Existing line transverse lifting strengthening method and structure

A technology of line and horizontal lift, applied in the field of horizontal lift reinforcement method and structure of existing line, can solve the problems of unfavorable operation of existing line, large investment of manpower, long construction period, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

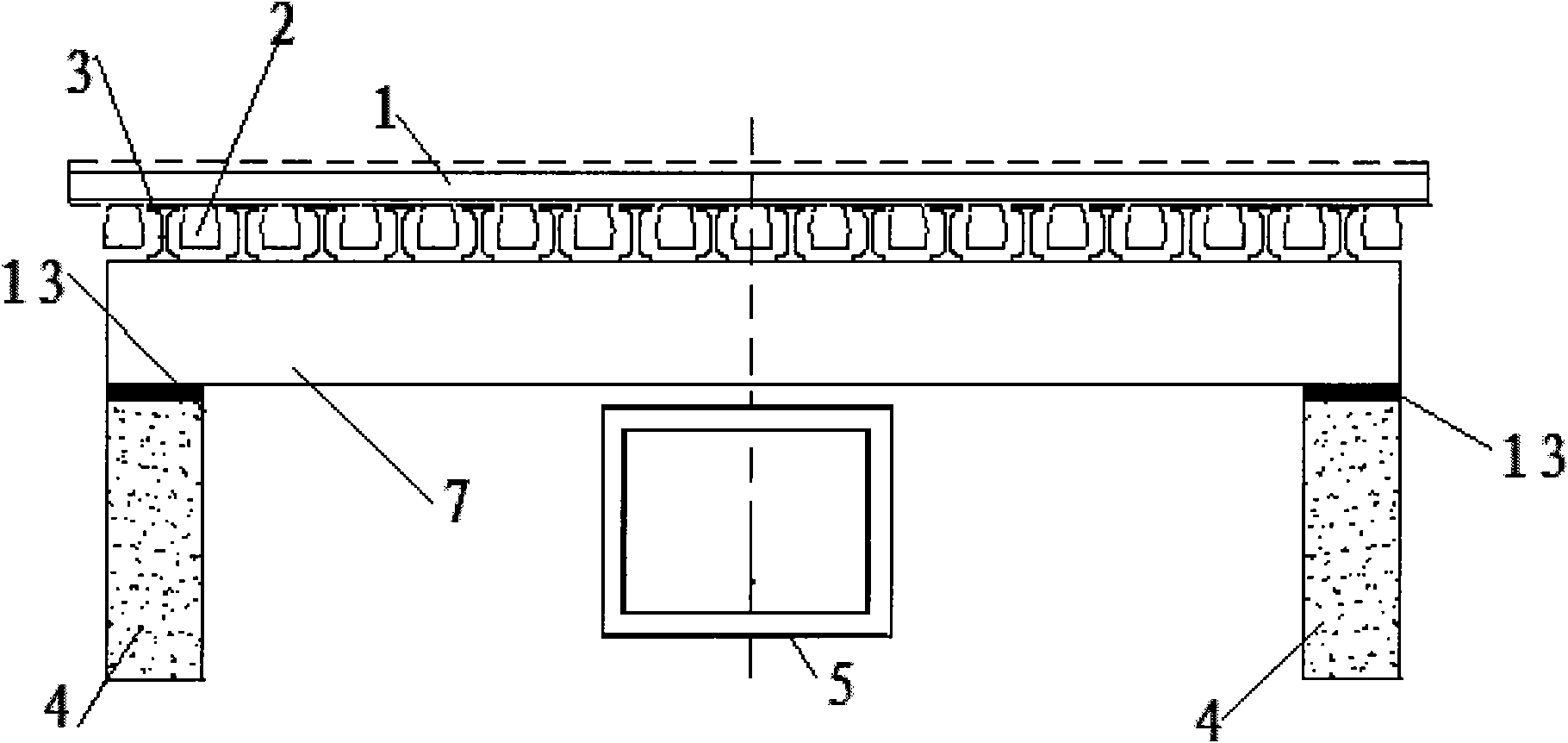

[0017] refer to Figure 1 to Figure 6 Examples of the present invention will be described.

[0018] Obviously, many modifications and changes made by those skilled in the art based on the gist of the present invention belong to the protection scope of the present invention.

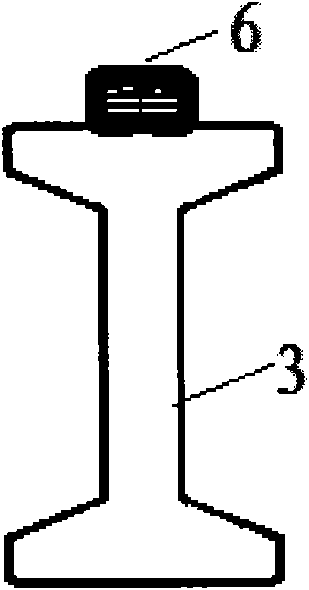

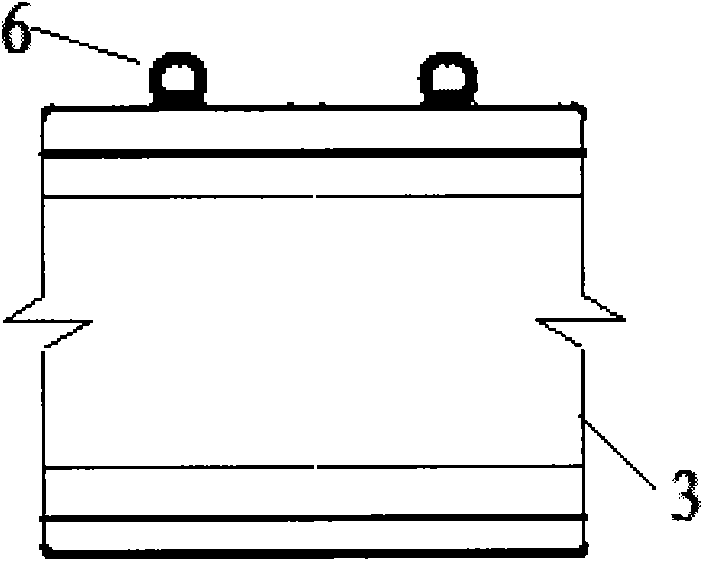

[0019] The present invention relates to an existing line horizontal lift reinforcement method, comprising the following steps: first dig hole piles, in order to ensure the overall safety of driving and lines, before the longitudinal beams are reinforced, place 56b At both ends of the I-beam 7, during construction, four φ1.2m hole piles 4 foundations are excavated on both sides of the culvert 5, and the hole pile 4 is topped with a φ1.0m thick 2cm steel plate 13 as a protective support, which is fixed by embedded parts. The length of the hole pile 4 is determined according to the geological conditions. The general determination method for the bottom elevation of the hole pile 4 is: the bottom elevation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com