Blowing slag-removing equipment for molten iron pretreatment

A technology of molten iron pretreatment and equipment, applied in casting equipment, metal processing equipment, mechanical cleaning, etc., can solve the problems of iron leakage accident maintenance and replacement, inconvenience, serious environmental heat radiation, etc., to reduce iron loss, good economic benefits, The effect of shortening the slag removal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

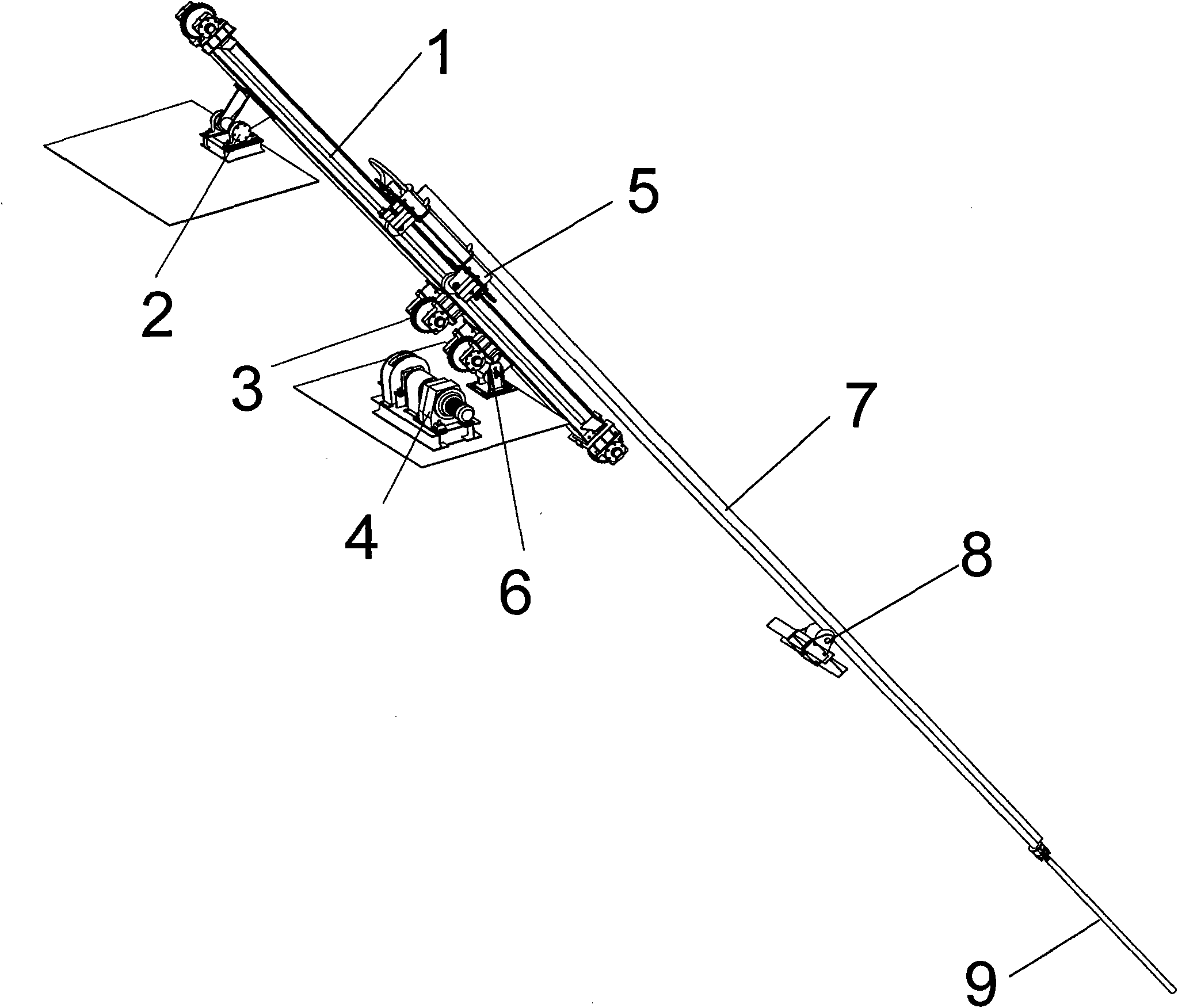

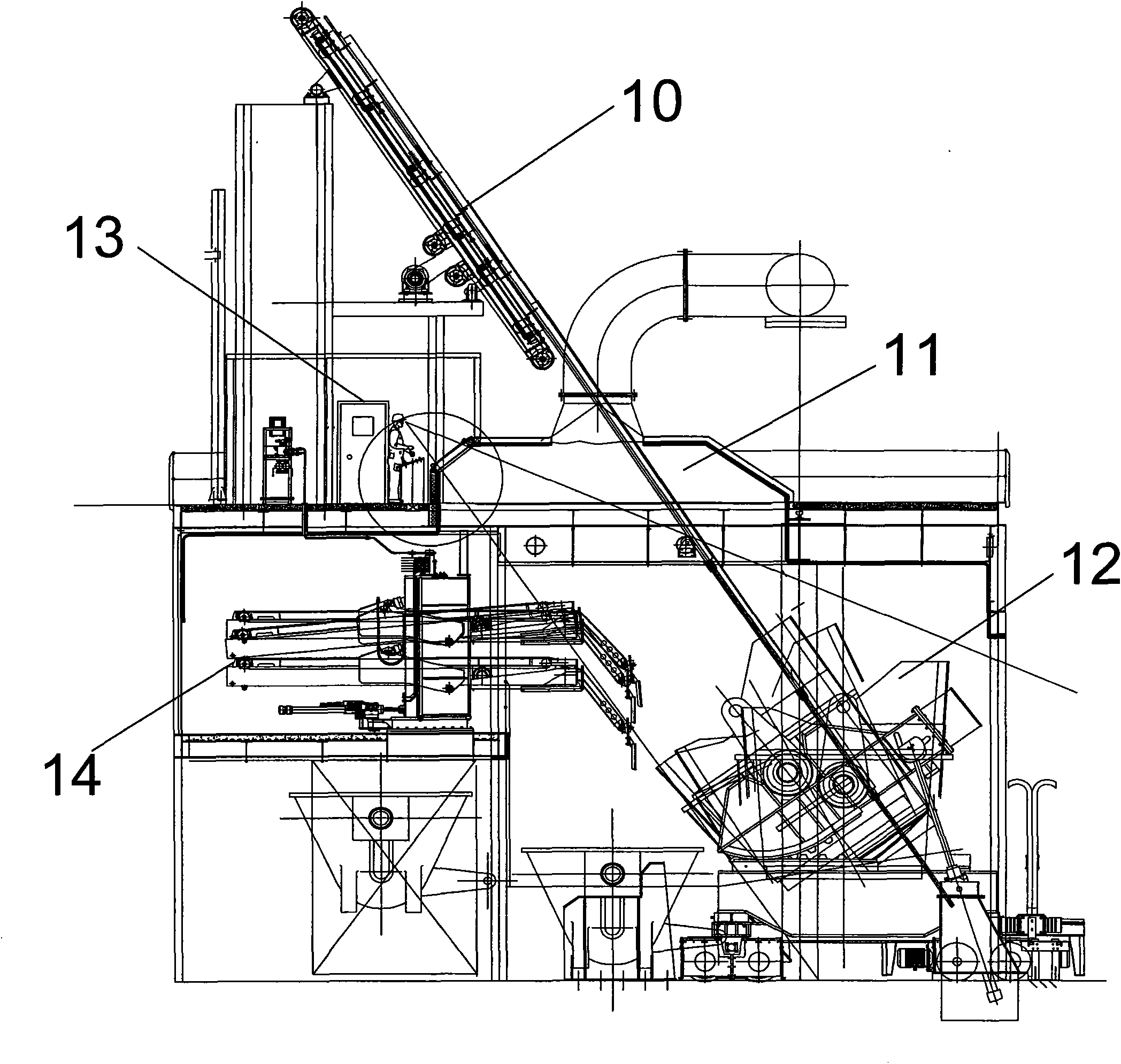

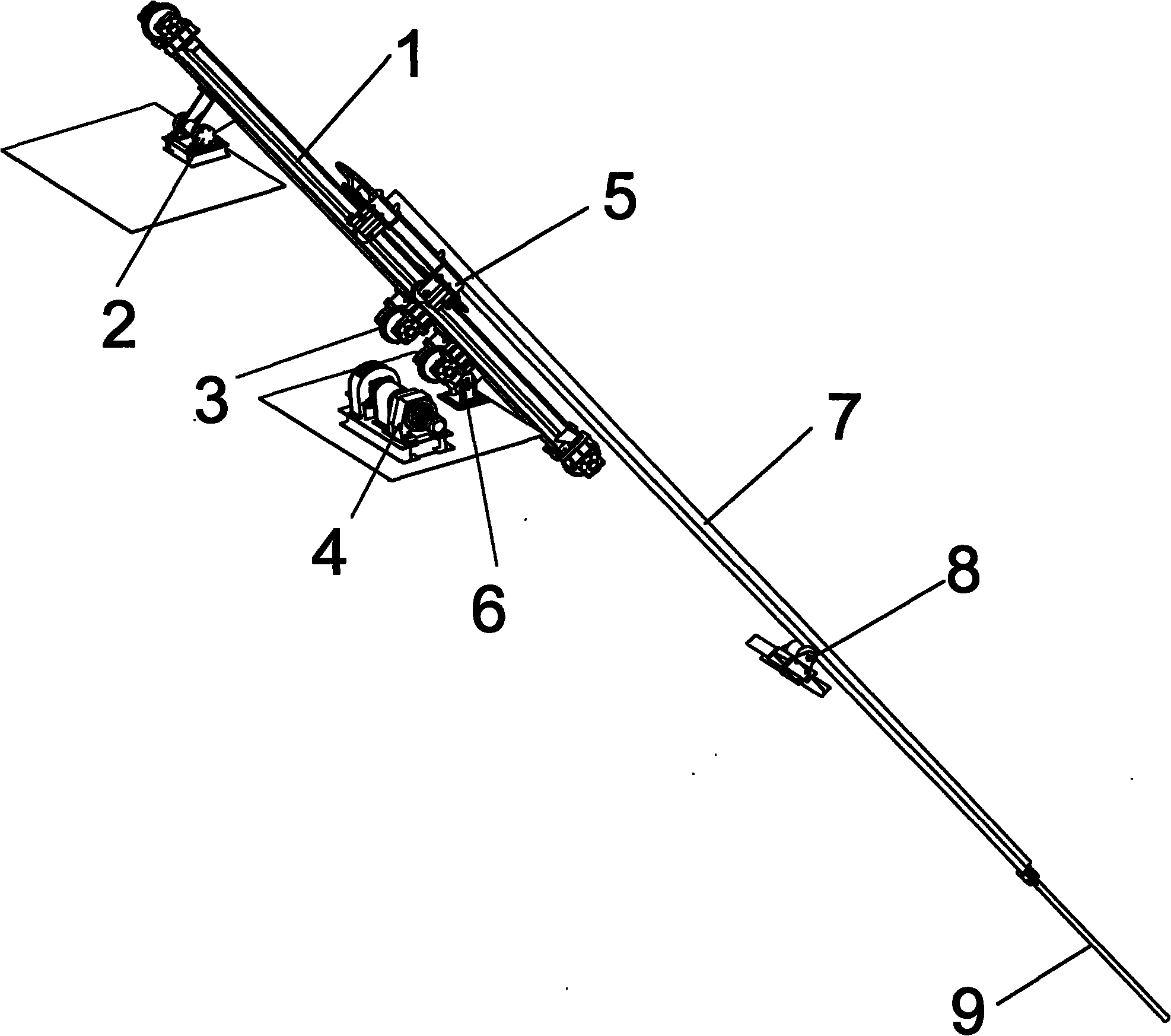

[0024] see figure 1 with figure 2 , the present invention provides a kind of hot metal pretreatment air blowing slag removal equipment, which is set on the molten iron tank slag removal machine 14 platform, mainly composed of guide rail 1, slewing support 2, guide sprocket 3, lifting drive device 4, lifting trolley 5. It is composed of adjustable support 6, air blowing rod 7, guide roller 8, refractory section 9 and air blowing slag removal device 10.

[0025] The guide rail 1 is obliquely arranged on the top of the molten iron tank 12, the lifting trolley 5 is arranged on the guide rail 1, and the lifting drive device 4 drives the lifting trolley 5 to move up and down along the guide rail 1 through the guide sprocket 3. The blowing rod 7 is arranged on the lifting trolley 5, and the refractory section 9 is connected to the blowing rod 7 bottoms. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com