Burner fuel mixer head for concurrently burning two gaseous fuels

a technology of burner fuel and mixer head, which is applied in the direction of burners, combustion types, combustion processes, etc., can solve the problems of uneven heat in the firetube and unacceptable levels of emissions, and achieve the effect of effectively drawing combustion air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

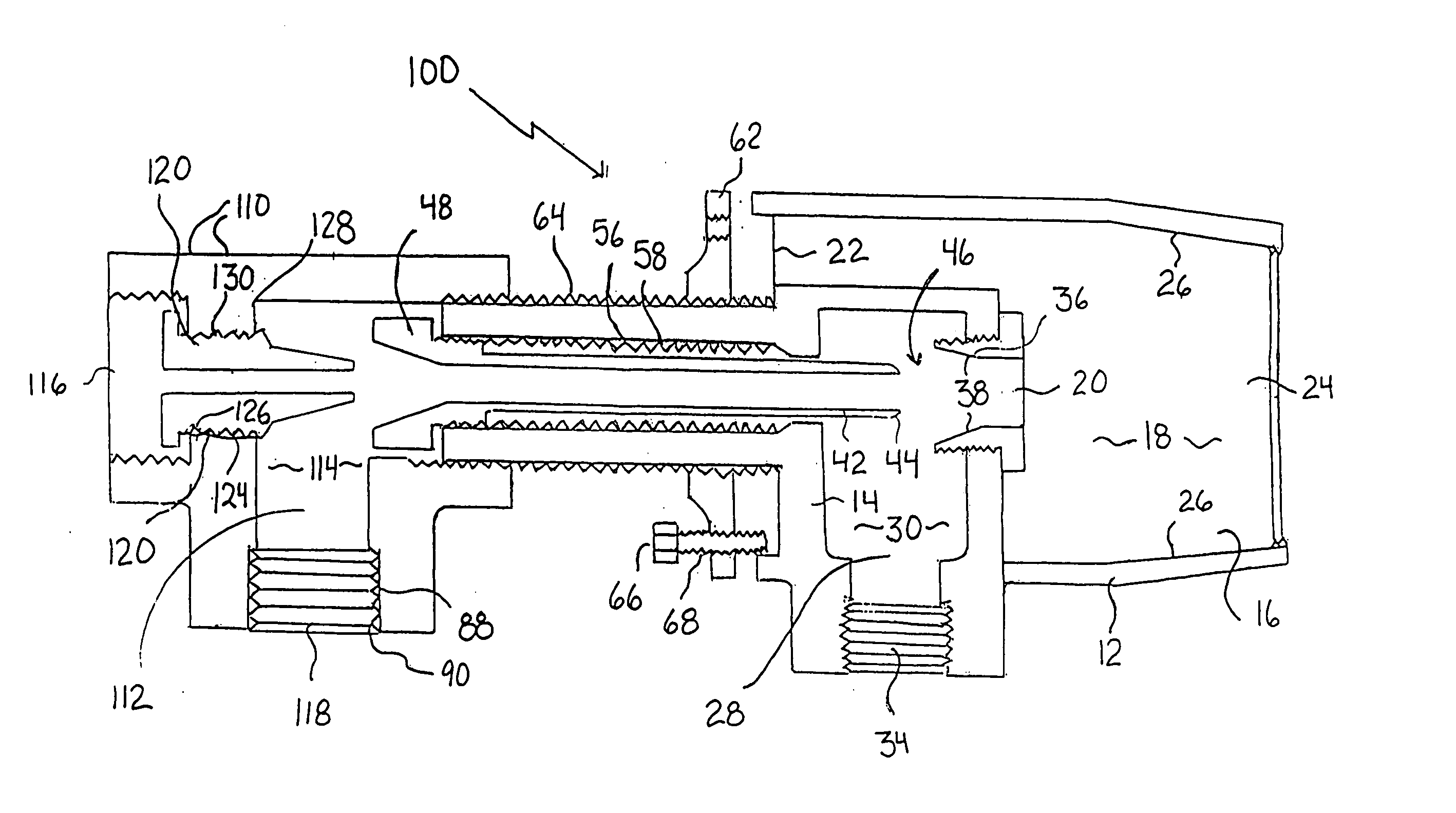

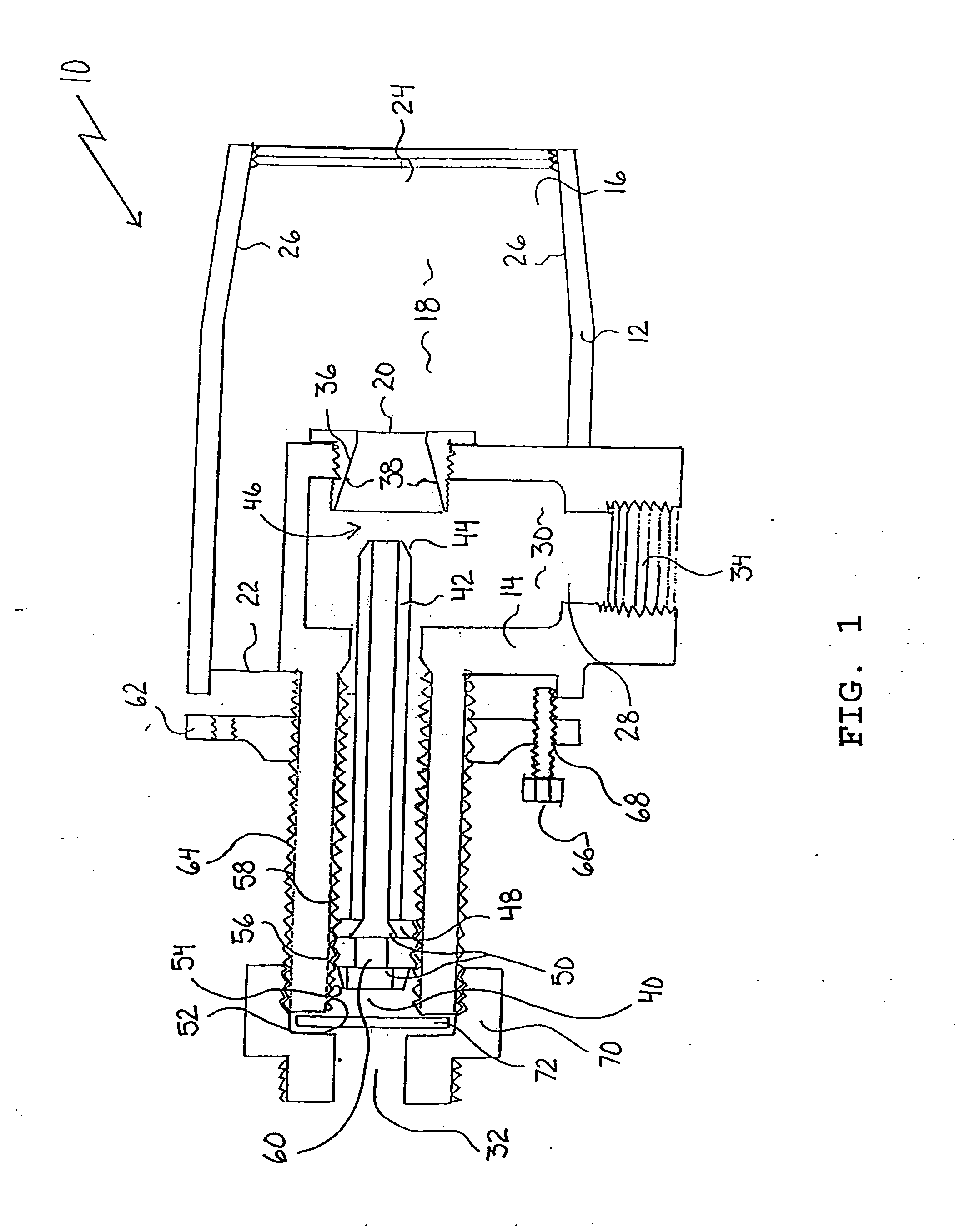

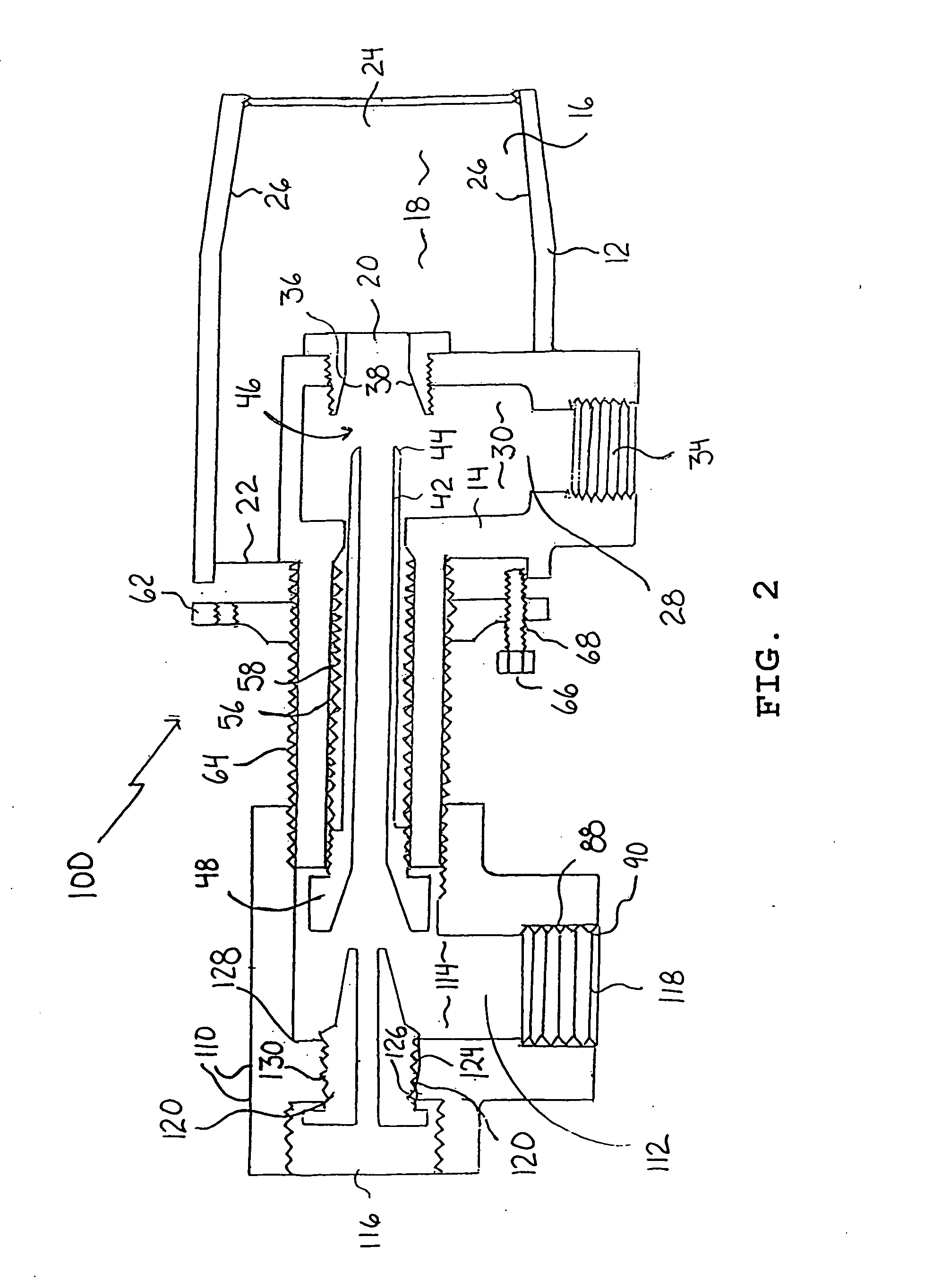

[0014] The preferred embodiment, a burner fuel mixer head generally identified by reference numeral 10, will now be described with reference to FIG. 1.

[0015] Structure and Relationship of Parts:

[0016] Referring to FIG. 1, there is provided a burner fuel mixer head 10 which includes a primary housing 12 and a secondary housing 14. Primary housing 12 has an interior cavity 16 that defines a fuel / air mixing chamber 18. Primary housing 12 has a mixed fuel gas inlet 20, a combustion air inlet 22, and a mixed fuel / air outlet 24 all of which communicate with interior cavity 16. Mixed fuel / air outlet 24 of primary housing 12 has converging sidewalls 26.

[0017] Secondary housing 14 has an interior cavity 28 that also defines a fuel mixing chamber 30. Interior cavity 28 of secondary housing 14 communicates with mixed fuel gas inlet 20 leading into primary housing 12. Secondary housing 14 has a pressurized fuel gas inlet 32 and a low pressure fuel gas inlet 34.

[0018] A venturi throat 36 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com