Interior material, panel forming body, and manufacturing method for interior material

a technology of interior material and manufacturing method, which is applied in the direction of roofs, instruments, transportation and packaging, etc., can solve the problems of work machines placed in a bad working environment with violent noise and vibration, placed in a very bad working environment, and affecting the quality of interior materials, so as to suppress the vibration of exterior materials and excellent noise insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] A preferable embodiment of an interior material and a panel forming body of an operator's cab of a work machine according to the present invention as well as a method of manufacturing the interior material will be explained below in detail with reference to the drawings.

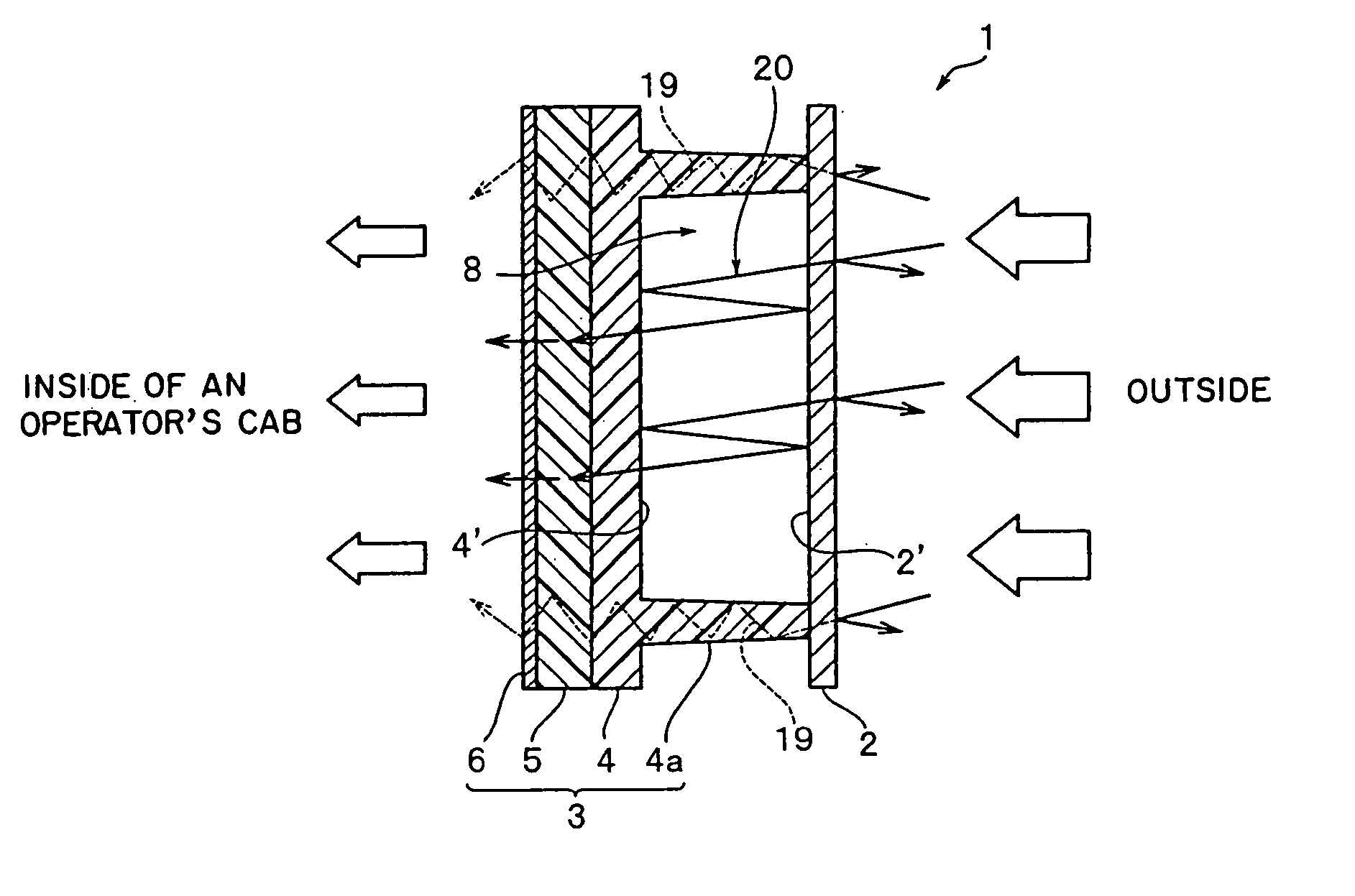

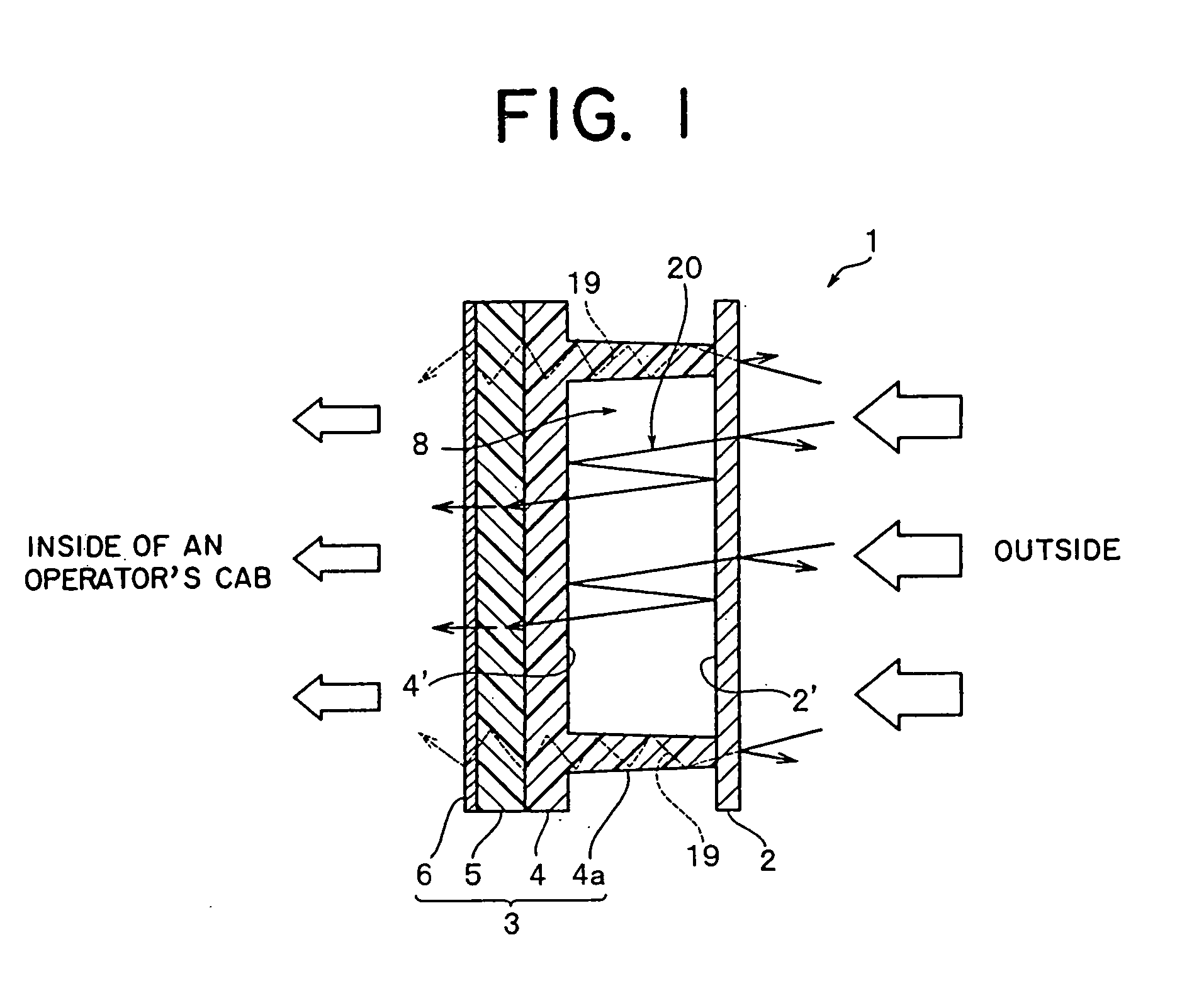

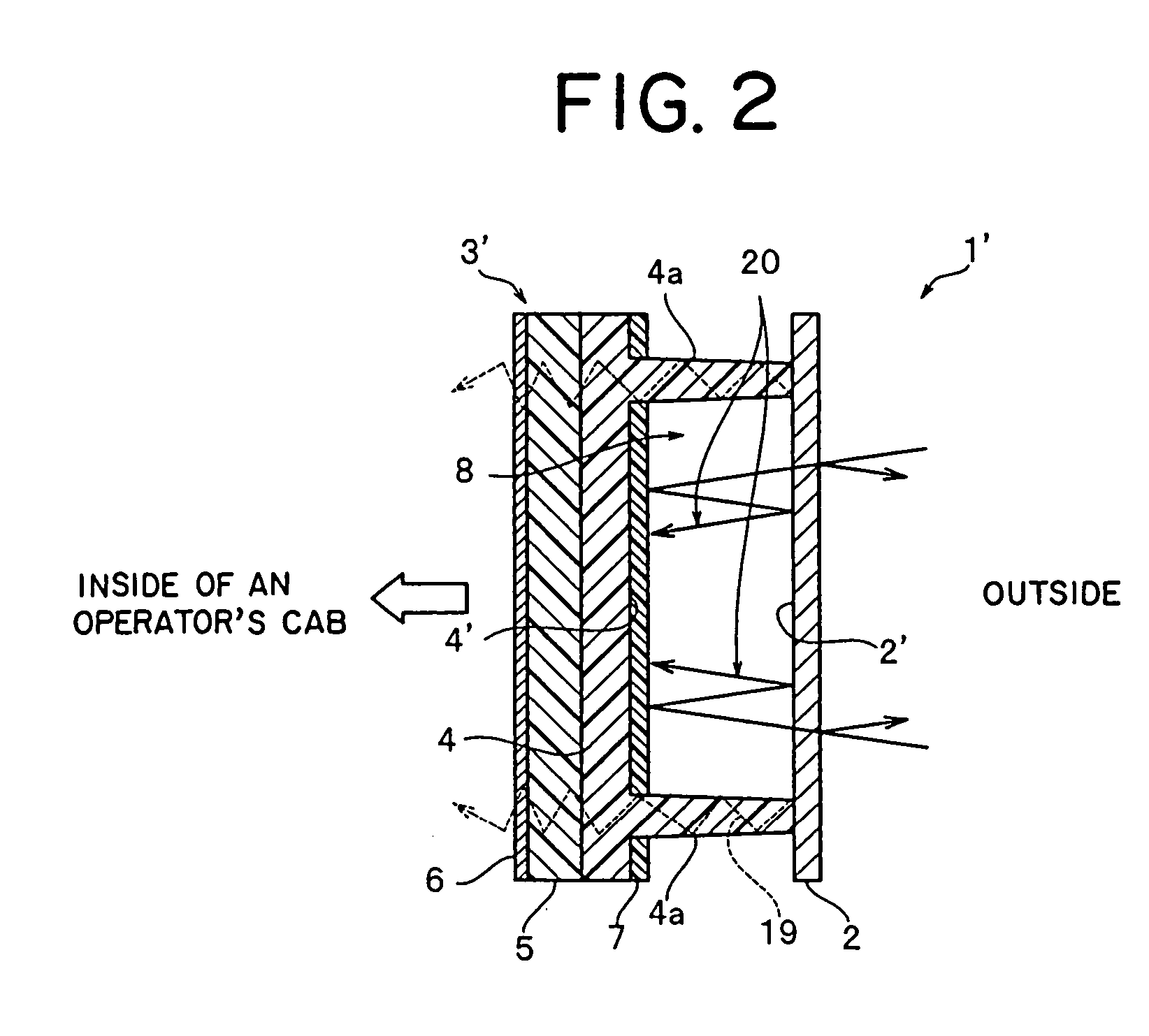

[0073] First, the interior material of the operator's cab of the work machine according to the present invention will be explained. FIG. 1 is a schematic sectional view of the interior material and the panel forming body having the interior material according to the embodiment.

[0074] The panel forming body 1 for use in the operator's cab of the work machine shown in FIG. 1 is composed of an interior material 3 which is disposed on an operator's cab side, and an exterior material 2 which is disposed in intimate contact with a rib 4a of the interior material 3 with the interior material 3 being integrated with the exterior material 2. The exterior material 2 and the interior material 3 are assembled by being j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com