Method for extracting ammonium molybdate from molybdenum concentrate through pressure ammonia leaching

A technology of molybdenum concentrate and ammonium molybdate, which is applied in the direction of chemical instruments and methods, molybdenum compounds, process efficiency improvement, etc., can solve the problems of low leaching rate, slow leaching speed, and long production cycle, so as to improve the recovery rate, Improve production efficiency and solve pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

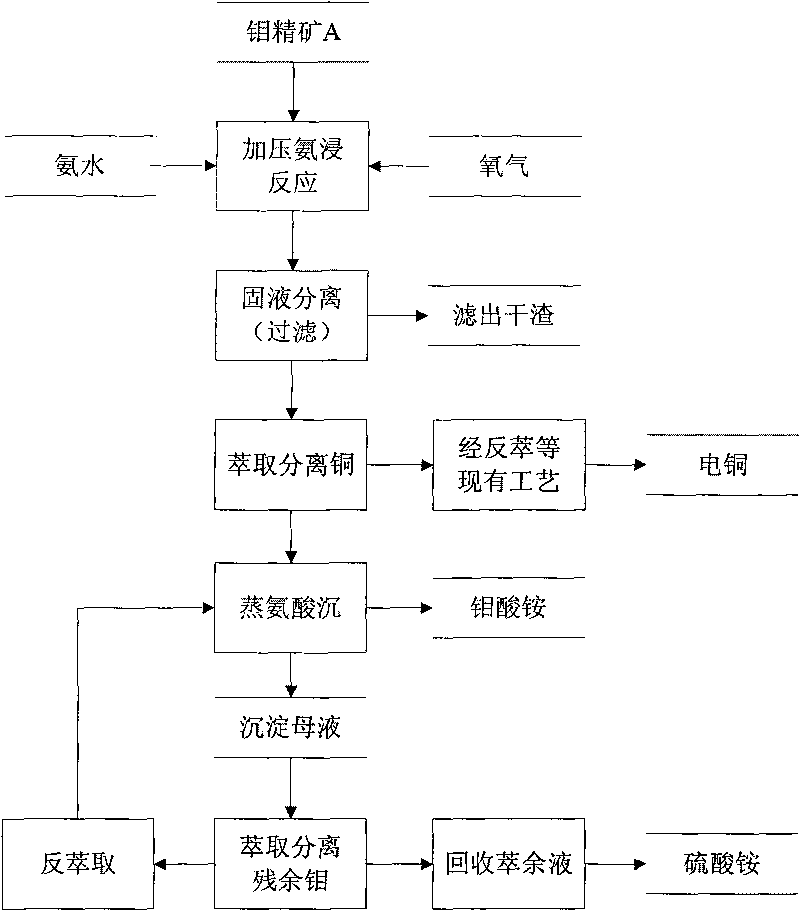

[0033] a kind of like figure 1 Shown the method for extracting ammonium molybdate from molybdenum concentrate by pressurized ammonia leaching of the present invention, may further comprise the steps:

[0034] 100g of the above-mentioned molybdenum concentrate A is added into an autoclave (2L) that is filled with 750ml of mass concentration of 10% ammonia (that is, the solid-to-liquid ratio is 1: 7.5), and after feeding oxygen, the oxygen partial pressure is controlled to be 1.0MPa , under the conditions of 160°C-180°C and a total reaction pressure of 2.0MPa, the pressurized ammonia leaching reaction was carried out, the stirring speed was 400r / min, the pulp obtained after the reaction for 3h was filtered, and the filtered dry residue weighed 52.3g. After filtering out the molybdenum content in the dry residue for detection and analysis, the leaching rates of molybdenum and copper are 94.6% and 85% respectively. The leaching solution after filtering the above-mentioned ore pulp ...

Embodiment 2

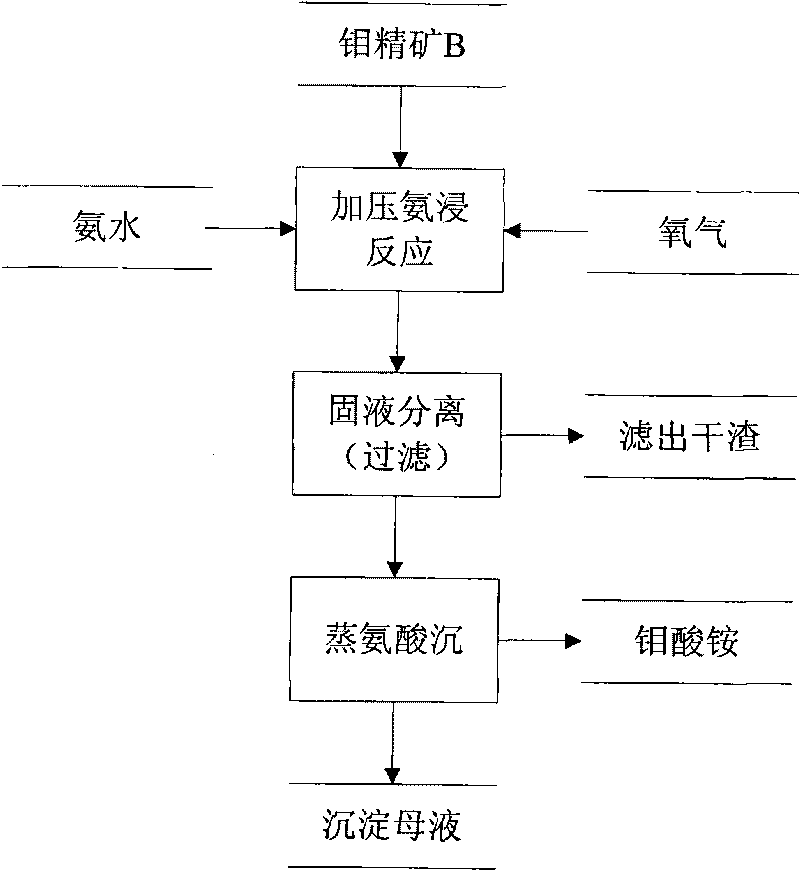

[0036] a kind of like figure 2 Shown the method for extracting ammonium molybdate from molybdenum concentrate by pressurized ammonia leaching of the present invention, may further comprise the steps:

[0037] Add 200g of the above-mentioned molybdenum concentrate B into an autoclave (2L) that contains 1L of mass concentration of 12.5% ammonia, the solid-to-liquid ratio is 1:5, and the oxygen partial pressure is controlled to be less than 1.0MPa. The pressurized ammonia leaching reaction was carried out at 1.6MPa, the stirring speed was 400r / min, the pulp obtained after the reaction for 4 hours was filtered, the filtrate was distilled with ammonia, acidified, precipitated, filtered and washed to obtain ammonium molybdate and precipitated mother liquor. The filtered dry residue weighs 46.3g. After detecting and analyzing the content of molybdenum, copper and rhenium in the filtered dry residue, the leaching rates of molybdenum, copper and rhenium reached 96.3%, 97.5% and 97.2...

Embodiment 3

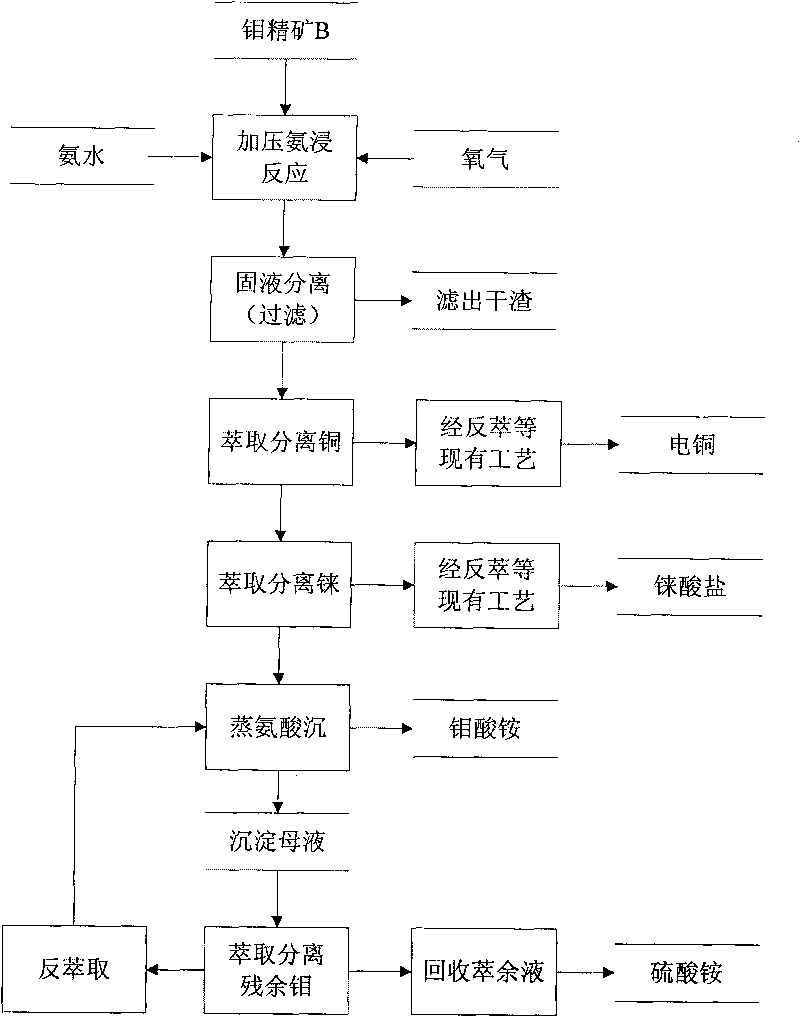

[0039] a kind of like image 3 Shown the method for extracting ammonium molybdate from molybdenum concentrate by pressurized ammonia leaching of the present invention, may further comprise the steps:

[0040] 1Kg of above-mentioned molybdenum concentrate B is added in the autoclave (10L) that fills 5L ammoniacal liquor (mass concentration is 12.5%) (being that solid-liquid ratio is 1: 5), after feeding oxygen, control oxygen partial pressure 1.0MPa , pressurized ammonia leaching reaction was carried out at 160°C-180°C and a total pressure of 2.0MPa, the stirring speed was 500r / min, and the pulp obtained after the reaction for 4h was filtered and washed, and the filtered dry residue weighed 226.3g. The contents of molybdenum, copper and rhenium in the dry slag were detected and analyzed, and the leaching rates of molybdenum, copper and rhenium were 96.7%, 96.9% and 96.1% respectively. The leaching solution contains Mo 75.14g / L, Re 0.126g / L, and Cu 5.74g / L. The leaching soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com