Tundish control

a technology of tundish and control, applied in the direction of reradiation, manufacturing tools, instruments, etc., can solve the problem of danger of the vortex, achieve the effect of improving yield and quality in steel strand casting and facilitating low-level tundish operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

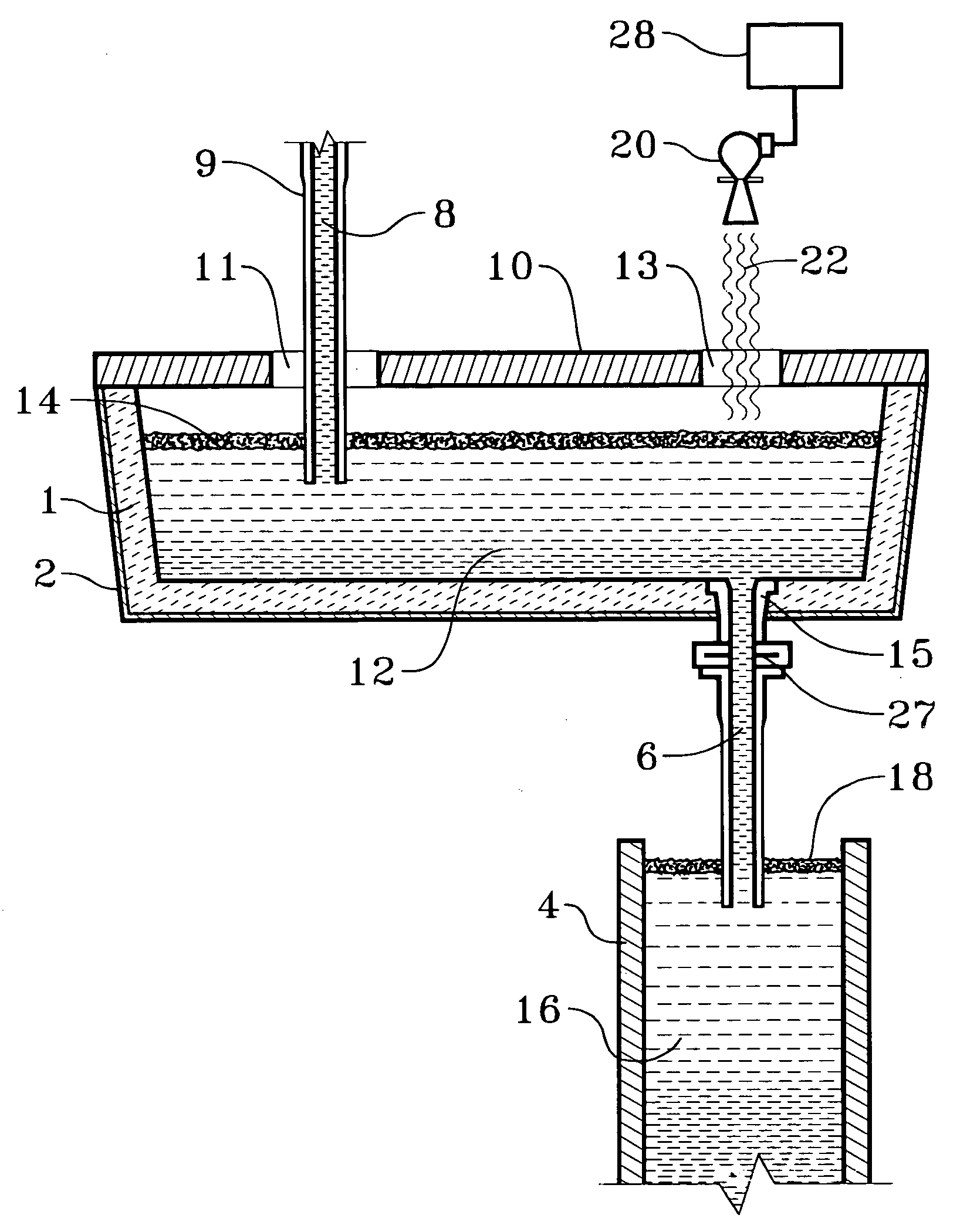

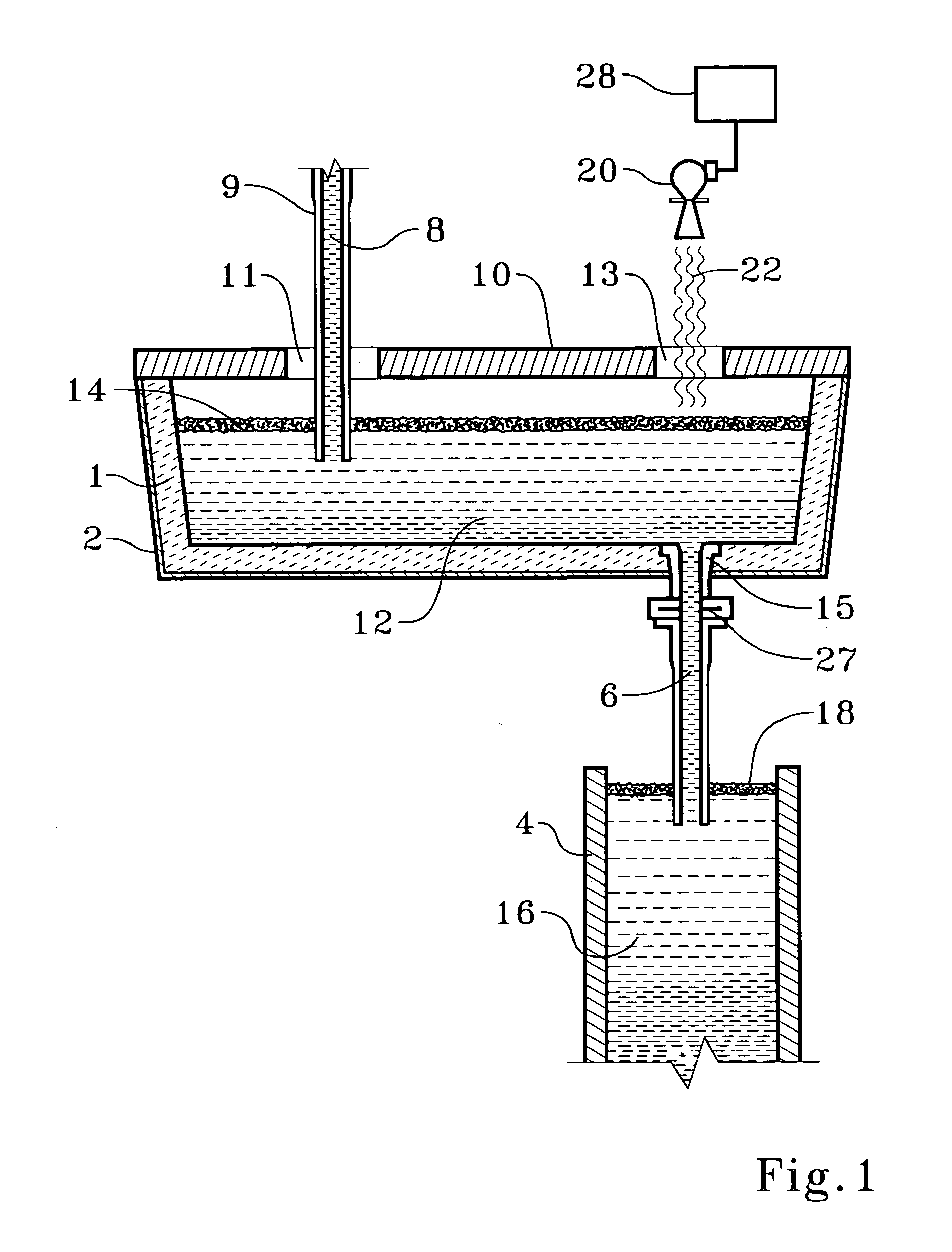

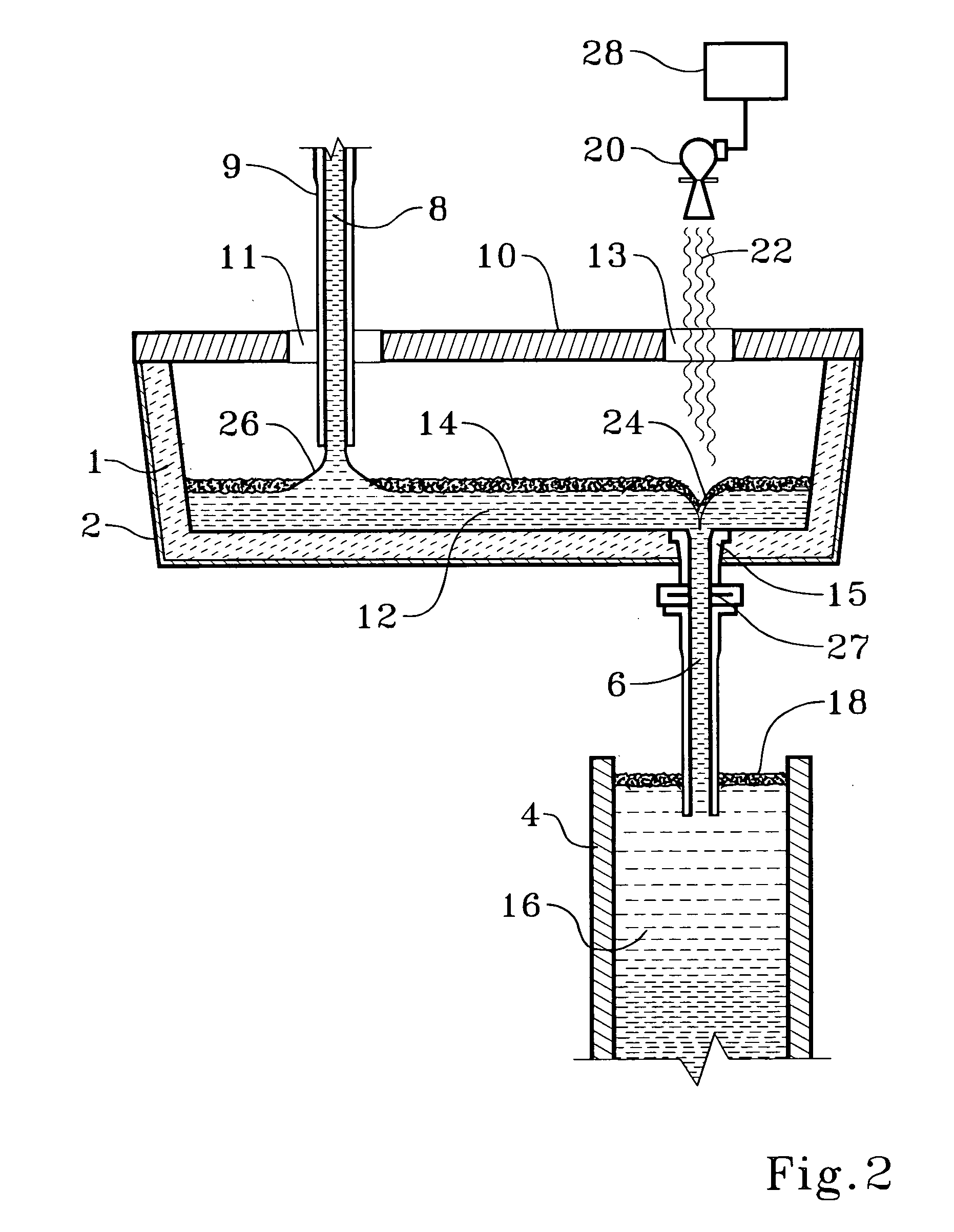

[0032] Referring first to FIG. 1, the tundish 2 has a refractory lining 1. It contains molten steel 12 on which floats a layer of slag 14. Molten steel 8 in refractory-lined shroud 98 is more or less continuously provided from a ladle not shown. Shroud 9 penetrates through the slag 14 to minimize the turbulence and exposure of steel to the air. Tundish 2 has a cover 10 having an aperture 11 for shroud 9. Another aperture 13 in cover 10 permits microwaves 22 to be transmitted into the tundish and strike the surface of slag 14. Microwaves 22 emanate from transmitter 20 placed preferably directly above aperture 13. Microwave transmitter 20 and aperture 13 are both directly over well 15 in the bottom of tundish 2. Well 15 is fitted with a sliding gate 27 which may be controlled to be closed or in various open positions. When sliding gate 27 is open, molten steel 12 drains through well 15 and conduit 6, through flux layer 18 and into mold 4, which forms the head 16 of a continuously movi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microwave analysis | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com