Existing line reinforcing method in under-crossing railway frame bridge small-included angle large-height inclined jacking construction

A frame bridge, high-height technology, applied in the field of frame bridge jacking construction line reinforcement, can solve problems such as the small angle between the frame bridge axis and the existing line, the formation of triangular pits on the line, and the lateral movement of the line, so as to reduce the workload and improve the The effect of work efficiency and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

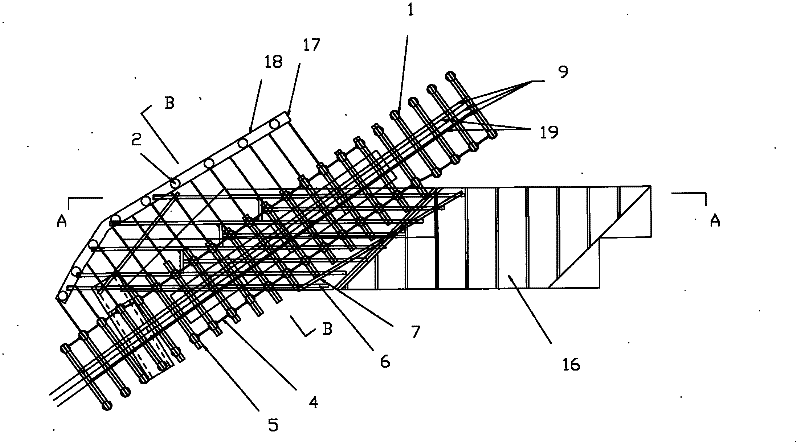

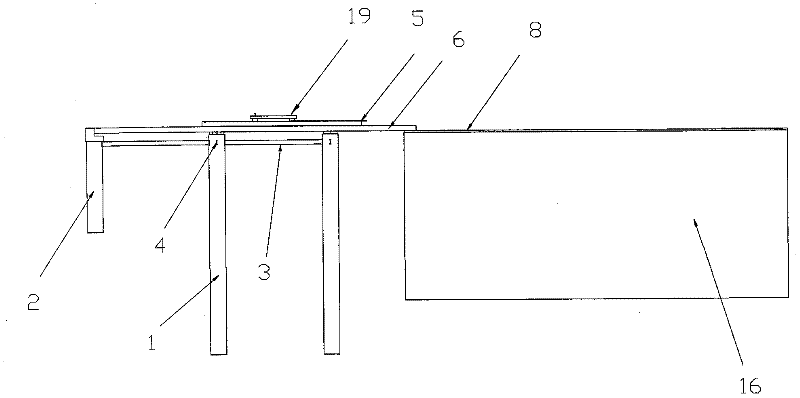

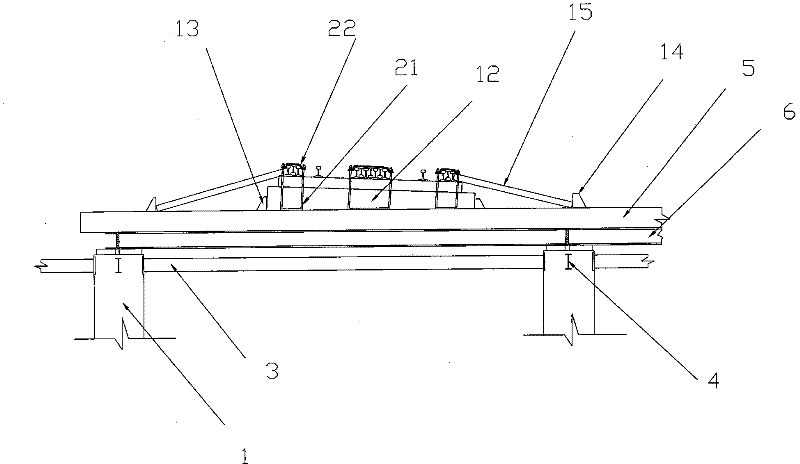

[0020] The technical scheme of the present invention is described below in conjunction with accompanying drawing and embodiment:

[0021] The invention is aimed at the existing line reinforcement method for oblique jacking construction with a small included angle and a large height of a railway frame bridge passing under it. For example, if two railway lines intersect, the existing line is a single-track railway, and the front and rear of the intersection are located on the right-handed curve with a radius of 4500m. The intersection angle between the underpass frame bridge and the existing line is 31°06′; the frame bridge is a 1-11m reinforced concrete oblique intersection The frame bridge is being built, the total height of the box is 12.80m, the front section width is 13.60m, the oblique width along the existing line is 26.33m, the transverse length is 41.50m, and the design net height of the frame bridge is 10.5m.

[0022] The present invention adopts the combination of han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com