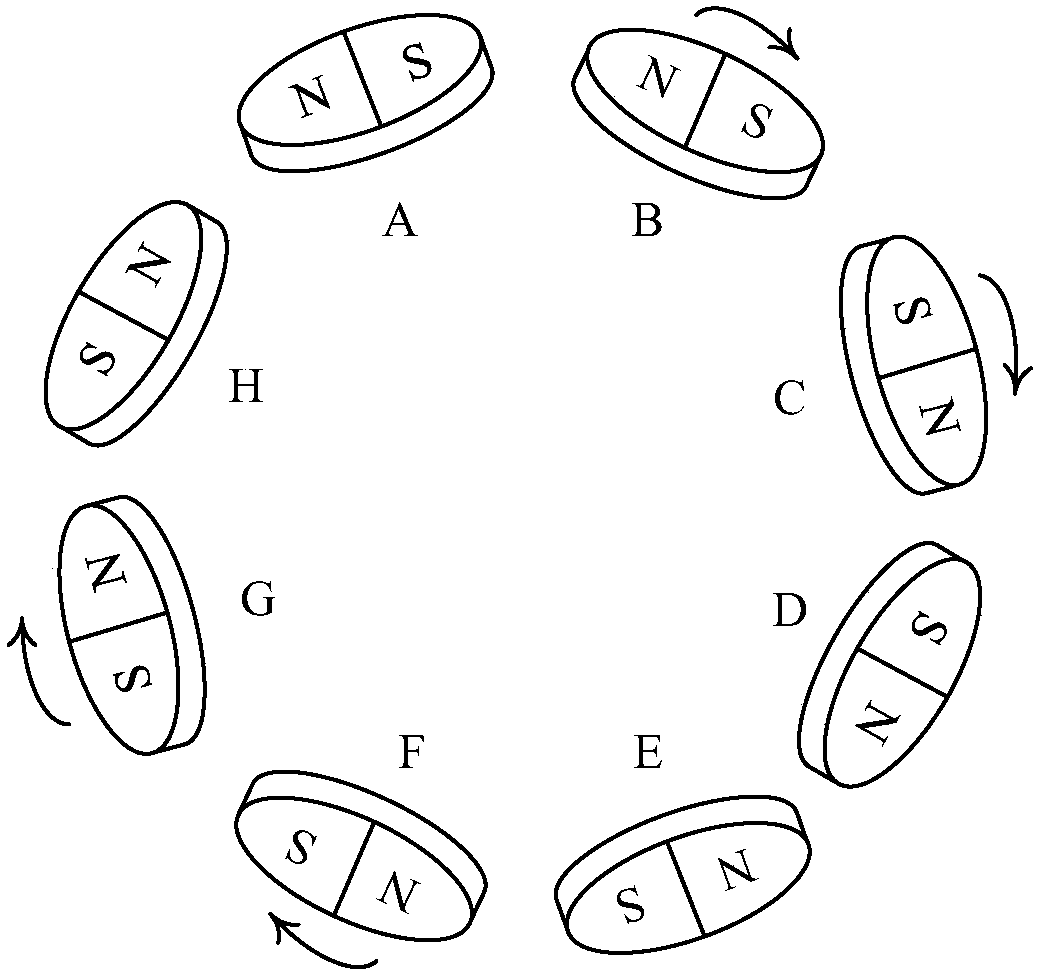

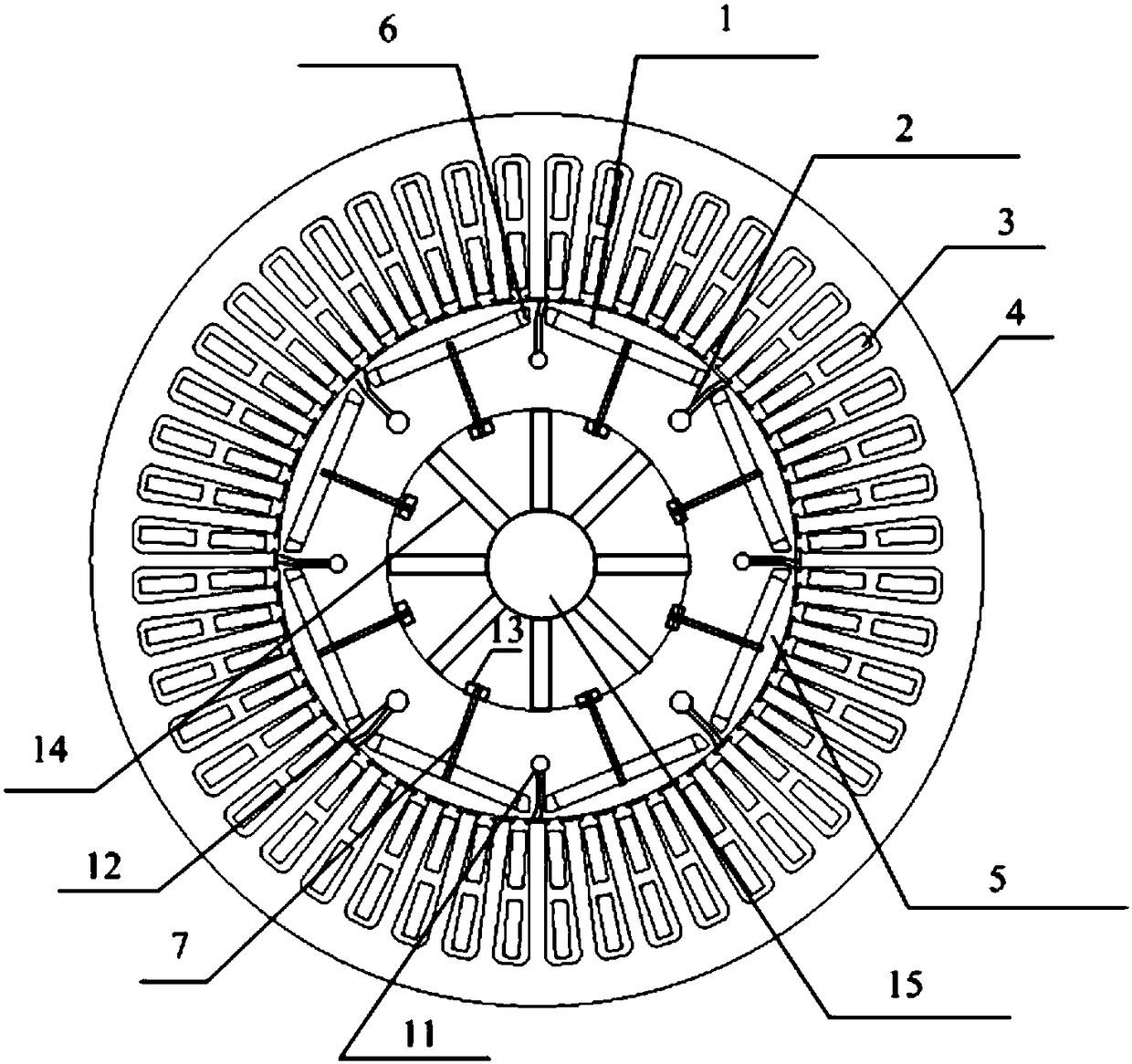

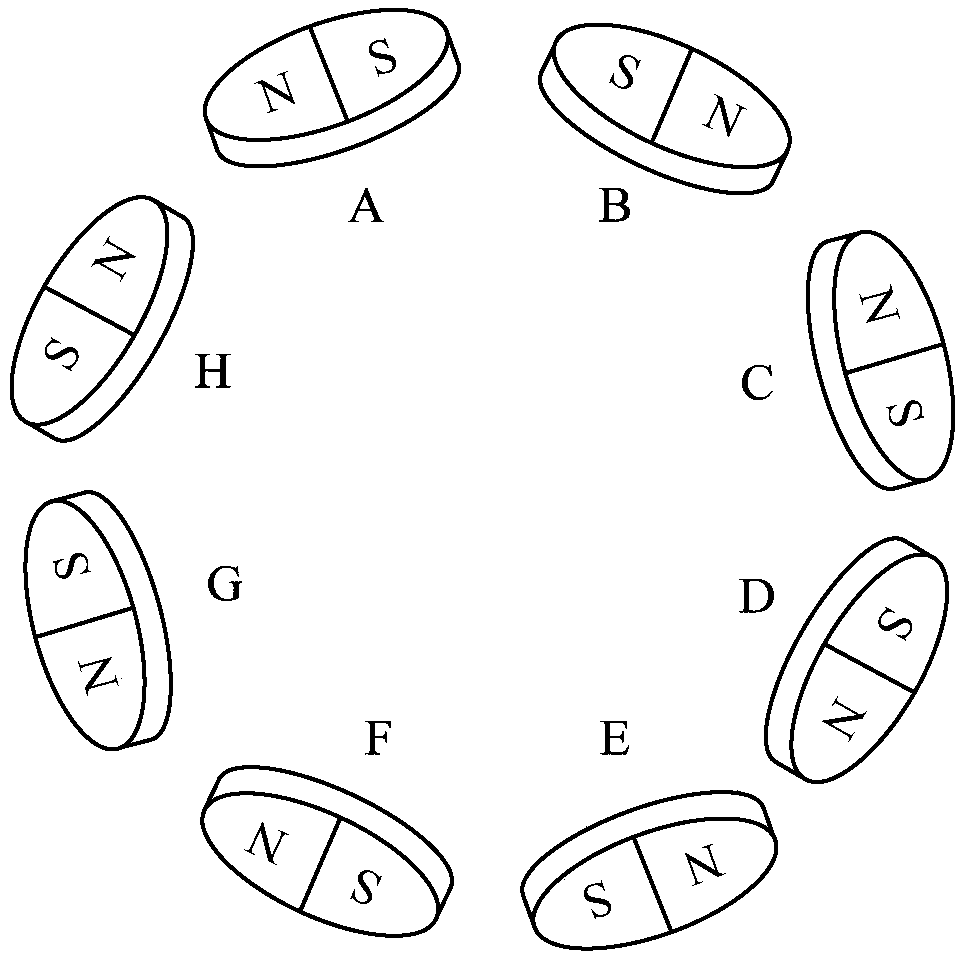

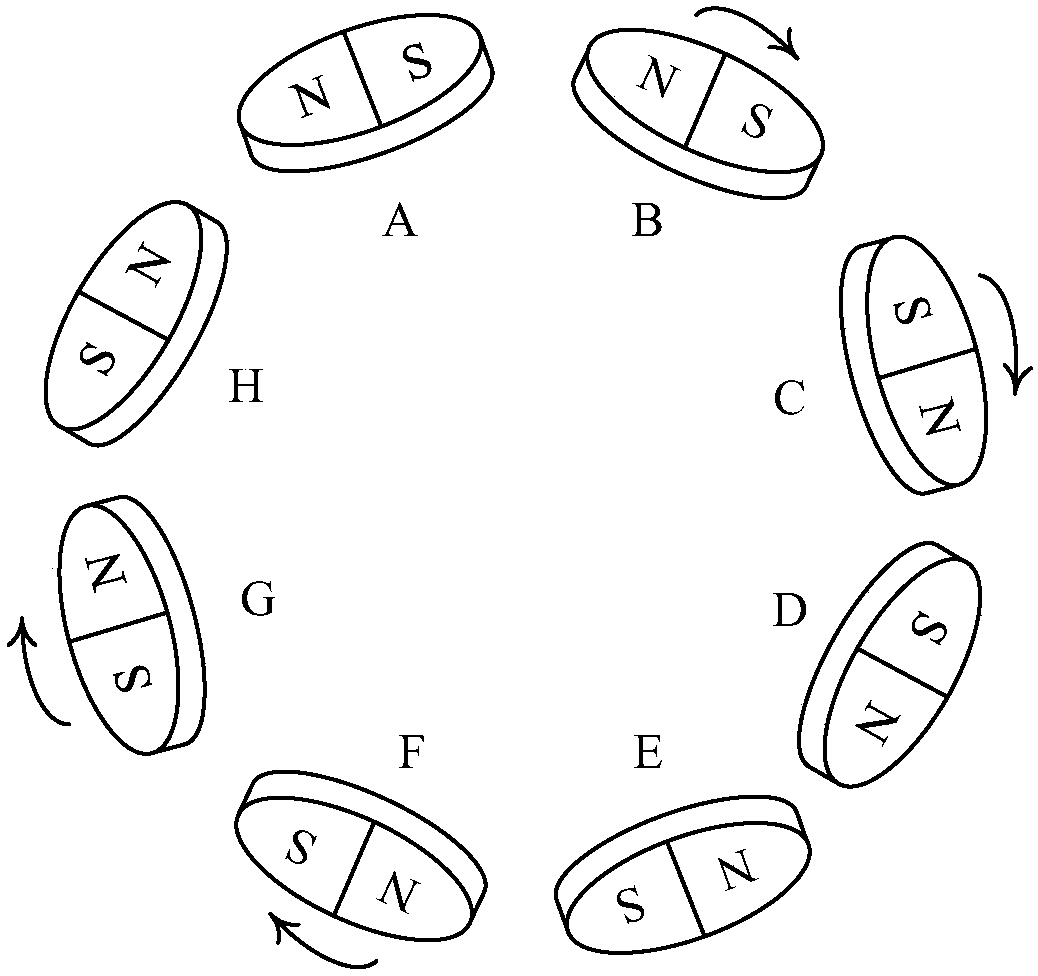

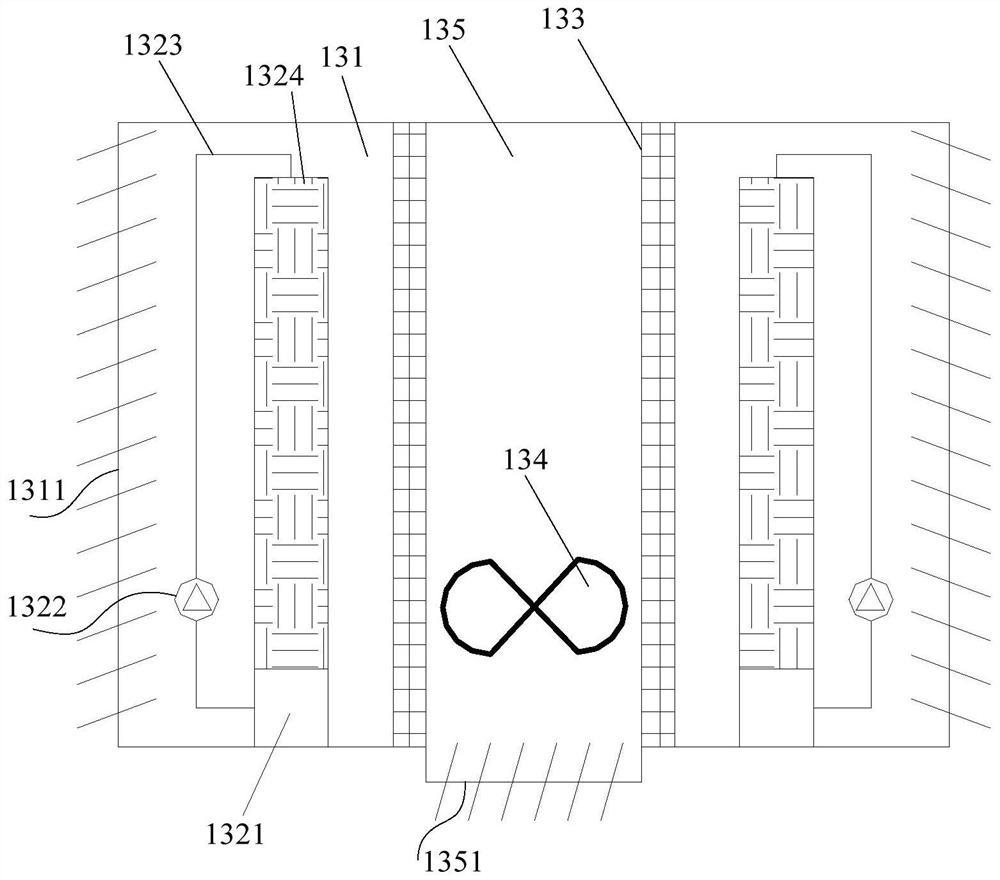

A self-powered inner-cooled permanent magnet motor with flipping magnetic pole speed regulation mechanism

InactiveCN108808913BRealize straddle gear shiftingRealize speed regulationSynchronous machine detailsMagnetic circuit rotating partsElectrical engineering technologyLow speed

The invention provides a self-powered internally cooled permanent magnet motor of an overturning magnetic pole speed-regulation mechanism, and belongs to the technical field of electric engineering. Control difficulty of a variable-frequency speed-regulation system during high-speed running of the permanent magnet motor is reduced by a rotary magnetic pole speed-change mode, multi-gear speed change of low speed, middle speed and high speed of a constant-frequency lower permanent magnet motor are finished, the speed-regulation range of the motor is broadened, and thus, the motor runs at high performance in a wide speed range. According to the technical scheme, the position of a pie permanent magnet is adjusted by controlling rotation of a rotating rod, multi-gear speed change of low speed,middle speed and high speed can be realized, and the control difficulty of the variable-frequency speed-regulation system during high-speed running of the motor is reduced favorably; and moreover, a self-powered tangential air-suction-radial air-guiding-axial exhaust integrated ventilating groove is formed in a rotor side, the cooling system is simple in structure, auxiliary equipment such as a fan pressure head and a cooler in a forced cooling mode is omitted, maintenance is facilitated, self-powered cooling on the rotor is realized by an automatic wind inducing mode, and temperature rising of the rotor and the permanent magnet is reduced effectively.

Owner:HARBIN UNIV OF SCI & TECH

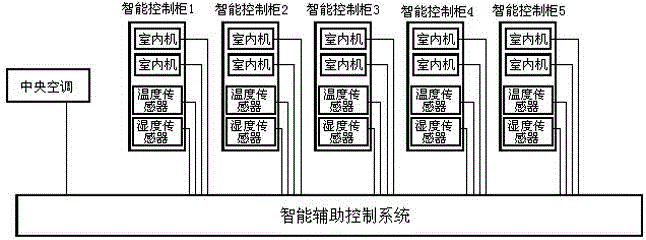

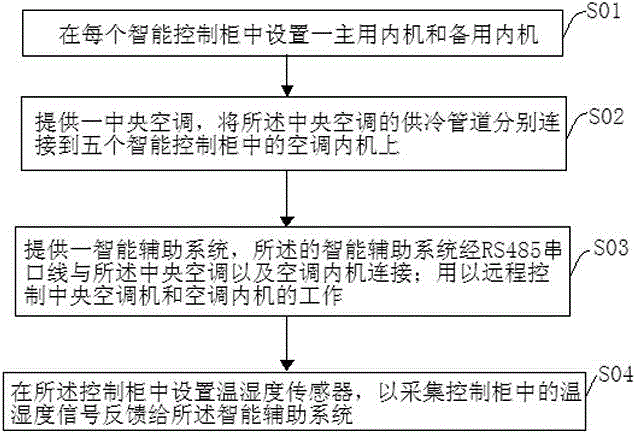

Method for remotely adjusting environments of intelligent control cabinets

ActiveCN103557581ASimple methodRealize centralized coolingSpace heating and ventilation safety systemsLighting and heating apparatusRemote controlEngineering

The invention relates to a method for remotely adjusting environments of intelligent control cabinets. The method is characterized by comprising the steps as follows: S01, a main inner unit and a standby inner unit are arranged in each intelligent control cabinet; S02, a central air conditioner is provided, and a cooling pipe of the central air conditioner is connected to air conditioner inner units of the five intelligent control cabinets respectively; S03, an intelligent auxiliary system is provided, connected with the central air conditioner and the air conditioner inner units through RS485 serial port lines, and used for remotely controlling the work of the central air conditioner and the air conditioner inner units; and S04, temperature and humidity sensors are arranged in the control cabinets and used for acquiring temperature and humidity signals in the control cabinets and feeding the temperature and humidity signals back to the intelligent auxiliary system. The method is simple, high in energy efficiency, low in construction and operating cost and capable of realizing concentrated cooling; the cooling reliability is improved, and each intelligent control cabinet is cooled by two air conditioners; and in addition, the degree of automation is high, and the remote control can be realized.

Owner:STATE GRID CORP OF CHINA +2

A frequency converter thermal management system for an air-conditioning unit, an air-conditioning unit and a control method

ActiveCN112460755BRealize any temperature controlImprove cooling reliabilityMechanical apparatusFrequency changerTemperature control

The invention discloses a frequency converter thermal management system for an air conditioner unit, an air conditioner unit and a control method, which specifically include a control unit, a temperature detection unit, a frequency converter cooling unit, a first switch module and a second switch module, wherein the control units are respectively It is connected with the temperature detection unit, the first switch module and the second switch module; the inlet end of the inverter cooling unit is connected to the condenser in the refrigeration system of the air conditioner unit through the second switch module, and the inverter cooling unit is connected to the condenser in the refrigeration system. The outlet end is connected to the main evaporator in the refrigeration system of the air-conditioning unit through the first switch module; the temperature detection unit is used to detect the temperature of the refrigerant in the inverter cooling unit and send it to the control unit, and the control unit according to The detected temperature controls the opening value of the first switch module and the second switch module, so as to maintain the refrigerant in the inverter cooling unit within a preset range. The above scheme has the advantages of precise temperature control and strong applicability.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Crystal growth furnace growth cavity cooling system

PendingCN113108610AImprove cooling reliabilitySafe to useAfter-treatment apparatusPolycrystalline material growthEngineeringCooling medium

The invention discloses a crystal growth furnace growth cavity cooling system. The system comprises a cooling pipe, the cooling pipe comprises a cooling medium containing cavity, and an area enclosed by the cooling pipe is set as a crystal growth cavity; a cooling medium inlet and a cooling medium outlet are formed in the cooling pipe, a main cooling medium feeding channel communicates with a cooling medium inlet flow path, and the cooling medium outlet communicates with a main cooling medium discharging channel flow path; the crystal growth furnace growth cavity cooling system further comprises an auxiliary cooling system and an electric control system, a medium outlet of the auxiliary cooling system communicates with the cooling medium inlet flow path, and a cooling medium outlet communicates with a medium inlet flow path of the auxiliary cooling system; and the auxiliary cooling system is controlled by the electric control system, and when media in the main cooling medium feeding channel and / or the main cooling medium discharging channel flow abnormally, the auxiliary cooling system provides cooling media for the cooling medium containing cavity. The crystal growth furnace growth cavity cooling system has the advantages of being reliable in cooling, safe to use, convenient to maintain, high in automation degree and the like.

Owner:上海天岳半导体材料有限公司

Self-powered internally cooled permanent magnet motor of overturning magnetic pole speed-regulation mechanism

InactiveCN108808913ASmooth inhalationRealize straddle gear shiftingMagnetic circuit rotating partsSynchronous machine detailsElectrical engineering technologyConstant frequency

The invention provides a self-powered internally cooled permanent magnet motor of an overturning magnetic pole speed-regulation mechanism, and belongs to the technical field of electric engineering. Control difficulty of a variable-frequency speed-regulation system during high-speed running of the permanent magnet motor is reduced by a rotary magnetic pole speed-change mode, multi-gear speed change of low speed, middle speed and high speed of a constant-frequency lower permanent magnet motor are finished, the speed-regulation range of the motor is broadened, and thus, the motor runs at high performance in a wide speed range. According to the technical scheme, the position of a pie permanent magnet is adjusted by controlling rotation of a rotating rod, multi-gear speed change of low speed,middle speed and high speed can be realized, and the control difficulty of the variable-frequency speed-regulation system during high-speed running of the motor is reduced favorably; and moreover, a self-powered tangential air-suction-radial air-guiding-axial exhaust integrated ventilating groove is formed in a rotor side, the cooling system is simple in structure, auxiliary equipment such as a fan pressure head and a cooler in a forced cooling mode is omitted, maintenance is facilitated, self-powered cooling on the rotor is realized by an automatic wind inducing mode, and temperature rising of the rotor and the permanent magnet is reduced effectively.

Owner:HARBIN UNIV OF SCI & TECH

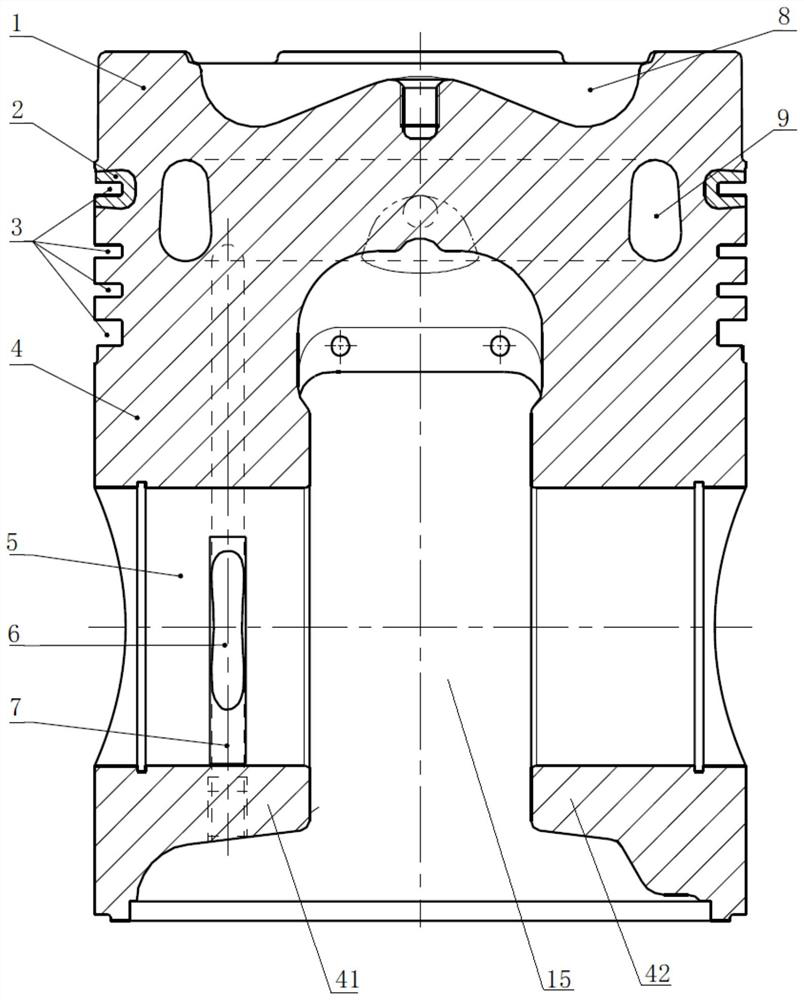

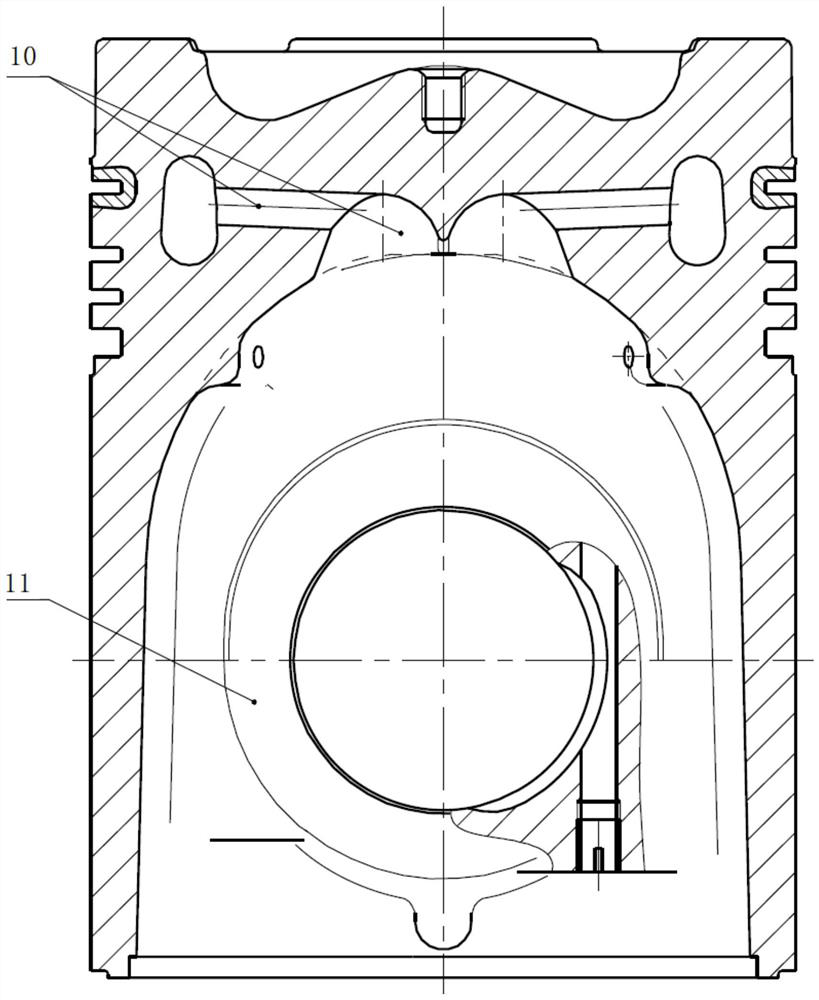

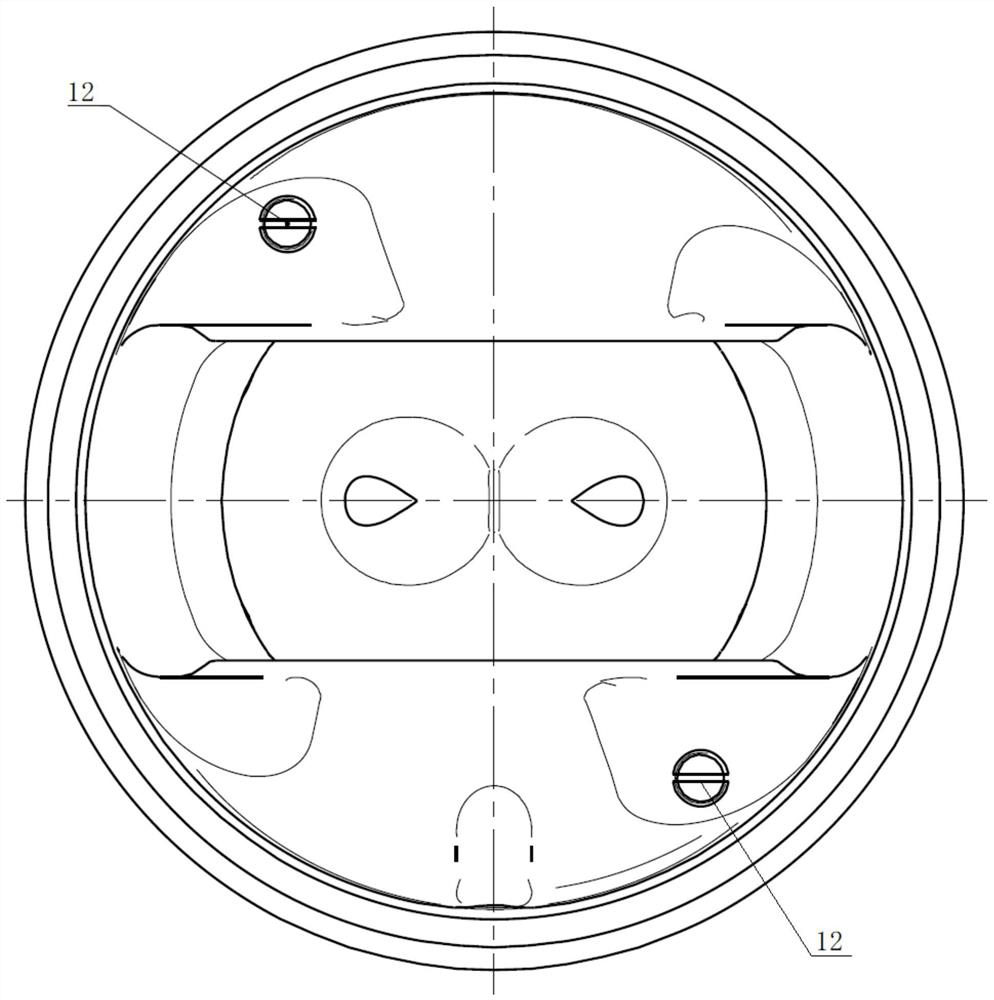

A Novel Integral Aluminum Piston Assembly for Internal Combustion Engines

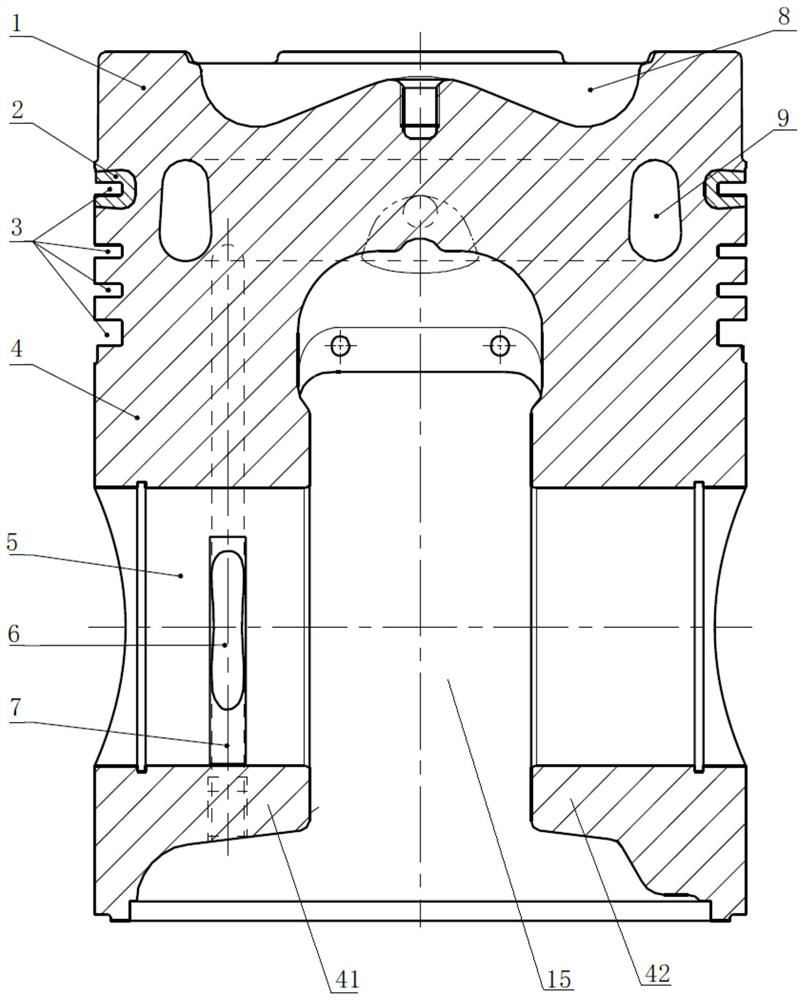

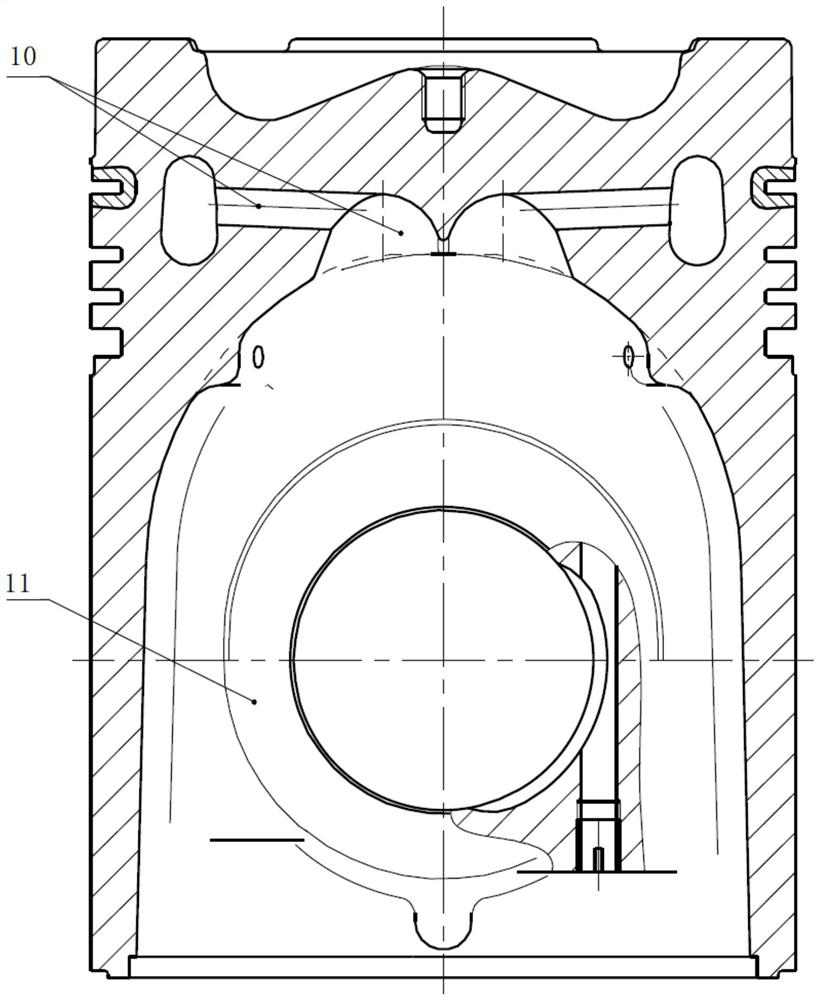

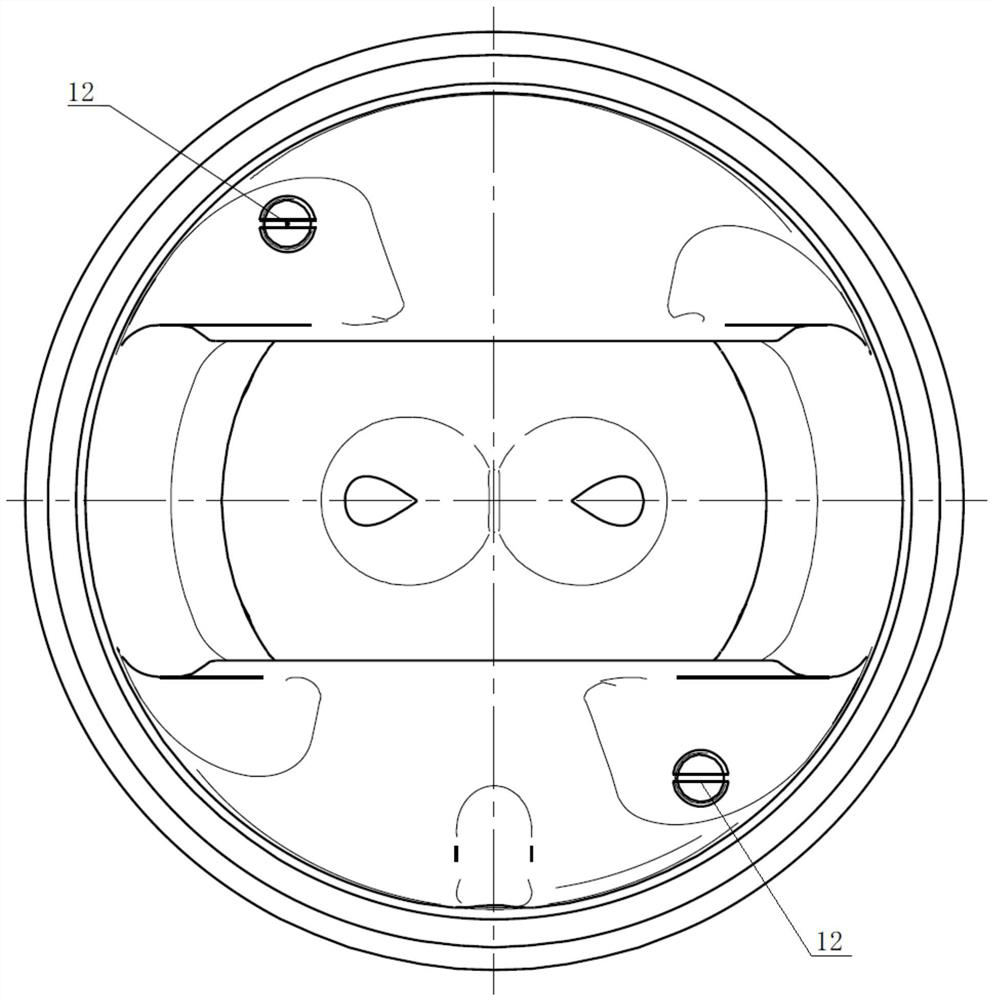

ActiveCN113309627BReduce heat loadReduce the risk of failureLiquid coolingConnecting rodsOil canCooling effect

The invention provides a novel integral aluminum piston assembly for internal combustion engines, which relates to the technical field of pistons of internal combustion engines. This new integral aluminum piston assembly for internal combustion engines includes an aluminum piston body, connecting rod and piston pin. In the novel integral aluminum piston assembly for internal combustion engines of the present invention, the oil continuously supplies oil to the aluminum piston body through the connecting rod oil passage and the piston pin oil passage, and then through the oscillation of the oil in the cold oil cavity of the integral aluminum piston, the oil can be continuously The whole aluminum piston body is cooled with high heat exchange efficiency, high cooling reliability and good cooling effect, which can significantly reduce the thermal load of the piston and improve the reliability and service life of the piston. In addition, the oil can realize the forced lubrication of the piston pin hole, the piston pin and the small end bearing bush of the connecting rod, enhance the lubrication effect of the fitting clearance, and reduce the failure risk of the piston pin hole, the piston pin and the small end bearing bush of the connecting rod.

Owner:BINZHOU UNIV

Cooling Systems and Data Centers

ActiveCN110691492BReduce resistanceRefrigeration intelligenceCooling/ventilation/heating modificationsTemperature controlData center

The invention belongs to the technical field of air conditioning and provides a refrigeration system and a data center. The refrigeration system includes a direct evaporative cooling device, an air conditioner, a main controller and an indoor temperature acquisition device; the direct evaporative cooling device includes a direct cooling mechanism arranged on the sky, and a blower connected with the direct cooling mechanism for supplying air to the data center. Damper, and the hot air return valve connected to the data center; the main controller is used to obtain the indoor temperature collected by the indoor temperature acquisition device, control the air supply temperature of the direct cooling mechanism according to the indoor temperature, and / or control the air supply of the air conditioner temperature, and control the opening of the air supply valve and hot air return valve. The data center includes at least one floor of data center rooms and the aforementioned cooling system. The present invention automatically controls the air conditioner and the direct refrigeration mechanism according to the indoor and outdoor temperatures, and the refrigeration is more energy-saving and space-saving.

Owner:厦门华睿晟智能科技有限责任公司 +1

An integrated water/oil/coke/coal slurry process burner with gas film protection

ActiveCN109810729BReduce direct contact frictionExtended service lifeGranular/pulverulent flues gasificationEpoxyTar

Owner:中国东方电气集团有限公司 +1

Novel integral aluminum piston assembly for internal combustion engine

ActiveCN113309627AImprove heat transfer efficiencyImprove cooling reliabilityLiquid coolingConnecting rodsLubricationGudgeon pin

The invention provides a novel integral aluminum piston assembly for an internal combustion engine, and relates to the technical field of internal combustion engine pistons. The novel integral aluminum piston assembly for the internal combustion engine comprises an aluminum piston body, a connecting rod and a piston pin. According to the novel integral aluminum piston assembly for the internal combustion engine, engine oil is continuously supplied to the aluminum piston body through a connecting rod oil duct and a piston pin oil duct, then the integral aluminum piston body can be continuously cooled through oscillation of the engine oil in a cold oil cavity in the integral aluminum piston, the heat exchange efficiency is high, the cooling reliability is high, the cooling effect is good, the thermal load of the piston can be obviously reduced, the reliability of the piston is improved, and the service life of the piston is prolonged; and in addition, the engine oil can achieve forced lubrication on a piston pin hole, the piston pin and a connecting rod small-end bearing bush, the lubrication effect of the fit clearance is enhanced, and the failure risk of the piston pin hole, the piston pin and the connecting rod small-end bearing bush is reduced.

Owner:BINZHOU UNIV

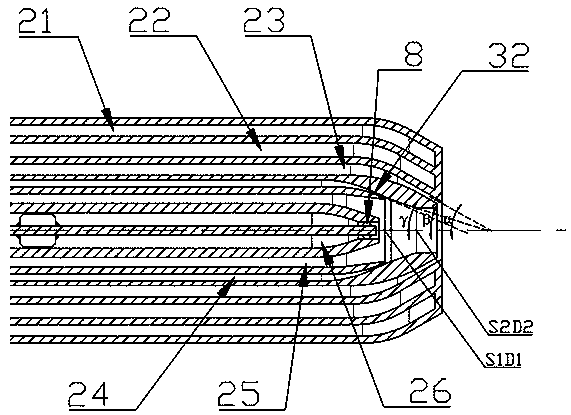

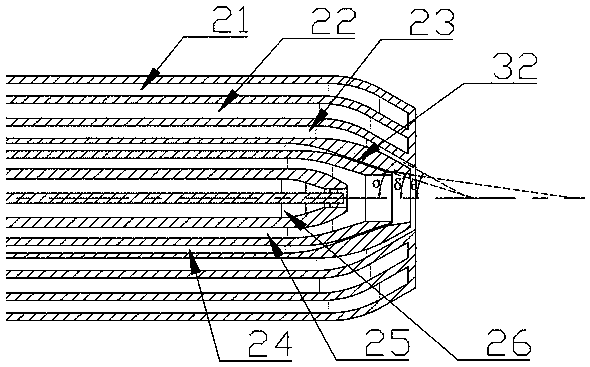

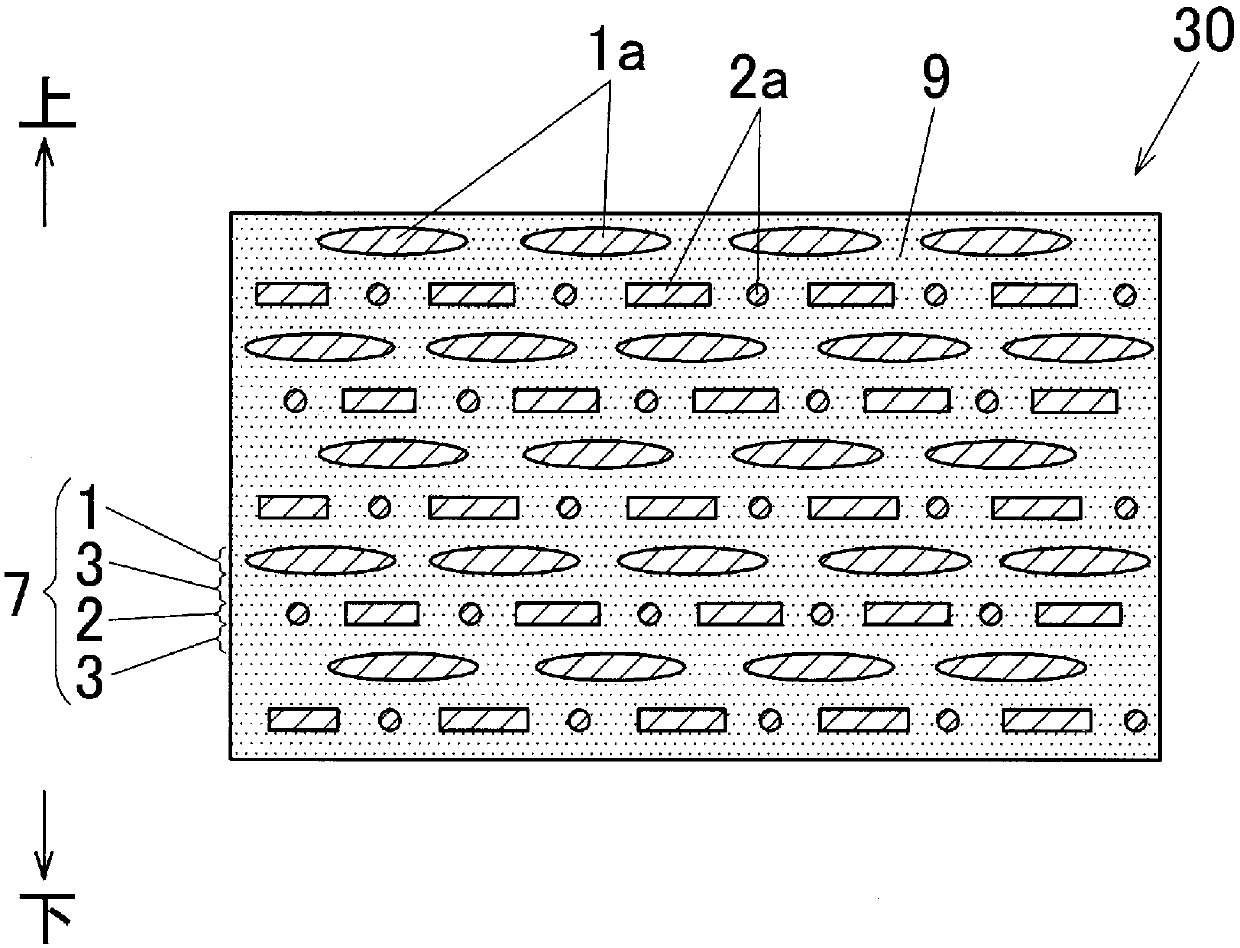

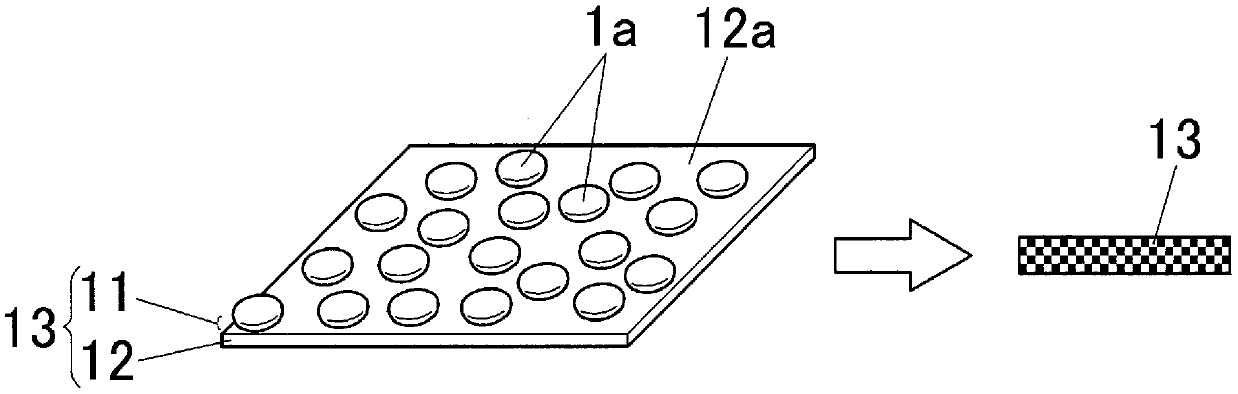

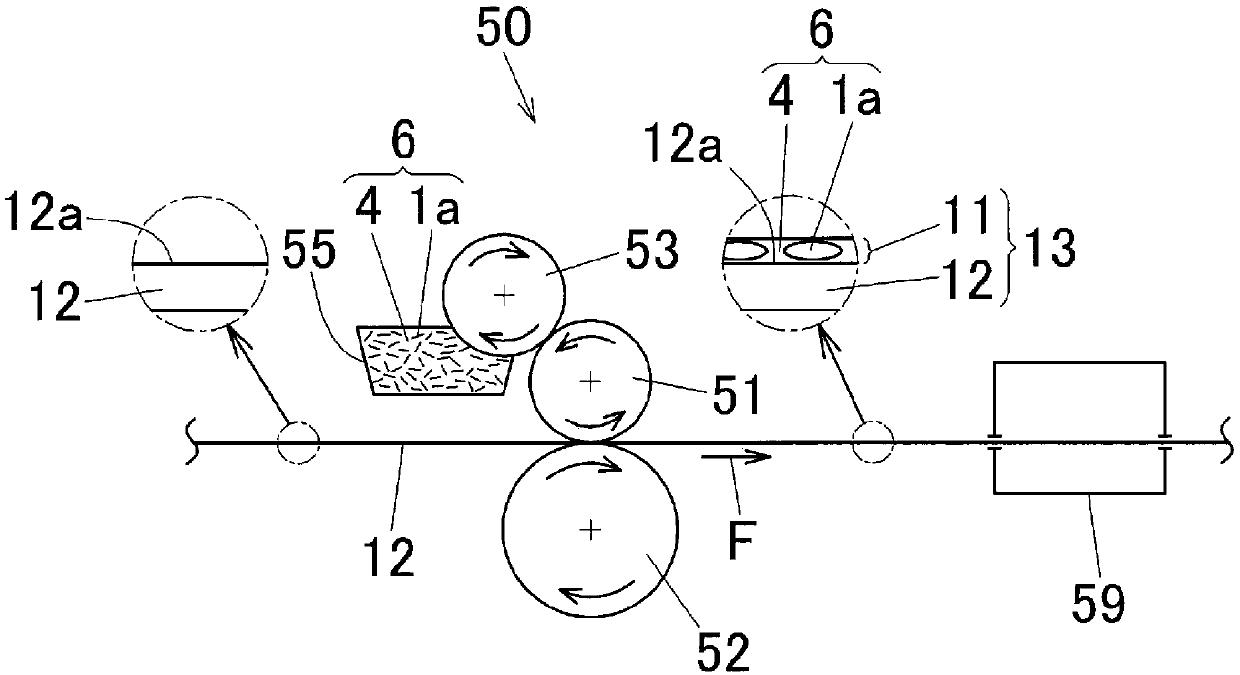

Metal-carbon particle composite material and method for manufacturing same

InactiveCN109562598AFast heat conductionLow linear expansionLiquid surface applicatorsSemiconductor/solid-state device detailsFiberCarbon fibers

In a metal-carbon particle composite material (30), one or more flake-graphite-particle dispersion layers (1) in which flake graphite particles (1a) as carbon particles are dispersed in a metal matrix(9), one or more carbon fiber dispersion layers (2) in which carbon fibers (2a) as carbon particles are dispersed in the metal matrix (9), and one or more metal layers (3) formed in the metal matrix(9) are provided in layered fashion. The one or more flake-graphite-particle dispersion layers (1), the one or more carbon fiber dispersion layers (2), and the one or more metal layers (3) are joinedand integrated. Either the flake-graphite-particle dispersion layer (1) or the carbon fiber dispersion layer (2) and the metal layer (3) are arranged in a state of being layered in alternating fashionthroughout substantially the entire thickness direction of the composite material (30).

Owner:RESONAC HOLDINGS CORPORATION

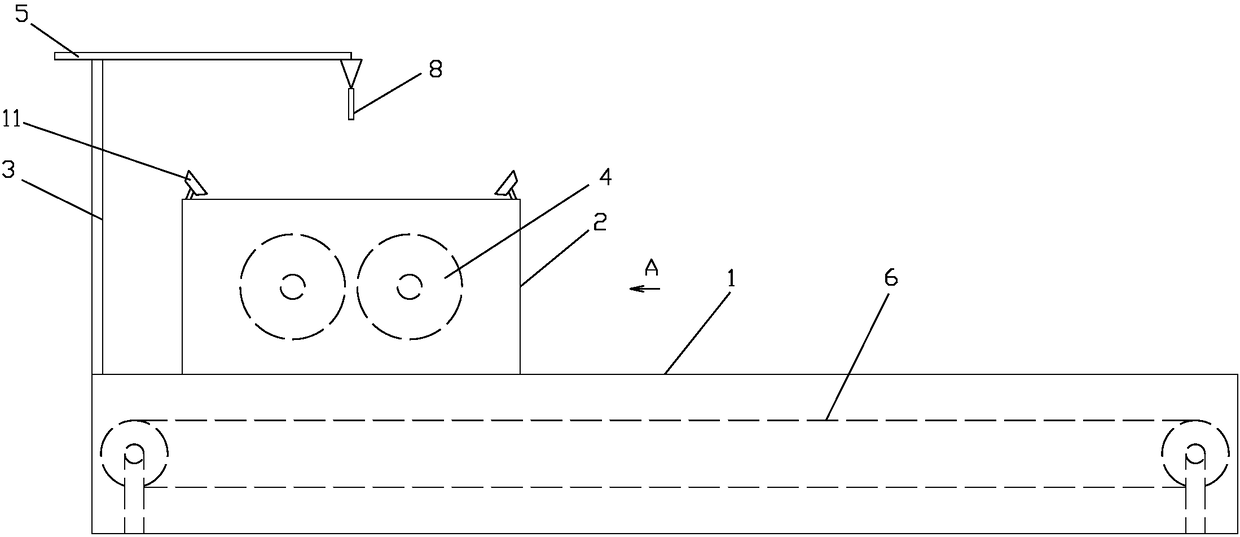

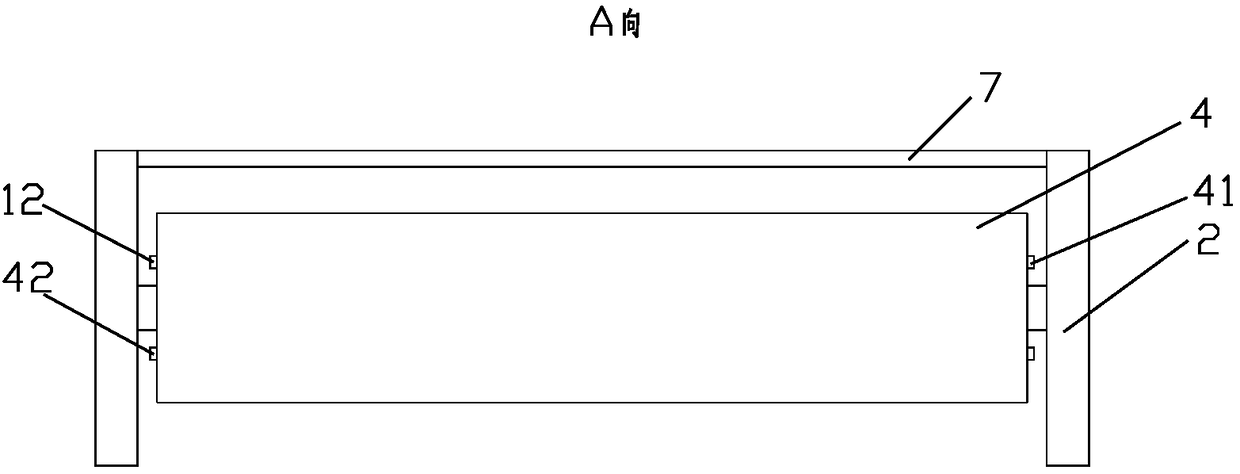

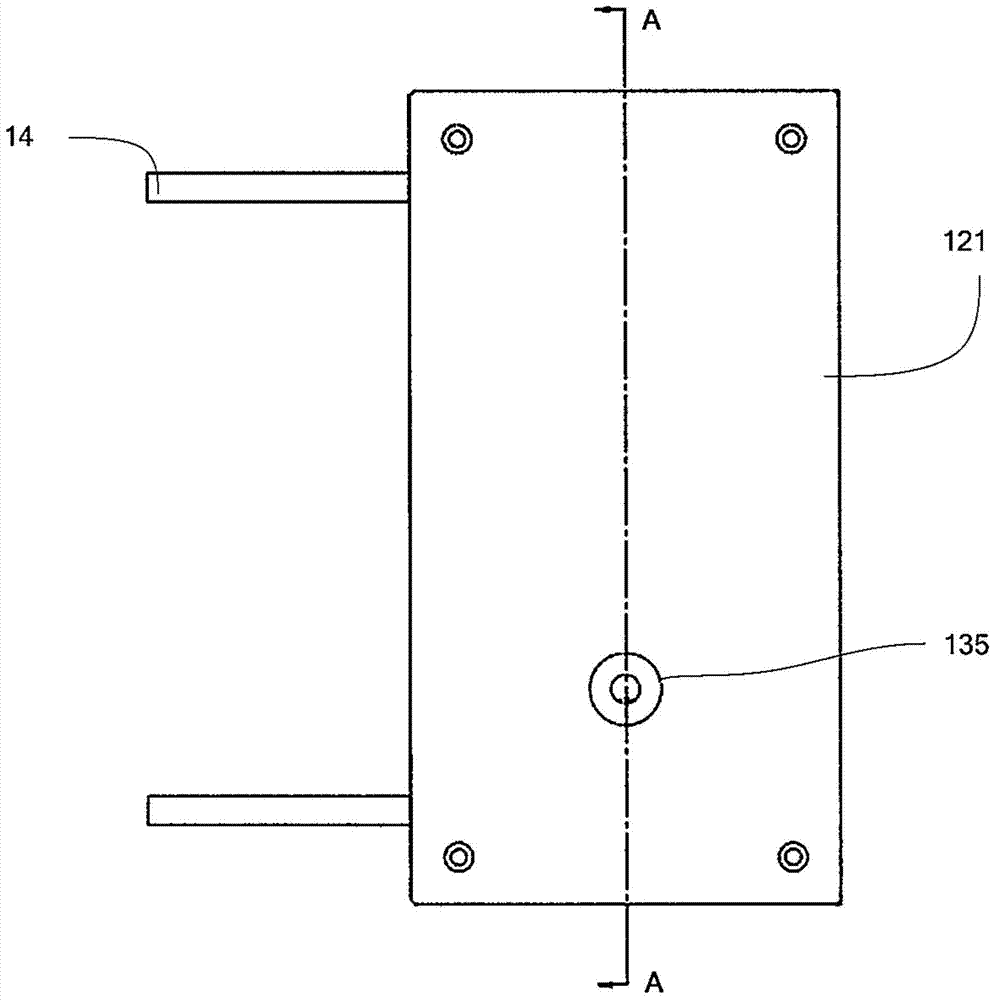

Extrusion cooler for powder coating

The invention provides an extrusion cooler for powder coating, and relates to the field of powder coating processing. The extrusion cooler has simple structure, performs extrusion uniformly and realizes reliable cooling. The extrusion cooler comprises a rack, wherein a pair of vertical plates and a stay bar are arranged on the rack, a pair of extrusion rollers is arranged between the pair of vertical plates, the stay bar is connected with a guide chute, an outlet of the guide chute is located above the middle of the pair of extrusion rollers, and a conveying belt is arranged in the rack; a triangular guide plate is arranged at the outlet of the guide chute, the vertex angle end of the guide plate is connected with the outlet of the guide chute, and guide grooves are formed in two sides ofthe vertex angle end of the guide plate respectively; a pair of parallel cross bars is arranged between the pair of vertical plates and located on two sides of the guide plate respectively, and opposite blowers are arranged on the pair of cross bars. The extrusion cooler facilitates processing and is reliable to operate.

Owner:YANGZHOU JINCHEN CHEM

Adjustable light source device and precise measurement equipment comprising same

ActiveCN104713487ARealize real-time positioning adjustmentAvoid thermal shockLighting heating/cooling arrangementsUsing optical meansLight beamOptoelectronics

The invention provides an adjustable light source device and precise measurement equipment comprising the same. The adjustable light source device comprises a cooling substrate, a multi-dimension adjustment bracket, a light source and a movable insulated heat-insulation connection assembly, wherein the cooling substrate comprises a shell, a division plate dividing the inner cavity into a cool cavity and a hot cavity, a cool cavity door and a hot cavity door, and an adjustment channel is arranged on the division plate; the multi-dimension adjustment bracket is located in the cool cavity and placed on the division plate; the light source is located in the hot cavity and connected with an external power supply; the movable insulated heat-insulation connection assembly passes through the adjustment channel and extends in the cool cavity and the hot cavity, one end is connected with the multi-dimension adjustment bracket and the other end is connected with the light source; and adjustment channel sealing mechanism is set to be connected with the movable insulated heat-insulation connection assembly and keeps sealing one end of the adjustment channel; and the shell is also provided with a light outlet to lead light beams emitted by the light source out of the shell. Heat shock on heat-sensitive components of the measurement system inside the precise measurement equipment by the light source can be effectively prevented while the light source is positioned and adjusted in real time.

Owner:RAINTREE SCI INSTR SHANGHAI

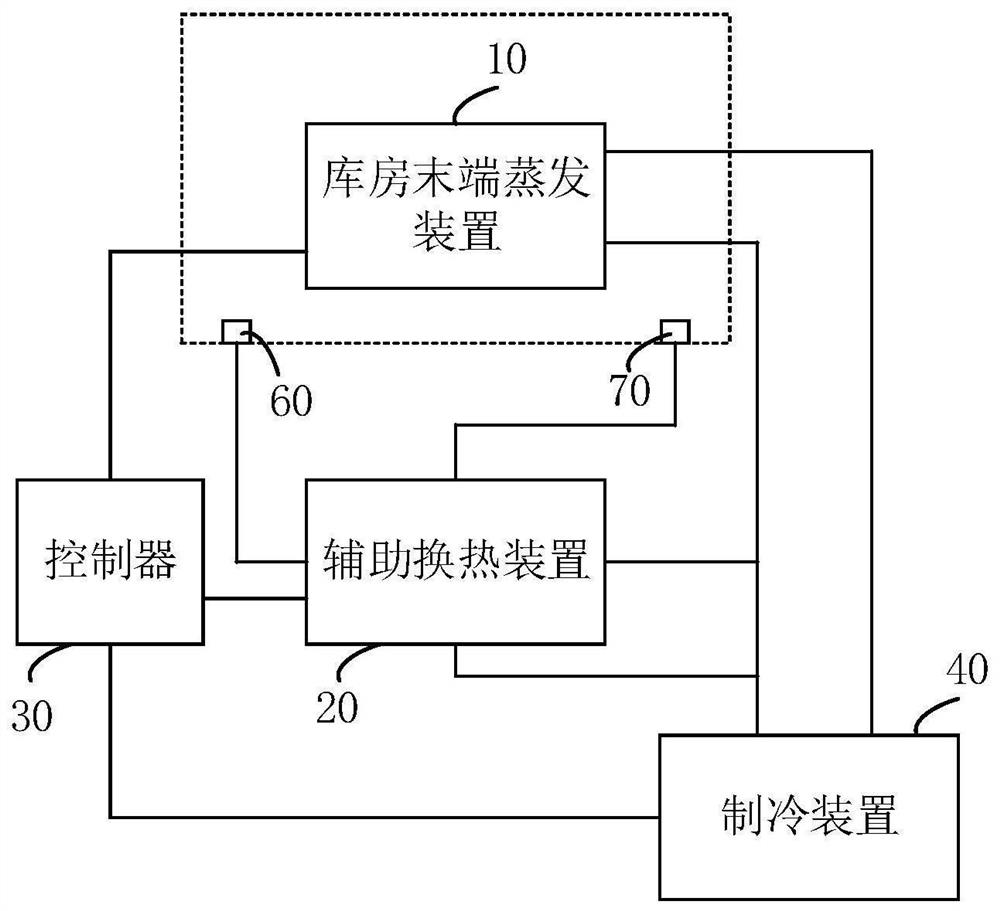

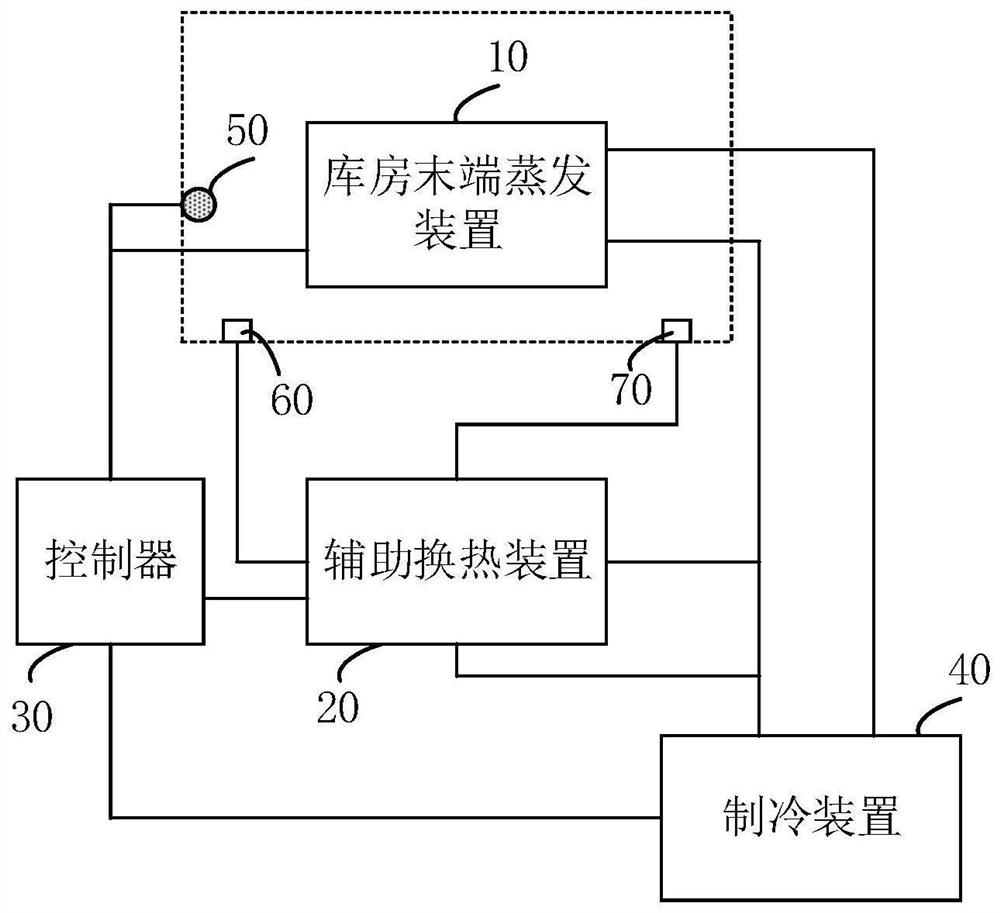

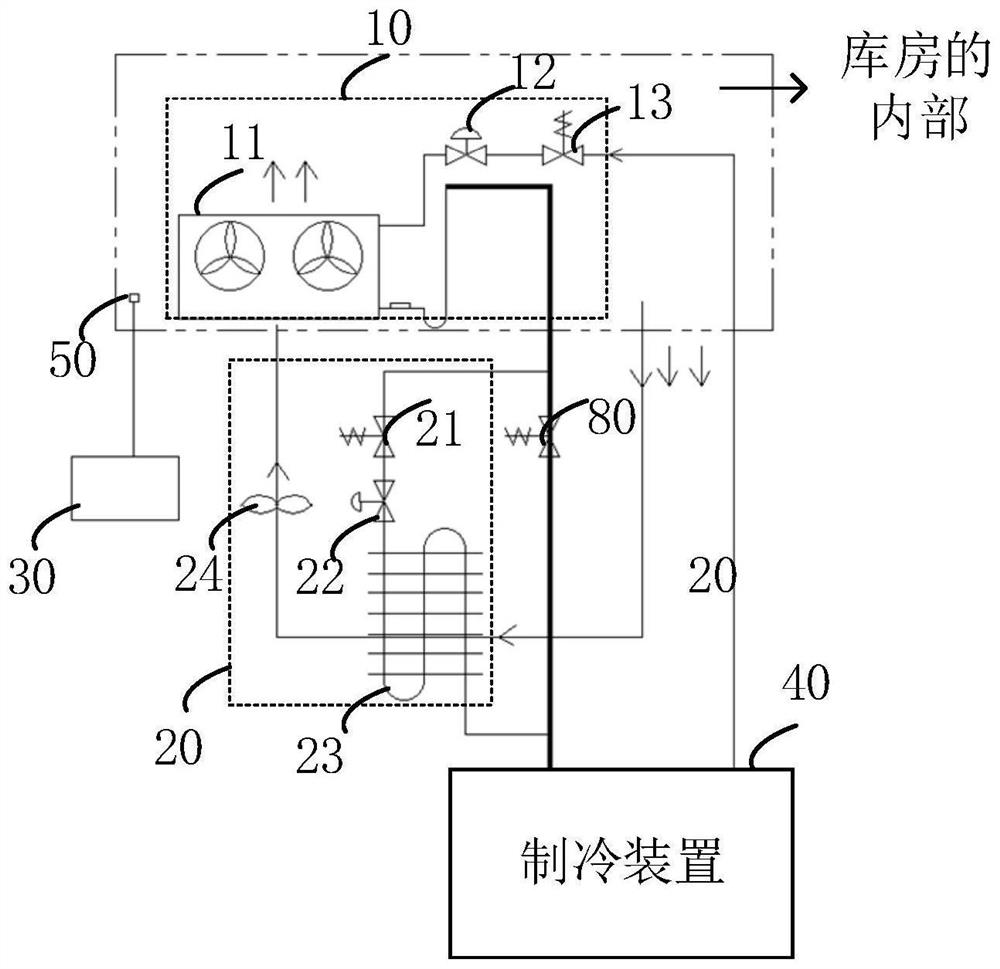

Warehouse operation control system and refrigerating unit

PendingCN112129026AImprove cooling reliabilityAchieve dehumidification operationLighting and heating apparatusStationary refrigeration devicesThermodynamicsHigh humidity

The invention relates to a warehouse operation control system and a refrigerating unit. An auxiliary heat exchange device is arranged between a warehouse tail end evaporation device and an external refrigerating device, and communicates with an air return port and an air inlet of a warehouse, so that air flowing out from the air return port can flow back into the warehouse through the air inlet after passing through the auxiliary heat exchange device. Meanwhile, after the auxiliary heat exchange device is started under the control effect of a controller, a refrigerant flowing out from the warehouse tail end evaporation device can further flow through the auxiliary heat exchange device to flow back into the external refrigerating device. In the process, the refrigerant absorbs heat to evaporate, and the air releases heat to frost and condense water vapor carried in the air on the auxiliary heat exchange device so as to realize the dehumidification operation. The dehumidified air flows into the warehouse through an air supply port to prevent the frosting of the air with higher humidity in the warehouse tail end evaporation device so as to effectively improve the refrigerating reliability of the warehouse.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com