Deep treatment method for printing ink wastewater by membrane method

A technology for advanced treatment and ink wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as poor stability, difficult water chroma to meet discharge standards, environmental pollution, etc. , to achieve good treatment effect, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

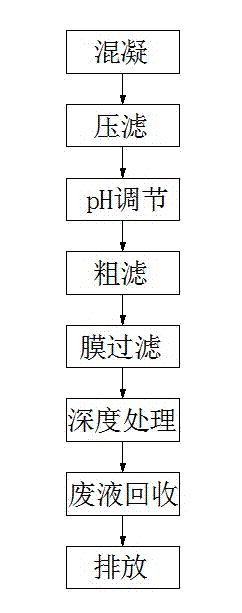

[0025] A method for the advanced treatment of membrane-based ink wastewater, comprising the steps of:

[0026] S1. Coagulation: inject ink wastewater into the reaction tank, add hydrochloric acid (pH regulator) to the reaction tank to adjust the pH value of the wastewater to 3, then add coagulant and coagulant aid to the reaction tank, and the coagulant The addition amount is 100mg / L, the addition amount of the coagulant aid is 0.6mg / L, stir to make the components in the reaction box fully mix and react to form flocs. Among them, the coagulant is a mixture of ferrous chloride, ferric sulfate, aluminum sulfate, polyaluminum chloride, polyacrylamide, and alum, and the coagulant aid is acid, alkali, lime, chitosan, activated silicic acid, diatom soil mixture.

[0027] S2. Press filtration: Use a suction pump to pump the flocs in the reaction tank into a plate-and-frame filter press (automatic or mechanical) for solid-liquid separation, and separate the solids pressed out by the ...

Embodiment 2

[0035] Step is with embodiment 1, difference is:

[0036] The pH value in step S1 is 4, the pH regulator is sulfuric acid, the add-on of coagulant is 50mg / L, the add-on of coagulant aid is 0.4mg / L, and coagulant is ferrous chloride, ferric sulfate, The mixture of aluminum sulfate, polyaluminum chloride, coagulation aid is the mixture of acid, alkali, lime, chitosan; The pH value in step S3 is 7; The membrane assembly in step S5 is a microfiltration membrane; Advanced treatment is nanofiltration.

[0037] The final target treated water has chromaticity<1, COD<60, SS<1, which has reached the discharge standard and can be directly discharged into the municipal sewage pipe network through pipelines.

Embodiment 3

[0039] Step is with embodiment 1, difference is:

[0040] The pH value in step S1 is 5, the pH regulator is nitric acid, the add-on of coagulant is 150mg / L, the add-on of coagulant aid is 0.3mg / L, and coagulant is ferrous chloride, ferric sulfate, The mixture of polyacrylamide and alum, the coagulation aid is a mixture of acid, activated silicic acid, diatomaceous earth, chitosan; the pH value in step S3 is 8; the membrane module in step S5 is an ultrafiltration membrane; step S6 The advanced treatment in the process is activated carbon adsorption.

[0041] The chroma of the final target treated water is <5, COD<100, SS<2, which has reached the discharge standard and can be directly discharged into the municipal sewage pipe network through pipelines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com