Method for preparing potassium formate and sodium formate from carbide furnace tail gas as raw material

A technology of calcium carbide furnace tail gas and potassium formate, applied in carboxylate preparation, organic chemistry, etc., can solve the problems of emission pollution, inability to directly recycle, complex carbon monoxide process, etc., and achieve the effect of solving pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

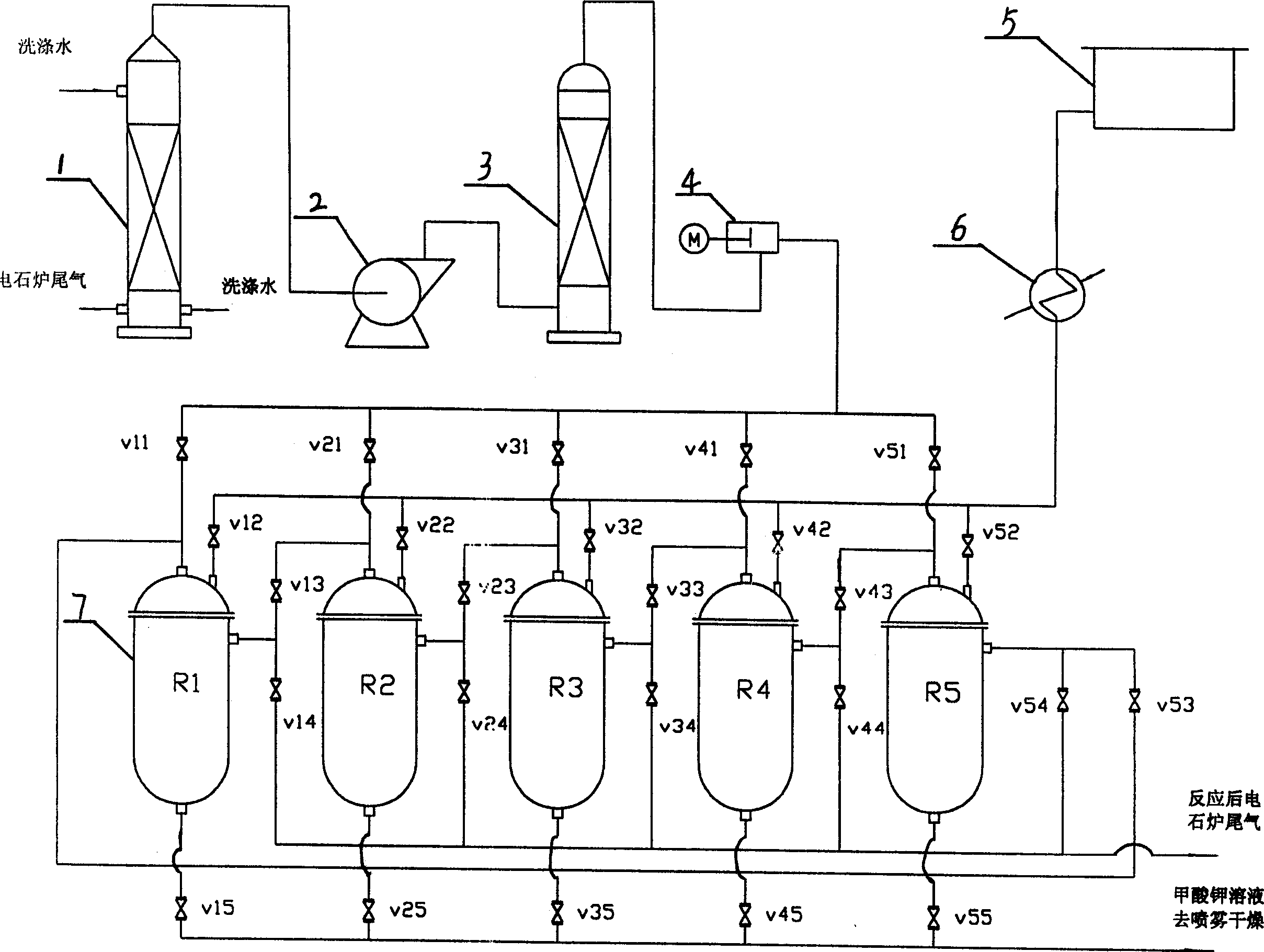

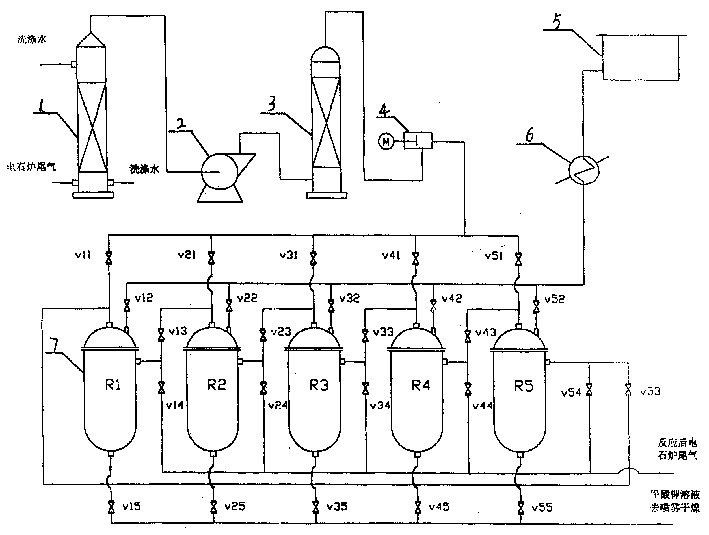

[0018] Such as figure 1 As shown, the tail gas of the calcium carbide furnace enters the scrubbing tower 1 from the bottom under the action of a fan, and at the same time, washing water is introduced to the top of the scrubbing tower 1, and the scrubbing water and the tail gas of the calcium carbide furnace flow in the scrubbing tower 1 to make the dust in the tail gas of the calcium carbide furnace flow. It settles to the bottom of the tower to be removed, and at the same time it can absorb part of the soluble gas.

[0019] Then the dust-removed tail gas from the top of the tower is introduced into the bottom of the purification tower 3 through the fan 2 into the purification tower. The purification tower 3 is equipped with ALGA-B01 type adsorbent, which can absorb and remove acid gases such as hydrogen sulfide and carbon dioxide. And a small amount of dust to further purify the tail gas of the calcium carbide furnace, reduce the generation of by-products, and improve the purity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com