Shredder paper feed mechanism and paper feeder

a technology of paper feeder and paper slitting machine, which is applied in the direction of grain treatment, thin material processing, article separation, etc., can solve the problems of preventing shredding, jamming and system downtime, and the number of sheets that can be shredded at one time being limited, so as to facilitate the penetration of sharp parts, facilitate the feeding of sheets, and ensure the effect of slitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

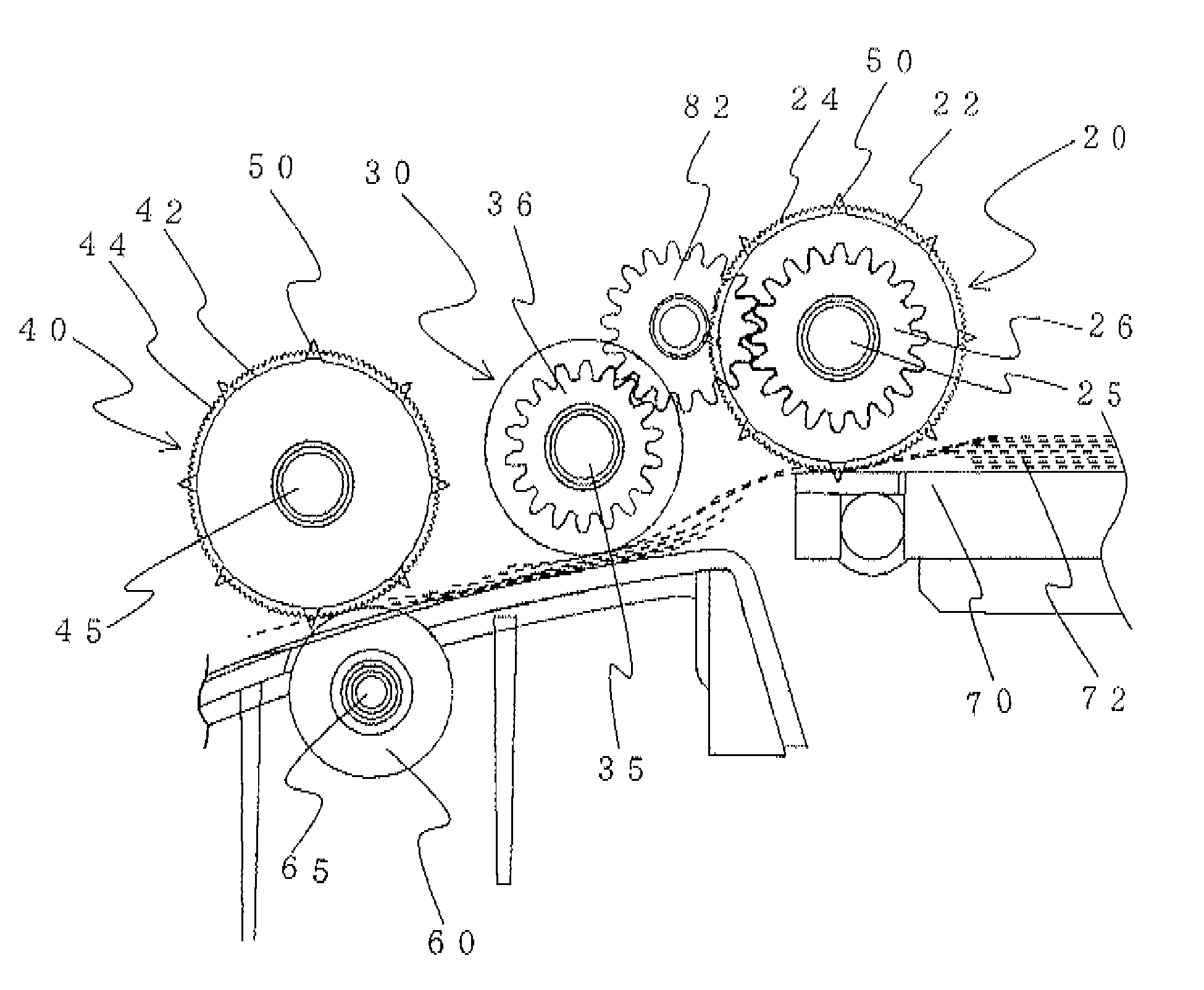

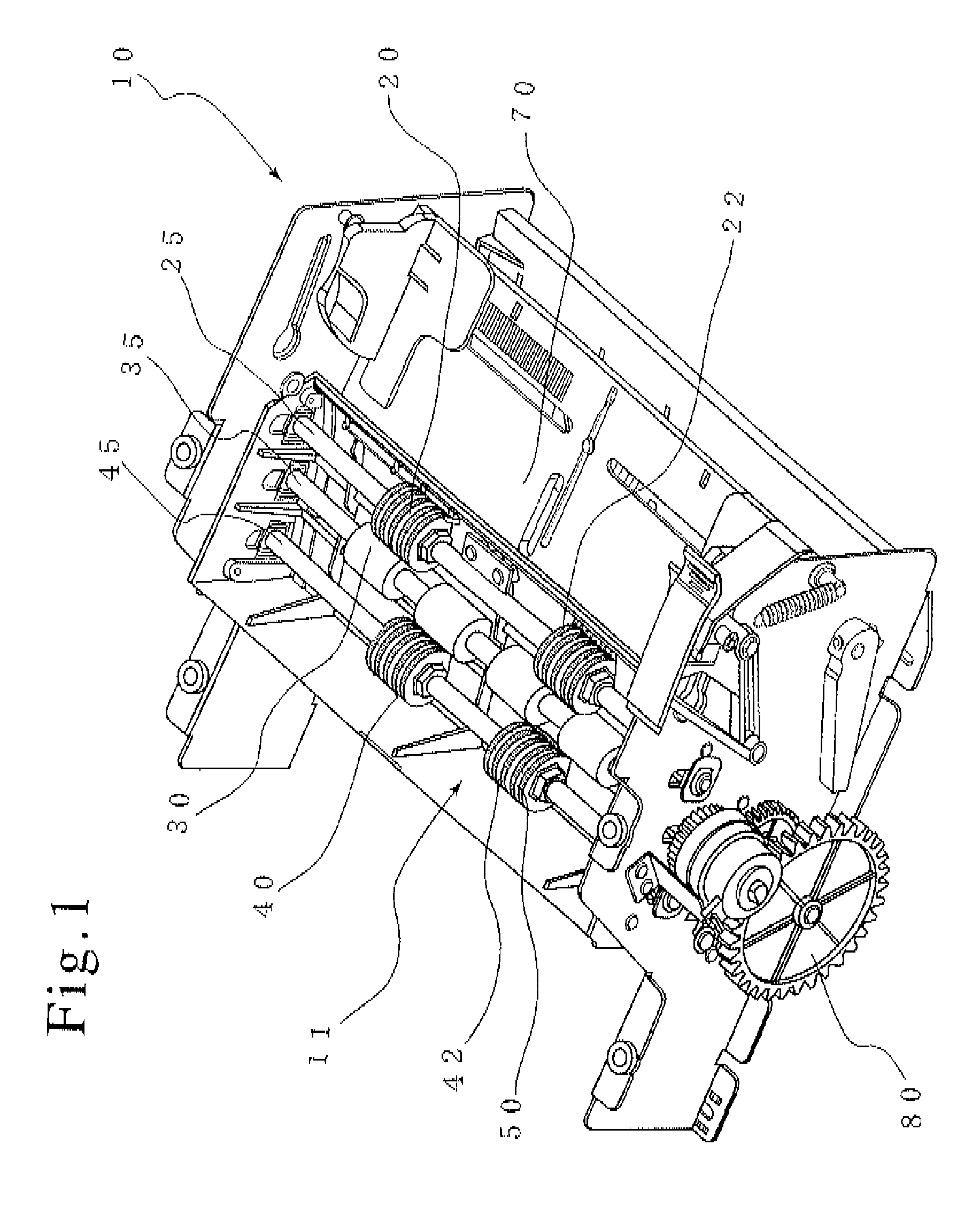

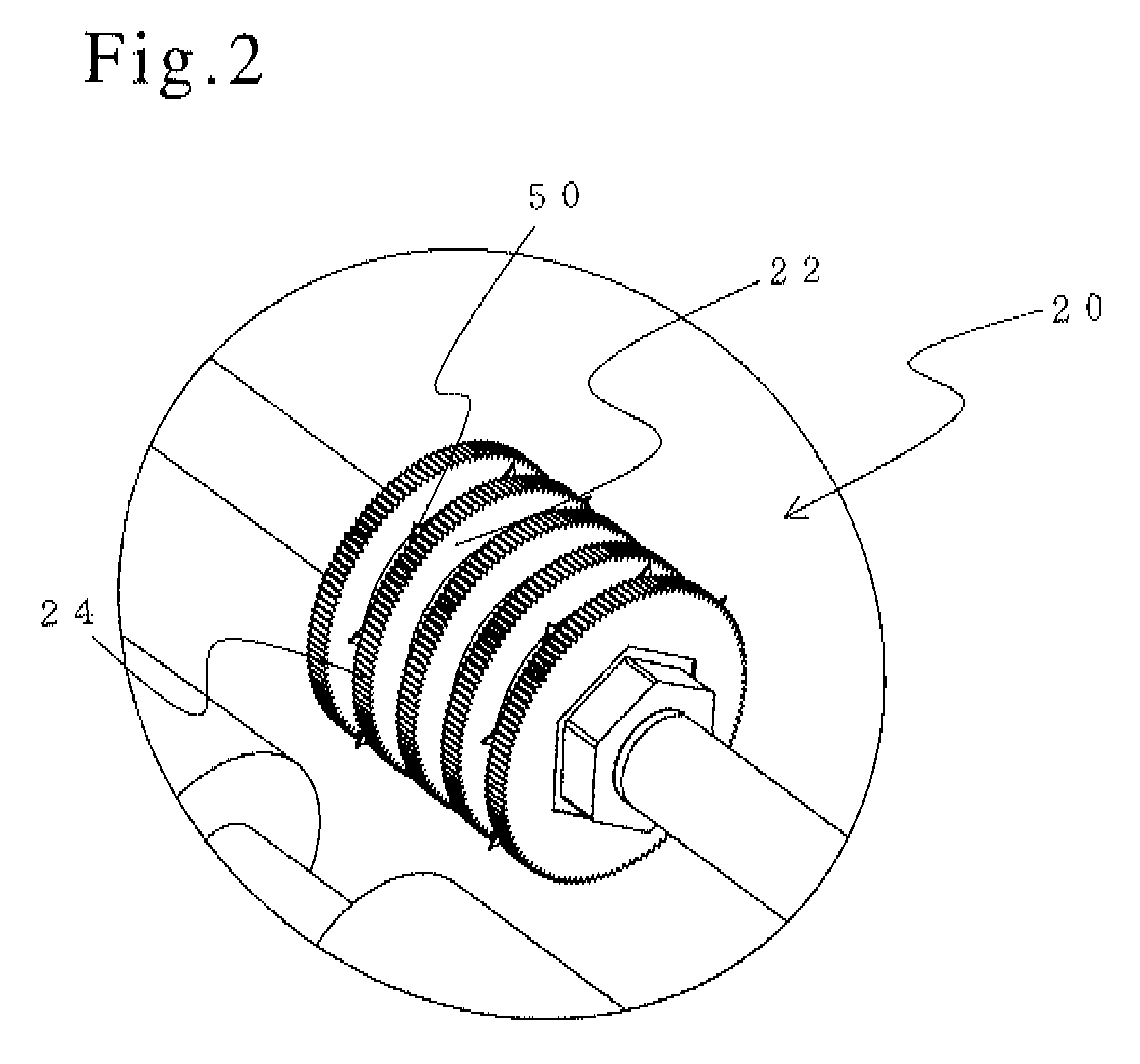

[0021]The paper feed mechanism according to the present invention will now be explained with reference to an embodiment shown in the drawings, in which FIG. 1 shows a perspective view of the paper feeder of the invention, FIG. 2 shows a perspective view of the first and second rotating members, FIG. 3 is a side view of a disc-shaped claw member of the invention, FIG. 4 is a side view of another disc-shaped claw member, and FIG. 5 is a sectional view of the gear engagement configuration in the paper feed mechanism.

[0022]The paper feed mechanism 11 of the invention comprises a first rotating member 20, a transport roller 30, a second rotating member 40 and a pressure roller 60. The paper feeder 10 of the invention comprises a paper feed mechanism 11, a paper feeding tray 70 and a gear unit 80.

[0023]The first rotating member 20 is a substantially cylindrical member that separates the stack of documents in the paper feeding tray 70 into a paper stack 72 having a number of sheets that ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com