Hot metal ladle slagging-off control system, slagging-off machine and hot metal ladle automatic slagging-off control method

A control system and control method technology, applied in the field of iron and steel metallurgy industry, can solve problems such as insufficient reliability and low efficiency of slag removal, and achieve the effects of improving the removal rate, reducing the time of slag removal, and reducing the sulfur content rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

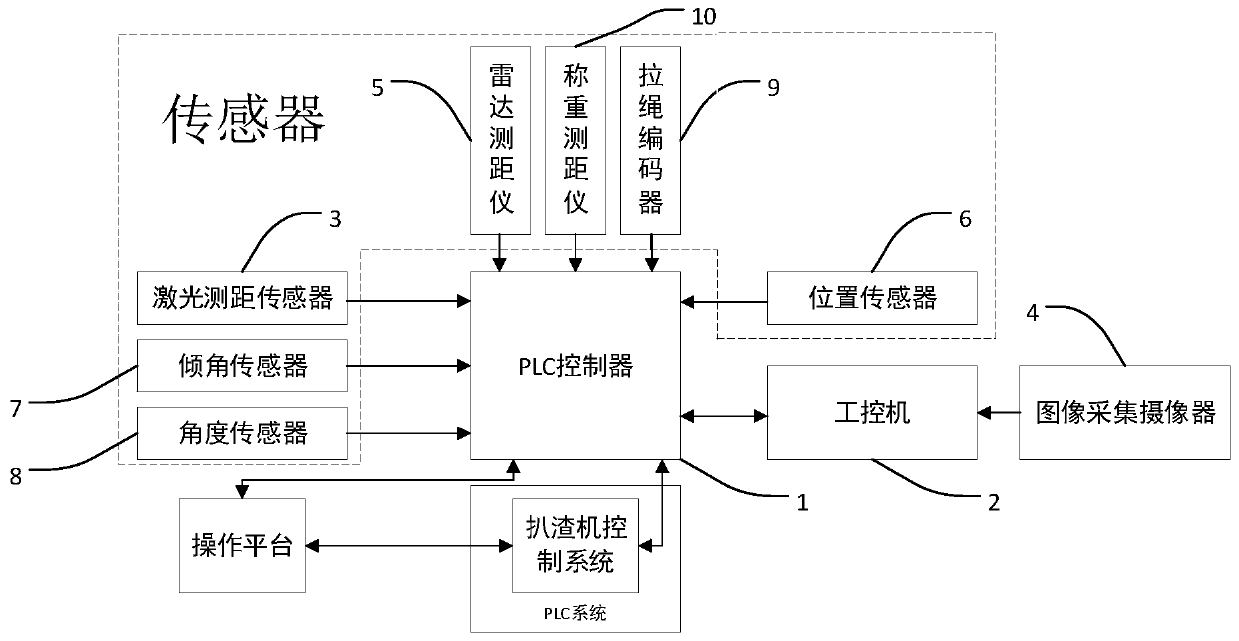

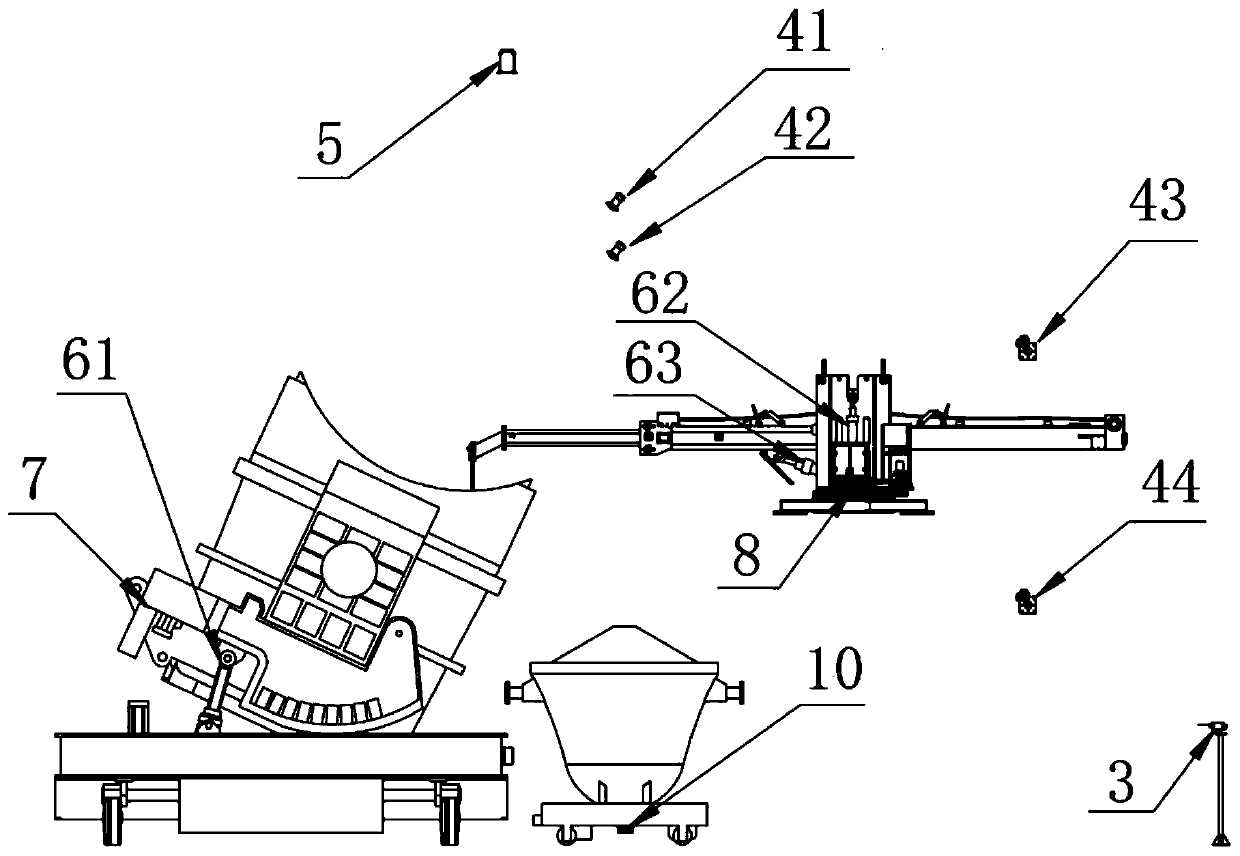

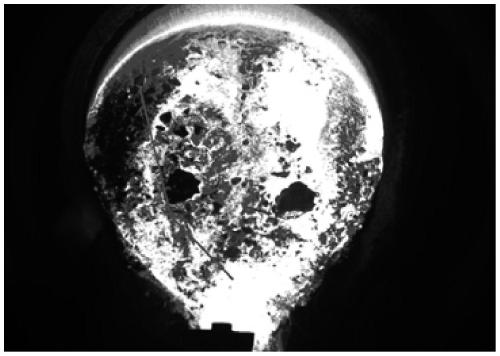

[0030] The molten iron tank slag removal control system of the present invention is constructed based on the comprehensive use of technologies such as image recognition, laser ranging, radar ranging, PLC control, position and angle detection, and path planning models. The slag removal system controls each part to perform corresponding actions, and cooperates with each other to realize the automatic slag removal function. The reduction of manpower, the reduction of molten iron loss and the improvement of slag removal efficiency in the process of steelmaking are realized.

[0031] A control system for removing slag from molten iron tanks provided by the present invention, see figure 1 and figure 2, including image acquisition camera 4, laser ranging sensor 3, radar rangefinder 5, position sensor 6, inclination sensor 7, rope encoder 9, load cell 10, PLC controller 1 and industrial computer 2:

[0032] The working steps of the molten iron tank slag removal control system are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com