Automatic feeding device for laser engraving machine

A technology of automatic feeding and laser engraving machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

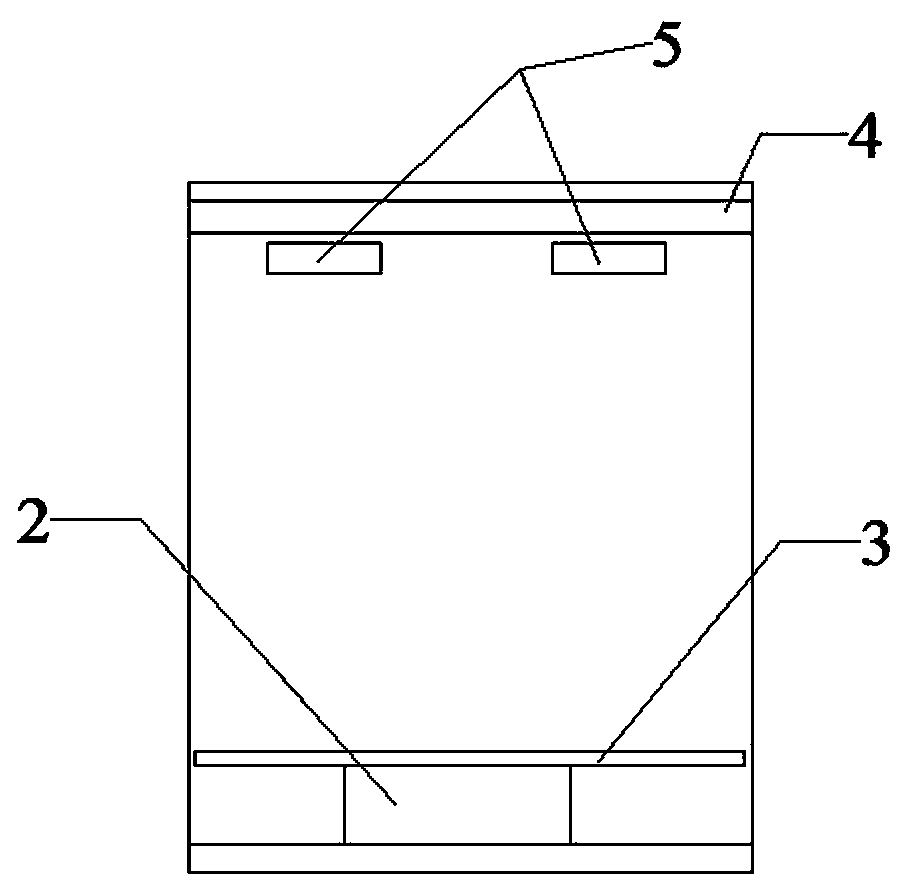

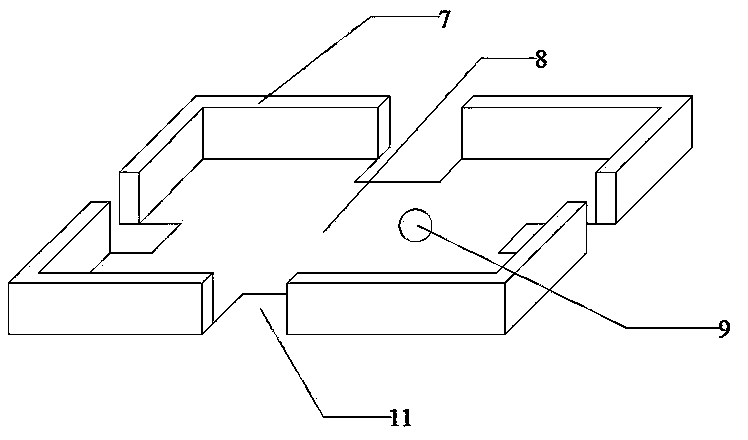

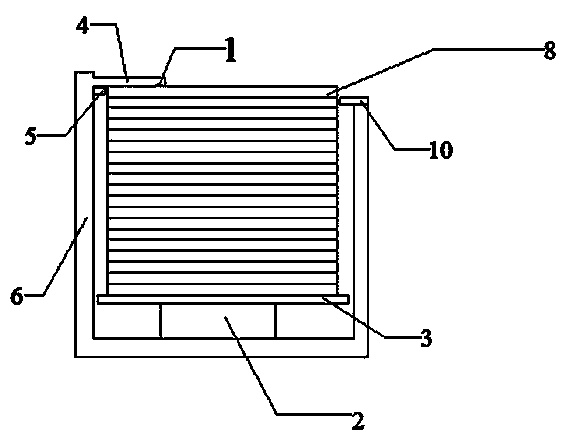

[0019] An automatic feeding device for a laser engraving machine, comprising a box body 6, a lifting platform 2 arranged at the bottom of the box body 6, a loading device located on the lifting platform 2, a baffle plate 4 located at the top of the box body 6 and a 6 on one side and close to the push handle 5 of the baffle plate 4, the loading device is composed of several layers of loading boxes 8 stacked, and the bottom of the loading device is provided with a loading platform 3 placed on the lifting platform 2, the loading platform 3 can be more Place the loading box 8 steadily.

[0020] The bottom of the material loading box 8 is a cuboid, and the walls 7 on the four sides are side walls with a thickness of 3-5 mm. In this way, due to a certain thickness, the stacking process will be more stable, and the pusher 5 can also be pushed du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com