Environment-friendly binding agent for corrugated carton

A corrugated box, environmentally friendly technology, applied in the direction of adhesive types, starch-derived adhesives, polymer adhesive additives, etc., can solve problems such as difficult to eradicate, easy to mildew, long pollution cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An environment-friendly adhesive for corrugated boxes, comprising the following components by weight: 100 parts of modified starch, 5 parts of polyvinyl alcohol and 0.5 parts of defoamer;

[0030] The preparation of this environment-friendly adhesive specifically comprises the following steps:

[0031] The first step: swelling of starch

[0032] Add 1kg of starch and 2.5kg of water into the mixer in turn, stir evenly at 10°C, then add 100g of 45% sodium hydroxide aqueous solution, heat up to 35°C, stir at constant temperature and high speed for 15min, and fully swell the starch;

[0033] Step 2: Preparation of Stabilizing Modifier

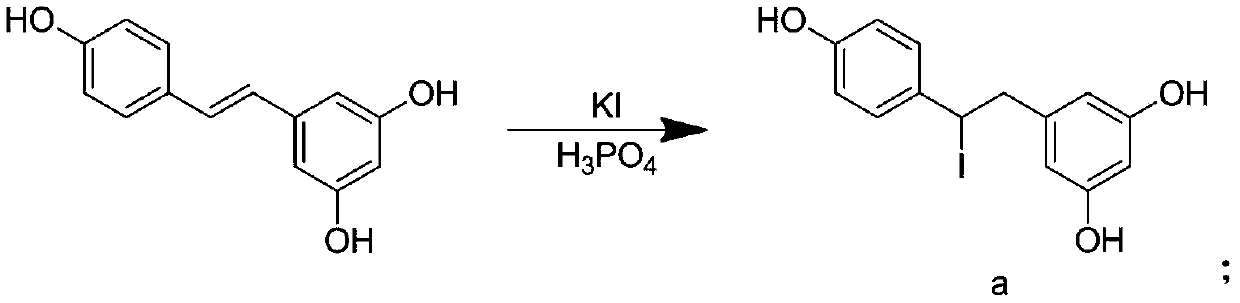

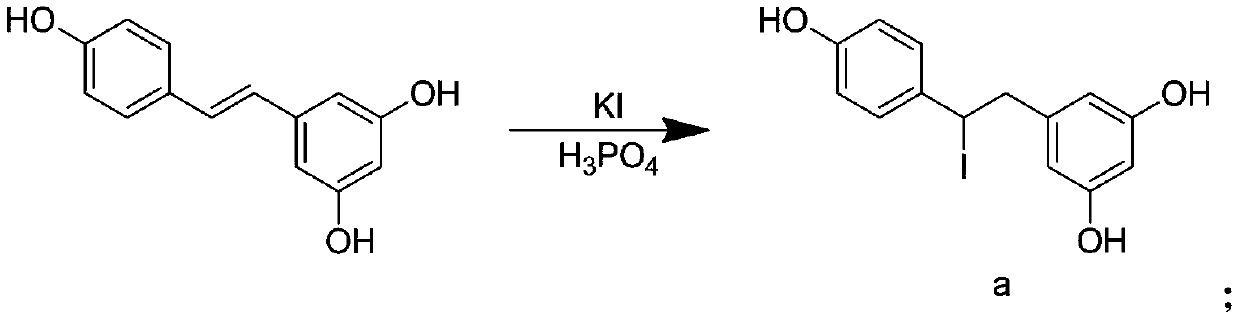

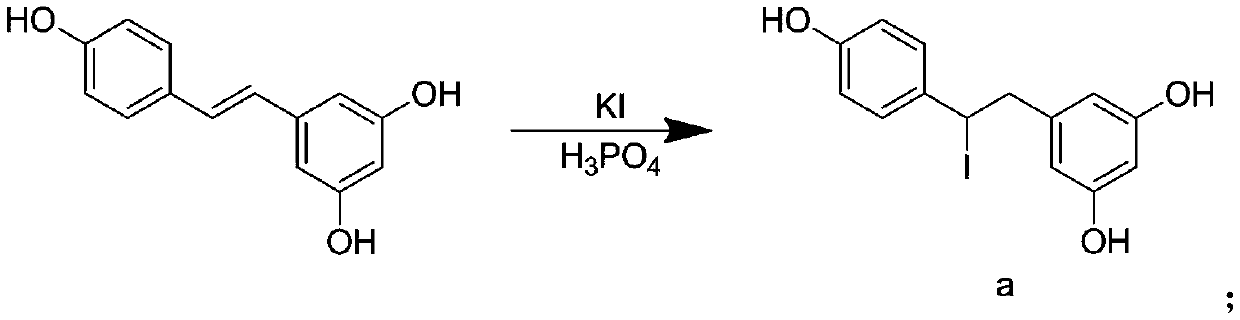

[0034] Add 10mol resveratrol into the reaction kettle, then add 30mol potassium iodide, stir and mix evenly, keep the temperature of the reaction kettle at 40°C, and the stirring speed is 180r / min, add 50mol phosphoric acid dropwise, and the addition rate of phosphoric acid is 1- 2 drops / s, after all the phosphoric acid is added, keep the ...

Embodiment 2

[0040] An environment-friendly adhesive for corrugated boxes, comprising the following components in parts by weight: 100 parts of modified starch, 10 parts of polyvinyl alcohol and 1 part of defoamer;

[0041] The preparation of this environment-friendly adhesive specifically comprises the following steps:

[0042] The first step: swelling of starch

[0043] Add 1kg of starch and 3kg of water into the mixer in turn, stir evenly at 15°C, then add 150g of 45% sodium hydroxide aqueous solution, raise the temperature to 0°C, stir at constant temperature and high speed for 18min, and fully swell the starch;

[0044] Step 2: Preparation of Stabilizing Modifier

[0045] Add 10mol resveratrol into the reaction kettle, then add 30mol potassium iodide, stir and mix evenly, keep the temperature of the reaction kettle at 45°C, and the stirring speed is 200r / min, add 50mol phosphoric acid drop by drop, the addition rate of phosphoric acid is 1- 2 drops / s, after all the phosphoric acid i...

Embodiment 3

[0051] An environment-friendly adhesive for corrugated boxes, comprising the following components by weight: 100 parts of modified starch, 8 parts of polyvinyl alcohol and 0.7 parts of defoamer;

[0052] The preparation of this environment-friendly adhesive specifically comprises the following steps:

[0053] The first step: swelling of starch

[0054] Add 1kg of starch and 2.7kg of water to the mixer in turn, stir evenly at 12°C, then add 120g of 45% sodium hydroxide aqueous solution, raise the temperature to 36°C, stir at constant temperature and high speed for 17min, and fully swell the starch;

[0055] Step 2: Preparation of Stabilizing Modifier

[0056] Add 10mol resveratrol into the reaction kettle, then add 30mol potassium iodide, stir and mix evenly, keep the temperature of the reaction kettle at 50°C, and the stirring speed is 180r / min, add 50mol phosphoric acid dropwise, and the addition rate of phosphoric acid is 1- 2 drops / s, after all the phosphoric acid is adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com