PMOS transistor forming method

A transistor and gas technology, applied in the field of formation of PMOS transistors, can solve the problems of unstable performance of PMOS transistors, saturation leakage current drift, large leakage current, etc., and achieve the effect of solving the problem of unstable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

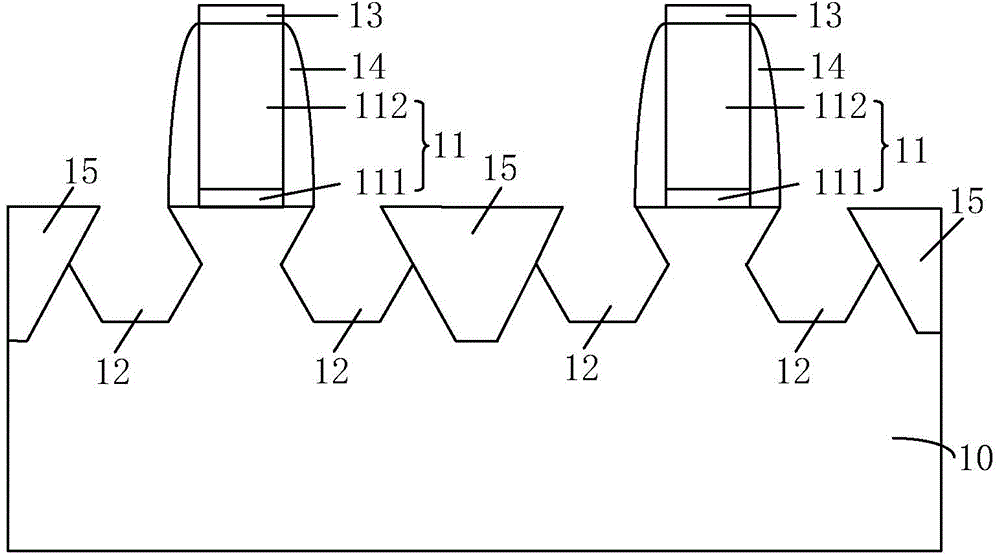

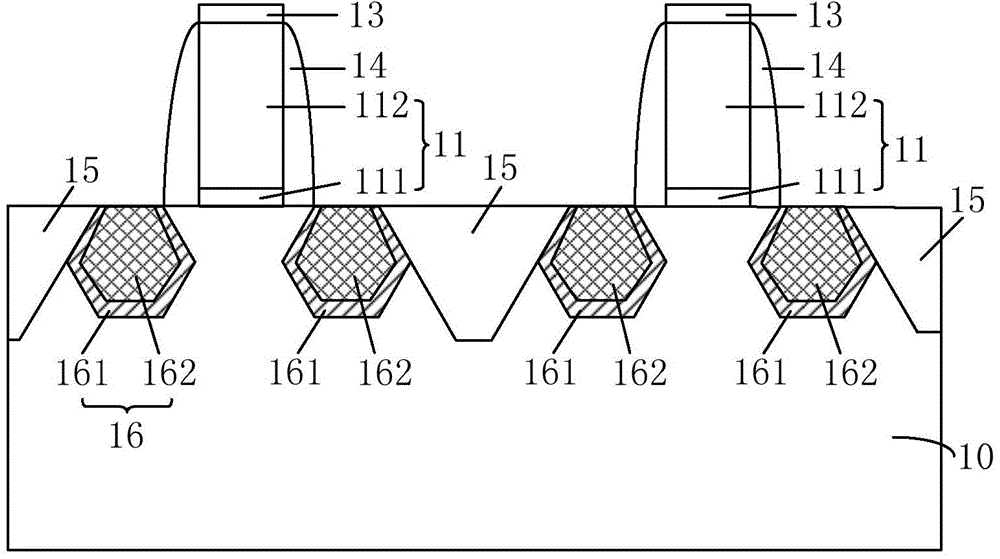

[0030] As described in the background art, the leakage current of PMOS transistors manufactured by the prior art is relatively large, and the performance of multiple PMOS transistors manufactured in the same batch is unstable. In view of the above problems, the inventors have analyzed and found that the reason is: for the formation stage of the silicon germanium seed layer in the sigma-shaped groove, the first sub-stage when the germanium source gas flow rate gradually increases and the gas flow rate is stable At the junction of the second sub-stage, the sudden change in the flow rate of the germanium source gas will cause the germanium content in the formed silicon germanium seed layer to suddenly increase, causing the silicon germanium material in the silicon germanium seed layer to be mismatched in the lattice, and then causing the sigma shape Defects appear on the sidewalls of the groove, and carriers in the source and drain regions enter the channel region to cause leakage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com