Chlorinated polyvinyl chloride pipeline

A technology of chlorinated polyvinyl chloride and pipes, which is applied in the field of pipes, can solve the problems of poor impact toughness of pipes, increased production costs of pipes, and poor effects, and achieve the goal of increasing softening temperature, increasing Vicat softening temperature, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following examples serve to illustrate the invention without limiting the scope of protection set forth in the claims.

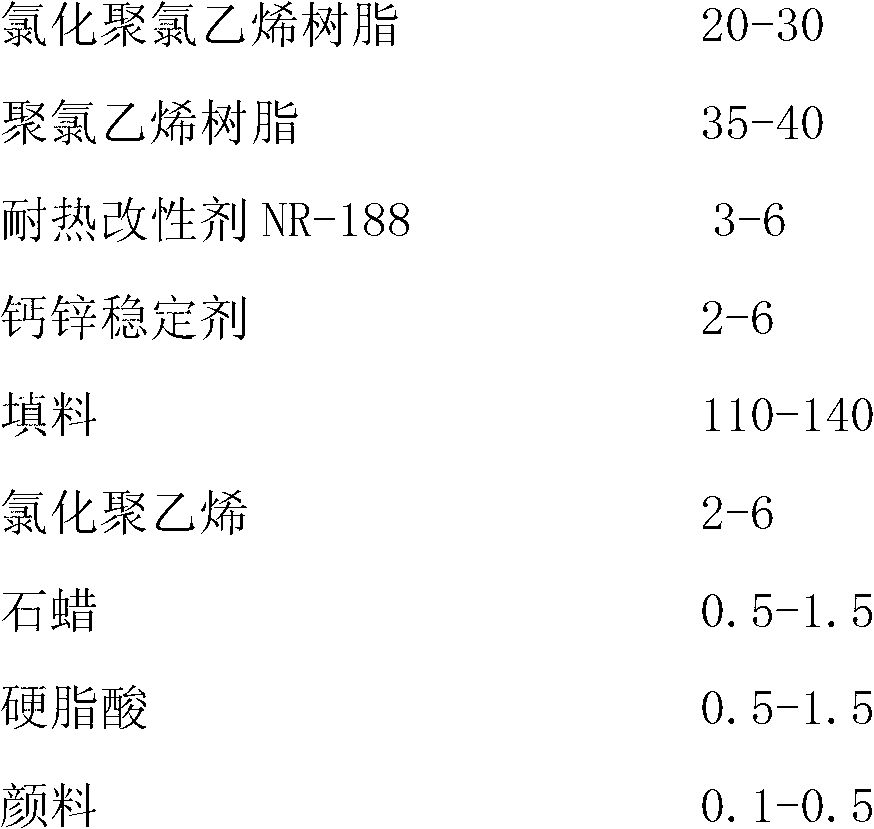

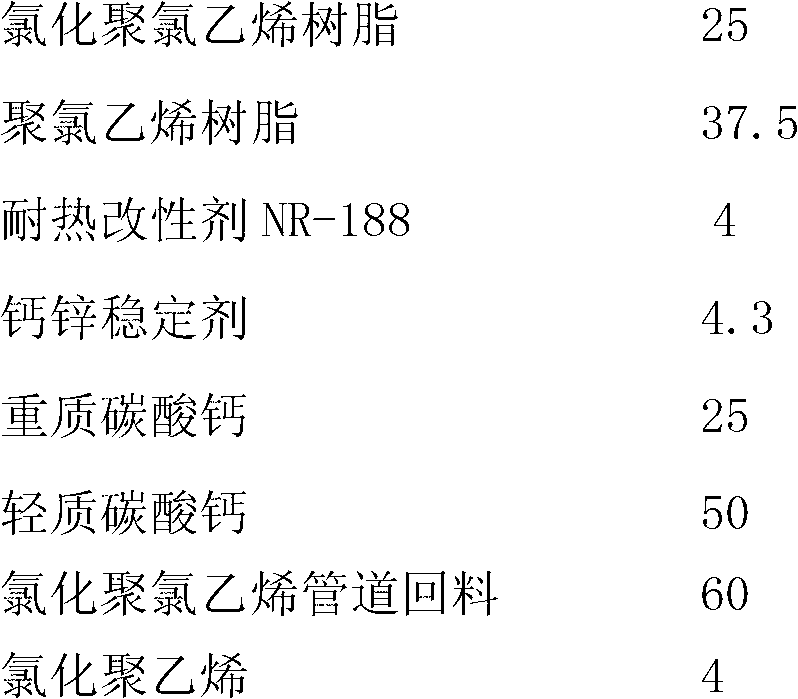

[0015] The formula of chlorinated polyvinyl chloride pipeline of the present invention is as follows:

[0016]

[0017]

[0018] The above-mentioned heat-resistant modifier NR-188 can be a product produced by Yixing Lilai Chemical Co., Ltd.; the above-mentioned calcium-zinc stabilizer can be a product produced by Hangzhou Rongshun Chemical Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com