Automatic slag removal machine for ingot casting

A slag cleaning machine and automatic technology, applied in ingot workshops, mechanical cleaning, casting workshops, etc., can solve the problems of high-temperature molten aluminum splashing damage to operators, limited slag cleaning speed, high operating environment temperature, etc., to achieve simple structure, The effect of low cost and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below by way of embodiments and in conjunction with the accompanying drawings.

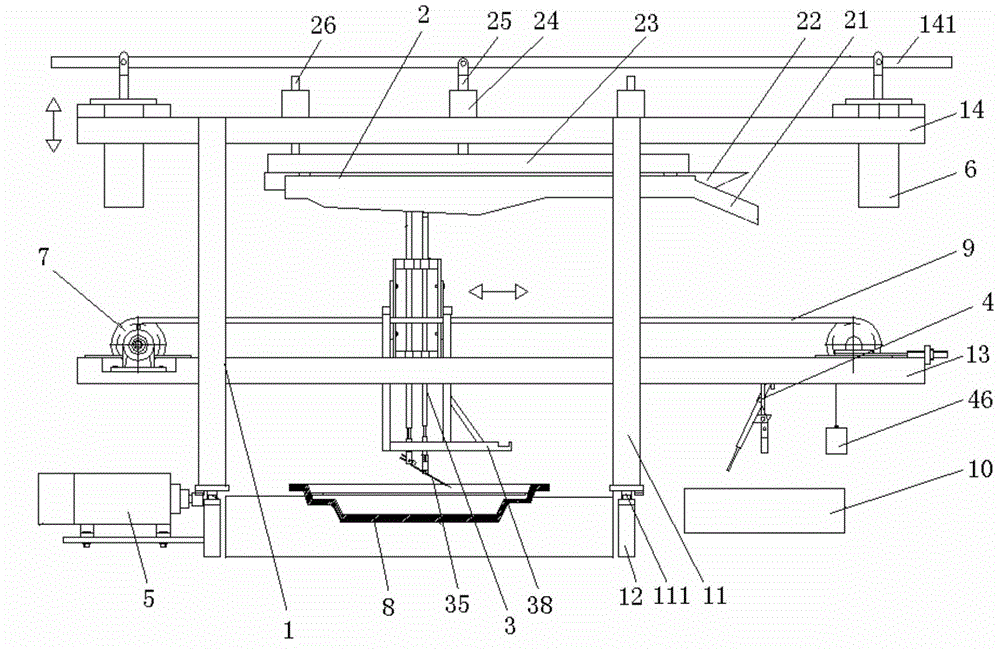

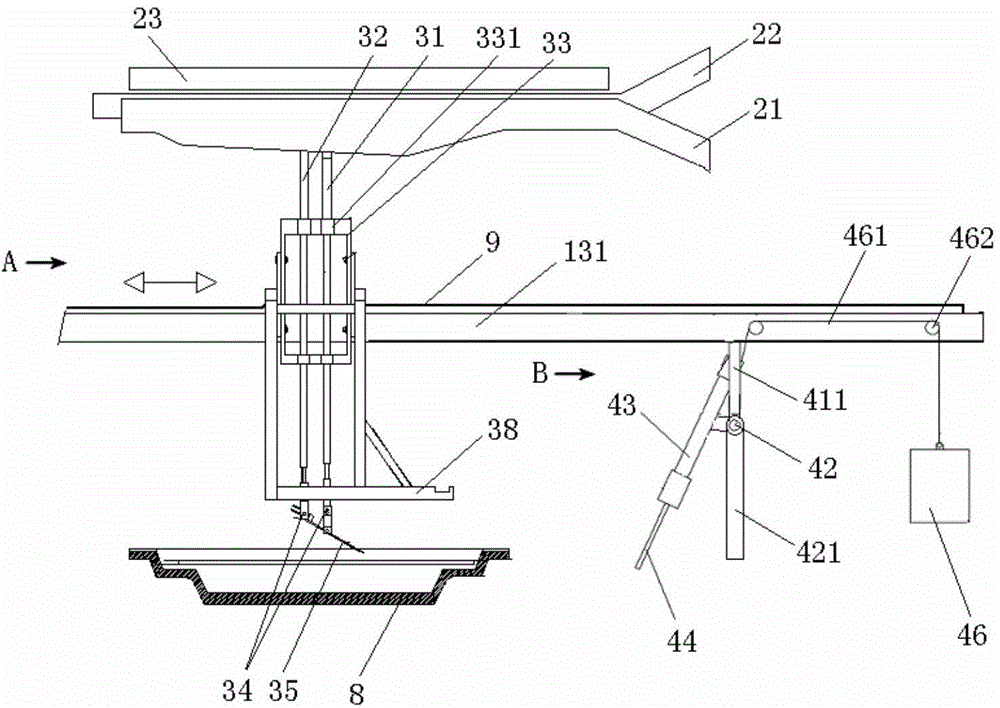

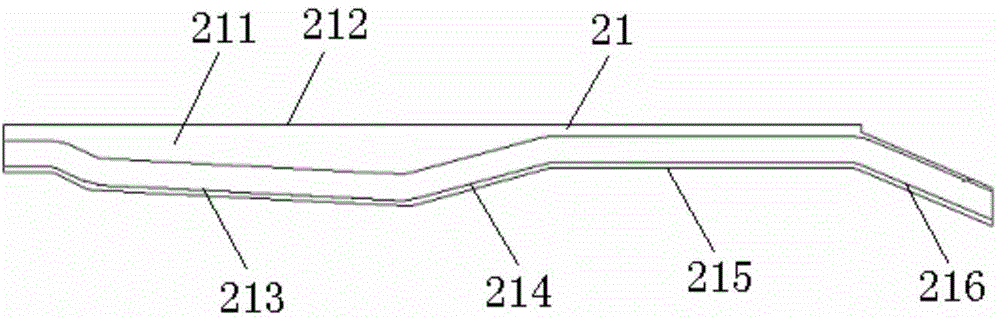

[0029] Such as Figure 1 to Figure 6 , the automatic slag removal machine for casting ingots provided by the present invention includes: a cart mechanism 1 that moves longitudinally synchronously with the continuous casting machine, a lifting guide rail 2 arranged on the upper part of the cart mechanism 1, and a slag removal mechanism 3 arranged at the lower part of the cart mechanism 1 , the upper end of the slag removal mechanism 3 is placed on the lifting guide rail 2, and moves back and forth laterally along the lifting guide rail 2 while rising or falling together with the lifting guide rail 2;

[0030]The cart mechanism 1 includes uprights 11 arranged on both sides of the continuous casting machine. The uprights 11 on the left and right sides are respectively provided with two according to the front and rear positions, and there are four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com