A smelting process of 25cr2ni4mov rotor steel

A rotor steel and process technology, applied in the field of 25Cr2Ni4MoV rotor steel smelting process, can solve the problems of rotor heat treatment grain coarseness, rotor cracking, product performance is difficult to guarantee, etc., to reduce non-metallic inclusions and gas content, prevent phosphorus return, The effect of improving the purity of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

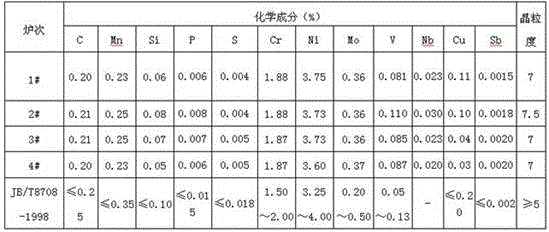

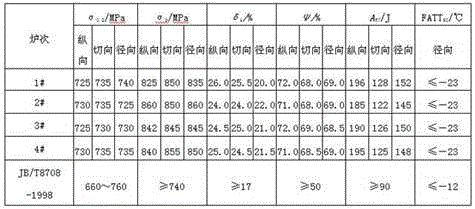

[0021] A 25Cr2Ni4MoV rotor steel smelting process, the weight percentage of each element content in the 25Cr2Ni4MoV rotor steel is: C content 0.20%-0.25%, Si content ≤ 0.10%, Mn content 0.20%-0.35%, P content ≤ 0.010%, S content ≤0.005%, Cr content 1.80%~2.00%, Ni content 3.55%~3.75%, Mo content 0.35%~0.45%, V content 0.05%~0.10%, Nb content 0.020%~0.030%, Cu content≤0.20%, Sb content ≤ 0.002%, Al content ≤ 0.010%, As content ≤ 0.015%, Sn content ≤ 0.010%, the rest is Fe; the smelting process of 25Cr2Ni4MoV rotor steel specifically includes the following steps:

[0022] (1) Select raw materials

[0023] Select high-quality scrap steel and scrap, and mix it into pig iron;

[0024] (2) Primary smelting in electric arc furnace

[0025] Put the raw materials into the electric arc furnace for smelting. After the molten pool is formed at the lower end of the electrode, oxygen blowing and fluxing are started to make foamy slag. When the temperature of molten steel is ≥1550℃, sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com