Epoxy resin mortar composite used for plate type fragment-free track

A technology of epoxy resin and composition, which is applied in the direction of track, track maintenance, track laying, etc., can solve the problems of poor durability, slow strength increase, freezing expansion, etc., and achieve scientific and reasonable component distribution ratio, good elasticity and mechanical Intensity, the effect of rapid increase in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

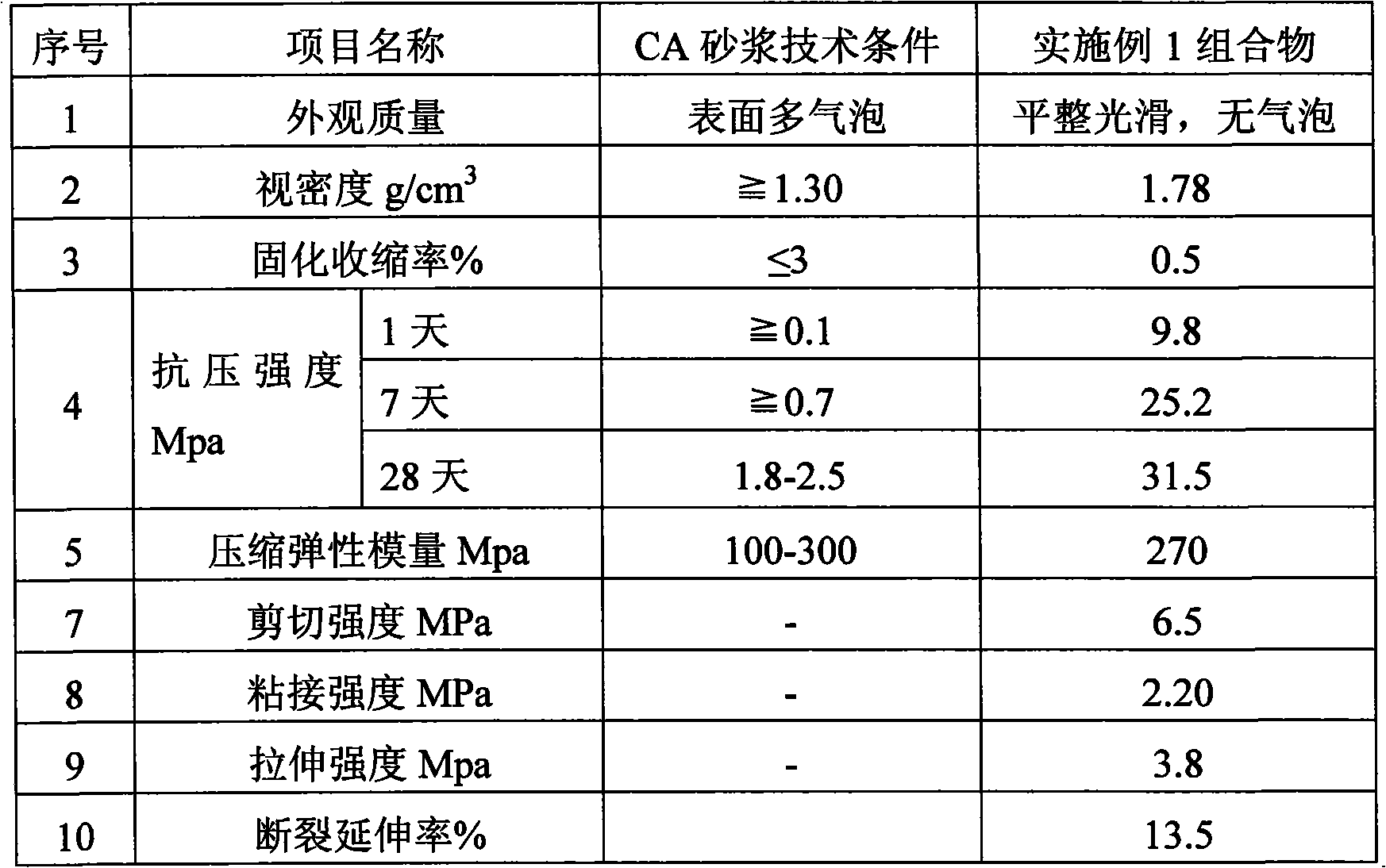

Examples

Embodiment 1

[0032] The composition of the epoxy resin mortar composition: Part A: Add 100kg of bisphenol A type E-51 epoxy resin, glycidyl ether type flexible epoxy resin (JEf-0212 of Changshu Jiafa Chemical Co., Ltd.) into the stirred reactor 40kg, diethylene glycol glycidyl ether epoxy resin reactive diluent (Changshu Jiafa Chemical Co., Ltd. JX-023) 30kg, carbon black 2g, defoamer A-530 (Germany BYK Chemicals) 0.1g, coupling agent KH-5601g, degassing and stirring for 1 hour at a speed of 100 rpm, a temperature of 60°C, and a pressure of -0.1Mpa. The output package is used as part A for use. The viscosity is 500mpa.s when tested at 25°C.

[0033] Part B: Add 142kg of triethylenetetramine into the stirred reactor, stir to raise the temperature to 80°C, add 71kg of o-cresol glycidyl ether (Changshu Jafa Chemical JX-017) dropwise, and 102kg of butyl glycidyl ether to maintain the reaction After 5 hours, 10101 kg of hindered phenol was added, and the material was defoamed and discharged at ...

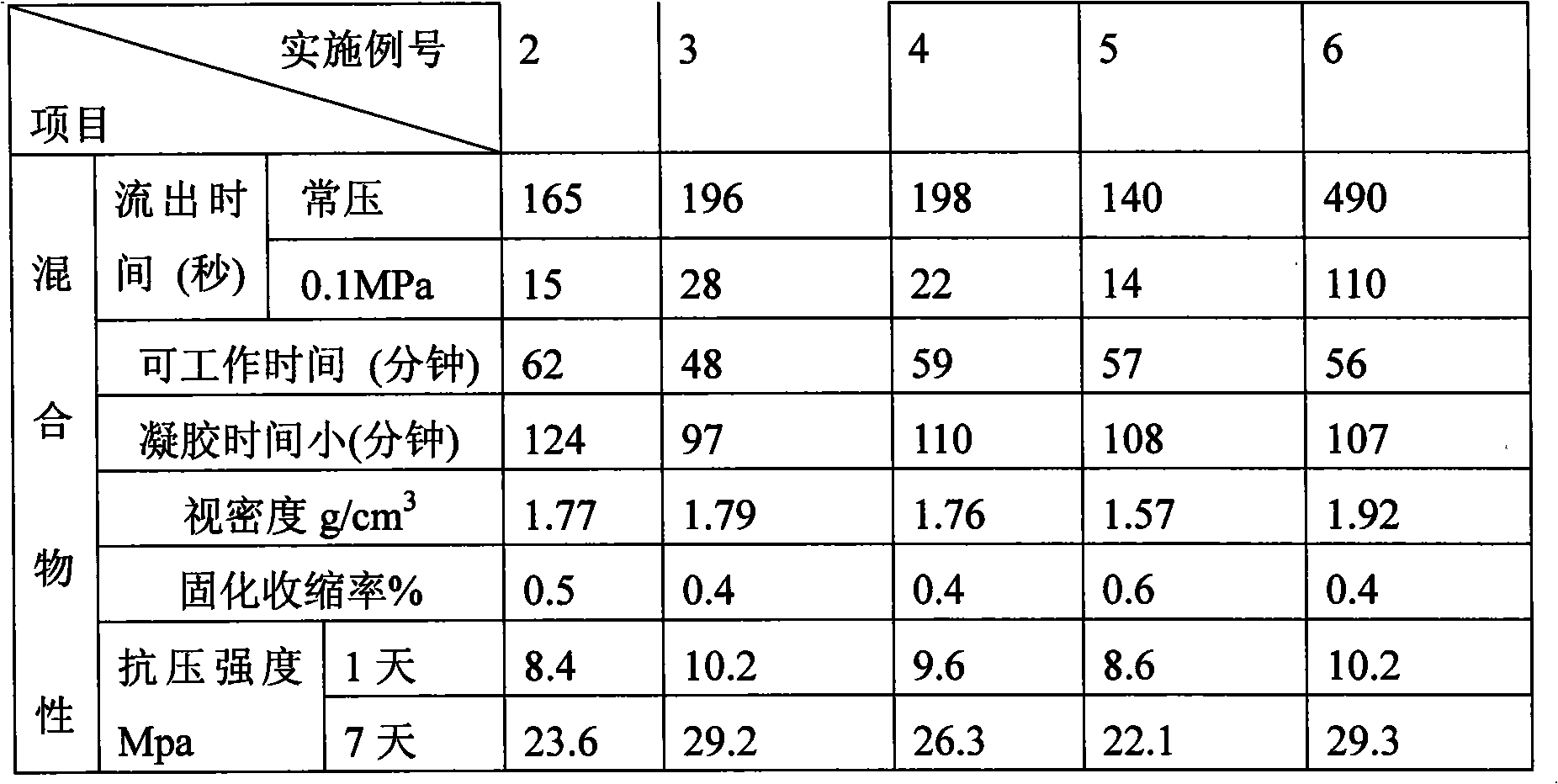

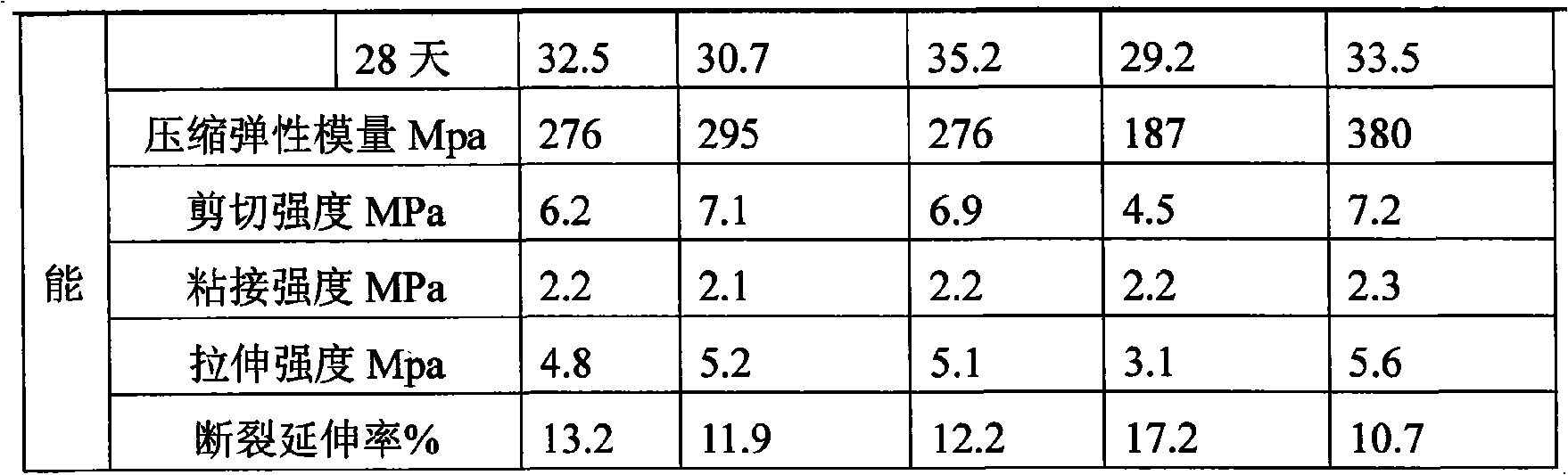

Embodiment 2

[0041] Composition of epoxy resin mortar composition: Part A: Add 100kg of bisphenol F epoxy resin with a molecular weight of 400 (epoxy equivalent 180, viscosity 3600mpa. Epoxy resin JEf-021240kg, neopentyl glycol glycidyl ether epoxy resin reactive diluent (Changshu Jiafa Chemical Co., Ltd. JX-022) 20kg, carbon black 3g, defoamer A-530 (German BYK chemical) 0.3 g, coupling agent epoxy silane KH-560 2g, defoaming and stirring at 80 rpm, temperature 25°C, pressure -0.1MPa for 1 hour, and the output package is used as part A for standby, and the test viscosity at 25°C is 490mpa .s.

[0042] The raw materials of Part B and Part C are the same as in Example 1, and the raw materials of Parts A, B and C are stirred and mixed in a weight ratio of 100:10:100 to obtain the epoxy resin mortar composition of the present invention.

[0043] The fluidity, usable period, gel time, and cured product performance of the above epoxy resin mortar composition were tested, and the specific test ...

Embodiment 3

[0045] The composition of epoxy resin mortar composition: A part and C part raw material are with embodiment 1, and B part raw material is obtained by the following method: add triethylenetriamine (DETA) 103kg, nonylphenol 220kg in stirring reactor, stir Raise the temperature to 80°C, add 101kg of 35% formaldehyde solution dropwise, maintain the reaction at 110°C for 5 hours, remove the generated water under reduced pressure -0.1MPa, cool down, filter and discharge the material as the raw material of Part B, and test the viscosity at 25°C It is 790mpa.s.

[0046] The above-mentioned part B raw materials and the same part A and C raw materials of Example 1 are stirred and mixed according to the weight ratio of A: B: C three materials 100: 58: 200 to obtain the epoxy resin mortar composition of the present invention.

[0047] The fluidity, service life, gel time, and properties of the cured product were tested for the epoxy resin mortar composition. The specific experimental res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com