Stepless separation ring for wire horizontal continuous casting and its usage method

A technology of horizontal continuous casting and separation ring, applied in the field of continuous casting, can solve problems such as breakage and easy damage of separation ring steps, and achieve the effects of strong crack sensitivity, high efficiency open drawing success rate, and long normal wire drawing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

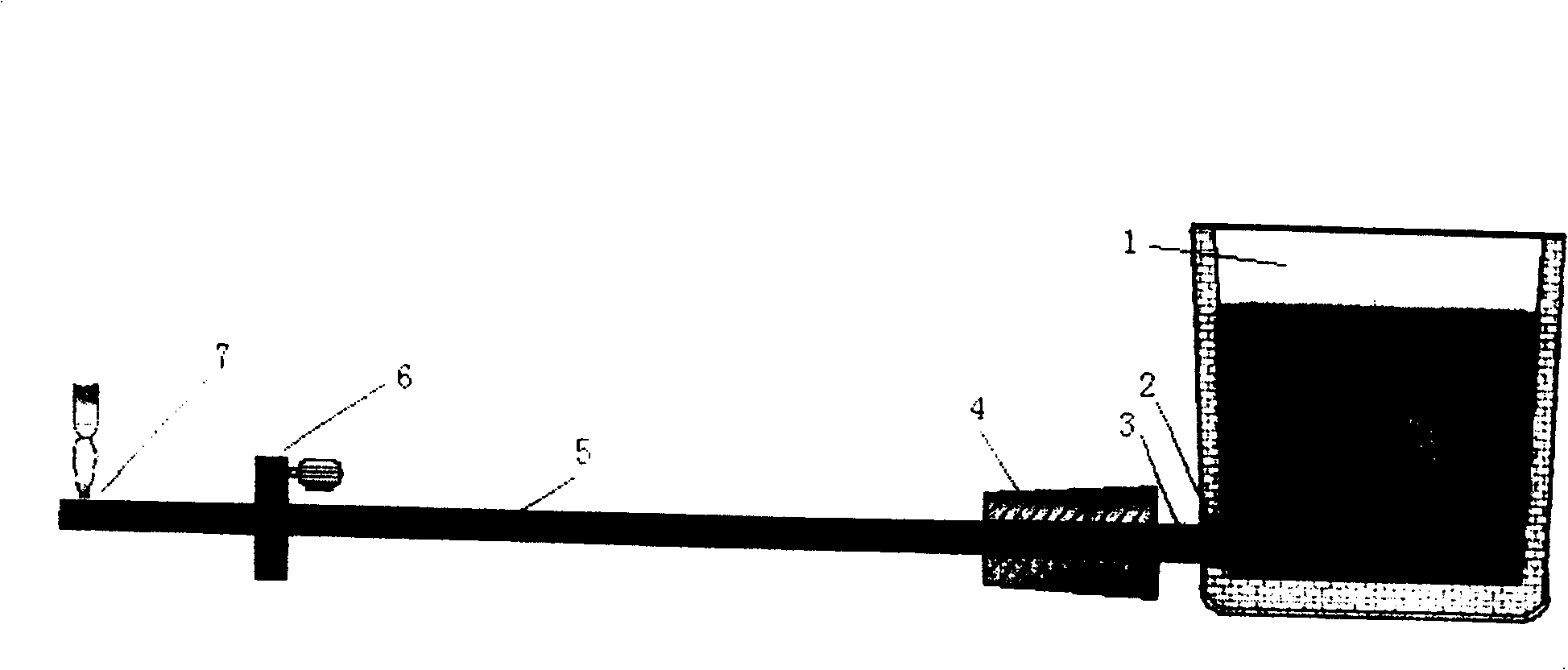

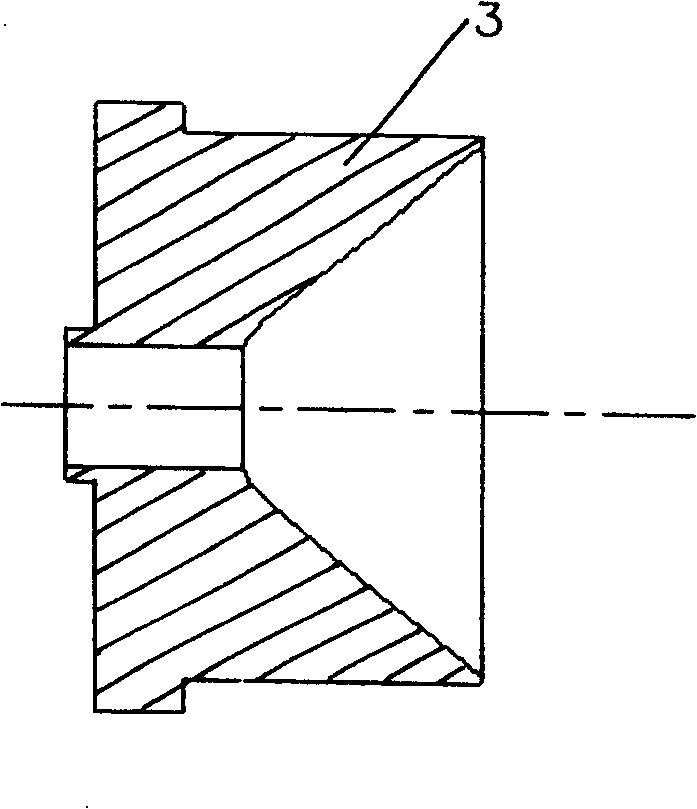

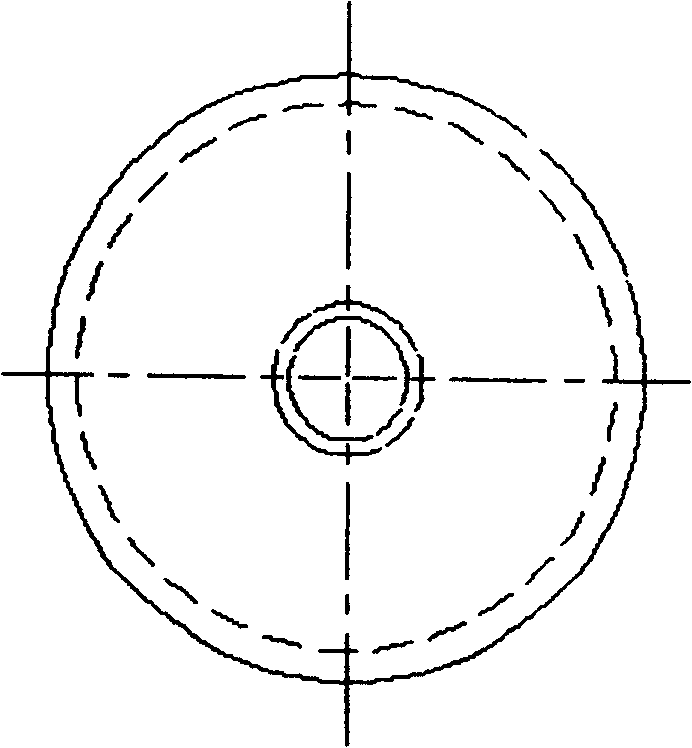

[0033]Wire rod horizontal continuous casting machine mainly includes melting furnace, tundish 1, nozzle 2, separation ring 3, crystallizer 4, billet (wire) 5, billet drawing machine 6, shearing mechanism 7, control system, hydraulic system, support and Secondary cooling device, etc., see figure 1 .

[0034] Among them, the separation ring is a key device connecting the tundish nozzle and the mold in the horizontal continuous casting process. It not only has to withstand the high temperature of the liquid steel for a long time, but also ensures that the molten steel flows from the tundish nozzle to the end of the mold. The continuous casting and solidification process goes smoothly; for horizontal continuous casting of wire rods, due to the small cross-section of the casting wire, the protruding outer edge (step) of the small hole at the center of the connection between the separation ring and the crystallizer is thinner and shorter; compared with conventional Compared with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com