Device and method for performing alkali desulfurization and dust removal on ship exhaust fume

A technology of ship and alkali method, applied in the field of atmospheric environmental protection, can solve the problems of not meeting the environmental conditions of ships, large pressure drop and resistance, and increased absorption efficiency, and achieves favorable absorption and reaction, large gas-liquid contact surface, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

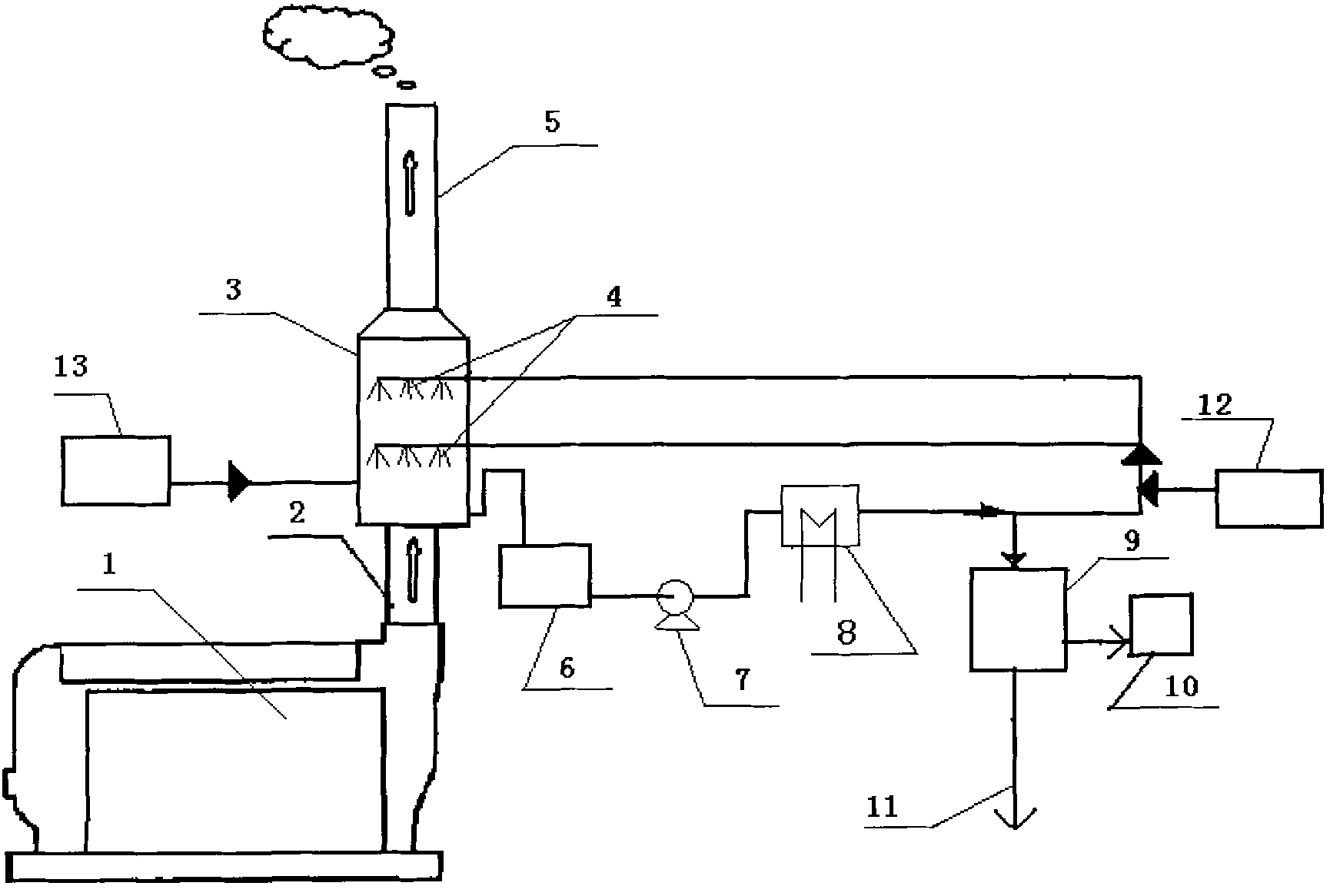

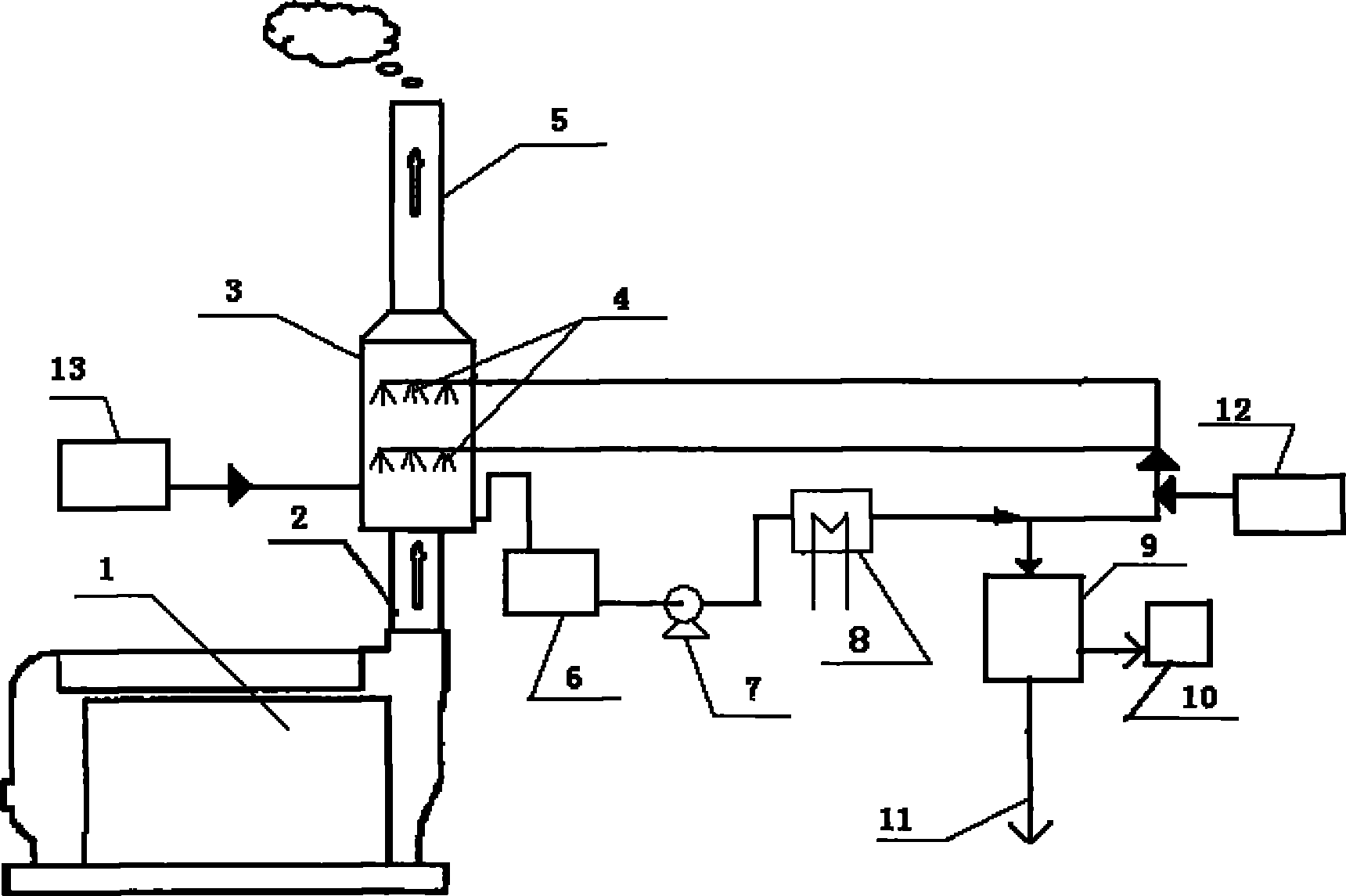

[0035] see figure 1 In the present invention, the exhaust gas of the engine / oil-fired boiler 1 on the ship is connected to the scrubber 3 through the flue 2 . The washing tower 3 is provided with a spray layer 4 connected to the lye supply pipeline, and the spray layer 4 adopts one-stage or multi-stage spray layers. The fresh water supply unit 13 is connected to the lower part of the washing tower 3 through a pipeline. The outlet at the bottom of the washing tower 3 is connected to the lye supply pipeline through the buffer tank 6, the pump 7 and the heat exchanger 8 in turn, and the outlet of the heat exchanger 8 is also connected to the inlet of the separator 9 using a one-stage or multi-stage cyclone separator , the two outlets of the separator 9 are connected to the discharge pipe 11 and the sludge tank 10 respectively. The outlet of the lye supply unit 12 is connected to the lye supply pipeline.

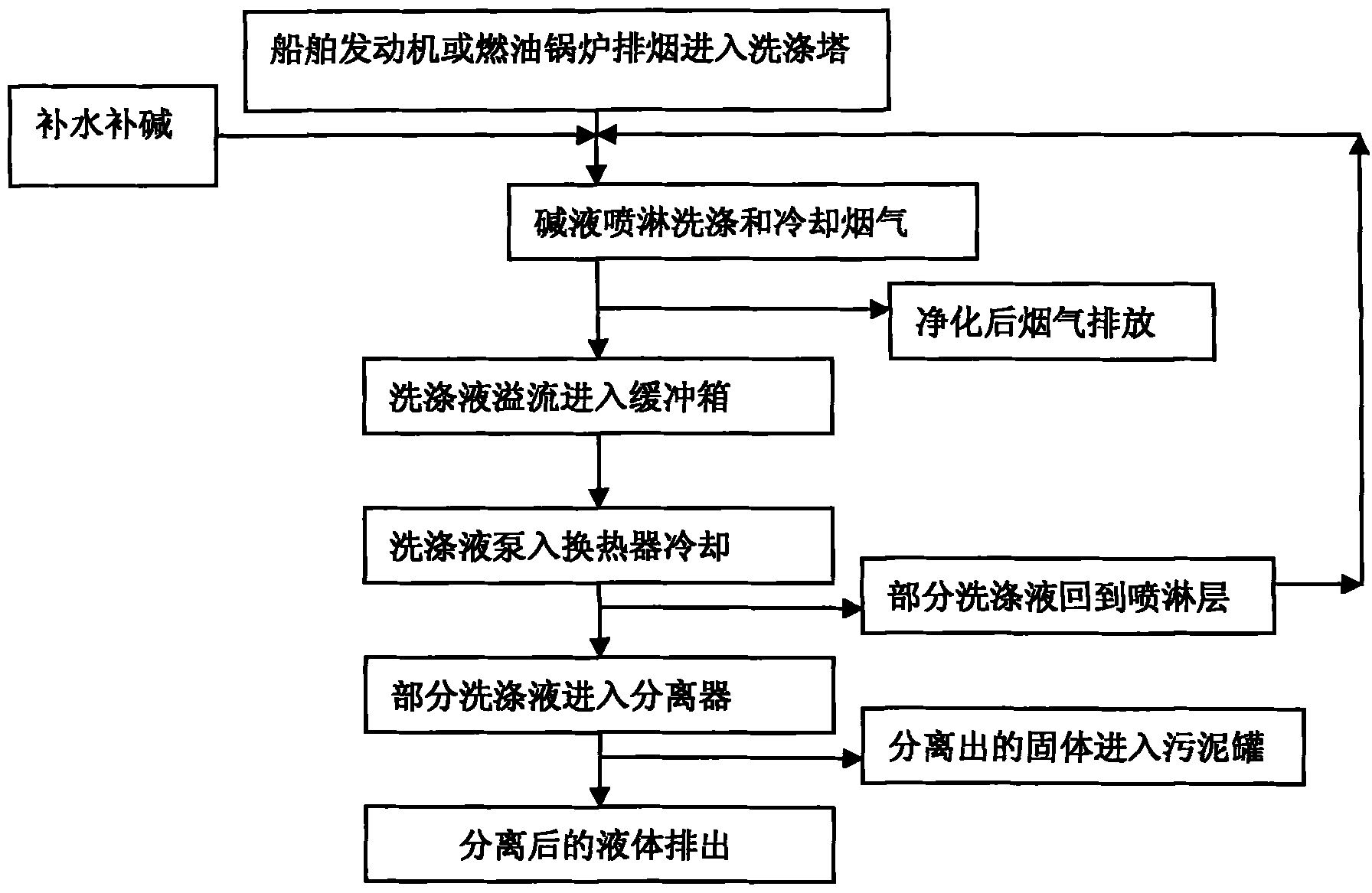

[0036] see figure 2 , the method step of device desulfurization of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com