Lifting correction device and method for CRTSI mould board type ballastless track on high-speed railway roadbed

A technology of ballastless track and deviation correction device, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problem of limited adjustment value of the fastener system, and achieve the effects of fast construction, good environmental protection and cost economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

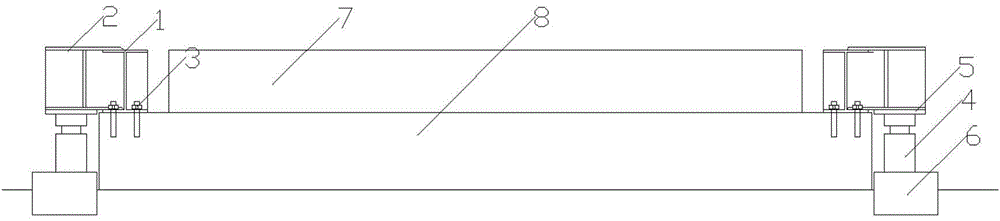

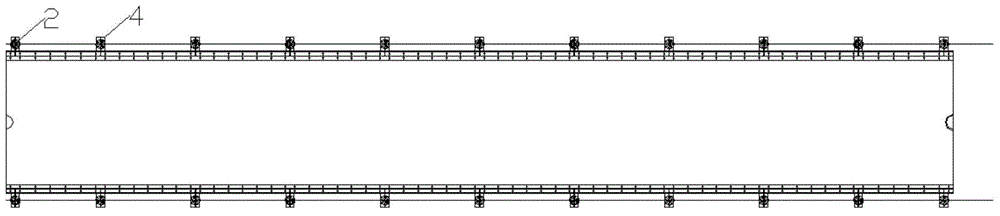

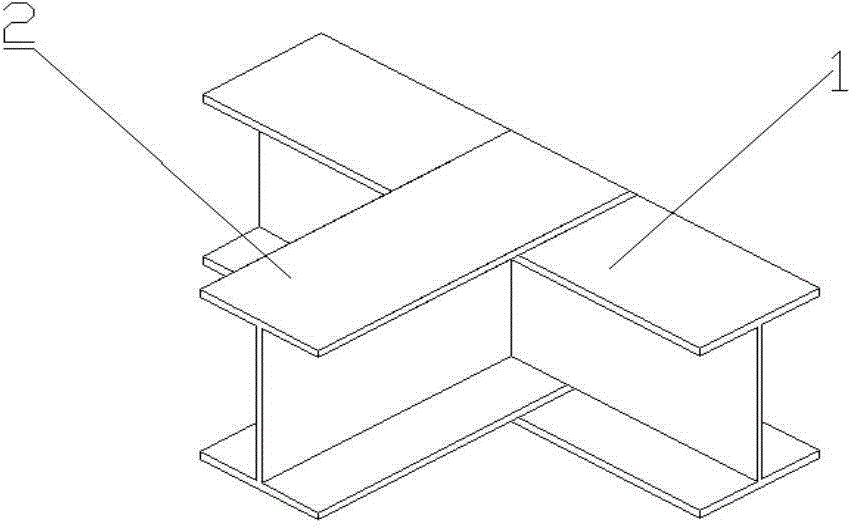

[0055] See attached Figure 1-4 , the lifting and correcting device for ballastless track in the present invention includes H-shaped longitudinal steel beam 1, H-shaped short beam 2, high-strength bolt 3, vertical jack 4, PTFE plate 5, vertical concrete pier 6, track plate 7, base plate 8. Among them, firstly, anchor holes are drilled on the base plate, and planting glue is injected into them to anchor high-strength bolts 3. The H-shaped longitudinal steel beam 1 is connected to the base plate 8 through high-strength bolts 3, and the H-shaped short beam 2 is then welded. Directly connected to the H-shaped longitudinal steel beam 1; under the H-shaped short beam 2, vertical concrete piers 6, vertical jacks 4, and PTFE boards 5 are arranged in sequence from bottom to top, so that the action of the vertical jack 4 can The displacement is transmitted to the base plate 8 sequentially through the PTFE plate 5, the H-shaped short beam 2, and the H-shaped longitudinal steel beam 1, t...

Embodiment 2

[0072] Compared with Embodiment 1, Embodiment 2 of the present invention has increased the function of level adjustment. In terms of structure, see Figure 8-10 , Embodiment 2 has increased horizontal concrete pier 9, horizontal jack 10, specifically, horizontal concrete pier 9 is set near vertical concrete pier 6, and a horizontal jack 10 is set between its side and H-shaped longitudinal steel beam 1.

[0073] When the ballastless track line on the subgrade described in this embodiment is lifted and corrected, the construction steps include height direction and horizontal displacement measurement and determination of the track plate 7 for lifting and correcting, drilling of the base plate 8, H-shaped longitudinal steel beams 1 and H Fixing of the short beam 2, making concrete piers, unloading the base plate 8, arranging jacks, synchronous lifting of the track plate 7 as a whole, translation of the track plate 7, grouting, review of the lifting value, and falling of the plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com