A kind of non-reactive mold flux for high aluminum steel

A non-reactive, mold slag technology, applied in the field of metallurgy, can solve problems such as uneven precipitation, easy to cause slag inclusions on the surface of the slab and subcutaneous slag, reduce the alkalinity of the mold slag, achieve stable composition and performance, and solve performance deterioration. The effect of high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The mold powder of this embodiment is composed of the following chemical components in weight percentage: CaO 30.4%, Al 2 o 3 21.3%, BaO26.2%, Li 2 O 4.1%, F - 7.1%, MgO 1.2%, C 7.0%, the rest are unavoidable impurities, and among the impurities (Na 2 O+K 2 O+SiO 2 )≤2%.

[0040] The mold flux in this example is prepared from commonly used industrial raw materials, and its preparation method is as follows:

[0041] 1) Detect the chemical composition of industrial raw materials limestone, fluorspar, bauxite, barium carbonate, magnesia, lithium carbonate and carbonaceous materials respectively, and select raw materials whose weight percentage meets the following requirements.

[0042] Limestone: CaO 53-55%, SiO 2 <4%, S<0.1%;

[0043] Fluorite: CaF 2 88-90%, SiO 2 <6.0%, S<0.05%;

[0044] Lithium carbonate: Li 2 CO 3 >98%;

[0045] Bauxite: Al 2 o 3 >75%, SiO 2 <4%;

[0046] Barium Carbonate: BaCO 3 >95%;

[0047] Magnesia: MgO>85%, SiO 2 2 o 3 <2%; ...

Embodiment 2~4

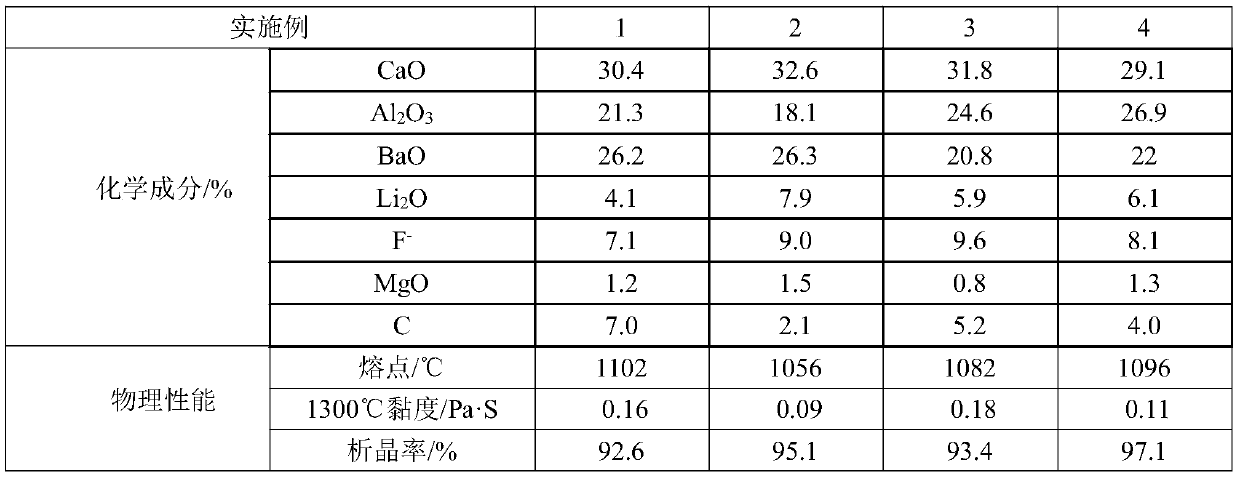

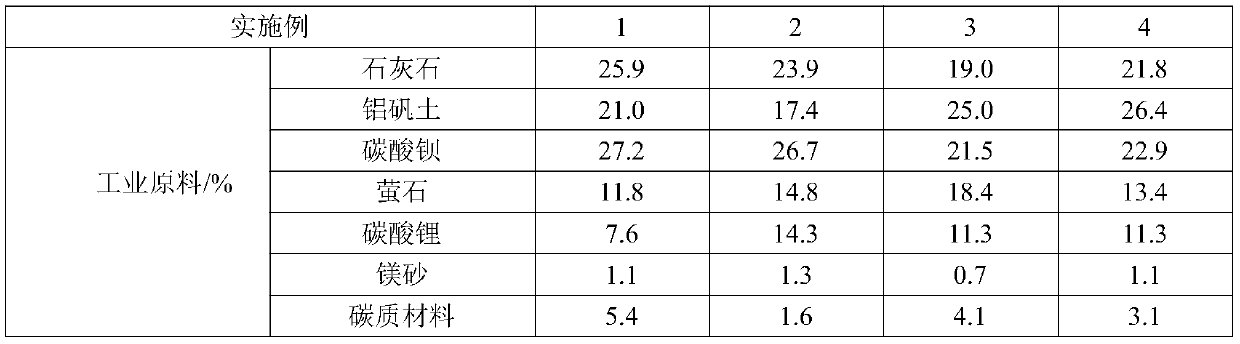

[0054] The components of mold flux in Examples 2 to 4 are shown in Table 1, the preparation method is the same as that of Example 1, and the weight percentage ratio of raw materials in each example is shown in Table 2.

[0055] Table 1 lists the weight percentages of the chemical components of mold flux in Examples 1-4 and the corresponding important physical properties.

[0056] Table 2 lists the ratio of the weight percentages of the raw materials for the mold flux in Examples 1-4.

[0057] Table 1 Chemical composition (wt%) and physical properties of mold flux in Examples 1-4

[0058]

[0059] Table 2 Ratio of each raw material for mold flux in Examples 1-4 (wt%)

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystallization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com