Pyrotechnically actuated separation impact reduction device based on inverse wavelength characteristic and preparation process thereof

A technology of pyrotechnic separation and impact device, which is applied in the direction of friction shock absorber, etc., can solve the problems of damage to precision instruments, inability to effectively reduce impact, and reduce the stability of system structure, so as to achieve good adaptability and improve the impact reduction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

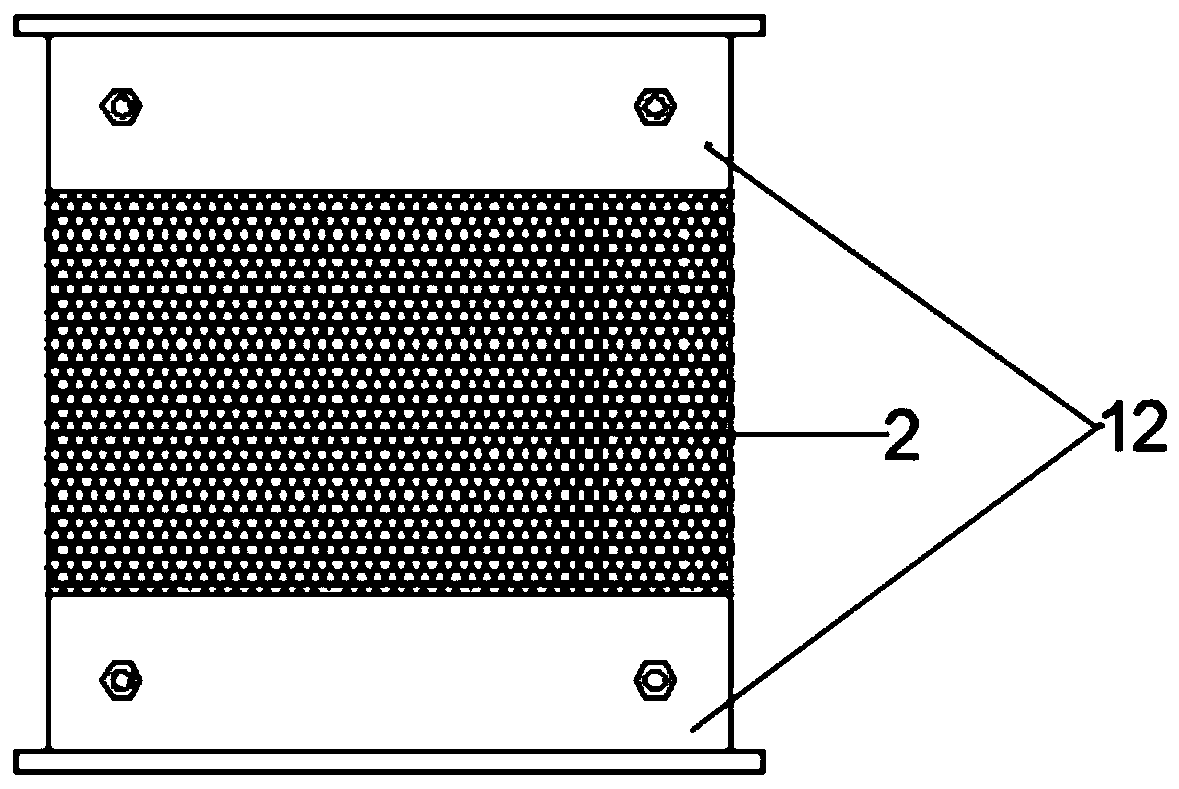

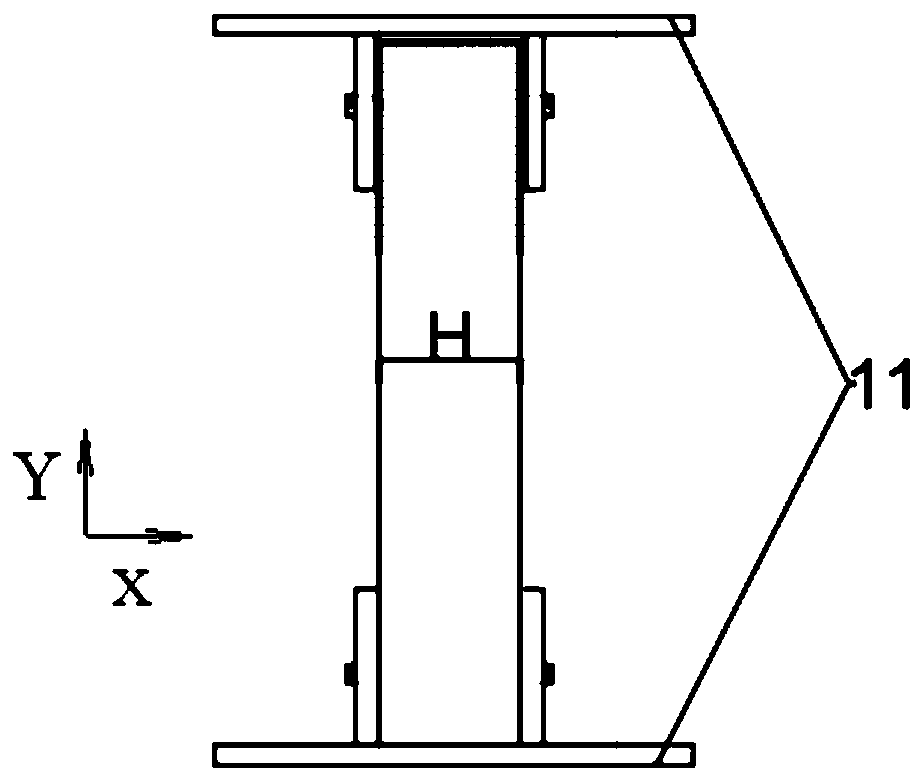

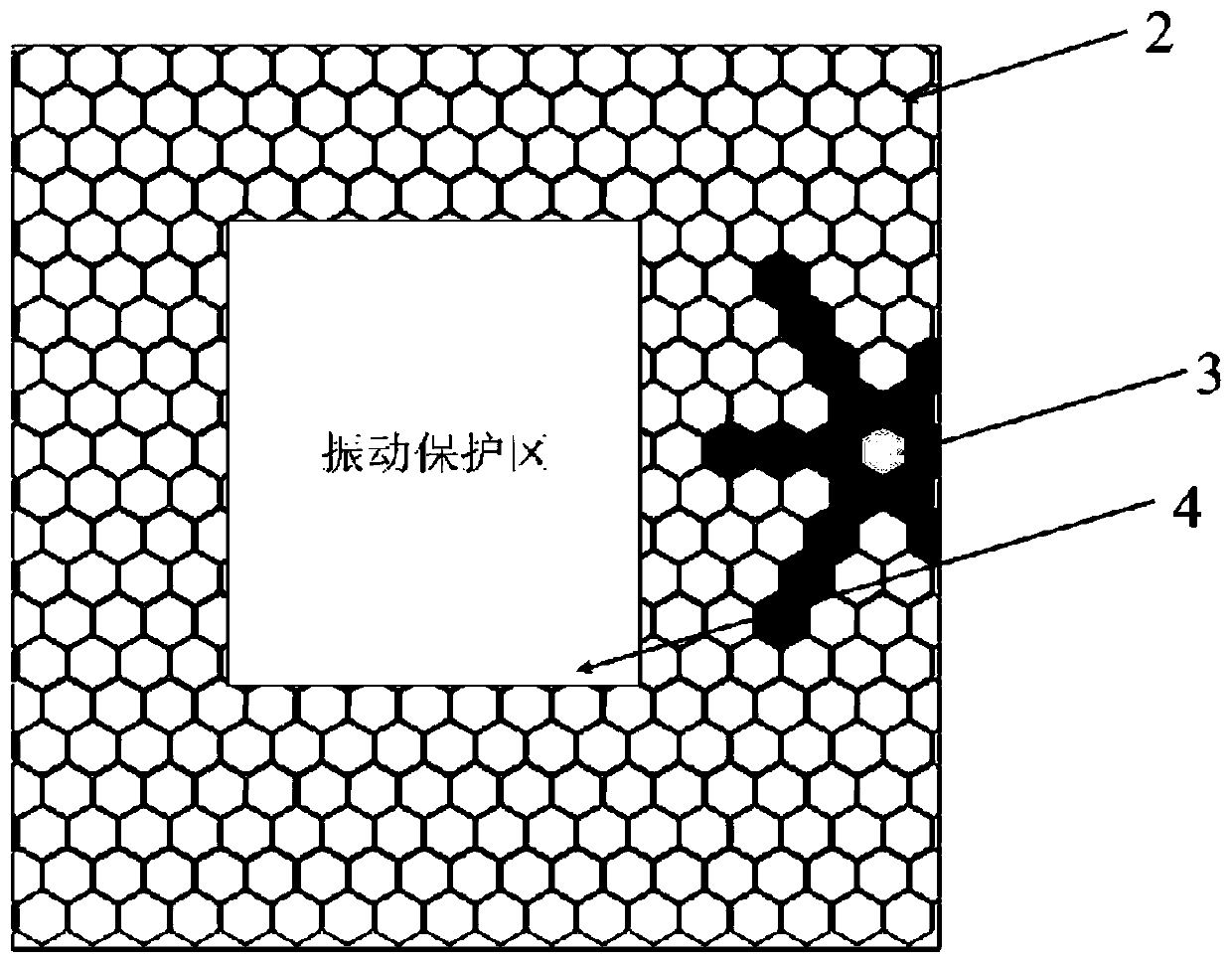

[0053] Please also see image 3 with Figure 4 ,in, image 3 A schematic diagram of the arrangement relationship of the cavity structure shown in this embodiment is shown, Figure 4 for image 3 side view. This figure shows the pyrotechnic separation and impact reduction device of the detonation bolt 3 type. When the pyrotechnic separation, the bolt 3 explodes, and the protected device is roughly located in the vibration protection zone 4 shown in the figure for illustration.

[0054] As shown in the figure, the position of the bolt 3 is the position where the pyrotechnic shock occurs, and the periodically arranged cavities 2 are arranged in a radial scattering form from the inside to the outside with this position as the center of the circle; That is, the cavity 2 shown in black in the figure is filled with damping particles.

[0055] The shock wave generated by the explosion of the bolt 3 will excite the damping particles filled in the cavity 2 arranged in the radial sc...

Embodiment 2

[0076] See Figure 7 , which shows a schematic diagram of the arrangement relationship of the cavity structure described in the second embodiment. In order to clearly show the differences and connections between this embodiment and Embodiment 1, structures with the same functions are indicated with the same reference numerals in the figure.

[0077] The core design concept of this solution is exactly the same as that of Embodiment 1. The difference in the arrangement of the cavity structure is that the periodically arranged cavity 2 is configured as follows: the position where the pyrotechnic impact occurs (bolt 3) is The center of the circle is nested and arranged around an arc from the inside to the outside; that is, the chamber 2 shown in dark gray in the figure is filled with damping particles. Implementation principles of other functions are the same as those in Embodiment 1, so details are not repeated here.

Embodiment 3

[0079] See Figure 8 , which shows a schematic diagram of the arrangement relationship of the cavity structure described in the third embodiment. In order to clearly show the differences and connections between this embodiment and Embodiments 1 and 2, structures with the same functions are shown with the same reference numerals in the figure.

[0080] The core design concept of this solution is exactly the same as that of Embodiment 1. The difference in the arrangement of the cavity structure is that the periodically arranged cavity 2 is configured as follows: the position where the pyrotechnic impact occurs (bolt 3) is The center of the circle is nested and arranged in a polygonal shape from the inside to the outside; that is, the cavity 2 shown in light gray in the figure is filled with damping particles. Implementation principles of other functions are the same as those in Embodiment 1, so details are not repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com