Process for processing waste sulfuric acid by virtue of pyrite acid-making roasting furnace

A roasting furnace and pyrite technology, applied in the direction of sulfur compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of waste of resources, high energy required for heating, etc., to reduce cracking costs, improve the overall efficiency of the enterprise, and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

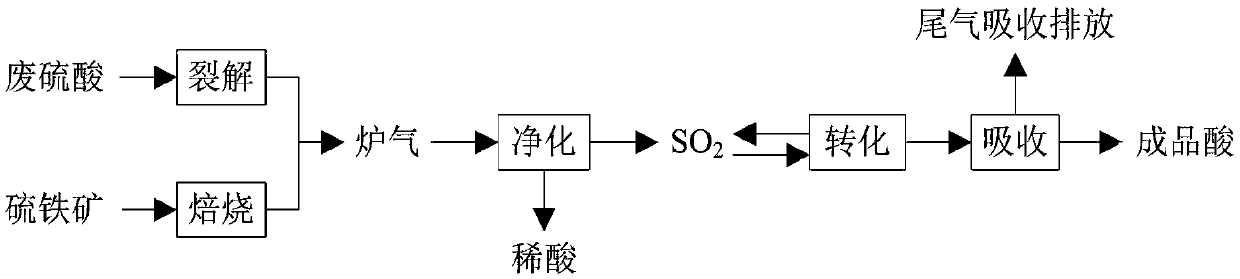

[0016] Example 1: Heat the roaster with external heat, send the pyrite into the roaster for combustion when the temperature reaches above 400°C, and send the alkylated waste sulfuric acid through the acid pump when the temperature reaches 850-1000°C Roasting furnace, and control the temperature to maintain at 850-1000°C, waste sulfuric acid is cracked at this high temperature to produce SO 2 gas, the organic matter in which is simultaneously incinerated into CO 2 , the mixed gas and the SO produced by pyrite combustion 2 The gases form the furnace gas together, and then the obtained furnace gas is purified and refined, that is, cooled, washed, demisted and dried to obtain qualified SO 2 Furnace gas, the furnace gas is transformed and absorbed to produce qualified sulfuric acid.

Embodiment 2

[0017] Example 2: Heat the roasting furnace with external heat. When the temperature reaches above 400°C, send the pyrite mixed with waste sulfur as a combustion accelerant into the roasting furnace for combustion. When the temperature reaches 900-1100°C, the alkylation waste Sulfuric acid is sent into the roaster through an acid pump, and the temperature is controlled by adjusting the amount of waste sulfur added to keep it at 900-1100°C. At this high temperature, the waste sulfuric acid is cracked to produce SO 2 gas, the organic matter in which is simultaneously incinerated into CO 2 , the mixed gas and SO produced by burning pyrite and waste sulfuric acid 2 The gases form the furnace gas together, and then the obtained furnace gas is purified and refined, that is, cooled, washed, demisted and dried to obtain qualified SO 2 Furnace gas, the furnace gas is transformed and absorbed to produce qualified sulfuric acid.

Embodiment 3

[0018] Embodiment 3: heating the roaster by external heat, when the temperature reaches above 400°C, the pyrite is sent into the roaster for combustion, and when the temperature reaches 900-1000°C, the alkylation waste sulfuric acid is sent into Roasting furnace, and by adjusting one or more of the amount of pyrite ore, the sulfur content in the ore, the amount of waste sulfuric acid added, and the cooling area of the cooling water tank to control the temperature to keep it at 900-1000 ° C, the waste sulfuric acid Cracked at this high temperature to produce SO 2 gas, the organic matter in which is simultaneously incinerated into CO 2 , the mixed gas and the SO produced by pyrite combustion 2 The gas forms furnace gas together, and a cracking furnace is added to the furnace gas pipeline at the outlet of the roasting furnace of the pyrite acid plant, and when the temperature of the furnace gas is used to raise the temperature of the cracking furnace to above 900°C, waste sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com