Adjustable light source device and precise measurement equipment comprising same

A light source device and precision measurement technology, applied in the direction of using optical devices, components of lighting devices, cooling/heating devices of lighting devices, etc., can solve problems such as inability to effectively prevent heat, improve cooling reliability, and improve stability performance, size and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

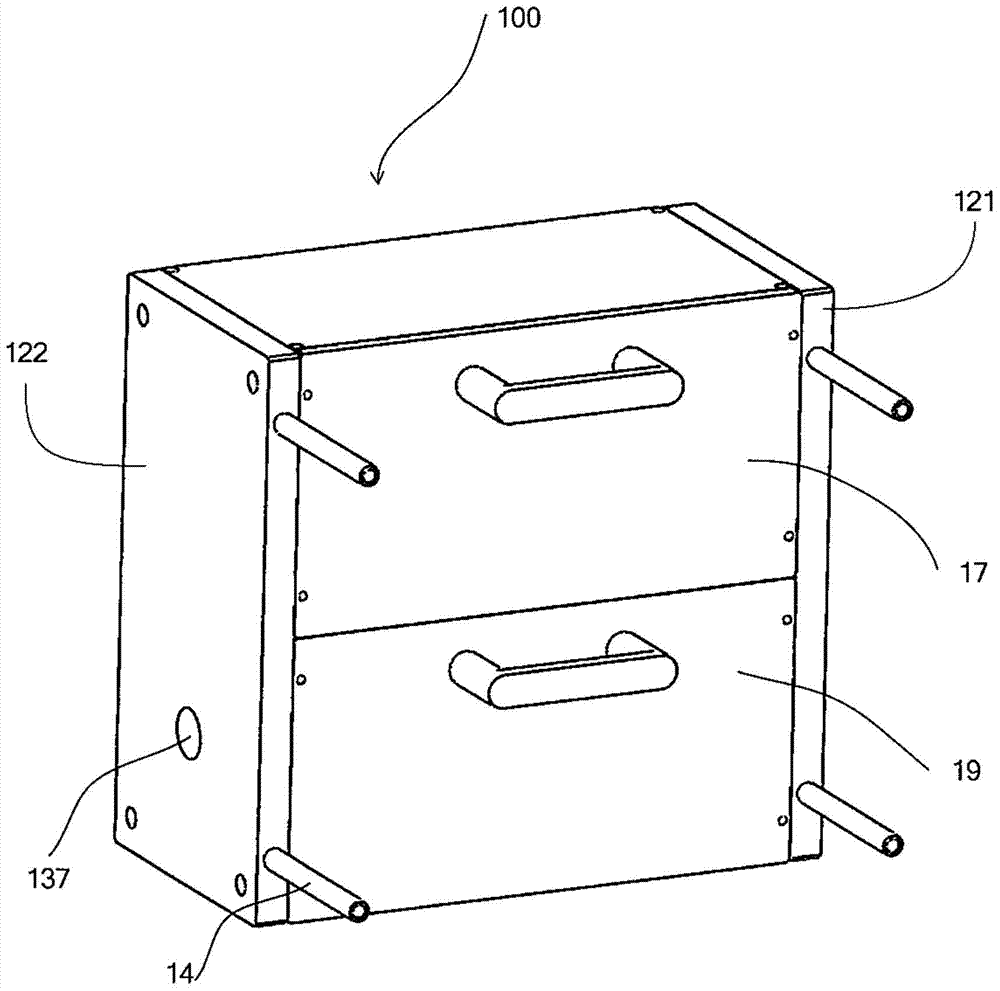

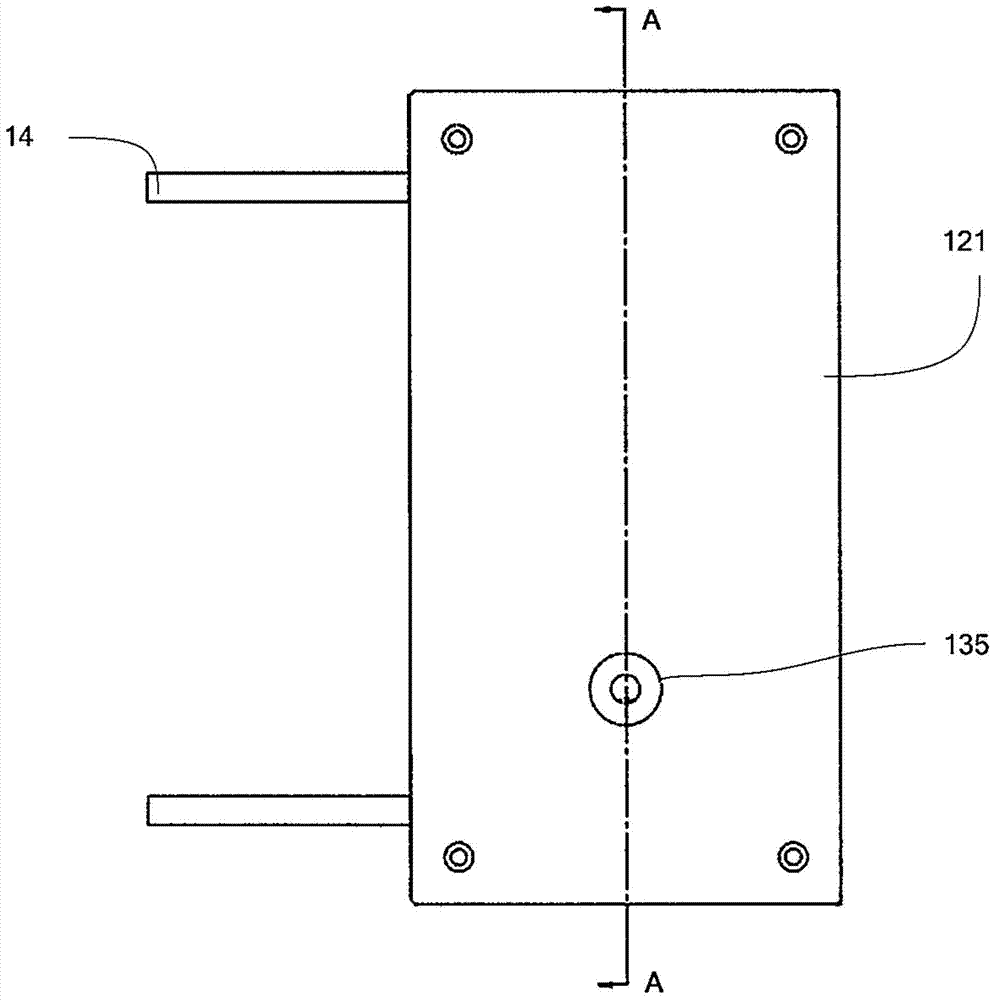

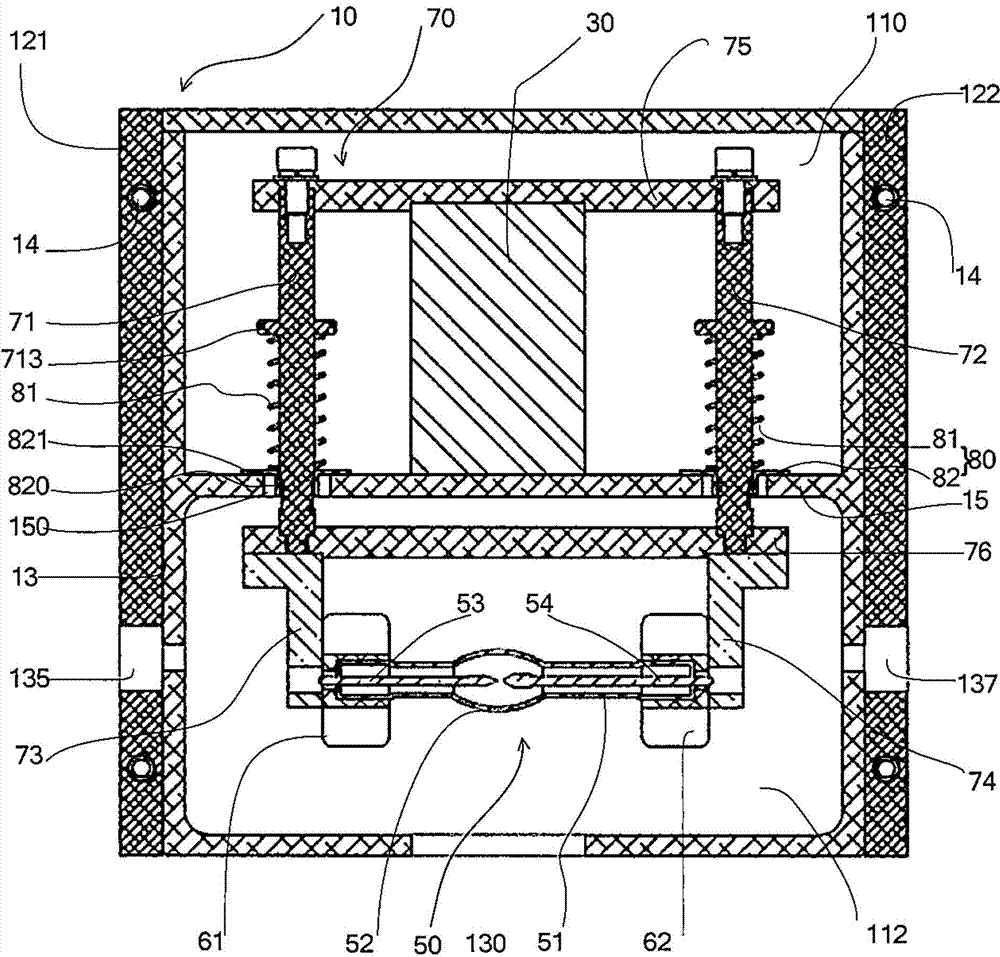

[0032] As required, specific embodiments of the invention will be disclosed herein. However, it should be understood that the embodiments disclosed herein are merely typical examples of the invention, which can be embodied in various forms. Therefore, specific details disclosed herein are not to be considered limiting, but merely as a basis for the claims and as a representative basis for teaching one skilled in the art to variously employ the invention in any appropriate way in practice, This includes taking various features disclosed herein and combining features that may not be expressly disclosed herein.

[0033] It should be noted that, herein, the directional representations used to explain the structures and actions of various parts of the disclosed embodiments, such as up, down, left, right, front, back, etc., are not absolute but relative of. These representations are appropriate when various parts of the disclosed embodiments are located in the locations shown in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com