Aluminum liquid submerged slag conveyor and slag conveying method

A technology of slag removal machine and aluminum liquid, which is applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve the problems of difficulty in realizing large aluminum ingots, polluting the environment, and high labor intensity, and achieves the goal of realizing mechanical automation and reducing the environment Pollution, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further illustrated through the description of specific embodiments below, but the protection scope of the present invention is not limited by the examples. Those skilled in the art can make various modifications or improvements according to the basic idea of the present invention, but as long as they do not deviate from the basic idea of the present invention, they all fall within the scope of the present invention.

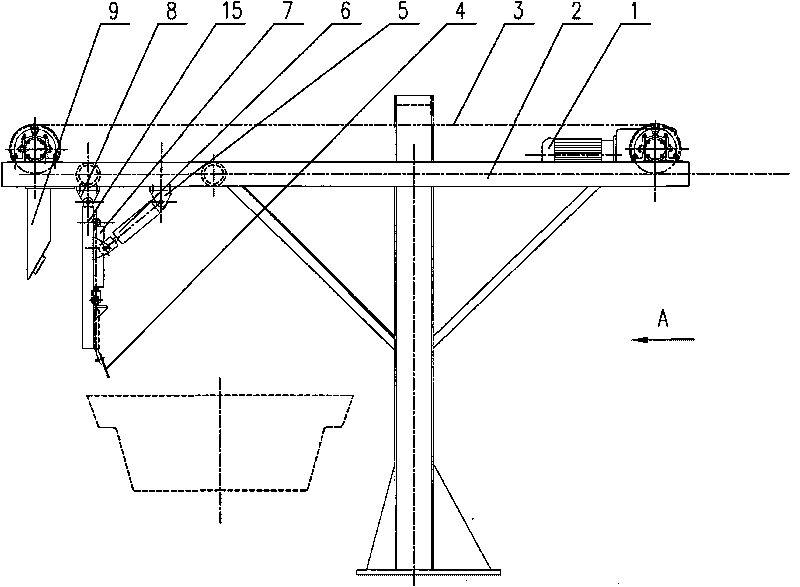

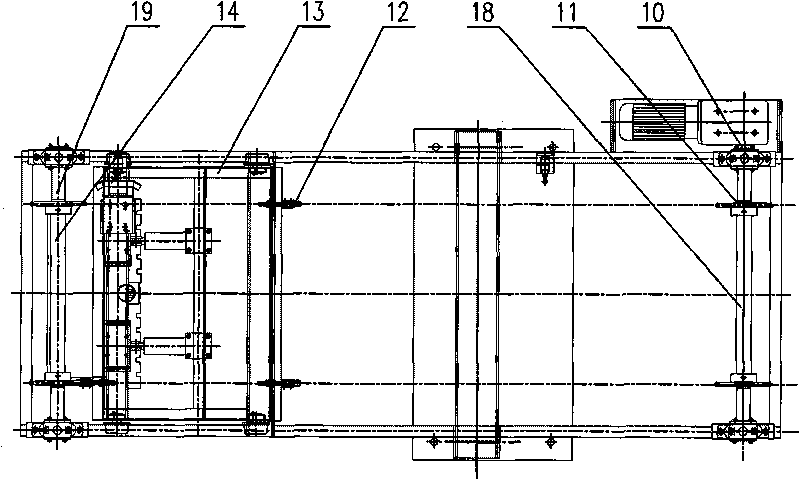

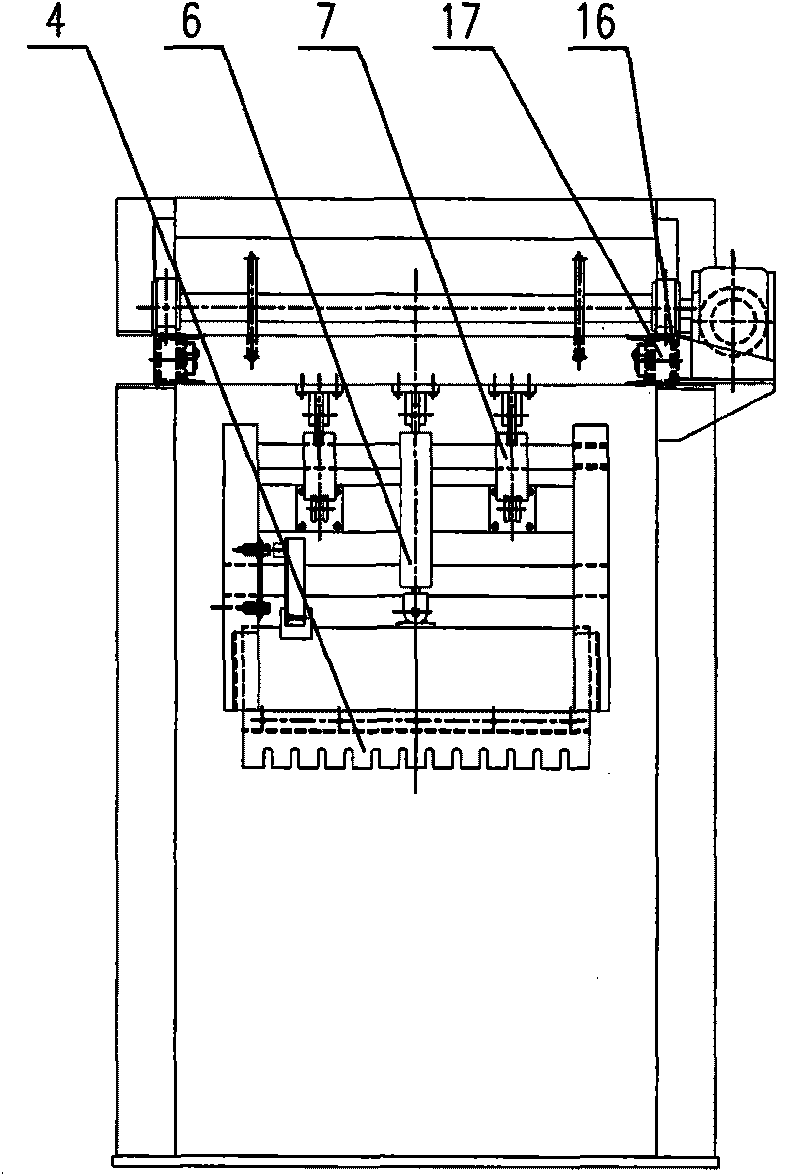

[0026] Such as Figure 1-3 As shown, a liquid aluminum slag removal machine of the present invention is composed of the following structure: a frame 2, a transmission device is arranged on the frame 2, a track 16 is arranged on the frame 2, a roller 17 is arranged in the track 16, and a 16 is two, and every track 16 is provided with 2-5 rollers 17, and roller 17 is located on mobile car 13, and transmission device is fixed with mobile car 13, and mobile car 13 is connected with mobile frame 15, and mobile frame 15 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com