Biomass fuel hot air stove

A technology of biomass fuel and hot blast stove, which is applied in the direction of air heater, fluid heater, lighting and heating equipment, etc. It can solve the problems of irreplaceable, large investment, complex system, etc., and achieve improved combustion efficiency, uniform fuel combustion, full burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

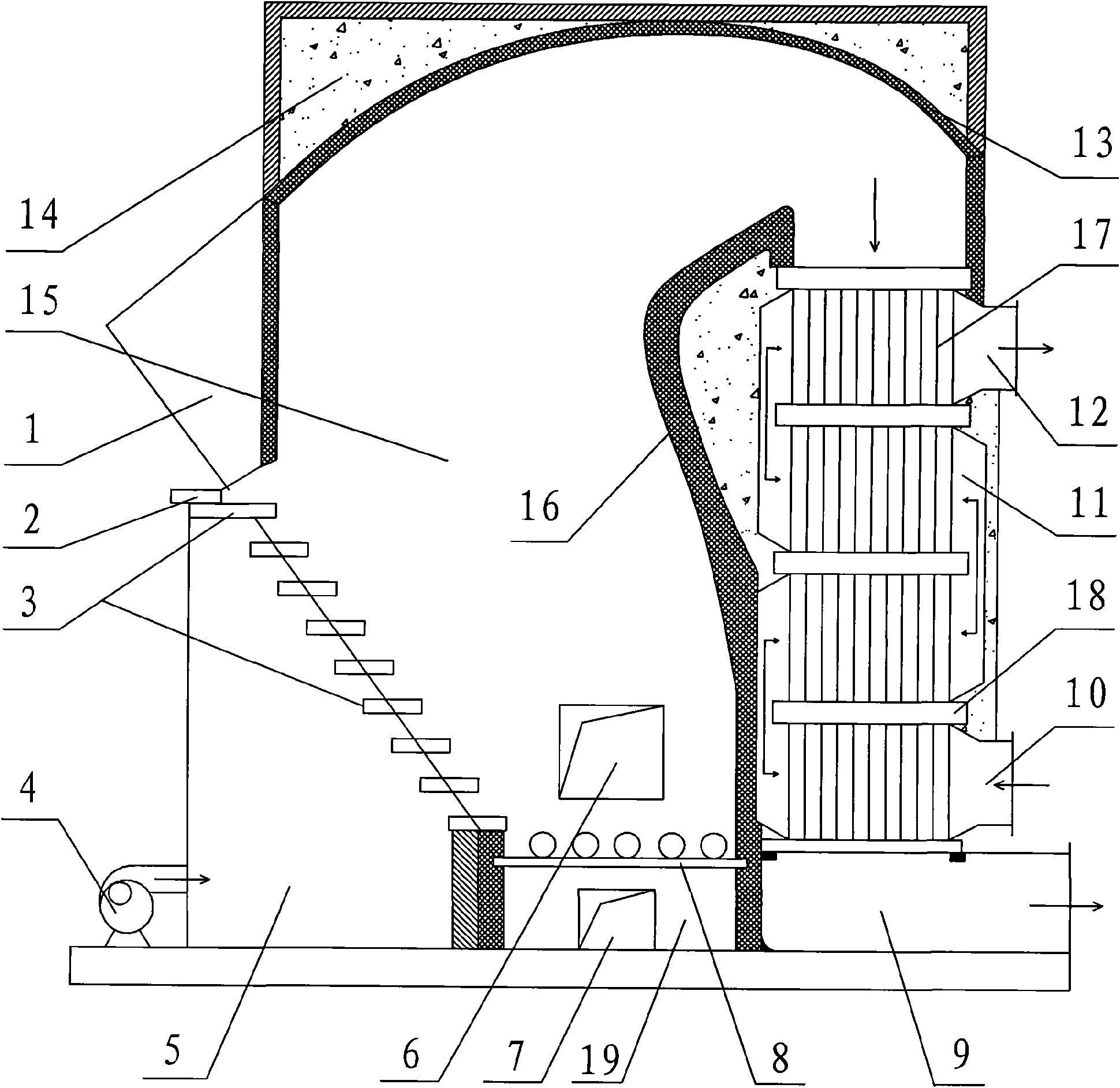

[0009] Such as figure 1 As shown, the present invention includes a furnace body, a feeding system, a blower 4, a fire grate 8, a flue 9, and a furnace arch 13. Fixed trapezoidal grate 3, the movable pusher block 2 is arranged at the fixed connection intersection between the fixed trapezoidal grate 3 and the fuel bucket 1, and an arc-shaped The arc-shaped reflective arch 16, the feeding system and the arc-shaped reflective arch 16 together divide the furnace body into three parts: the air chamber 5, the combustion chamber 15 and the heat conversion device, and the heat conversion device includes a cold air inlet 10 , air duct 11, hot air outlet 12, flue tube bundle 17, said flue tube bundle 17 is fixedly arranged inside said air duct 11, said flue tube bundle 17 runs through said combustion chamber 15 and said flue 9 , the flue 9 is fixedly arranged on the base of the furnace body at the lower end of the heat conversion device, and the fire grate 8 is fixedly installed between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com