Horizontal constant-speed material receiving device

A horizontal, material-distributing turntable technology, applied in thin material handling, transportation and packaging, transportation of filamentous materials, etc. Speed and other issues to improve the efficiency of material collection and improve the effect of material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

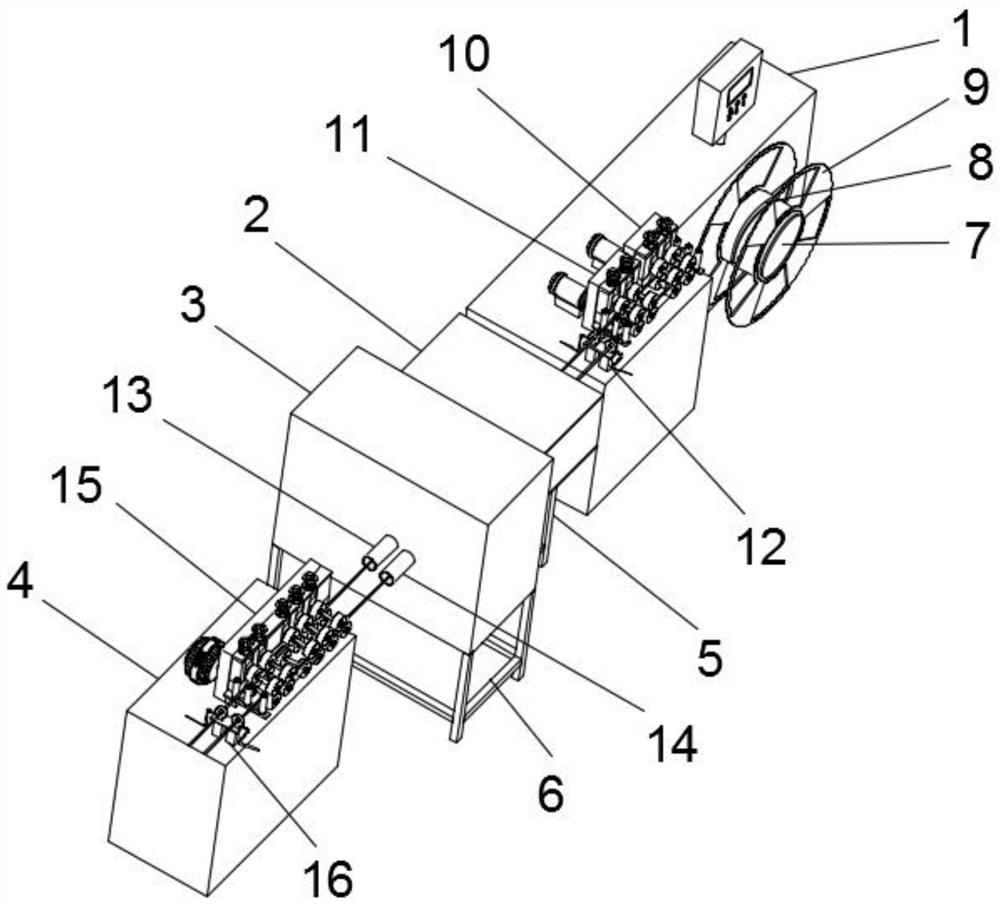

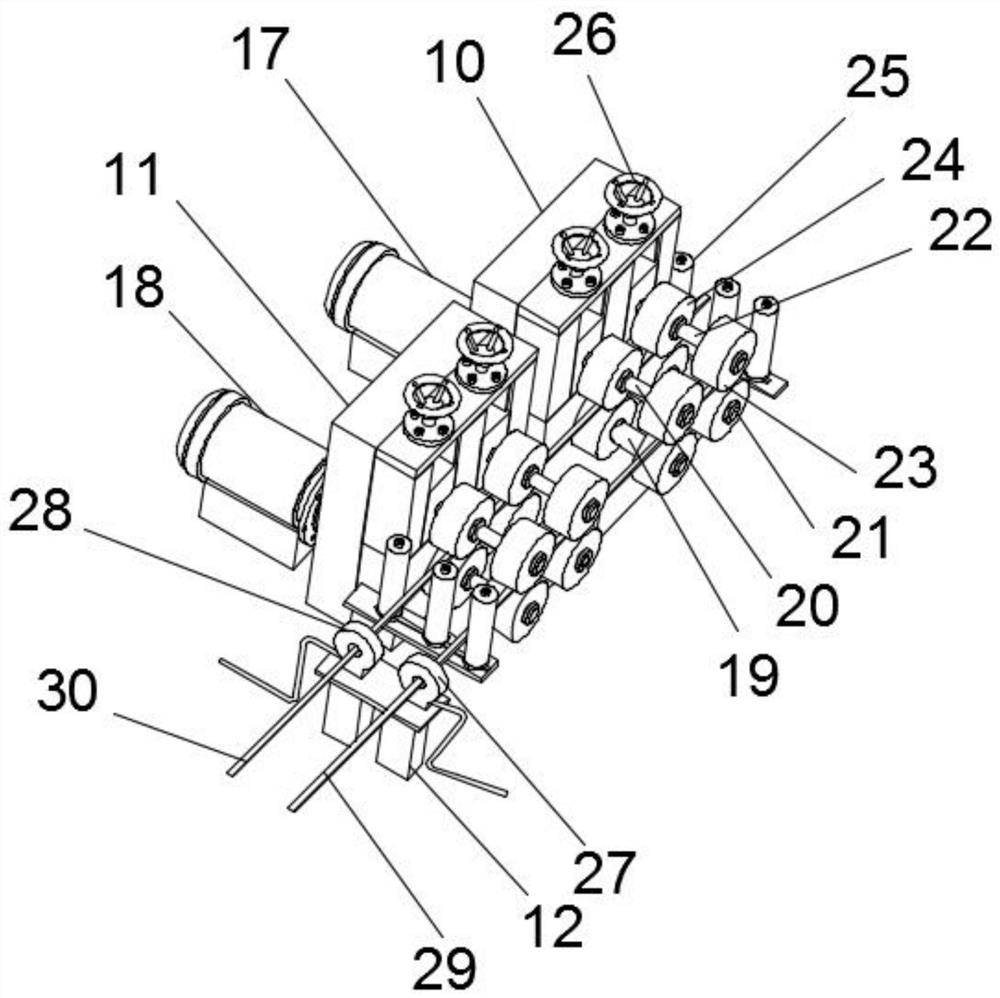

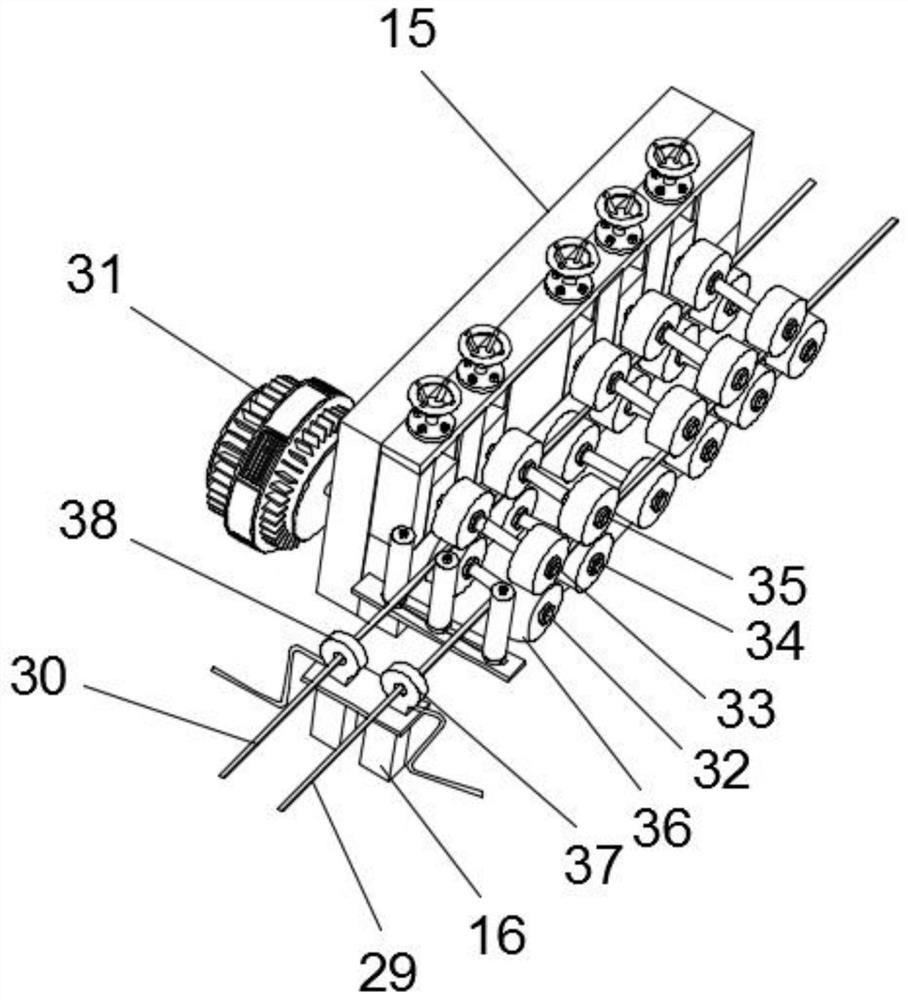

[0033] Such as Figure 1-5 As shown, a horizontal uniform speed receiving device includes a first support seat 1, a first connection seat 2, a second connection seat 3, a second support seat 4, a separation ring 8, a material distribution turntable 9, a first roller Sending mechanism 10, the second rolling mechanism 11, the first encoding mechanism 12, the tension mechanism 15 and the second encoding mechanism 16, the first connecting seat 2, the second connecting seat 3 and the second supporting seat 4 are all arranged on the second One side of a supporting seat 1, the second connecting seat 3 is located between the first connecting seat 2 and the second supporting seat 4, and the first connecting seat 2 is located between the first supporting seat 1 and the second connecting seat 3 Between, the front end of the first support base 1 is connected with a distributing rotating column 7 near the right side, and the distributing rotating disc 9 is installed at a position near the ...

Embodiment 2

[0042] The working method of the device comprises the following steps:

[0043] Step 1: Wrap the first metal strip 29 and the second metal strip 30 on both sides of the separating ring 8 on the distribution carousel 9 respectively, pass one end of the first metal strip 29 and the second metal strip 30 through several Between the first rollers 23 and between the second rollers 24, the first ring encoder 27 and the second ring encoder 28, the first connecting seat 2 and the second connecting seat 3, several first tension wheels Between 36 and the second tension wheel, and the third ring encoder 37 and the fourth ring encoder 38, the first metal strip 29 and the second metal strip 30 are rewound;

[0044] Step 2: Start the first drive motor 17, the second drive motor 18, the motor 31, the first hydraulic cylinder 40 and the second hydraulic cylinder 41, drive the first drive column 19 to rotate through the first drive motor 17, and pass through the first drive column 19 rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com