An integrated water/oil/coke/coal slurry process burner with gas film protection

A process burner and gas film technology, applied in the petroleum industry, manufacturing combustible gas, granular/powdered fuel gasification, etc., can solve the problem of increasing the circumferential velocity of mixed media, prolonging the service life of burners, reducing direct contact friction, etc. problem, to achieve the effect of increasing heat transfer effect, prolonging service life and reducing direct contact friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention designs an integrated water / oil / coke slurry process burner with gas film protection. The integrated burner includes an ignition start-up burner and a process burner and integrates an electric spark ignition device. The ignition start-up burner and the process burner are integrated. The process burners are operated separately.

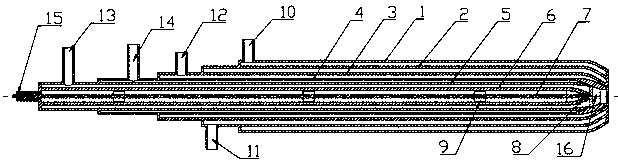

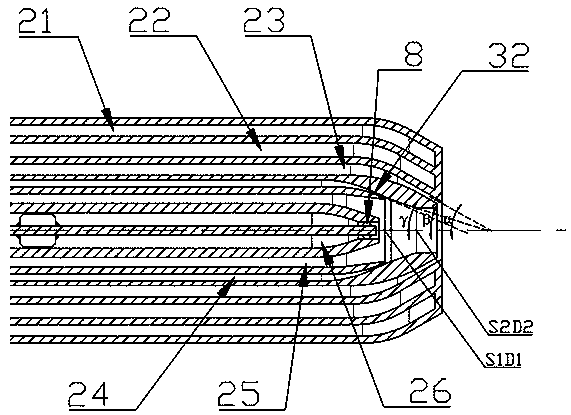

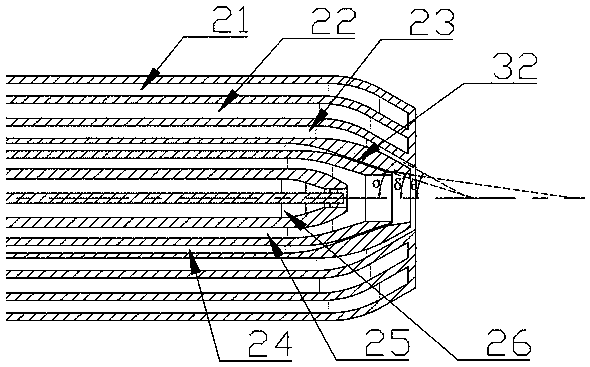

[0032] The main body of the process burner is a sleeve structure, such as figure 1 As shown in , including: burner cooling water outer pipe 1, burner cooling water inner pipe 2, outer epoxy pipe 3, gas film oxygen pipe 4, coal slurry pipe 5, central oxygen pipe 6, ignition rod 7, ignition rod Swirl support 8, ignition rod support 9, inner mixing chamber 16, burner cooling water inlet 10, burner cooling water outlet 11, outer epoxy inlet 12, coal slurry inlet 13, film oxygen inlet 14, central oxygen inlet 15 . Wherein, the central oxygen pipe 6 is also used as a fuel pipe.

[0033] The burner cooling water outer pipe 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com