Metal-carbon particle composite material and method for manufacturing same

A technology of composite materials and carbon particles, which is applied in the direction of metal layered products, chemical instruments and methods, cooling/ventilation/heating transformation, etc., can solve problems such as sintering of difficult composites, inconsistent joint interfaces, insufficient joints, etc., to achieve High cooling reliability, easy thickness, and high heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Next, some embodiments of the present invention will be described below with reference to the drawings.

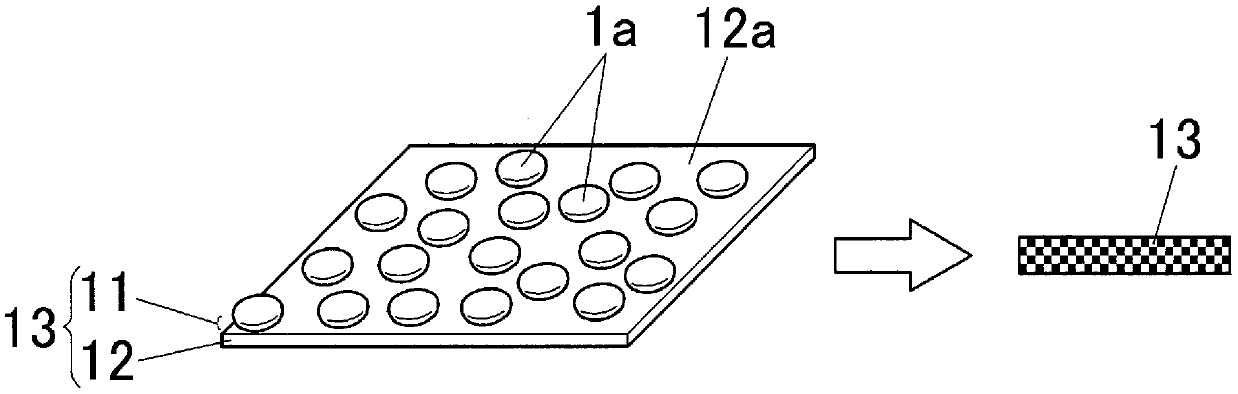

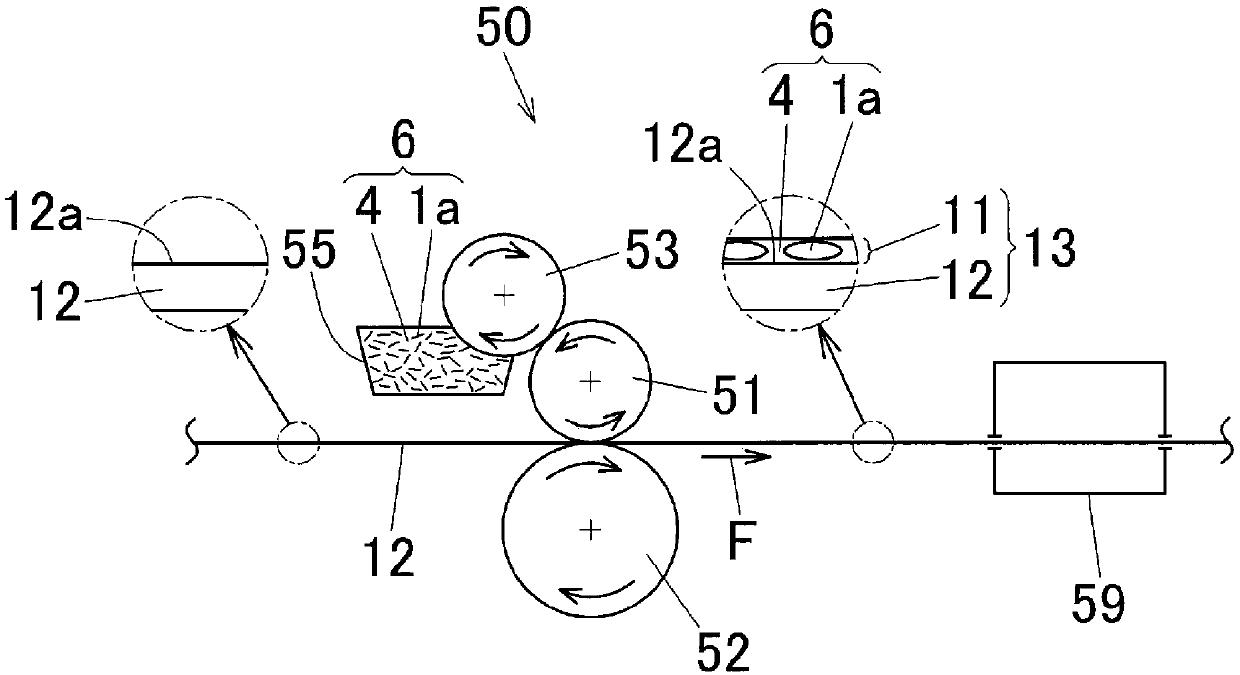

[0052] Figure 1~5 It is a figure for demonstrating the metal-carbon particle composite material and its manufacturing method of 1st Embodiment of this invention.

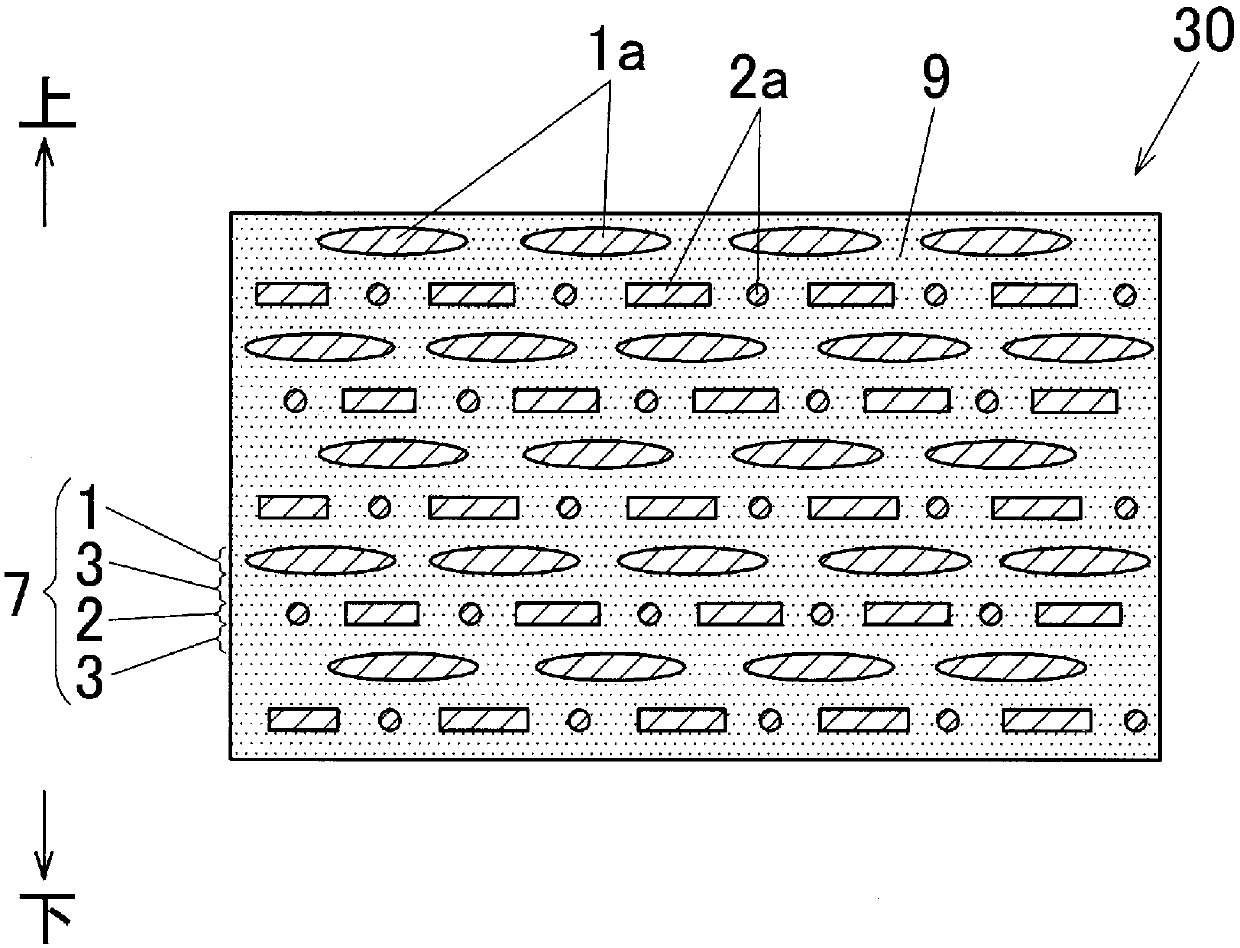

[0053] Such as figure 1 As shown, the metal-carbon particle composite material 30 of the first embodiment includes one or more scaly graphite particle dispersion layers 1, one or more carbon fiber dispersion layers 2, and one or more metal layers 3 in a laminated form. The graphite particle dispersion layer 1 is obtained by dispersing the scaly graphite particles 1a as carbon particles in a metal matrix (shown by hatching) 9, and the carbon fiber dispersion layer 2 is obtained by dispersing carbon fibers 2a as carbon particles in the metal matrix 9. Yes, the metal layer 3 is formed by the metal base 9.

[0054] In addition, one or more flaky graphite particle dispersion layers 1 , one or more carbon f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com