Treatment method of low grade titanium-riched material chlorination dust collecting slag

A treatment method and a technology for collecting dust and slag, which are applied in the direction of protection devices against harmful chemicals, etc., can solve the problems of polluting the environment, difficult industrial waste, and inability to achieve non-waste (hazardous) treatment, and achieve low treatment cost, The effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

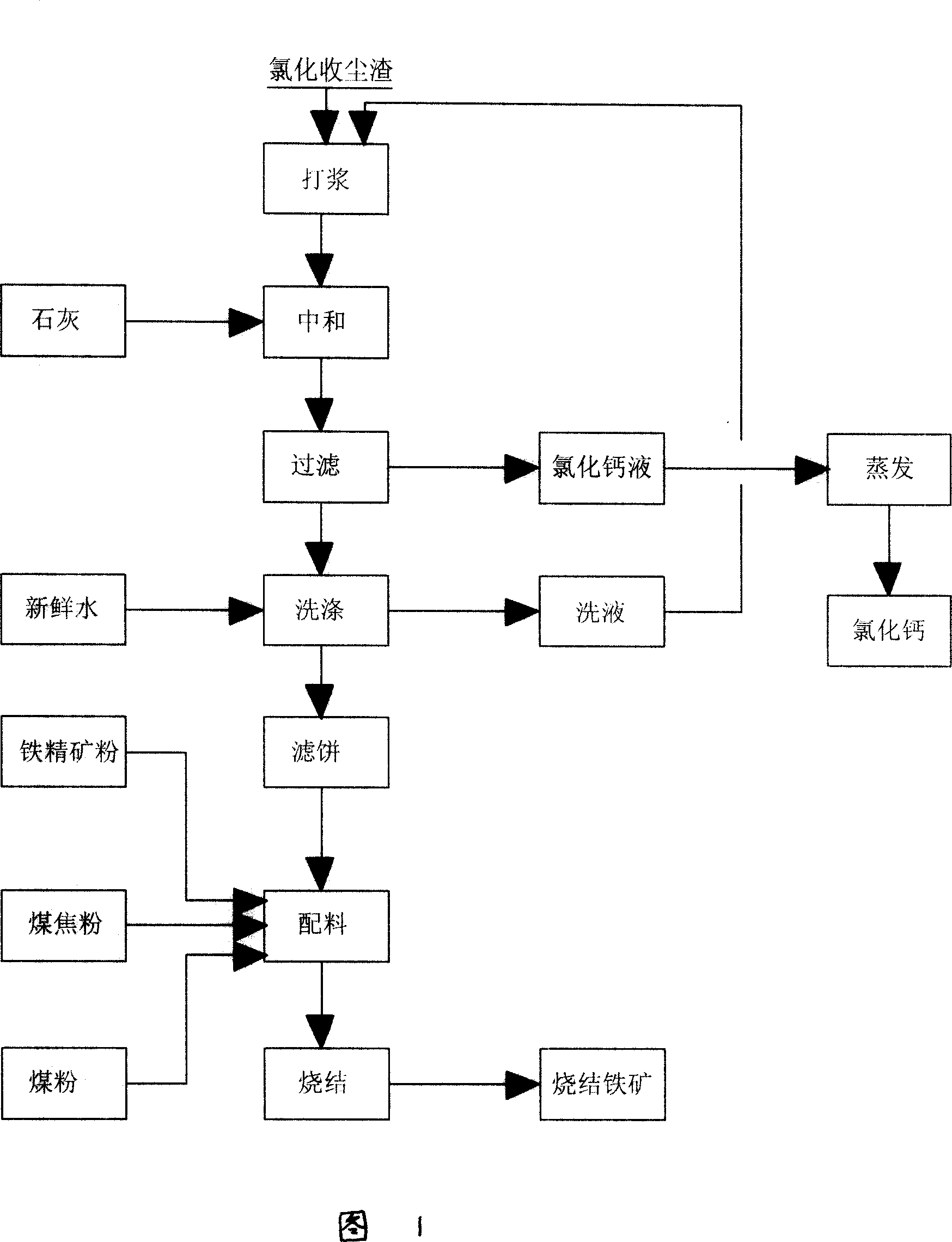

[0011] As shown in the figure, the corresponding metal chlorides produced in the process of producing titanium tetrachloride are dust-collected and the dust-collected slag is discharged using a rotary valve under the protection of an inert gas. The dust-collected slag directly enters the beating tank for beating, and the beating liquid is used Corrosion-resistant mud pumps are used for circulation. When the chloride content of the circulating mud reaches 5-30%, it is poured into the neutralization reaction tank, and the neutralization reaction is carried out with lime while stirring, and the pH value of the neutralization liquid is controlled at 6-9. Then, these mixed muds are filtered in the filter, and the filtrate is calcium chloride solution, and the calcium chloride solution is further evaporated and concentrated to reach the required concentration, and then it can be sold as calcium chloride commodity. The filter cake is washed with fresh hot water at a temperature of 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com