Micro-electrolysis method for lead and zinc smelting waste water

A lead-zinc and waste water technology, which is applied in the micro-electrolysis treatment of lead-zinc smelting waste water and the field of smelting waste water treatment, can solve the problems of secondary pollution, difficulty in disposal, easy scaling of treated water, etc., and achieve simple treatment process and high treatment effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A lead-zinc smelting smelting waste water volume of 80m 3 / h (continuous flow), composition (mg / L):

[0029] pH: 3.5, Zn: 141.00, Pb: 10.80, Cu: 3.66, Cd: 15.60

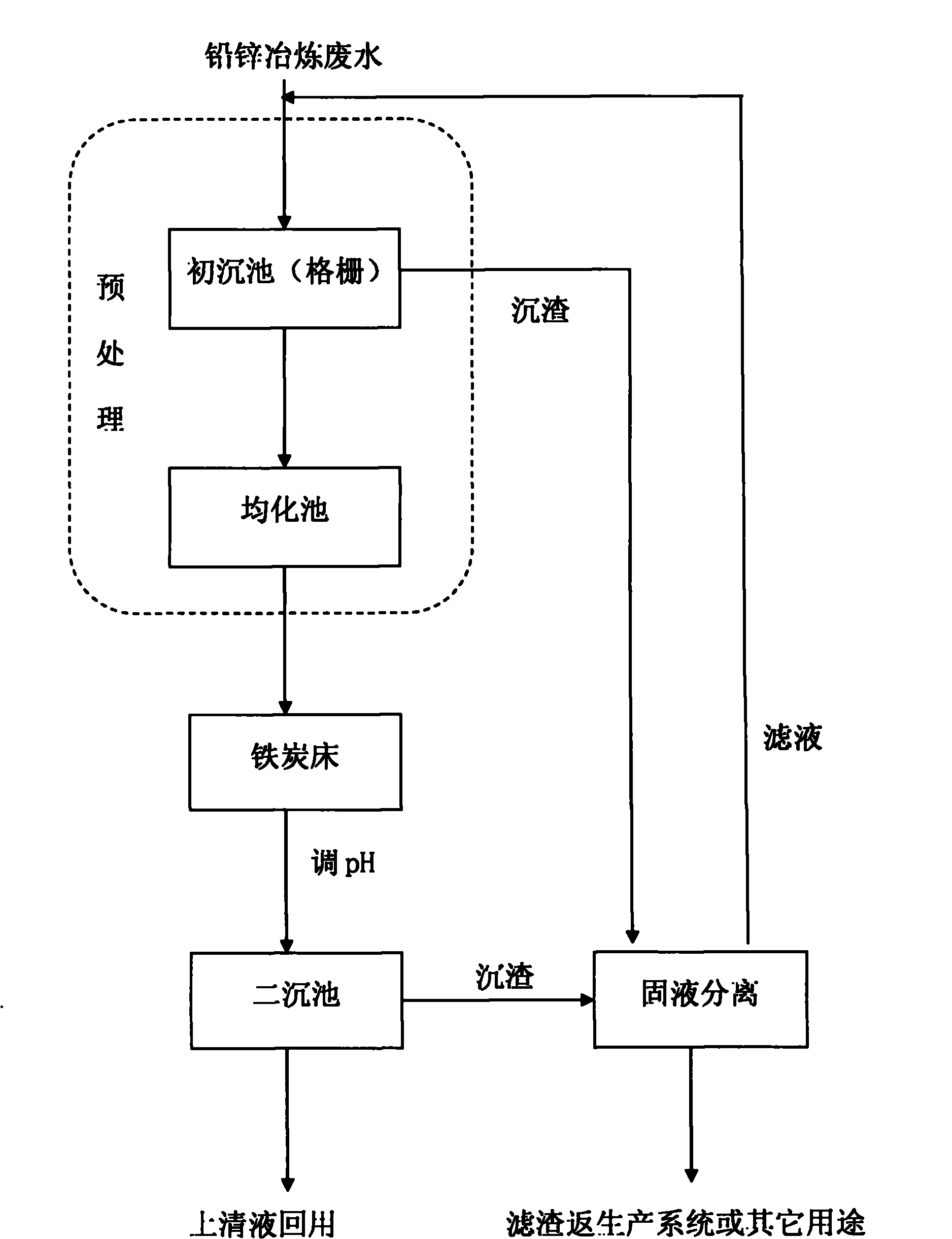

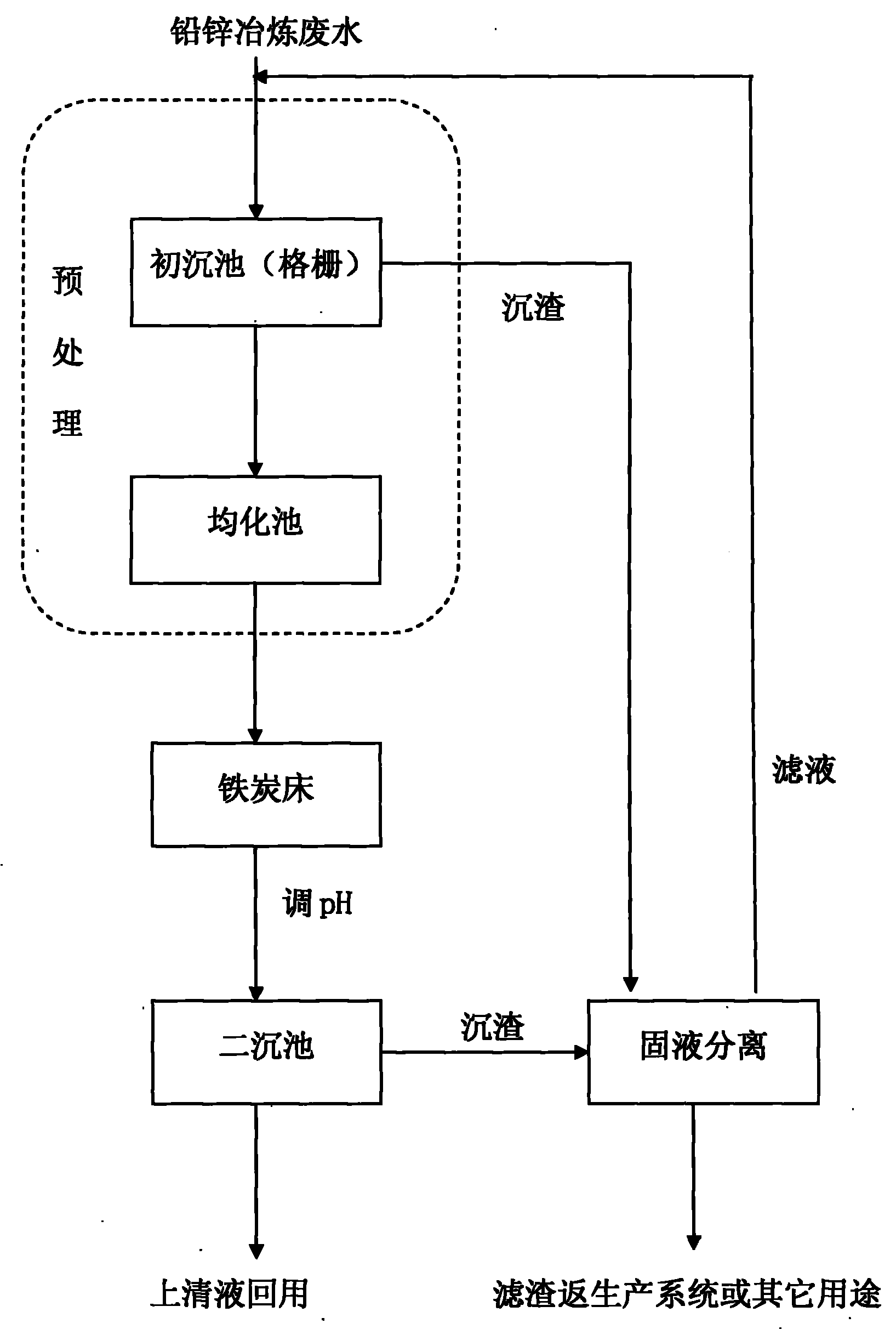

[0030] Using the process shown in the drawing, the acidic waste water from lead and zinc smelting is homogenized in the sedimentation tank and enters the iron-carbon bed. The mass ratio of iron to activated carbon is 0.6:1. The clear liquid is reused, and the underflow of the sediment is discharged and then filtered by a filter press. The filtrate is returned to the homogenization tank for treatment, and the filter residue is sent to the production system.

[0031] The hydraulic retention time of the iron-carbon bed is 30 minutes, the pH of the effluent is 6.2, and the pH is adjusted to 7.5 with sodium hydroxide. After precipitation, the supernatant of the sedimentation tank is taken to test the composition (mg / L): pH: 7.1, Zn: 1.69, Pb: 1.20, Cu: 0.23, Cd: 0.65.

Embodiment 2

[0033] A lead-zinc smelter's comprehensive waste water volume is 200m 3 / h (continuous flow), composition (mg / L):

[0034] pH: 3.0, Zn: 148.30, Pb: 9.50, Cu: 2.27, Cd: 11.60, As: 1.21, F: 11.05.

[0035] Using the process shown in the drawing, the acidic wastewater from lead and zinc smelting enters the iron-carbon bed after being homogenized in the grit chamber, and the mass ratio of iron to activated carbon is 1.5:1. The supernatant is reused, and the bottom flow of the sediment is discharged and then filtered by a filter press. The filtrate is returned to the homogenization tank for treatment, and the filter residue is sent to the production system.

[0036] The hydraulic retention time of the iron-carbon bed is 45 minutes, the pH of the effluent is 5.9, the pH is adjusted to 9.5 with sodium hydroxide, and the supernatant of the sedimentation tank is taken to test the composition (mg / L): pH: 8.6, Zn: 2.23, Pb: 1.01, Cu: 0.45, Cd: 0.21, F: 3.22.

Embodiment 3

[0038] A lead-zinc smelting acid production waste water volume 28m 3 / h (continuous flow), composition (mg / L):

[0039] pH: 1.8, Zn: 256.52, Pb: 7.60, Cu: 18.90, Cd: 6.63, As: 4.70, F: 25.20.

[0040] Using the process shown in the drawing, the acidic wastewater from lead and zinc smelting enters the iron-carbon bed after being homogenized in the grit chamber, and the mass ratio of iron to activated carbon is 3:1. The supernatant is reused, and the bottom flow of the sediment is discharged and then filtered by a filter press. The filtrate is returned to the homogenization tank for treatment, and the filter residue is sent to the production system.

[0041] The hydraulic retention time of the iron-carbon bed is 40 minutes, the pH of the effluent is 5.8, and the pH is adjusted to 9.5 with sodium hydroxide. After precipitation, the supernatant of the sedimentation tank is taken to test the composition (mg / L): pH: 8.9, Zn: 4.47, Pb: 0.80, Cu: 0.71, Cd: 0.13, As: 0.48, F: 9.27.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com