Extrusion cooler for powder coating

A powder coating and cooling machine technology, applied in the field of powder coating processing, can solve problems such as low cooling efficiency, reduced product processing reliability, uneven extrusion, etc., and achieve the effects of convenient processing, improved cooling reliability, and improved uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

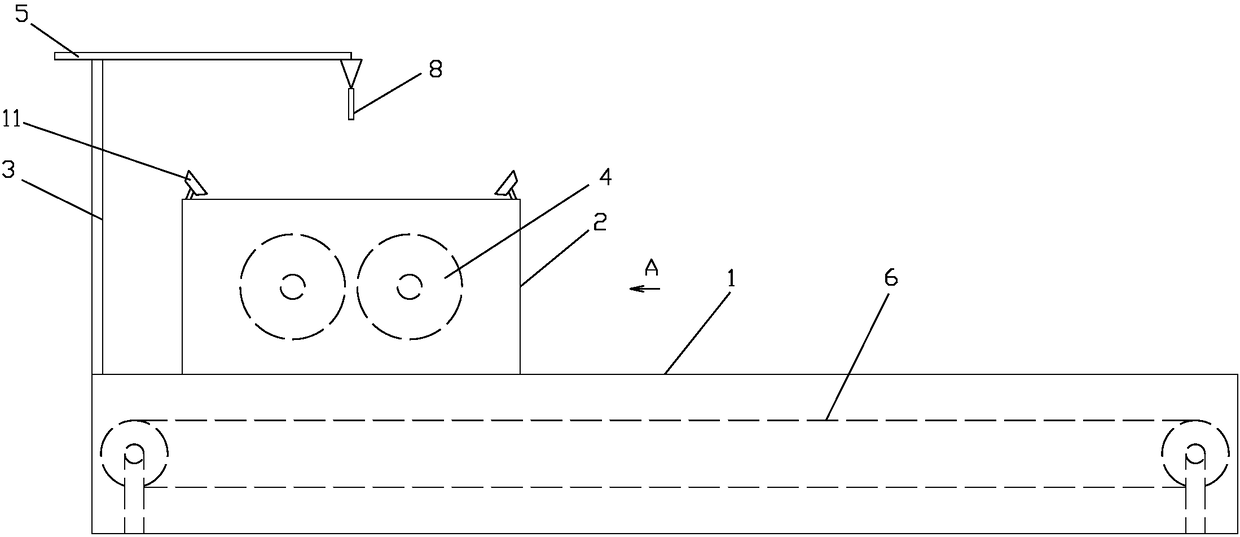

[0019] The present invention as Figure 1-4 Shown, comprise frame 1, described frame 1 is provided with a pair of vertical plate 2 and a strut 3, is provided with a pair of extruding roller 4 between a pair of vertical plate, and described strut connects guide groove 5, described The outlet of the guide groove 5 is located above the middle of a pair of squeeze rollers 4, and the frame 1 is provided with a conveyor belt 6;

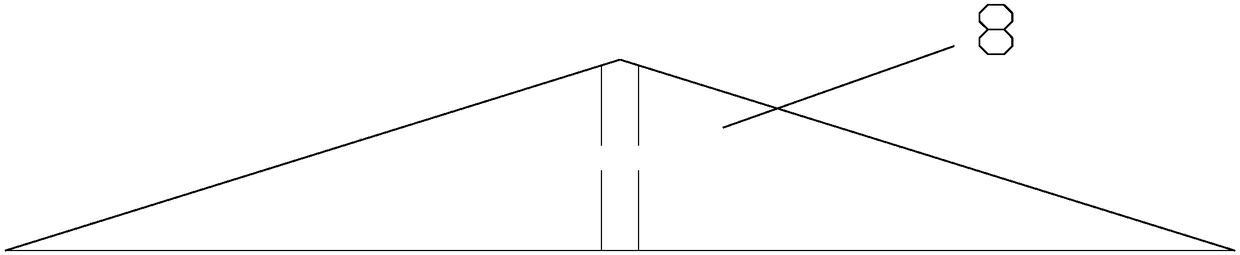

[0020] The outlet of the guide trough is provided with a guide plate 8, the guide plate is triangular, and the top angle end of the guide plate 8 is connected to the outlet of the feed groove, and the both sides of the top angle end of the guide plate are respectively provided with a guide groove 9;

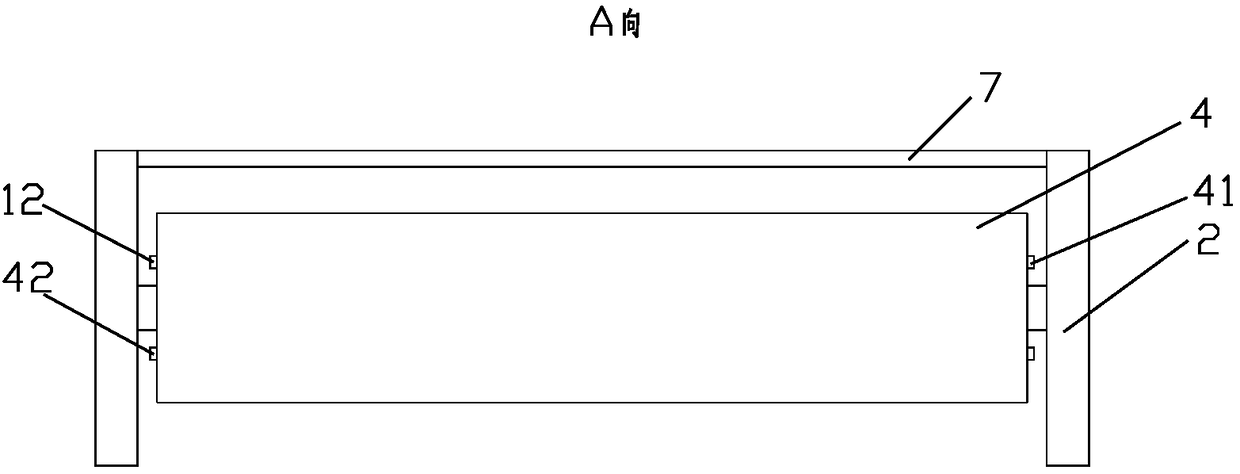

[0021] A pair of crossbars 7 arranged in parallel are arranged between a pair of vertical plates, and a pair of crossbars are respectively located on both sides of the guide plate, and a pair of crossbars are provided with blowers 11 arranged oppositely.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com