A self-powered inner-cooled permanent magnet motor with flipping magnetic pole speed regulation mechanism

A permanent magnet motor and speed regulation technology, which is applied in the field of permanent magnet motors and self-cooled permanent magnet motors, can solve the problems of limited operating performance of permanent magnet motors, high requirements for control systems, and complex operating systems of permanent magnet motors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

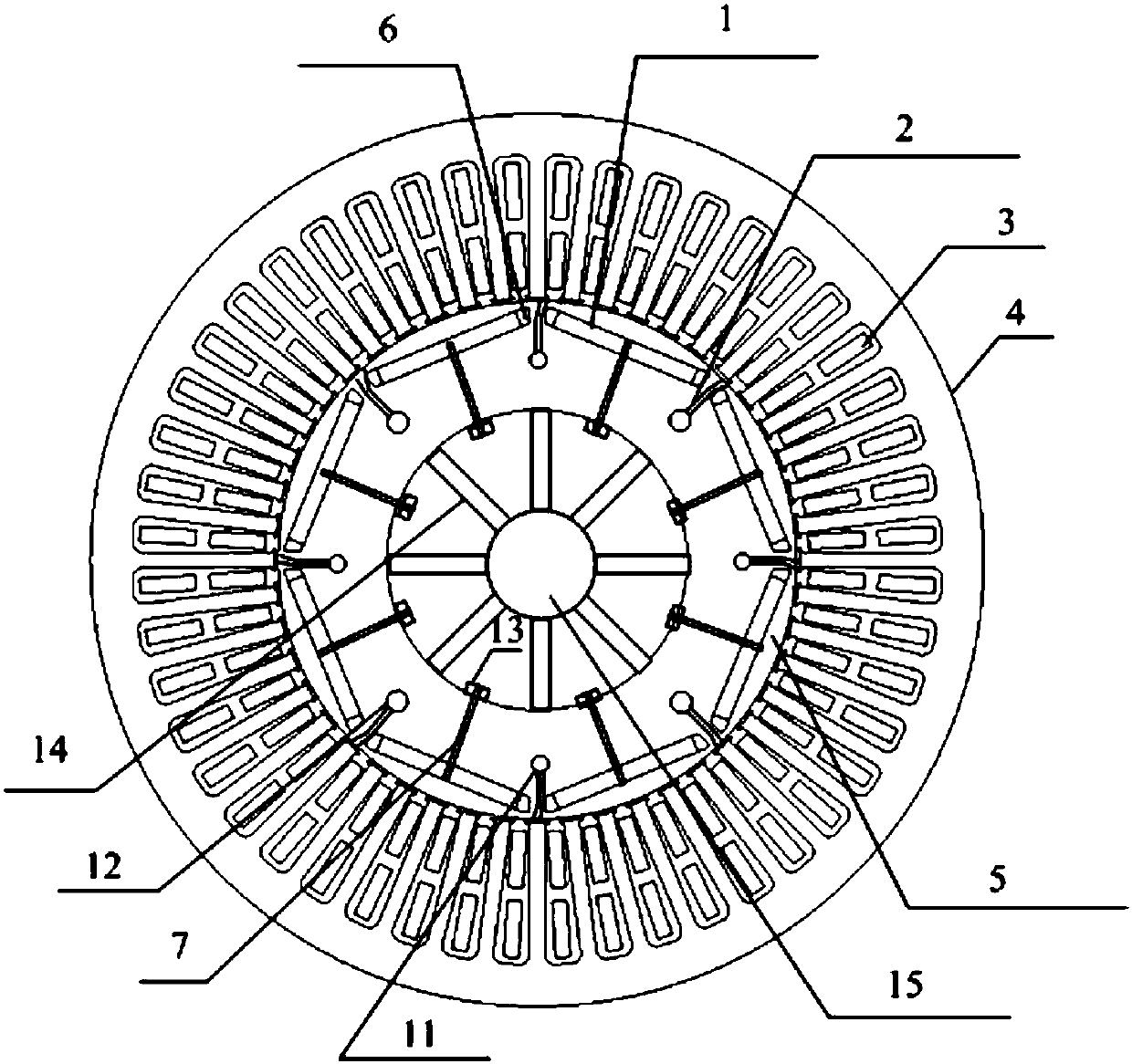

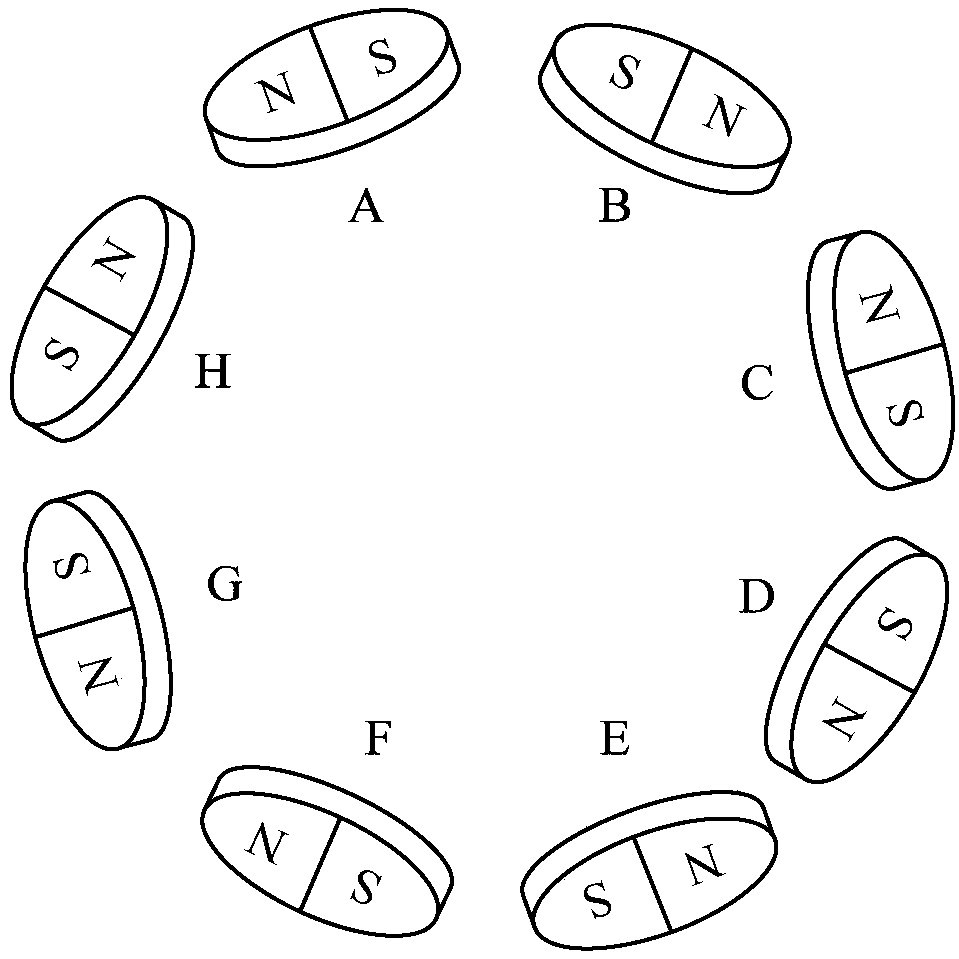

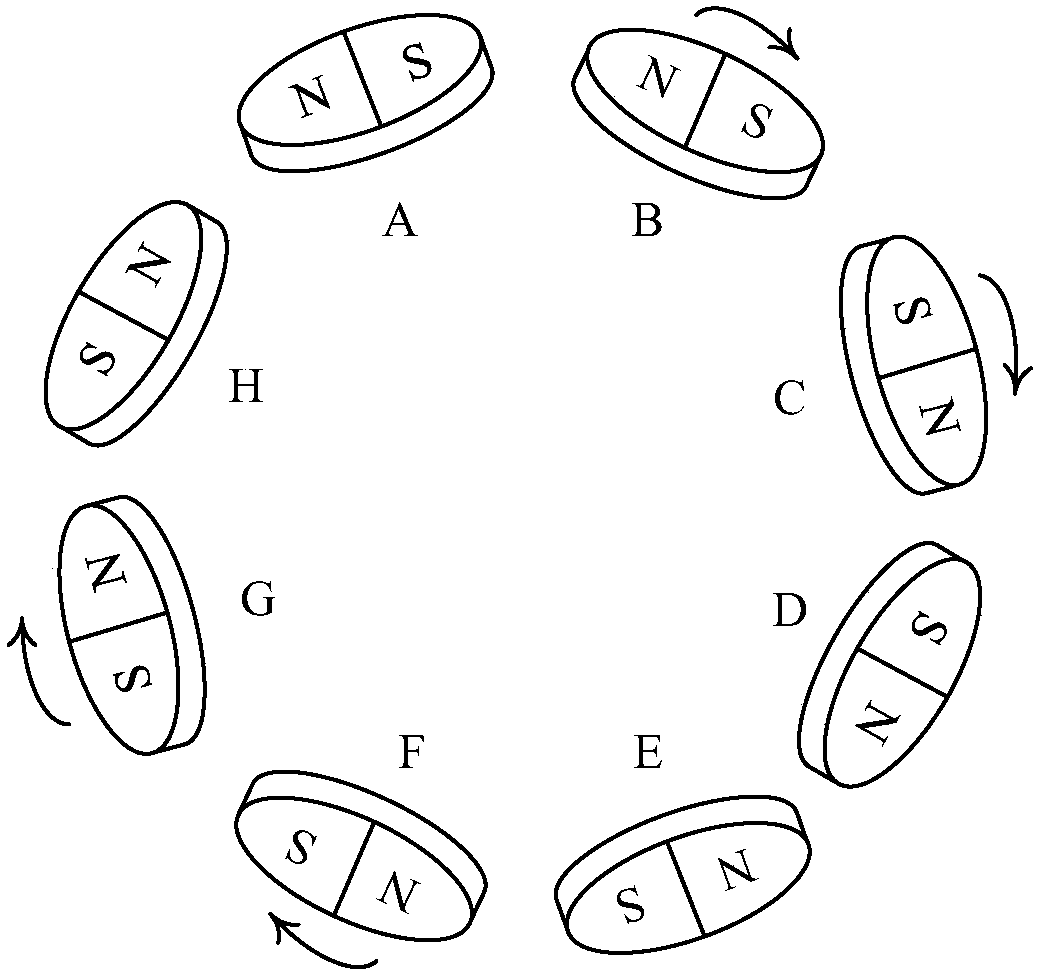

[0027] Example: see figure 1 , a self-operated internally cooled permanent magnet motor with a flipping magnetic pole speed regulation mechanism in this embodiment, including a permanent magnet 1, a stator winding 3, a stator core 4, a rotor core 5, a rotating rod 7, a rotating screw handle 13, and a rotor bracket 14 and rotating shaft 15; a plurality of permanent magnets 1 are cake-shaped structures, each permanent magnet 1 is connected with a rotating rod 7, and is tightened inside the rotor core 5 by rotating the screw handle 13; the stator winding 3 is embedded in the stator core 4 slots; the rotor core 5 has a plurality of circumferentially evenly distributed rotor internal cooling ventilation slots 2, the number of permanent magnets 1 and rotor internal cooling ventilation slots 2 is the same, and the permanent magnets 1 and rotor internal cooling ventilation slots 2 are arranged alternately ; The magnetic potential direction of each independent permanent magnet 1 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com