Mechanical pulping method for biological bacteria liquid

A technology of mechanical pulping and biological bacteria, which is applied in the field of paper pulping, can solve the problems of polluted air, large amount of waste liquid discharge, and inability to eliminate pollution, etc., and achieves the goal of simple and effective method, strong operability, and power saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The biodegradation process of lignin in broad-leaved tree species is the same. The mulberry, poplar, and eucalyptus are all broad-leaved tree species.

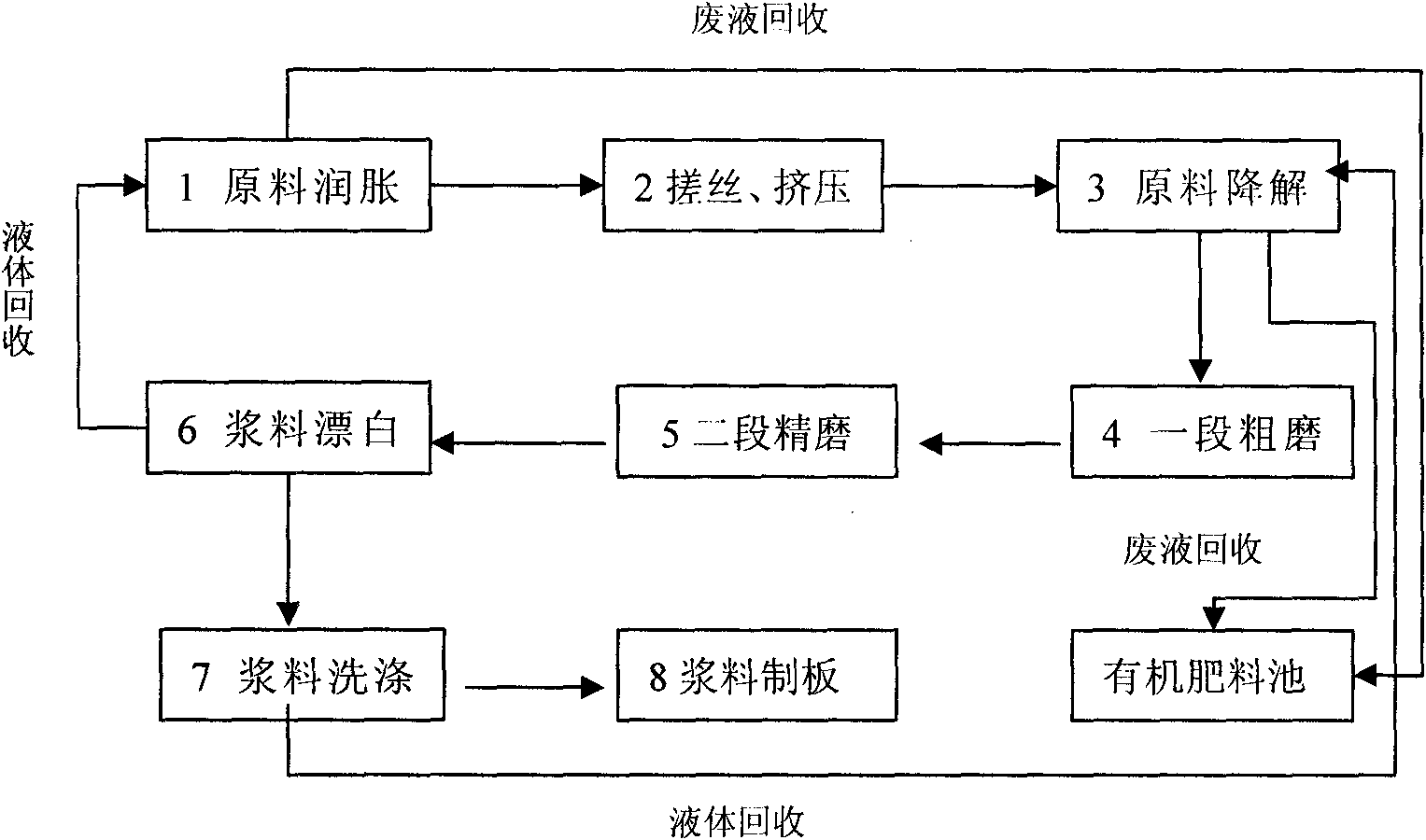

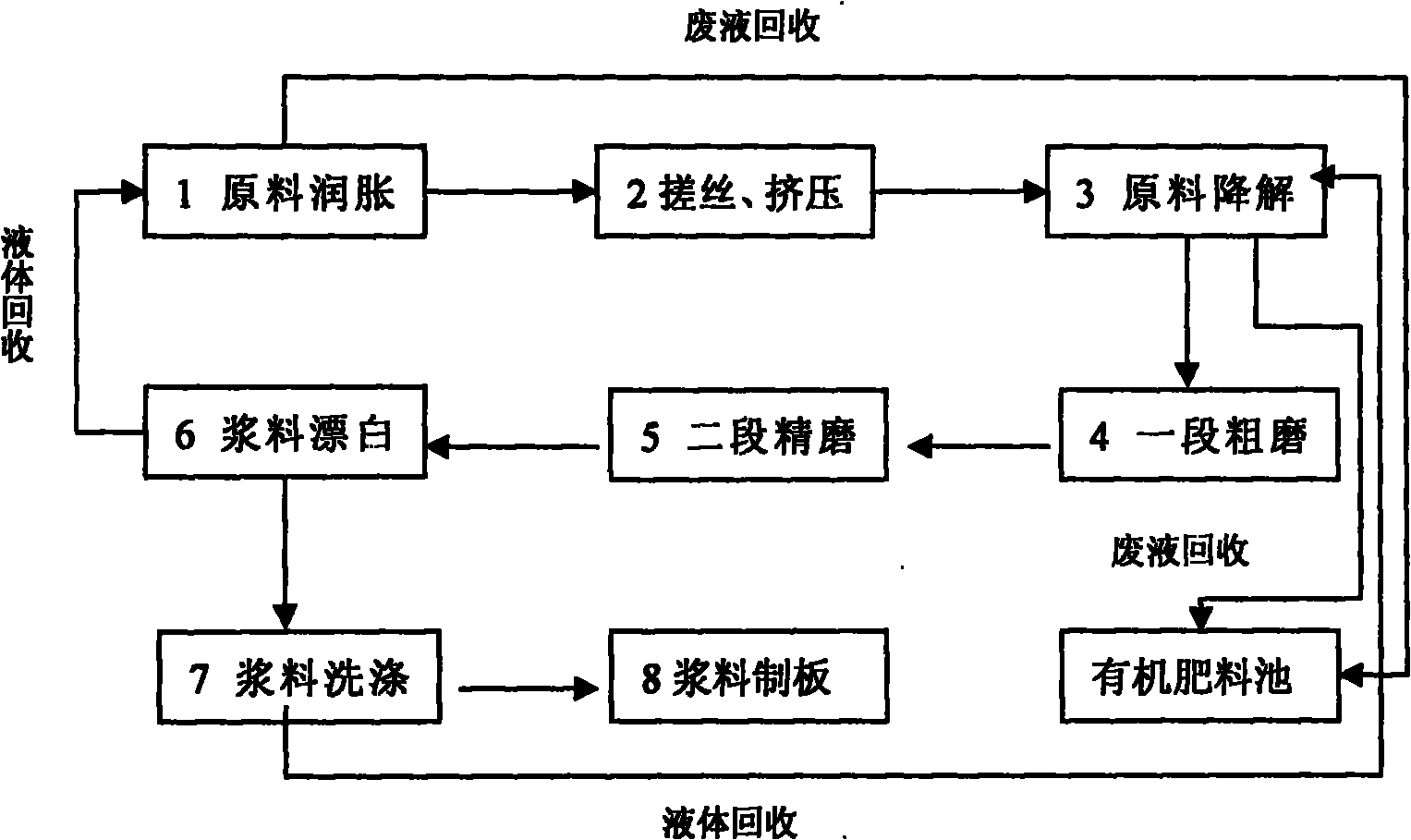

[0031] Liquid mechanical pulping method of mulberry, poplar and eucalyptus biological bacteria:

[0032] Step 1: Cut the branches of mulberry, poplar, and eucalyptus into sections (whole poles), preferably peeled and then cut into sections, with a length of 4-5cm. Soak them in water-absorbing and swelling liquid, remove them after 4 hours, and drain .

[0033] Step 2: Put the raw materials after the first step into the thread rolling machine for extrusion and thread rolling.

[0034] The third step: Soak the raw materials after rubbing in the prepared compound bacterial solution, and the bacterial solution should not pass through the raw materials. The soaking time is 48 hours.

[0035] Step 4: Take the raw materials completed in the third step out of the bacterial liquid and drain. Then put it in boiling water for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com