Fender mounting structure

A technology for installing structures and fenders, which is applied in the direction of upper structure, upper structure sub-assembly, transportation and packaging, etc. It can solve the problems that the appearance gap of the car cannot be guaranteed, so as to reduce connection errors, protect life safety, and ensure the appearance gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

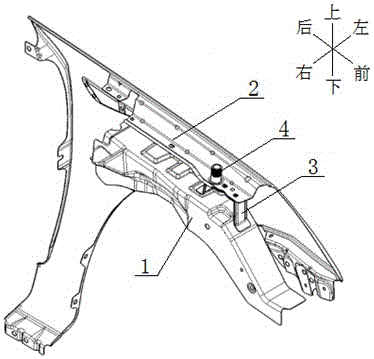

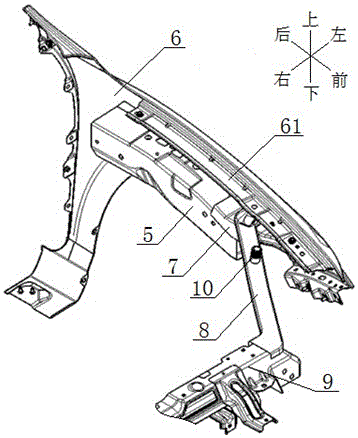

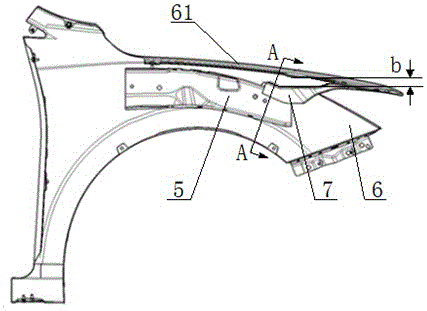

[0025] see figure 2 or image 3 , a fender mounting structure, comprising a front hub reinforcing beam 5, a fender 6, a fender bracket 7 located between the front wheel hub reinforcing beam 5 and the fender 6, the fender bracket 7 and the described The front end of the front wheel hub reinforcement beam 5 is connected to support the fender 6, and its prominent substantive feature is that it also includes a headlight beam 8 connected with the fender bracket 7 at one end, and the The front upper member assembly 9 to which the other end of the light beam 8 is connected. Because one end of the headlight beam 8 is connected with the fender bracket 7 and the other end is connected with the front upper member assembly 9, the connection rigidity can be ensured, and a certain impact toughness can be ensured at the same time.

[0026] see Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com