Method and device for cleaning surface of dual-roller thin-strip casting roll

A twin-roll thin strip continuous casting and cleaning device technology, which is applied in the direction of mechanical cleaning, casting equipment, manufacturing tools, etc., can solve the problem that the relative distance between the brush roll surface and the casting roll surface is not easy to control, and the cleaning quality of the roll surface is not good. Uniformity, cast belt surface quality defects, etc., to improve the cleaning quality of the roll surface, improve the cleaning effect, and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

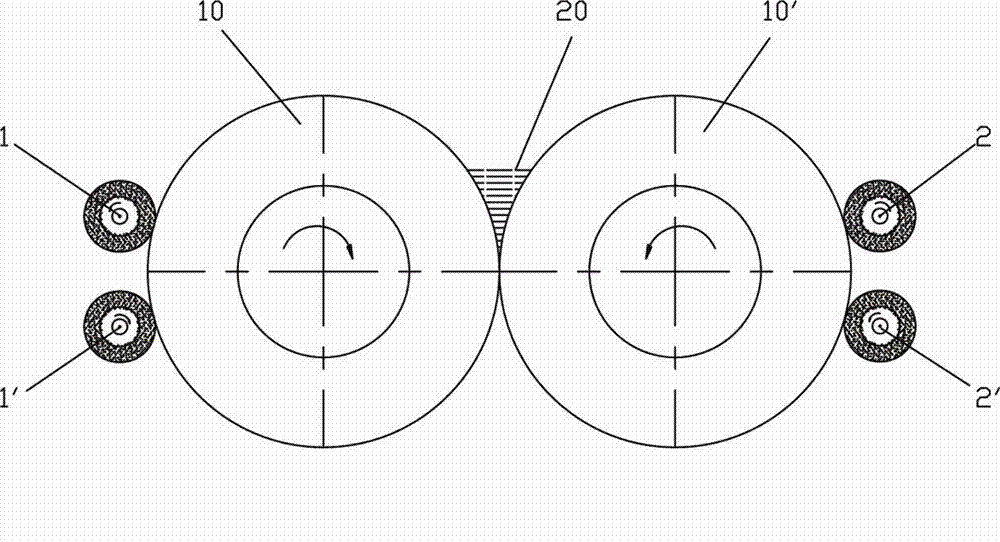

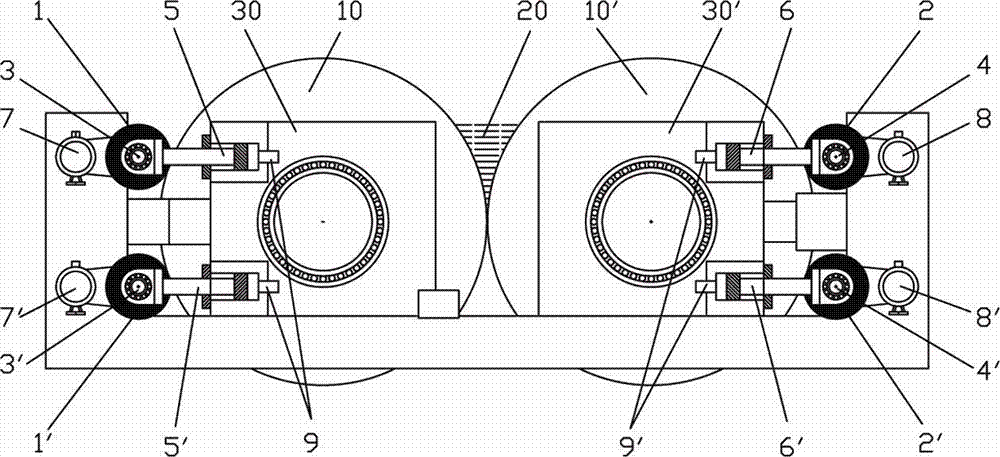

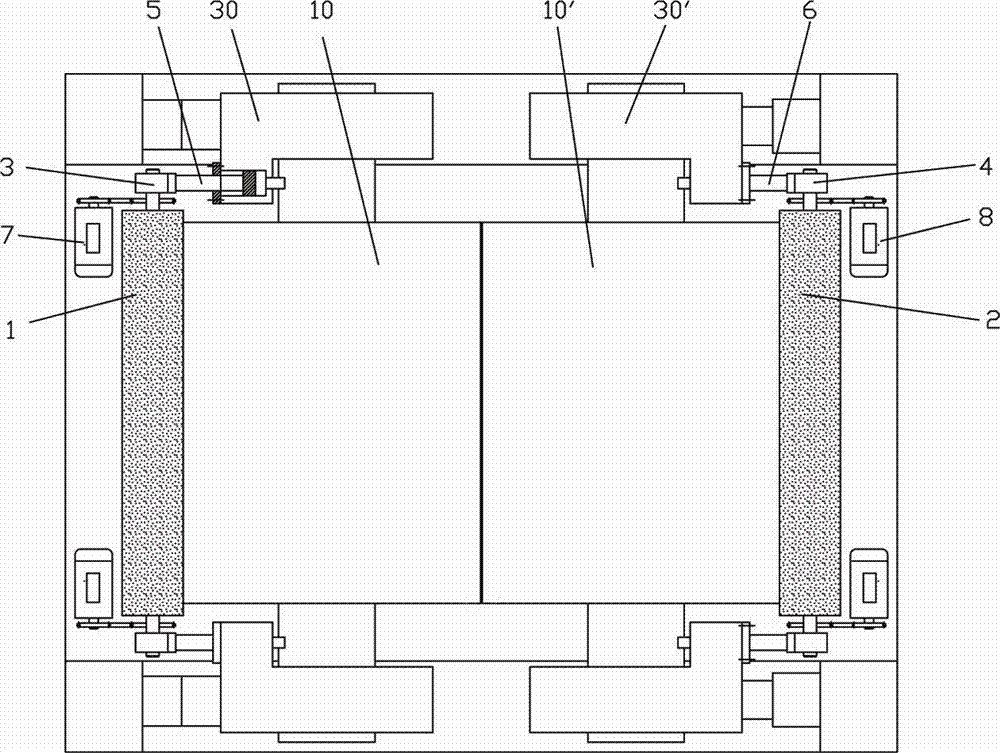

[0037] see Figure 1 ~ Figure 4 , the method for cleaning the surface of twin-roll strip continuous casting rolls of the present invention, each casting roll 10, 10' of the twin-roll thin strip continuous casting machine adopts two brush rolls 1, 1 arranged up and down and opposite to the direction of rotation of the casting rolls ', 2, 2' to clean the surface, the linear speed of the casting roll is constant and greater than the speed of the casting roll, the roll surface cleaning device controls the distance and pressure between the brush roll and the casting roll through the hydraulic cylinder fixed on the casting roll bearing seat .

[0038] At the beginning of casting, the brush roll is close to the surface of the casting roll and starts to clean. As the casting progresses, the roll surface cleaning device makes corresponding displacement adjustments according to the expansion of the casting roll to maintain a constant pressure between the brush roll and the casting roll ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com