Method for preparing inorganic lead-free halide perovskite film by coevaporation

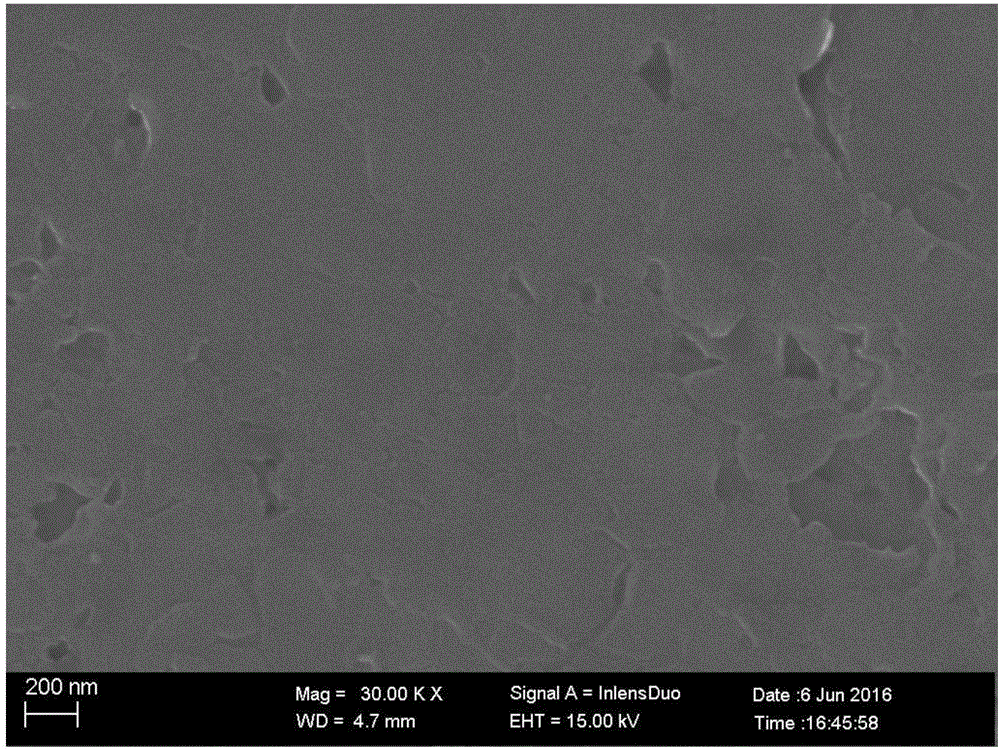

A halide perovskite and inorganic non-ferrous technology, which is applied in the field of co-evaporation to prepare inorganic non-lead halide perovskite thin films, can solve problems such as Pb pollution and organic instability, and achieve smooth surface, less internal defects, and better performance. unstable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

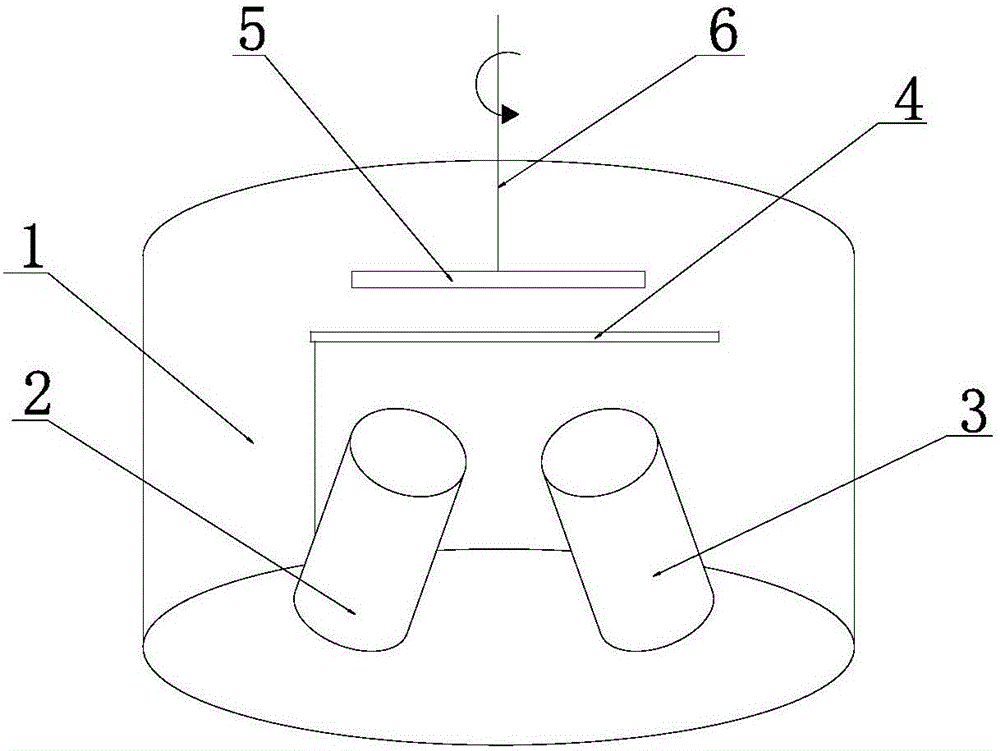

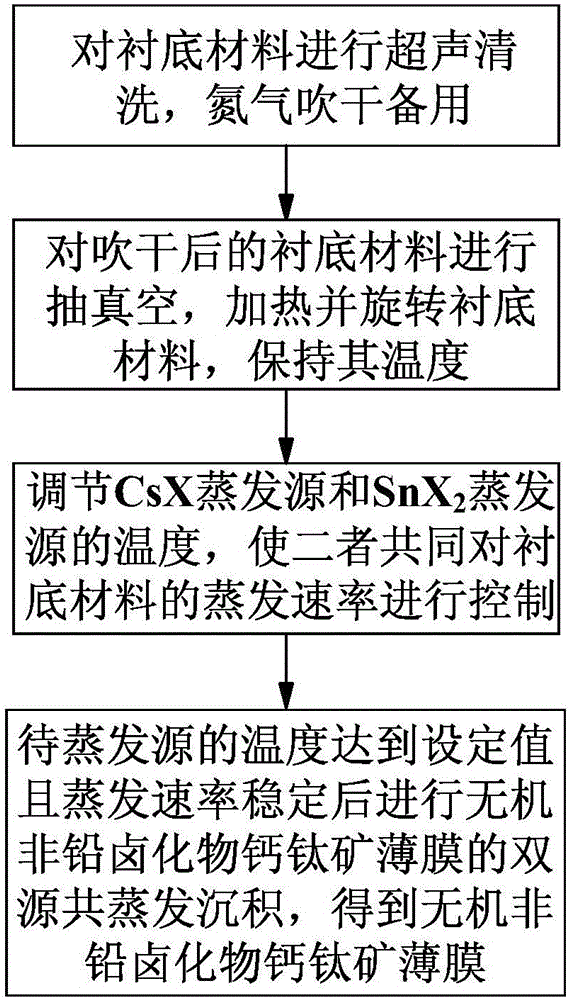

[0028] The invention provides a kind of inorganic non-lead halide (chemical formula is CsSnX 3 or Cs 2 wxya 6 , X is one or more of the halogen elements Cl, Br or I) perovskite thin films, which are mainly used in perovskite batteries. The present invention adopts figure 1 The co-evaporation equipment shown is for the preparation of inorganic non-lead halide perovskite thin films, the co-evaporation equipment includes a vacuum chamber 1, a CsX evaporation source 2, a SnX 2 Evaporation source 3, sample baffle plate 4, sample rack 5 with heating, sample rotation axis 6, the CsX evaporation source 2, SnX 2 The evaporation source 3, the sample baffle plate 4 and the sample holder 5 with heating are all arranged in the vacuum chamber 1, wherein X is one or more of Cl, Br, and I; the sample rotation axis 6 is in contact with the sample rack 5 is connected for rotating to open the vacuum chamber 1, such as figure 1 indicated by the rotation arrow in .

[0029] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com