Method for Improving the Surface Quality of High-Strength Weather-resistant H-beam Steel

A surface quality, H-shaped steel technology, applied in the field of metallurgical continuous casting, can solve the problems of easy cracks in the web, affect the surface quality, uneven cooling, etc., and achieve the effect of reducing the longitudinal cracking of the web of weathering steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be described in detail below with reference to exemplary implementations. Example embodiments may, however, be embodied in many forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the concept of example embodiments to those skilled in the art.

[0014] Continuous casting process of shaped billet: hot metal desulfurization by KR method → 90t top-bottom compound blowing converter → 100t LF refining furnace → ladle rotary table → tundish → crystallizer → sector section secondary cooling zone → drawing straightener → flame cutting → output roller table → Walking cooling bed → Slab sent to rolling steel heating furnace → Rolling mill → Straightening → Cooling.

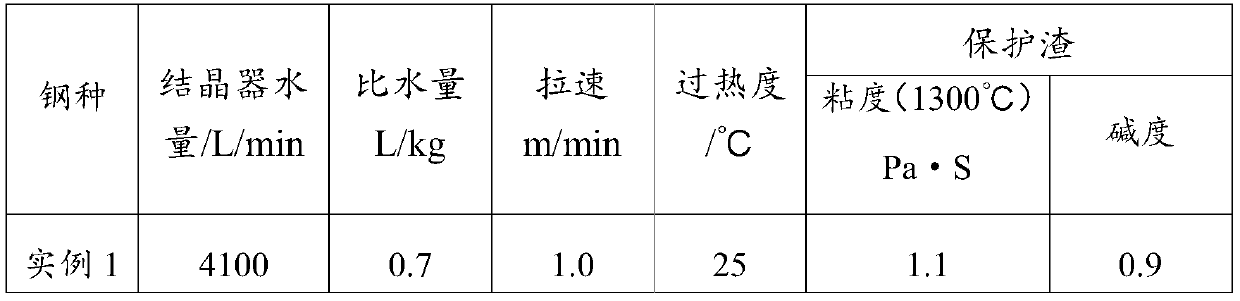

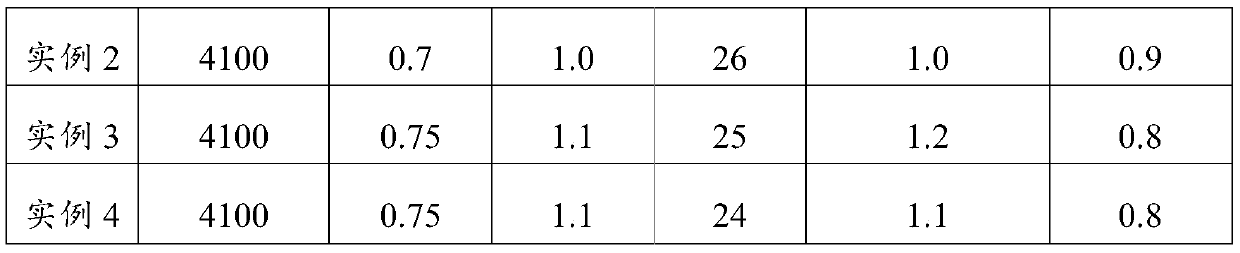

[0015] The invention adopts a high-speed weak cooling process, and according to the characteristics of the molten s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com